Have you been trying hard to create a bronze model using the conventional technique without any success? If yes, why not try 3D printing. Yes, you have heard it right.

Without any doubt, one can create designs in bronze using additive manufacturing. You must be all ears by now. So, why not find out more about bronze 3D printing?

Bronze is not as easy to print as plastics are. Therefore, there aren’t many users who try working with this material. However, things are changing with time. As we are progressing towards a smarter tomorrow, the 3D printing industry has been evolving too.

And, there is not just one 3D Printing process to complete designs in Bronze, but quite a few. Moreover, if you feel that the task would be too difficult for you to manage, you always have the option to order your designs from 3D printing services.

But for those who are looking to invest some time finding out the basics of Bronze 3D printing to give it a try, why not start from the beginning. Well, it may seem overwhelming for some. However, as you will go on exploring more facts about the topic, you will feel more familiar with the process of working with this popular metal.

So, with no further ado, let’s get started!

Bronze 3D Printing – An Introduction

Before you go ahead and start working with the bronze metal, it is wise to find out about its properties. After all, your aim is to utilize its properties for the best.

If we talk about its composition, usually the metal comes as an alloy for printing. In other words, Bronze is made from the composition of two or more metals.

Usually, copper contributing to 90 percent of the composition along with others such as tin, contributing to around 10 percent of the exact composition. Moreover, the material is available in two finishes: Raw and Polished.

The metal is reddish yellow in color and comes in a standard 14K finish. In addition, bronze showcases higher resistance to tarnish when compared to brass. What’s more fascinating is its resistance to oxidation! The metal has a harder outer surface. That makes it safe from oxidation.

What else? Let us look at the technical specification of the metal for further clarification.

Technical Specification

As stated before, the material is an alloy with more than two metals combining together to provide the metal with its unique properties. often has 10 percent of other impurities.

The most common choice to prepare bronze is copper and Tin. Moreover, 3D printing larger designs with bronze are difficult. Usually, the design with 88 x 88 x 120 mm could easily be printed with bronze.

When it comes to the other properties of bronze, its fragility is notable. The percentage of different metals provide a different level of fragility. When printing, it is necessary to eliminate keep thin parts of the models.

For better results, one must take care of the 3D models during the design phase and ensure that every section is considerably thicker.

Again, while printing, users must keep the minimum clearance of walls to 0.3 mm. This allows the excess liquid to flow away from between these walls without any issues. Hence, providing the perfect finish for your designs.

The metal has around 0 70% of elongation at break. The percentage changes as per the temper. It has a tensile module of 96 to 120 GPa while the tensile strength of 70 to 800 MPa. The melting point is around 913 degrees Celsius.

3D Printing Processes for Bronze 3D Printing

Now that you have got some idea of the metal properties, why not jump to the bronze 3D printing, using different techniques. So, here are some of the ways you can create full models with this material.

FDM 3D Printing

Some may think that this is a joke. However, it isn’t. It is possible to print bronze models with FDM 3D printers. Among the various filaments available for printing, there is this one material that you may haven’t listened about so far.

The bronze filament offered by the Virtual Foundry. The material allows users to create bronze models on FDM printers. However, the process requires an extra step to complete bronze 3D printing.

After the model come out just fine from the 3D Printer, it must go through the heating process inside a Kiln. This step fuses the model into a completely solid metal design.

You must be thinking about the brittleness that may come along with the basic property of the material. And, it is certainly one of the most concerning topics. However, as the Virtual Foundry claims, they have been able to modify their filament’s formulation for reducing the problem of brittleness far away.

Well, the perk comes with its price too. The cost of the filament is not very cheap and maybe unreasonable for some. But the cost of ease is something many makers would be happy to pay. You can expect it to cost around $182 per kilogram.

Despite the fact that the material is pricey along with the cost of the Kiln, it still is one of the most accessible methods for 3D printing bronze directly.

Just remember that the precision may not be very impressive, as the sintering process may reduce the accuracy. But the parts are completely metal retaining all of the physical properties you look forward to seeing in your 3D models.

DMLS (Direct Metal Laser Sintering)

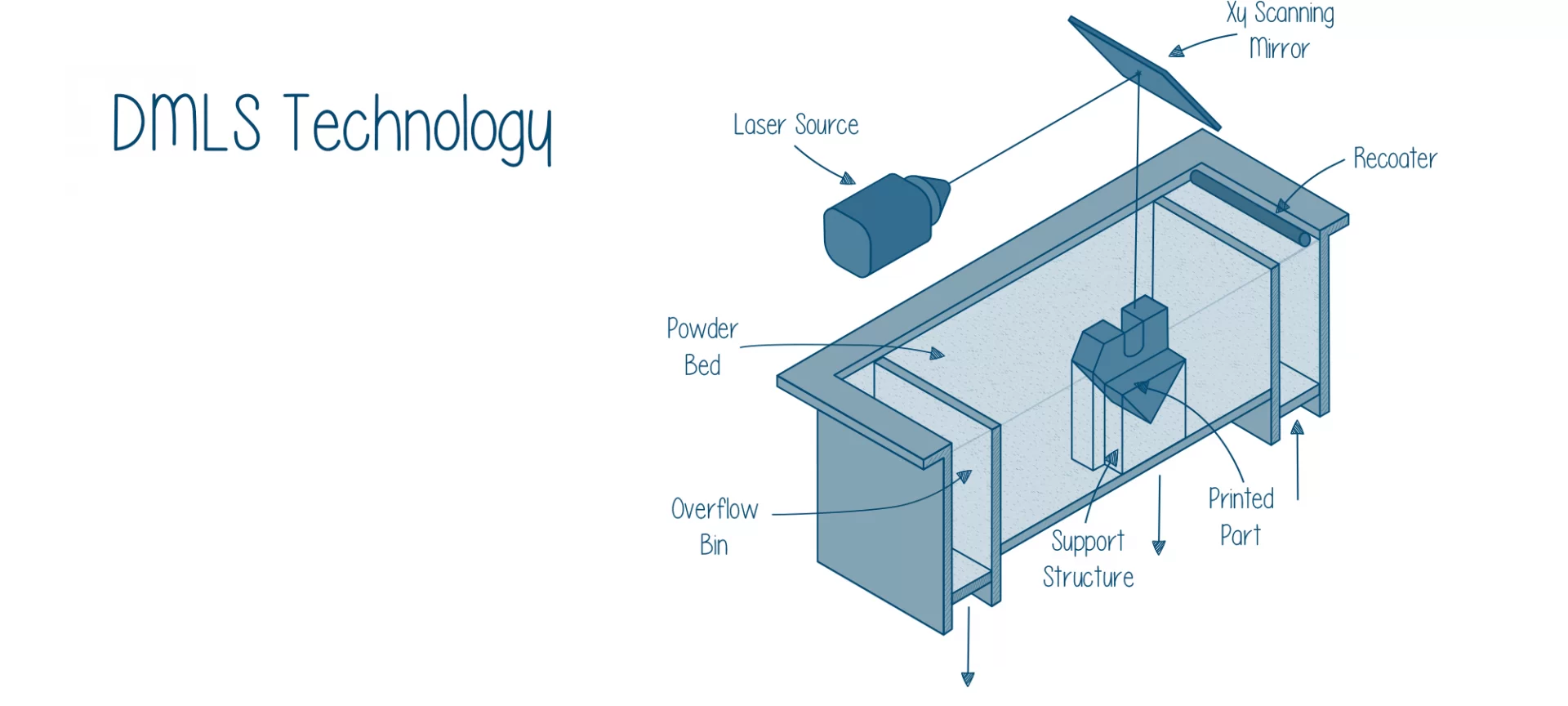

As the name suggests, the 3D Printing process could easily work with metals for creating parts. In the process, the powered metal is sintered using the laser source, one layer at a time.

But it is not the most accessible method of all. DMLS 3D printers are very expensive. Usually, these machines’ cost starts from $100,000. Moreover, the process needs great caution.

The metal powder could pose great health hazards if inhaled. Therefore, it is important to take care of printing in a completely safe environment with proper guidelines.

Users must wear proper gear when working with DMLS machines. For instance, gloves, eyewear, and more. Also, the machines are not available for home users. Instead, these are found in industries that are skilled to work with DMLS 3D printers.

What’s best is the precision of the parts. The models are very accurate, being able to achieve a minimum layer thickness of 38 microns.

Lost PLA Casting

Then comes the most popular method for bronze 3D printing – lost PLA casting. As the name suggests, it is similar to lost wax casting. The only difference is the material used for preparing casts. And, as you can guess, it’s PLA instead of wax.

Using the PLA, FDM 3D Printers can produce casts that can further help in preparing the end models. From intricate designs to bigger models, one can print a variety of designs using this method.

Starting with a 3D model, one must design the file with the help of CAD software. Making use of the PLA model, one simply needs to create the plaster mold. This then needs to be heated above the melting point of the PLA for burning out the material and leaving the void ready for bronze casting.

Hence, after the removal of the PLA, all you need to do is pour the bronze inside the plaster mold. Cool everything down. This will settle the metal in solid form.

Once that happens, just remove the plaster and cut away the tubes helping to pour the metal inside the mold. Later, if needed, sand the model and polish it for further finishing the surface for the end application.

If you choose to complete bronze 3D printing using lost PLA casting, remember to tackle the loss of tiny features due to shrinkage during the 3D design. This will help compensate for any precision variation.

This particular process for Bronze 3D printing is not very accessible noting the cost for kiln and required experience with casting. However, you can easily prepare designs with 20-micron precision.

The Conclusion

Bronze is a very popular metal used for plenty of applications in the real world. From jewelry to sculptures to the belt buckle, one can think of many uses of the metal in day-to-day lives.

However, as it is with other metals, the process of creating models isn’t very handy. You may need a lot of help and invest quite a lot of money to accomplish the entire process.

Although it is difficult to fight the cost part, the ease could certainly be enhanced. Using 3D Printing and additive manufacturing processes, creating parts with bronze could further be simplified. Instead of using multiple methods involved in conventional manufacturing, 3D printing can complete the design in less time and effort.

Therefore, you can certainly look for the right Bronze 3D printing process suitable for your application. And, could use all the knowledge shared here to complete your project into a huge success.

If you already know how to deal with bronze and tame it to lessen its physical limitations, you can start printing easily. And, if not ready yet, check for the 3D Printing services that could help make your models ready without any trouble.