The thermoplastic polymer named PEEK, widely recognized in traditional manufactured, can also be 3D printed.

PEEK filament’s demand in the 3D printing market is obvious, owing to the material’s uniquely valuable set of properties such as

- High-temperature performance.

- Mechanical strength.

- Excellent chemical resistance.

Applications of metals, do not suit any other 3D printing materials as much as it does to PEEK and because of this reason, PEEK filament is the most sought after material, for additive manufacturing.

Manufacturers increasing efforts to produce more and more affordable as well as accessible PEEK filament. A result of these efforts is, more and more printers that can not only print huge build volumes of parts and functional prototypes using PEEK, but also high quality in layer resolution.

This has led to many types of brands available in the market which you have to have a look towards, before buying the final PEEK for your 3D printer.

In this article, we are trying to list down various brands of PEEK filament and provide you with insights regarding that brand. But before doing so let’s look at the general properties of PEEK and the points to keep in mind while printing with PEEK.

Properties of PEEK Material

The full form of PEEK is polyether ether ketone. It is a semi-crystalline material that is renowned in the 3D printing market for its excellent strength as well as chemical resistance. The creation of PEEK takes place by a step-growth polymerization process which is conducted at high temperatures. PEEK has a high resistance to biodegradation, as well as chemical degradation in both, organic as well as aqueous environments.

The operating temperature range of this material is 250 degrees Celsius, tensile strength range of 90 to 100 Megapascal, whereas the young’s modulus of 3.6 gigapascals. Overall, PEEK is rigid as well as strong.

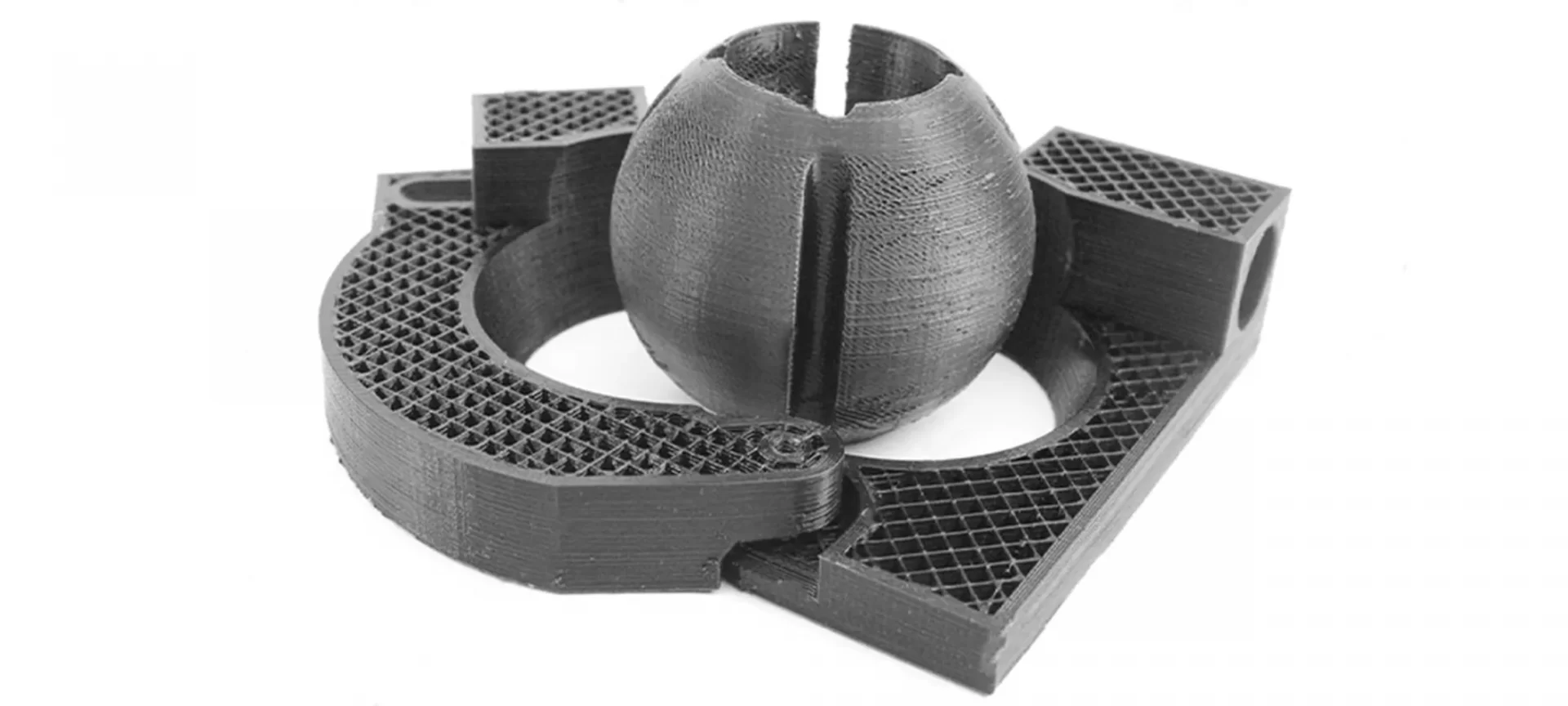

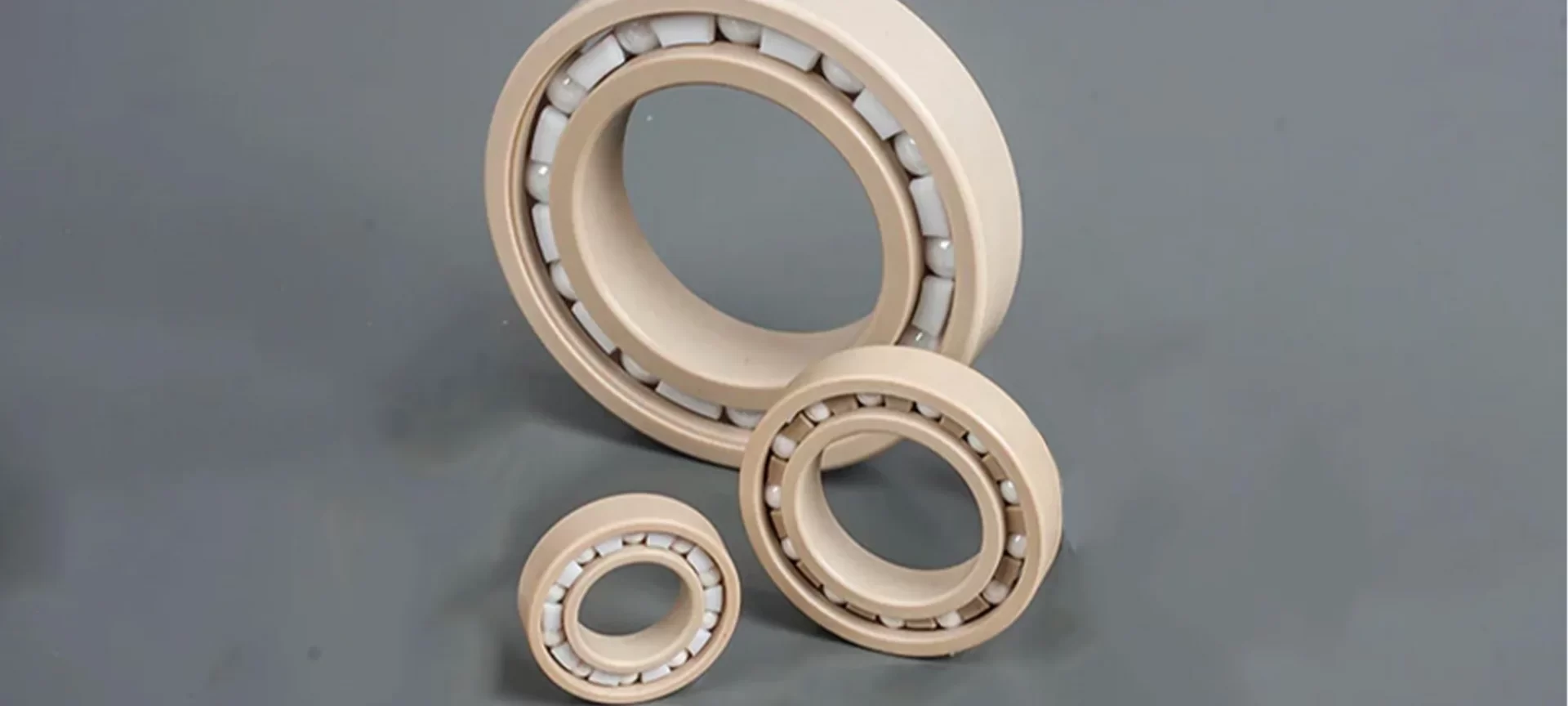

PEEK has excellent physical as well as chemical properties which make the use of this material for manufacturing engineering parts such as piston parts, pumps, bearings, compressors, valves, etc wherever metals are used.

For Printing Using PEEK

When you are out there in the 3D printing market, for buying a 3D printer, notice that not a lot of desktop 3D printers are compatible with PEEK filament.

This is because you need to have a high-end nozzle, printing bed as well as a print bed enclosure to make PEEK 3D printing possible.

For printing with PEEK, you need to have a temperature range of 360 to 400 degrees Celsius. The optimal range of 3D printing temperature may vary from one brand to the other, but the upper half range is the best stop in the case of any confusion.

You need a heated print bed while printing with PEEK filament because you will need to set high temperatures i.e. in the range of 130 to 145 degrees Celsius.

Also, PEEK is prone to warping, so you will have to apply some of the other kind of adhesion that ensures that the printed part or functional prototype sticks to the print bed.

Some websites do recommend glue sticks, however, we would like to recommend you thermally stable adhesives such as Kapton tape, or hairspray.

To ensure that there aren’t any blobs, it is best to start printing with a low speed such as 10 mm per second, but according to your printer, you can then go up to as high as 50 mm per second.

As far as the question of “whether to expose PEEK layer after layer is concerned” it is recommended by experts to isolate the unfinished print from the cooling effect of any kind of external drafts.

It is therefore recommended to have an enclosure around your printer while printing with PEEK.

List of Brands Offering PEEK Filament

PEEK is not as easily available in the market as ABS or PLA is. So, even if you are into 3D printing or have been into 3D printing for years, the brand mentioned below would not have yet crossed your eyesight, if you haven’t received a PEEK printing project.

ThermaX

Available from the website 3DXTech, Thermax is available in 1.75 mm diameter. It has exceptional mechanical, thermal as well as chemical resistance properties that make PEEK a go-to material in some of the most demanding applications.

The price of this PEEK filament is $195. By buying it from the 3DX Tech website, you can get a discount offer of $195.

The glass transition temperature of this filament is 143 degrees Celsius, whereas the melting temperature is 343 degrees Celsius.

Thermax PEEK 3D printing filament is available in Natural as well as Tan colors.

For printing this 3D printing filament, one needs to have the extruder temperature range of 375 to 410 degrees Celsius.

Whereas the bed temperature range should be around 130 to 145 degrees Celsius.

As mentioned above the print speed while printing parts and functional prototypes of PEEK should be in the range of 10 to 50 millimeters per second depending on the intricacies of the part or functional prototype that you wish to print as well as the printer you are using for printing PEEK.

The continuous use temperature of this filament is 260 degrees Celsius.

Tractus

The glass transition temperature of this brand’s PEEK filament is 145 degrees Celsius. Whereas its melting temperature is 345 degrees Celsius.

This PEEK can be used in materials that require equipment that can withstand extreme temperatures as its temperature resistance can go up to 260 degrees Celsius.

The medical industry uses Tractus’ PEEK a lot because it has a low moisture absorption rate and is easy to sterilize.

The PEEK filament of Tractus has a neutral dielectric strength, low dimensional stability, whereas high impact resistance and durability. Although it has lower flexibility, its heat and chemical resistance is very high.

It is flame retardant, as well as has high water and very high wear resistance. For printing Tractus’ PEEK filament you are recommended to and the nozzle temperature range between degrees Celsius whereas the heated bed temperature range between 120 to 150 degrees Celsius.

Tractus PEEK filament offers many advantages such as:

- Enhanced performance: It eliminates corrosion, increases fuel efficiency with lower friction, and handling higher loads or speeds for operating in more extreme chemical environments.

- Weight reductions up to 80 percent: Thermoplastics are known to create lightweight parts and functional prototypes that are strong and having low specific gravity which is less than that of aluminum as well as steel. This decreases the maintenance as well as its transportation cost.

- Lesser Waste: Compared to other thermoplastics used in additive manufacturing, PEEK is known to create lesser waste while printing parts or functional prototypes. This helps increase metal efficiency.

3D4Makers

Available in natural color, the PEEK filament of the 3D4Makers brand can be bought in 1.75 mm as well as 2.85 mm filament diameter. You can buy this printer is 500, 750 as well as 200 grams weight.

This brands’ PEEK filament has unique properties as it does not come in contact with water during the complete production process and is directly packaged in a vacuum.

Properties like these make 3D4Makers PEEK filament suitable especially for printers operating on FDM 3D printing technology.

PEEK material has an excellent adhesion between layers which ensures that the parts or functional prototypes made from the material are of high-quality, impact-resistant, has high strength, and durability.

The filament by this company is compliant with European regulations. The recommended printer settings while printing this PEEK filament is:

- The printer’s nozzle temperature should be in the range of 370 to 420 degrees Celsius.

- The heated bed temperature should be able to withstand no less than 120 degrees Celsius.

- You should adjust the print speed range to around 15 to 30 mm per second.

- For ensuring there is good adhesion between the print bed and the part or functional prototype printed in the printer the manufacturer recommends Magigoo HT on glass or a PEI sheet.

Luvocom

The melting temperature of this brand of PEEK filament is 341 degrees celsius, whereas its glass temperature range is 143 degrees Celsius.

Luvocom’s PEEK can be also processed by conventional methods such as:

- Injection molding,

- Extrusion,

- Compression molding

The credit for such flexibility can be given to the properties of this material. PEEK and its composites are widely used in industries such as:

- Aerospace.

- Automotive.

- Structural.

- High temperature electrical.

- Biomedical applications.

Despite being a high price polymer, the added value that PEEK materials bring by offering the possibility of manufacturing parts includes lightweight, strength, or toughness and able to survive longer in harsh environments make the price worth paying for.

Some of the main properties of Luvocoms’s PEEK:

- PEEK filament exhibits exceptional tensile properties, which when reinforced with carbon fibers, a tensile strength of 29000psi can be achieved.

- Additionally, they can be achieved with excellent properties retained at 299°C. PEEK, as a polymer also exhibits excellent creep resistance.

- When PEEK is integrated with flexural & tensile characteristics, it provides an excellent balance of properties where the PEEK material is required to withstand high loadings for long periods, especially at high temperatures without permanent deformations.

- PEEK’s flexural modulus is known to be further improved at very high temperatures can further with glass- or carbon-reinforcement. Reinforcement is also known to increase creep and fatigue resistance, the thermal conductivity of the polymer as well as heat distortion temperature.

General Applications of Parts Printed with PEEK Filament

Below mentioned are the fields in which parts manufactured from PEEK filament are used.

- Aerospace:

Parts, as well as functional prototypes made from PEEK polymers and their composites, are replacing aluminum and other metals in several aircraft parts.

In the aerospace market, parts and functional prototypes made by 3D printing PEEK filament find use in: Critical engine parts as the polymer can withstand high temperatures and the tribological interaction of dry and lubricated material contacts. Also, in aircraft exterior parts, parts and functional prototypes made using PEEK material provides excellent resistance to rain erosion.

- Medical and Healthcare:

Objects made by 3D printing of Polyetheretherketone provide cost-effective, innovative parts with excellent wear, heat, electrical and chemical resistance.

Applications of parts and functional prototypes made from PEEK in healthcare mainly consist of dental instruments, endoscopes, and dialyzers.

PEEK is replacing aluminum especially which is used for making the handles on dental syringes and sterile boxes that hold root canal files PEEK polymer can withstand up to 3,000 autoclave sterilization cycles in which temperatures typically reach 134°C

- Electrical and Electronics:

Polyetheretherketone possesses excellent electrical properties, which makes it an ideal material for making electrical insulators.

Parts made from Polyetheretherketone Possesses Excellent Electrical Properties. They provide applications with long-term operating reliability over widely fluctuating ranges of:

- Temperature.

- Pressure.

- Frequency.

The inherent purity of this material, combined with excellent mechanical and chemical stability. Joined with minimize contamination and maximize safety makes it appropriate for handling silicon wafers.

Outstanding thermal properties enable PEEK polymer parts to withstand the elevated temperatures associated with the process of soldering.

The Conclusion

PEEK filament isn’t as well-known as many of the other 3D printing filaments like ABS, PLA, or PETG.

But if you look at it closely, you might find a very good reason for this: It is a high-performance filament that doesn’t have as much appeal to hobbyists.

Secondly, the filament has superior mechanical and chemical properties across the board. This also makes the filament one of the more preferred filaments for engineering and medical applications.

Lastly why PEEK isn’t as widely used is because it’s very demanding in terms of 3D printing parameters!

You would notice that the typical desktop 3D printers aren’t equipped for the temperatures needed for PEEK filament 3D printing. So one has to upgrade to something a little more high-end.

The PEEK filament itself is also very expensive compared to the usual 3D printing filament, so you have to be completely sure before using this filament for making parts or functional prototypes.