Technology has reached incredible heights in modern times and there is no question that there are many ways that we are now able to create intelligent and complex structures of high quality.

One of the most rapidly developing ways to do that is through 3D printing. This novel technology enables designers, manufacturers, artists, engineers, and hobbyists to make economical prototypes and parts.

The manufacturing of metal parts often produces a lot of waste. However, by using a 3D printer, manufacturers reduce wastage and consume less energy.

Nowadays, many companies are investing in technology that is cost-efficient and easy to use. Therefore, when searching for a 3D printer, they look for a user-friendly model.

There are various metal 3D printers in the market with a number of specifications and serve many different preferences. If you have an interest in designing models and objects in 3D, you can learn 3D modeling and printing and enhance your technical and creative skills and possibly have a bright future in 3D printing.

What is 3D Printing and How Does it Work?

3D printing uses CAD software to create designs and then print them into tangible objects. It speeds up the production of prototypes and models. By using this technology engineers, manufacturers and hobbyists can create various products in multiple designs and shapes and carry out repetitive printing in an exceptionally short time.

3D printing is enabling a much-needed change for big and small business owners to design and build their products. Especially in engineering, massive developments have been brought forth in technology and those with engineering degrees are exploring more and widening their skills.

3D printing or additive manufacturing defies the use of traditional printing methods such as printing designs on ink and paper. You can 3d print complex and stunning designs into objects, prototypes, or models with materials such as metal, wood, and various forms of plastic.

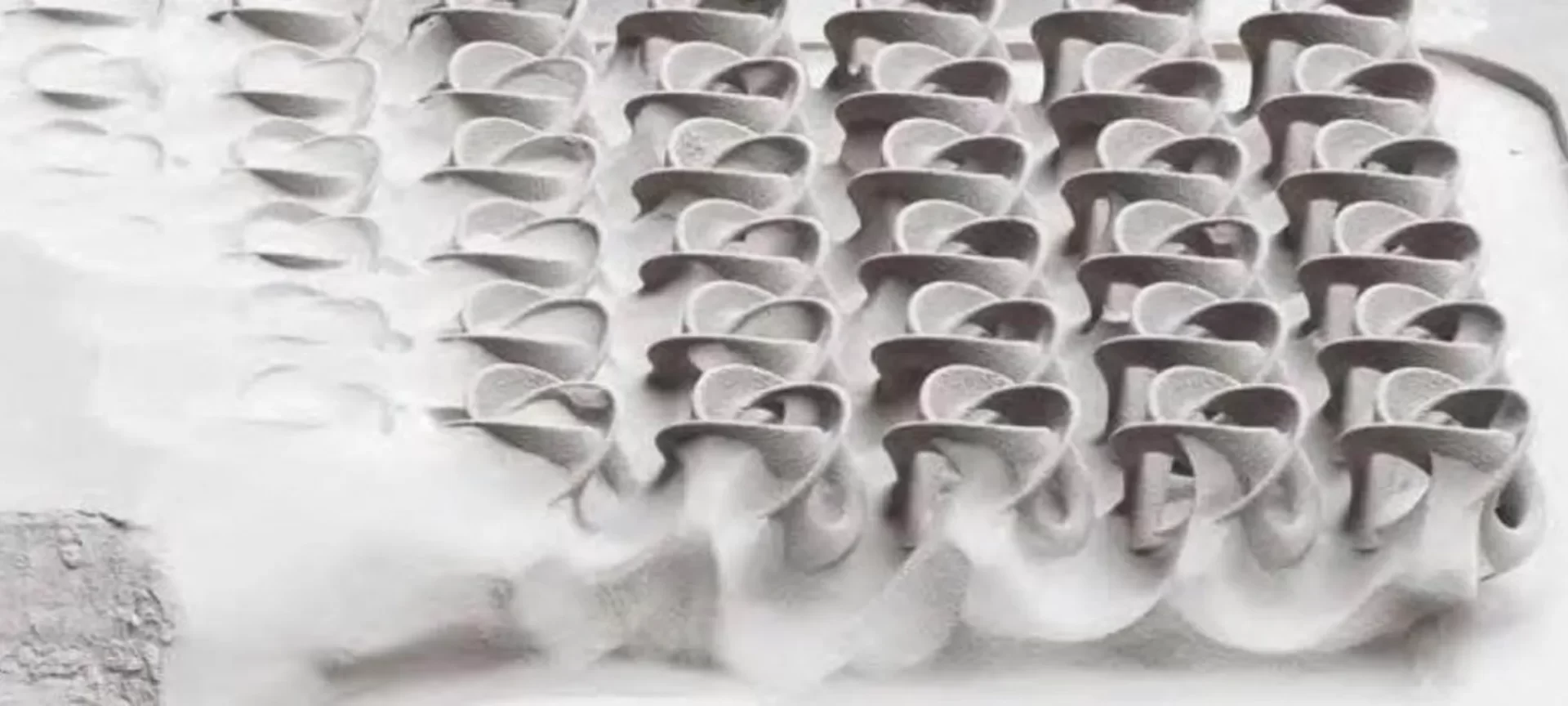

3D printers create layer upon layer of your designed image using your preferred 3d printing material and technology, which allows people, companies to quickly prototype their ideas and cut down costs through savings in supply chains, product waste, and storage.

Every consumer needs their products to work well, the demand for them is now, and it is the responsibility of the manufacturers to live up to these demands. 3D printing can aid in meeting the consumers’ expectations for new products by decreasing design-to-production times.

By using 3D printing technology, designers come up with ideas and create models using CAD software. Then, they forward these designs to be 3D printed and produce functional parts and prototypes.

Designers and Engineers are then able to use these 3D printed products to assess their test features and design. This whole ordeal takes only a few days to complete as compared to traditional printing methods that took several weeks.

3D printing’s advantages have revolutionized many industries such as automotive and aerospace as they aid from shorter lead times as compared to traditional methods of engineering like machining or casting. This allows rapid development and testing of parts.

3D printing has allowed the printing of electronic circuitry points, which enables manufacturers to print 3D products such as mobile phones, and it is even possible in the future that customized consumer products will also be 3D printed.

3D Printing in the Field of Engineering

Since the advent of 3D printing, the field of engineering has massively flourished, giving countless opportunities for students in engineering to learn and experiment and for engineers to speed up their work process and explore their skills.

With 3D printing, engineers can design new and interesting prototypes with complex geometries and internal structures. They are able to find problems and promptly address them without leaving their working place.

What’s more, employees can work from home and produce on-demand products for companies, or work freelance. Engineers can 3D print high-quality objects in less time and cost which would have a competitive advantage in the market.

It frees engineers from long and tedious hours of work, as they can create CAD designs or download them, print them just in a few hours, and reduce errors as well.

Further prototyping, design companies, and engineering are opting for 3D printers. They are outsourcing their projects by owning a 3D printer or by using 3D printing services.

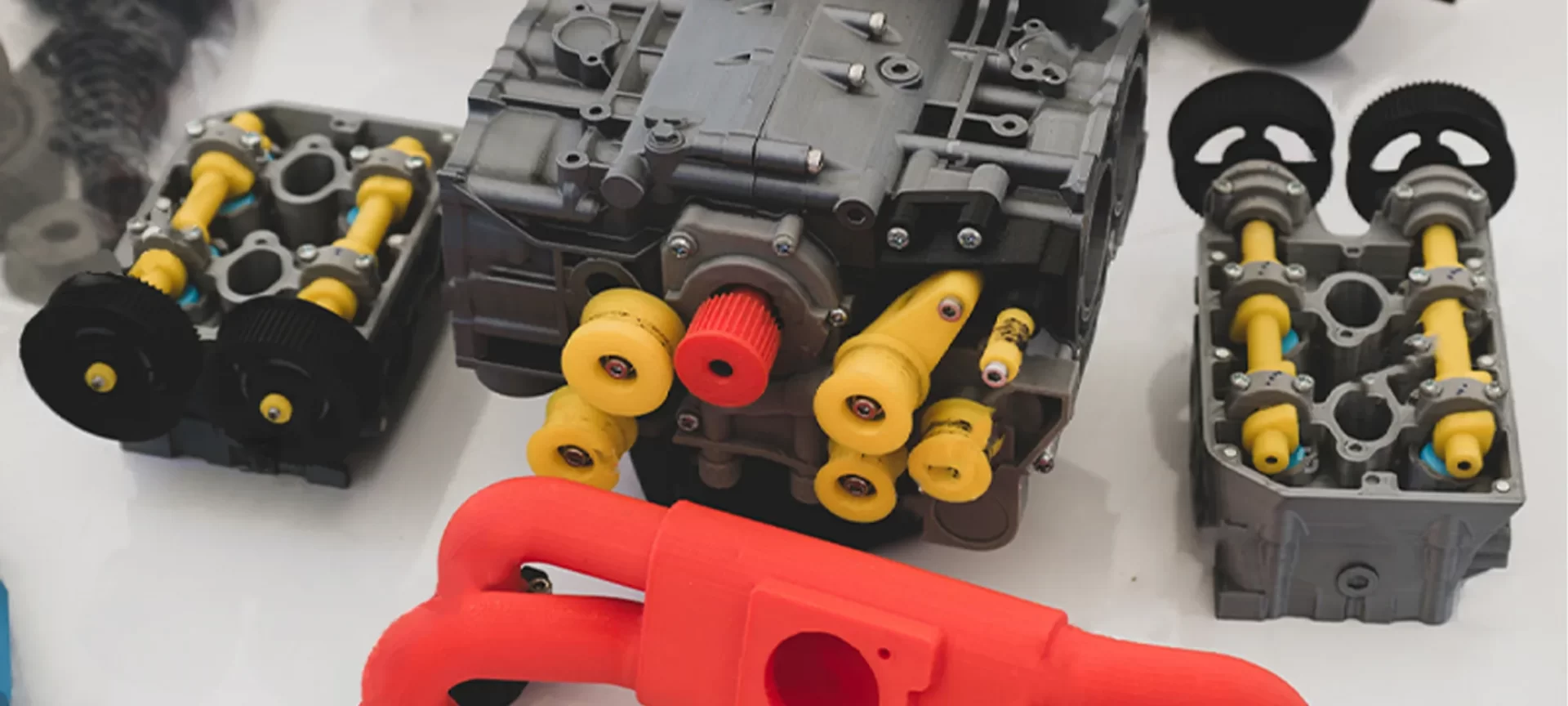

Mostly, 3D printers are used for visual ideas and concepts and for printing prototypes. However, since drastic developments in material science, professional 3D printers are able to print sturdier and higher-quality parts.

By 3D printing in the engineering field, you can test and repeat designs, thus communicating with manufacturers and stakeholders about their preferences which allows you to explore and create customized products.

You can create from a range of materials from rubber to rigid and produce models that are of supreme quality and smooth finish.

Mechanical Engineering

Mechanical engineering is by far the major field in engineering that will greatly benefit from 3D printing. With learning 3D printing, mechanical engineers can revolutionize manufacturing methods by producing complex and visually appealing structures.

From industrial machinery, vehicles, and robotics, mechanical engineers can open up new, innovative, and endless possibilities to design prototypes and models that will amp up the production process.

Modern courses like aerodynamics and fluid mechanics are enabling students to print 3D parts and test them in the wind tunnel by using the same approach where it copies the real-world environments.

Models like basic shapes such as a sphere or a fisk are more progressive models like aerofoils, car models, wings, and truck models.

It has been observed from constant practice and experience, the students of mechanical engineering are taking extra interest and getting more excited when they are allowed to use 3D printing in their coursework.

The process allows them to be more innovative and involved in learning. It is predicted that in the future a separate course will be allotted for scanning and 3D printing technologies, especially in the field of mechanical engineering.

Electronic Engineering/Mechatronics

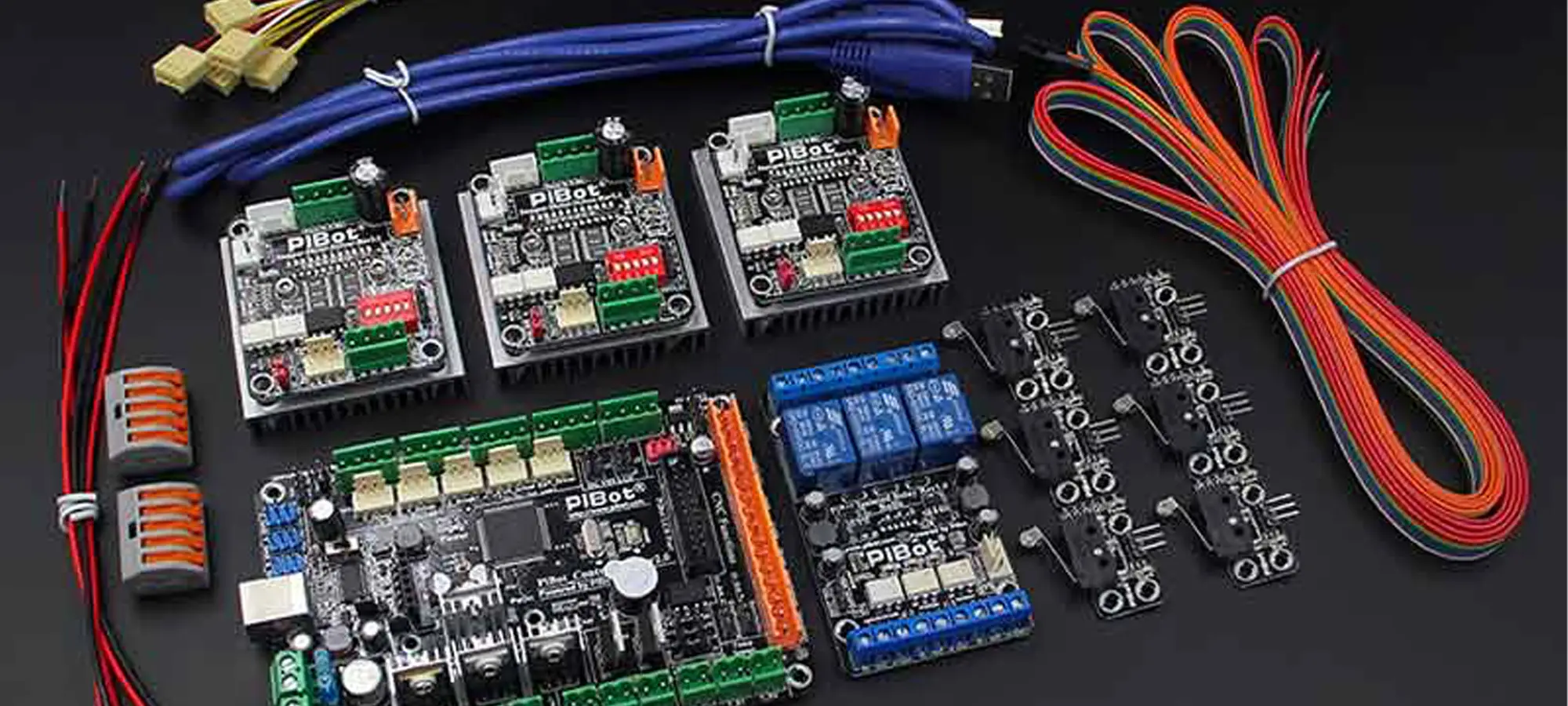

By 3D printing in electronic engineering or mechatronics, you will be able to integrate electronic components and circuitry in 3D printer parts or study electronics and robotics that will enable you to control the manufacturing process in the future.

By gathering expertise in electronics and mechatronics, you will be able to produce hybrid electro-mechanical solutions in areas like motors and intelligent control, detection and machine vision, custom robotics, servo mechanics, high voltage control, and actuation, the list is endless and immensely interesting!

Civil Engineering

3D printing’s impact has been huge and significant on manufacturing, architecture, and building designs. Civil engineers are now able to create entire houses and buildings by using giant 3D printers.

3D printing engineering enables civil engineers to design and come up with exceptional shapes and geometries that may not be financially possible with current building techniques. Being a civil engineer, you will learn how you can address industrial problems and come up with improved solutions and creative ideas.

Teaching 3D Printing in Engineering

If you are passionate about teaching with a background in engineering, you can widen your expertise in 3D printing and teach future engineers interested in 3D printing. You can come up with innovations and invent your own 3D printed prototypes or 3D printing methods.

It will be a rewarding process for you and for your pupil as well. You can also find out your own interests in 3D modeling and printing and be a part-time teacher with a great job in 3D printing and engineering.

Manufacturing Engineering

Manufacturing engineers design fixtures and tools to come up with solutions to problems on the factory floor. All tools are often customized and can be extremely expensive and take tedious amounts of work and time.

The process of making new tools to replace the ruptured ones means losing time in manufacturing, hence decreasing the time to restore tools can drastically decrease costs as well.

3D printed tools can be easily replaced in a few hours rather than many days and today’s materials and composites are lightweight, less expensive, and strong.

Conclusion

There are many interesting aspects of Engineering that will greatly assist the advancements in 3D printing. If you are interested in 3D printing engineering, you must explore your interests and research the areas you are interested in.

You may have to study how you can contribute to the production process and what skills you will be able to harness, and the services you will be able to provide.

By applying 3D printing, engineers can manufacture new and interesting prototypes.

In 3D printing engineering, you will learn about the 3D printers that carry the ability to decrease the development time from months to days, encourage teamwork, and allow effortless 3D printing engineering to ensure the production of projects that meet the deadline within budget and bring about exceptional results.