CNC machining has turned into an immensely famous type of manufacturing lately, with its key advantages in providing shops with increased proficiency, ability, and waste decrease.

Because of this expanded prevalence, we have seen a few unique kinds of CNC machines being produced in the market, each with its own particular provisions and benefits.

CNC machining has been the go-to innovation for assembling custom parts, with its use expanding massively lately. Current manufacturing involves a wide cluster of machines, yet probably the most well-known ones are CNC routers and CNC mills.

These machines use various kinds of materials but may perform comparable tasks, and the two of them use computer-aided design and computer-aided manufacturing programs.

They additionally have various provisions and can perform at high efficiency. A few of the reasons why CNC machining is turning out to be more famous are the decrease in waste and upgraded production capacities.

It is essential to comprehend the distinctions of a CNC router versus a CNC milling machine before you invest in any of them.

Here is the know-how of what CNC machines aim to achieve and what are the main differences that exist between a CNC router and CNC milling.

What Exactly is CNC Machining?

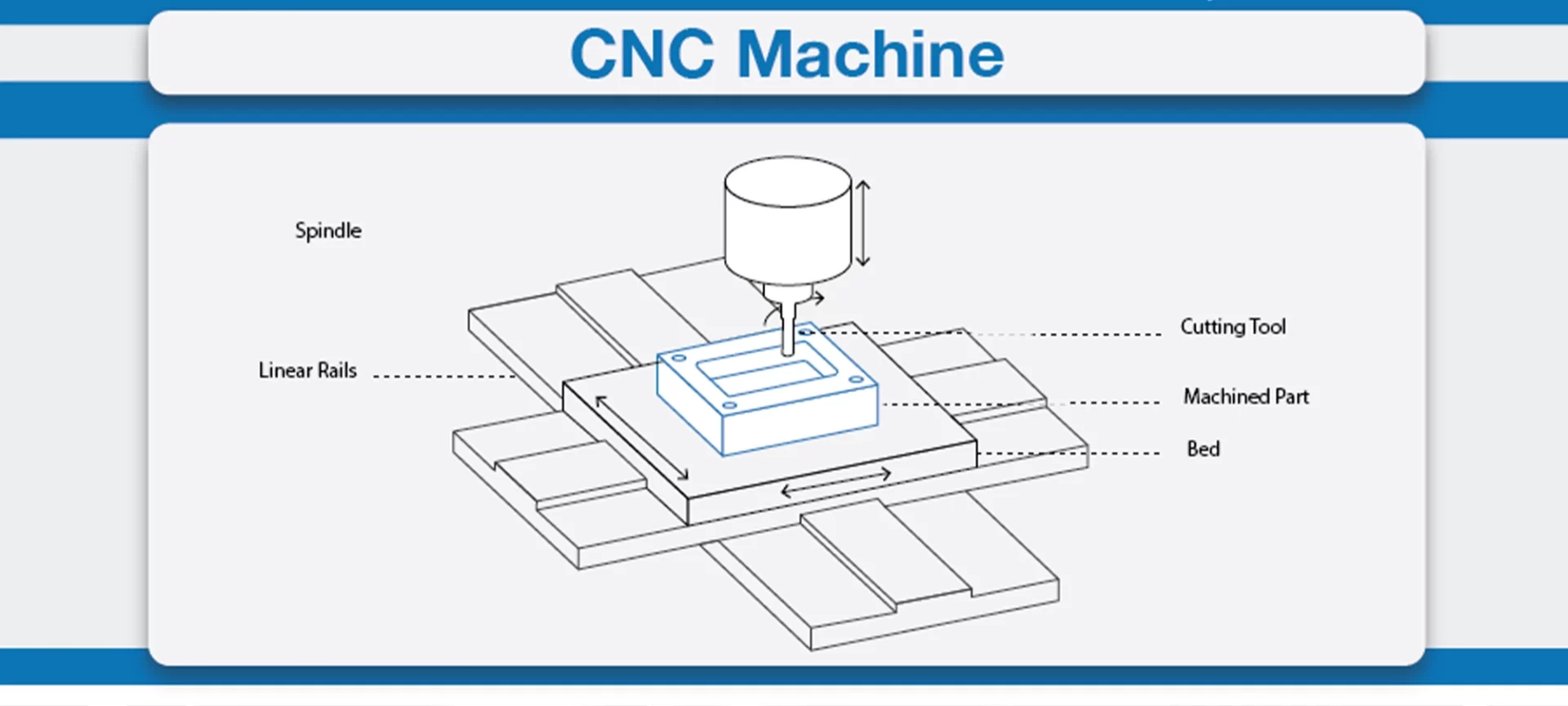

CNC machines are computer-controlled systems that automatically move a tool around a workpiece on series of axes to work out cuts. All CNC machines apply subtractive assembling to create the final product, which means that they remove material from a current piece instead of adding to it.

The speed of movement, speed of rotation, and movement type are general points that are modified to assist with deciding the particulars of cutting with the help of a CNC machine. While both routers and milling give great accuracy, there are various differences you ought to know about.

Clients of CNC milling and CNC routers communicate in a comparative language. Both are very much aware of the difficulties that searching for the right speed and feeds plan involved, discovering new instruments, and using CAM to make parts stand out.

To the veteran machine user, the contrasts between CNC milling and a CNC router, however to the beginner, it is difficult to characterize what separates them.

The principle distinction between a mill and a router is the axis movement. A router has a fixed workpiece and a shaft that moves in X, Y, and Z. While on a mill, the part moves in X and Y, and the axle moves in Z.

Applications of CNC Milling and CNC Routing

CNC milling and routing provides gain for a number of organizations and businesses that need intricate and visually pleasing designs. Every industry in a manner is dependent on these machining measures as they use valves, plates, nozzles, and fasteners. A few of the ventures that use CNC mills and routers include:

- The medical industry

- Oil and gas industry

- Automobile industry

- Hardware and electronic industry

- Military and aerospace industry

CNC Router

The CNC router is known as a reasonably usable device in current machine shops, with its main agenda to cut milder materials like acrylic, wood, foam, plastic, and certain softer metals. It is ordinarily mounted on a fixed table with a bigger desktop, including an axle that moves along three axes – X, Y, and Z.

While routers commonly have three axes, there are varieties with 4-6 axes that may suit more complex or detailed tasks.

CNC routers usually function at higher speeds when compared to CNC mills, using rotational speed as the main thrust in making cuts.

CNC Router Features:

- Chosen to cut milder materials like foam, wood, and plastic

- Kept on a fixed table with a bigger desktop

- Equipped with a spindle that functions on the lines of X, Y, and Z axes

- Functions at fast speed

- Applies rotational speed to perform cuts

- Makes 3D Cutting a lot simpler

Routers, similar to Tormach’s 24R CNC Router, are intended for bigger parts, frequently cut from sheet materials.

Being less inflexible means most routers can’t cut things like steel or titanium, rather, they are explicitly intended to cut wood, plastics, foam, and even aluminum. This likewise implies they influence higher speed spindles, with speeds between 10,000 – 24,000 RPM (in some cases considerably higher).

The 24R was intended to fit a 2’x4′ sheet of material inside the work envelope. That implies that you can even cut the edges of a 2’x4′ piece of plywood without indexing the part.

On account of their bigger – frequently gantry-style – design, routers are regularly less inflexible than their mill counterparts.

Best CNC Routers

Best 4×8 CNC Routers – The Ultimate Buyer’s Guide

CNC Mill

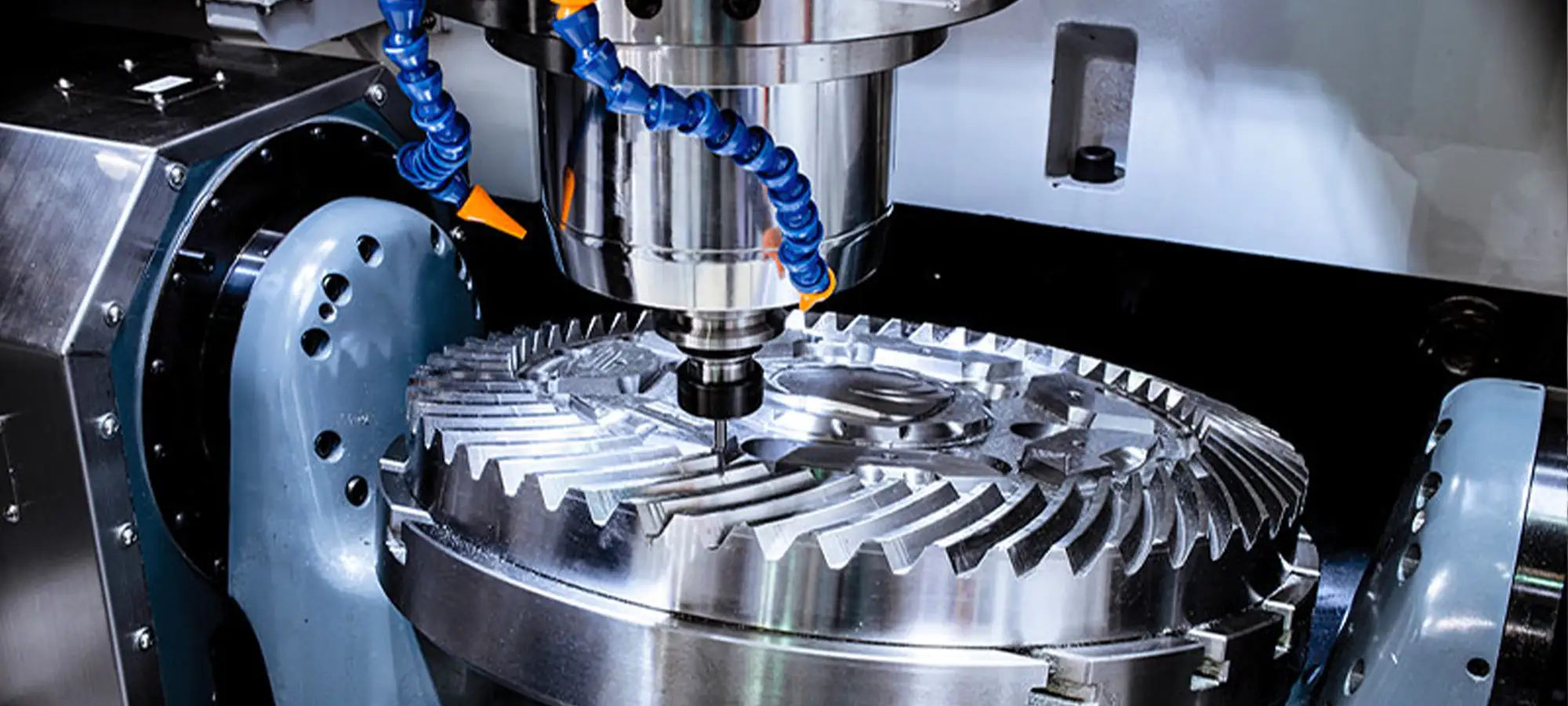

While routers are for the most part taken for softer materials, mills are by and large chosen to cut metals and harder materials. It uses rotating slicing tools just like a router; however, the working speeds are much slower with mills.

Usually, a CNC mill can perform similar jobs as a CNC router but it comes with its own differences. CNC mills, similar to the 770M or the 1100MX, are intended to be more powerful so they can deal with harder materials like steel, cast iron, or titanium.

Instead of using a fixed table, many CNC mills move in an X-Y arrangement, with the shaft continuing on a straight axis on the workpiece.

This gives vast freedom along the Z-axis and allows mills to make thicker cuts, as mills perform cuts using power as opposed to rotational speed.

Mills generally have spindles that are slower in speed; however have a higher force, than a router. That is another reason why a mill is better at harder materials.

This smaller envelope and inflexible nature additionally take into account more exact parts. Thus, in case you’re hoping to remain inside a specific resistance, a mill could be the right arrangement.

CNC Mill Features:

- Selected to cut tougher materials and metals

- More slow working rates than CNC routers

- Maneuver in an X-Y design

- Spindle moves on the lines of a direct axis on the workpiece for wider freedom along with Z rotation

- Ready to perform thicker cuts

- Makes cuts using higher force

CNC Router vs CNC Milling: In-Depth Comparison

- Materials: CNC routers are regularly used to cut gentler materials like wood, plastic, and foam, while mills usually handle metals and harder materials.

- Speed: CNC routers are typically worked higher speeds, and the CNC mills are slower.

- Torque: CNC mills use force to make cuts, and CNC router has less force, it uses rotational speed to drive the power.

- Mass or Quality: The mass of a CNC milling machine is for the most part bigger than that of a CNC router.

- Precision: CNC router isn’t pretty much as exact as a CNC mill, which is the better choice for high accuracy machining parts.

- Axis Design: The bigger freedom along the Z-axis make the CNC milling machine ideal for thicker cuts and more complex designs

- Application or Parts: For instance, the part for crucial hardware for aerospace requires high accuracy and subtleties given by CNC mills, yet for less demanding applications, CNC routers might be sufficient.

- Cutting Area: CNC router has a bigger cutting area as the materials like wood frequently comes in enormous sheets, while the milling machine offers a deeper cut.

- Cost: The cost of a CNC mill will be higher than that of a router equivalent in size.

Which One Is Better?

The two machines are extremely productive in what they do. However, one of the disadvantages of milling machines is that they are huge and have a smaller cutting region. They compensate for that by their capacity to deal with solid materials and produce more detailed, complex designs.

CNC routers then again are quick and cut enormous surfaces, yet they will require a huge work area to set up and are additionally less precise when compared with CNC mills.

Conclusion

The two machines have their own set of requisites and functions and are not to be used reciprocally.

For example, assuming you need items that include slicing through weighty metals then a CNC milling machine is a superior decision, yet assuming you need items that can be made with milder materials the CNC router is better.

Consider different factors, for example, the mass of creation and how precise you need your designs to be while picking the best machine for your requirements.

Depending on the kinds of materials you want to work with, the size of your project, and your budget; it is up to you to decide whether you want to choose a CNC mill or CNC router.