Among all, gold 3D printing has emerged as one of the most successful applications of 3D printing. The popularity is higher among those belonging to the jewelry designing industry and those crafting gold watches.

The technology is making a huge shift inside the workflow of jewelry niche. You can search for 3D printing jewelry service online only to know that there are numerous options.

Not just the technology is able to produce prototypes in the least turnaround time, it also helps designers to freely create unimaginable prints that aren’t possible through traditional methods.

If we talk about conventional methods, craftsmen with even the highest skills were also unable to create some complex designs. However, with 3D printing, it has become possible to give shape to almost every image.

Making items by hand is very restrictive, hence, 3D printing is finding it easier to take over. Those working with 3D printers have time and again deemed that the technology has helped them create a variety of models without feeling pulled back due to a lack of proper tools.

It has considerably minimized the constraints that were usually left designers craving for more.

Isn’t that exciting to know how 3D printing is benefitting the jewelers? Or, how gold 3D printing is carried on? To answer those questions, we have come up with this article that addresses the major section of the technology.

What is The Process of Gold 3D Printing?

Like many other applications that can be accomplished with a typical desktop FDM 3D printer, gold 3D printing isn’t that straight forward.

You may get a variety of PLA filaments from different brands offering gold color options or some providing blends of real gold. However, none of these filaments is able to compete with the jewelry created with actual gold.

They do not look at all like golden ornaments. Hence, the popularity of FDM printers in jewelry making isn’t flourishing. So far, there have been two additive manufacturing processes that are often used for gold 3D printing.

One is the direct metal laser sintering abbreviated as DMLS. This technology uses layers of gold powder which later solidifies using a laser to create the final model.

The model is then extracted from the leftover powder. To further enhance the quality of the end model, the print is cleaned and polished for increasing its shine and attractiveness.

But the affordability is the main concern when it comes to buying a DMLS 3D printer. Moreover, the powdered gold is also very expensive.

Adding to the problems, if the powder is inhaled while operating the 3D printing, it can result in dangerous outcomes. These reasons make it impossible for every business to carry out gold 3D printing using this particular 3D printing process.

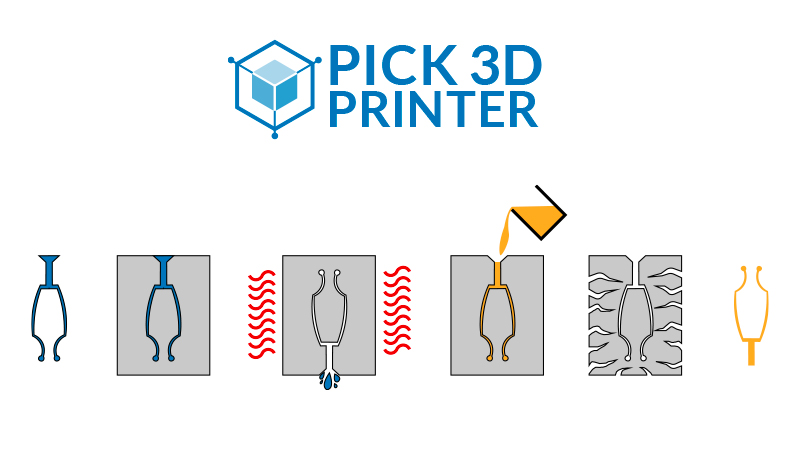

That is the reason, the second option is more convenient. It is done through Stereolithography, commonly known as SLA. The process takes into account a few steps of the conventional lost wax casting combined with the power of 3D printing.

In this process, a high-resolution SLA 3D printer is used for creating a wax model. This wax model is used for making molds. Once the mold is ready, the wax is melted to take it out of the mold.

To create the final piece of jewelry, gold is poured into the mold to create the final model. Later is it polished for adding shine to it?

More About the Gold 3D Printing Technology

Let us know a bit more about the Stereolithography technology that has helped survive many independent jewelers who wanted to try 3D printing, but could not afford to own a DMLS 3D Printer.

SLA has helped many companies to set up their own service centers to cater to the needs of end customers directly.

Using SLA, the gold items are printed indirectly rather than printing them directly out of the 3D printer. The technology uses wax 3D printing and lost wax casting to finally process the end design.

In this case, a wax-like resin is used to create wax models with SLA 3D printers. In this case, liquid resin is cured with the help of laser and bond the layers together.

These models always require support structures that help these models stay strong and not fall apart. Later, these support structures are removed manually.

To create the mold, fine plaster is used. This fine plaster is utilized to cover the wax model. Once the plaster solidifies, the entire mold is heated to a very high temperature, usually inside an oven.

This process burns out the wax and the melted wax is easily removed from the mold. The next step is to pour the melted gold into the empty cast.

Hence, coming up with the 3D printed gold jewelry. As with the conventional methods, the item is further polished to add shine to it.

What are The Properties of Gold?

It is important to know that the items created in pure gold are very fragile. The pure gold models are very soft and can break easily. This is the reason why gold is often combined with other metals when used to create fine jewelry pieces.

The other metals add durability to the entire design. Among the different metals, the most commonly used ones are silver, copper, and zinc. This is done to make jewelry stronger and tougher from within. So, what does karat mean?

The karat which is usually signified as “k” is an indication of the actual amount of pure gold present in the 3D printed item. In other words, if the karat is higher, the jewelry will have a higher percentage of gold inclusion in its design. A 24 karat or 24K jewelry will have 100% pure gold.

In most of the cases, the items are made with 14K and 18k gold content. In 14K gold items, the amount of pure gold contributes to 58% purity.

However, in 18K gold items, the pure gold content is 75%. When deciding to buy a 24K gold item, one must understand the challenges.

The product would be easier to break and would be prone to scratch. However, if you still wish to buy a gold item with a maximum percentage of pure gold, you can opt for 22K gold items. It contains 91% of pure gold and is stronger and durable than the 24K gold.

Talking about the prices, the higher the karat, the expensive is the item, even for the similar weight of less pure items. So, if you are looking for an affordable option, you can for 14K gold items which is the most popular choice in the USA.

The Blended Gold for Varying Colour Difference

As mentioned above, the 14k, as well as the 18k gold items, aren’t created with 100 percent pure gold. These jewelry contain other metals that are used to add strength to these fine designs of art.

Most of the common metals mixed with gold are silver, copper, and zinc. Hence, they do have an impact on the color of the final item. That is why, gold is bought in three different colors: Yellow, White, and Red.

Here is the percentage of different metals added to come up with varying color options of gold jewelry.

- Yellow Gold (14k): 58% Gold, 31% Copper, 10% Silver, and 1% Zinc.

- Rose Gold (14k): 58% Gold, 40% Copper, 1% Silver, and 1% Zinc.

- White Gold (14k): 58% Gold, 24% Copper, 9% Zinc, and 9% Nickel.

- Yellow Gold (18k): 75% Gold, 10% Copper, and 15% Silver.

- Rose Gold (18K): Gold 75%, Copper 22.25%, Silver 2.75%

- White Gold (18K): Gold 75%, Platinum or Palladium 25%

Why Gold is a Friendly Metal for Jewellery Designing?

To start, let us go back to that one property that makes gold easy to mold in different shapes. The reason this is possible is because of its softness.

Although gold is heavy and isn’t prone to tarnish, it is softer at the same time. This is helpful in making gold highly malleable. This means that the metal can be carved in different shapes easily as compared to other metals.

Moreover, the metal is skin-friendly. Hence, you do not have to worry about rashes or allergies when wearing gold jewelry.

This is the reason why the metal is in so much demand within the consumers. Also, one can create intricate designs using gold. All these properties make gold the perfect metal for designing jewelry.

And, gold jewelry often pays well when sold out. This means that the jewelry that you bought at a certain rate may create a return at an exponentially inflated rate.

Few Important Terms of Gold 3D Printing

There are terms that are often used when 3D printing with gold. Here are a few of the basic ones that you would come across when creating a fine piece of gold jewelry using additive manufacturing.

Wall Thickness

Wall thickness is the thickness of the faces of the jewelry. There are either supported walls or unsupported walls. The ones connected on at least two sides are termed as supporting walls.

If not, those are unsupported walls. If you are creating gold jewelry, you must consider the minimum wall thickness to ensure the item survives the printing alongside the cleaning process.

This is because the walls thinner than the required thickness can warp easily during printing or can even break when cleaning.

Wires

Wires are most difficult to work with. These can break when cleaning if are very thin. So, their wall thickness must be selected with extreme accuracy.

For those who do not know what wire is, here is what you can expect. Any geometry which is thinner in both unconnected directions as compared to its length is known as wire.

Escape Holes

When creating hollow products, it is important to clean the unprinted material from inside the hollow item. In the case of gold 3D printing, escape holes are essential for two important reasons.

First, to allow the liquid plaster to enter the hole in order to occupy the hollow area. Secondly, the escape hole must be spacious enough to exit the hardened plaster from the hollow space once the metal is cast.

Accuracy

As the metal properties go, the items are prone to shrinking to about 0.25 mm in addition to 2.5% once it is cast and finished. Hence, you must consider these constraints when gold 3D printing comes up with an accurate size.

Few Tips to Better your Gold 3D Printing Technique

You can always have few tips up your sleeves to produce the best results when 3D printing with gold.

Care While Polishing:

Every designer understands the importance of polishing. The process provides extra shine to the metal.

However, it does impact the fine details, if any, present in the model.

While polishing, designers often end up breaking the fine details, it did not take necessary action. Either you can create designs that have less fine details or you can leave those details when polishing.

Keep Stone holding prongs Short:

Especially in the case of rings, the prongs are often required to hold the stones. However, these prongs must not be too long if there is nothing to connect them.

The connecting beam is usually added to prevent the wax from breaking away. Moreover, when the prongs are thin as well as long, holding off bigger stones becomes a challenge.

Hence, it is important to find the perfect length that keeps your stone stuck tightly inside.

The Conclusion

It is always interesting to learn about new technologies that can help accentuate the quality of the products.

In the case of jewelry designing, the same has been achieved through 3D printing.

That is the reason why many jewelers and designers have already started using 3D printing for printing with precious metals.

In the case of gold 3D printing, the results are awesome. Because of the many supporting properties of the metal and the perks of 3D printing, the items designed with additive manufacturing seems far better.

And, can be created with varying designs and complex geometries, not possible through traditional methods.