The 3D printing empire has extended its reign towards the military, navy, and airforce. It is no surprise that the military is using 3D printed products to produce weapons, machinery, various military tools, and aid doctors or medical practitioners in making prosthetics and instruments.

As 3D printing saves costs and is less time-consuming, the military is applying it on grounds by taking portable 3D printers to combat.

They are exceptionally useful for many operations and help soldiers in problem-solving and coming up with intelligent solutions for military purposes. 3D printing is now being used to save lives and honor the country by producing extremely useful products.

What Are 3D Printers And How Do They Work?

3D printers are known for creating something out of nothing, fashioning a powdered construction material into any object the user wants. As 3D printers are evolving, with additional materials now used for printing, the potential applications are also increasing.

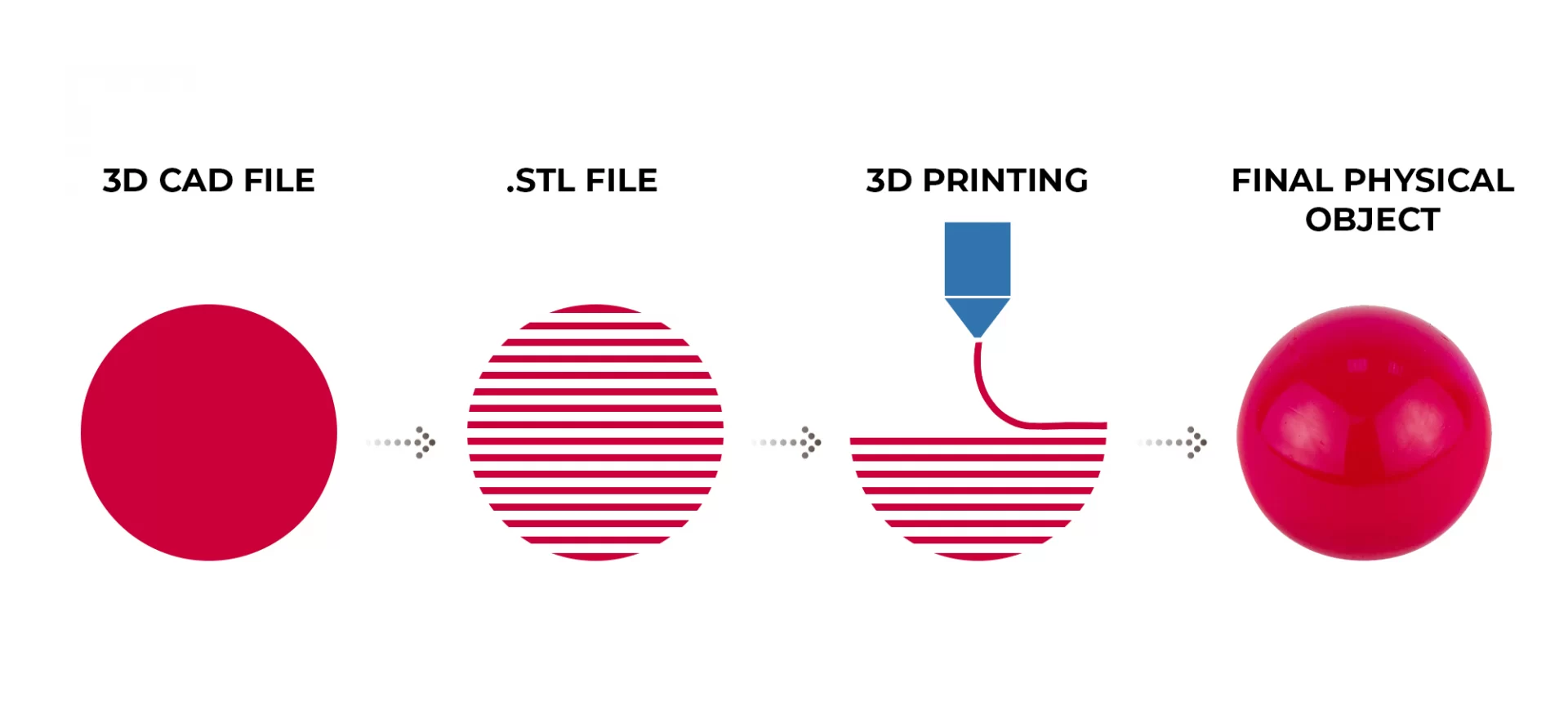

3D printing is done by creating a digital model in a 3D CAD (Computer-Aided Design) file and then producing a physical 3D object. The object is scanned or an already scanned object is used, which is processed by software known as a “slicer.”

The slicer then converts the model into a series of thin, 2D layers and produces a file with instructions (G-code) fashioned to the specific type of 3D printer.

3D Printing in the Military Field

The top militaries from around the world are spending billions of dollars on research and development with 3D printing. They understand the wide range of benefits that they can avail of by opting for this technology to produce parts.

By making 3D printing accessible to the front lines, they can reduce the cost and time involved in shipping parts from overseas. The militaries across the world are constantly appreciating the range of applications of additive manufacturing and using them extensively. The technology is in use to produce parts for a wide range of military vehicles.

Furthermore, these products are known for being durable and long-lasting and have extremely high safety requirements. The requirements include vast mechanical or thermal loading, especially when the planes are taking off or landing.

3D printing can also help reduce turbulence. The uses of 3D printing in the military field are vast, including parts of fighter jets, prosthetics, as well as the door handles of Humvees.

In a nutshell, 3D printing can prove a trendsetter in the military field, leading to greater innovation and producing a wider range of items.

Let’s take a look at how the military is taking full advantage of 3D printing.

3D Printing for Combat

Credit: 3dnatives

Credit: 3dnatives

The US military is working on a project to print out hulls for combat vehicles via 3D printing. There is a strong chance that the forces might eventually decide to make the 3D printed hulls the standard issue for all combat vehicles.

As per the initial research and development, hulls produced using this technology will prove sturdier and be able to resist a larger amount of damage. In addition, the cost and time required to produce the hulls will also reduce.

Save Time on Field

In only 36 hours, a 3D printer from manufacturer Icon, operated by US Marines, created a concrete structure bunker large enough that can entirely hide a system for launching rockets mounted on a truck.

The printer is able to construct entire buildings with quick-drying concrete. The icon allows the Marines to produce prototypes of various structures, which include robotics and software.

The trainees only need to shadow the operators from the company for a few hours, in addition to a few hours spent on training. The technology gives tablet-based system controls that enable even brand new operators to produce high-quality printing.

3D Printing for Night Vision

Credit: additivemanufacturing

Credit: additivemanufacturing

One of the triumphant recent applications of 3D printing in the US Army was a seemingly harmless vehicle hatch plug. This major component allows the Marines to carry out missions in low light, enabling the drivers to see clearly at night.

The Army invested in a metal 3D printer produced by Markforged. Using the printer, they produced hatch plugs at a lower cost, with enhanced sophistication and efficiency of design.

Additive manufacturing simplified the design of crucial equipment. Using this technology, they have complete freedom to design any items they need, while reducing the time and cost required for production.

Create Effective Experimental Parts

Credit: popularmechanics

Credit: popularmechanics

The research labs operated by the Army are working on manufacturing a wide range of vehicle parts. They can do so while reducing the weight of the components.

The items they are testing currently including weapons, brackets, and even turret components. Moreover, the flexibility of 3D printing allows them to try different metals, including titanium.

Less Transportation and Hassle

Credit: armyrecognition

Credit: armyrecognition

Thanks to 3D printing, the military is able to cut the supply chain short. In essence, they can produce items closer to the field, rather than having to ship them all the way from a factory.

The military is already working towards manufacturing components that will improve this process, via land and sea. This phase involves placing a 3D printing pod in a shipping container for ease of transportation. As a result, they can take the technology to any location where they need to print items.

Smart and Secure 3D File Storage

Credit: afrso

Credit: afrso

Thanks to additive manufacturing, users can easily transmit the part files to any printers that are connected to the network. This readiness is essential when it comes to 3D printing in the military field. Research is underway to enhance the secrecy and security around these files, using Blockchain.

Medical Resources

Credit: defensenews

Credit: defensenews

The Department of Veterans Affairs is investing heavily in 3D printing. They run more than 30 facilities across the country, through which they are producing different items, including medical and dental parts and tools.

The purpose of this investment is to enhance the capacity and capability of the hospitals and medical facilities operating under the department to produce a wider range of medical equipment. In fact, the FDA gave special approval on the grounds of compassion for the use of 3D printing in this realm.

Save Costs

3D printing also allows for the convenient production of explosive charges, as per the needs and specifications of the military. Additive manufacturing allows users to print complex items without the need to scale up.

Problem Solving

Credit: military

Credit: military

Problem-solving is one of the major benefits for soldiers and technicians in the military field. Being in the military means being always prepared on-field and otherwise.

3D printing allows the personnel to upgrade their skills, especially when it comes to solving problems.

They can easily customize products for combat, and also produce weapons and tools they need. It is easy to say that 3D printing in the military has offered life-saving solutions in less time and costs.

3D printing offers a wide range of applications in the military field. In fact, as technology continues to progress, there is a good chance that the range of applications will continue to increase.

Therefore, you should not feel surprised if more countries around the world start investing in 3D printing specifically for military purposes.

Most of the projects mentioned above are in their nascent stages and it could be a while before they receive complete approval.

Benefits of 3D Printing in the Engineering Field

Aerospace 3D Printing Guide: All You Need To Know

The Role of 3D Printing in Medical Applications

Conclusion

As you can see, 3D printing can offer a lot in the military field. Hence, the US military in particular is spending billions of dollars on not just buying 3D printers but also research and development to explore hitherto undiscovered uses of this technology.

Only time will tell the direction in which additive manufacturing goes with regards to the military, but all indicators state that the use of 3D printing in the military field will continue to increase.