Titanium is an element that has a partially-filled d subshell. Scientifically what this means is that Titanium has its outermost electron orbit isn’t filled to capacity.

And what does this imply? Titanium can bond with other elements by sharing their electrons. And what does this practically imply?

That Titanium can play well with others, especially with certain ions, it can get an electrical charge. The other characteristic of Titanium is that it has got low density and high strength.

So, it can hold a lot without getting bogged down by its own weight. And, also what differentiates Titanium from others is that it is resistant to corrosion in salt water and chlorine.

By 3D printing Titanium parts and functional prototypes, you can expect products that have higher strength.

The process that is applied for 3D printing titanium is also known as direct metal laser sintering. This is an additive metal fabrication process that was developed in Germany.

In this article, you will study in-depth this process. But one thing for a starter that you need to know about this process is its build on the basic principles of 3D printing. Here is the Best Titanium 3D Printers Buying Guide of 2020.

And so far, this technology has been utilized for the creation of articles of titanium jewelry, mechanical parts for bicycles, and other transportation equipment.

Direct Metal Laser Sintering

This is one of the few 3D printing technologies that directly creates a metal part or functional prototype from its 3D computer model. Rest requires support structures for 3D printing Titanium.

Direct Metal Laser Sintering is an advancement in the technology of manufacturing that is named powder metallurgy.

This technique uses a mature metal-molding technology in which heat and pressure are used for forming powdered metal parts and functional prototypes such as Titanium.

As mentioned above, the working material for this process is Titanium because we are 3D printing Titanium.

But it is not in solid form, rather it is in powdered form.

The exact size of manufactured metal particles is 20 – 40 micrometers. What limits the detail resolution of the final part or functional prototype and even produce a better one is the particle size and shape limit.

Layer height and size of the laser spot are other resolution limits in this technology

. Like other 3D printing processes, the model in direct metal laser sintering is also divided into many fine layers, which are then printed one-by-one to build the final part or functional prototype.

The maximum size of the metal powder used is approximately the Printable layer heights.

How does the process of 3D printing Titanium work?

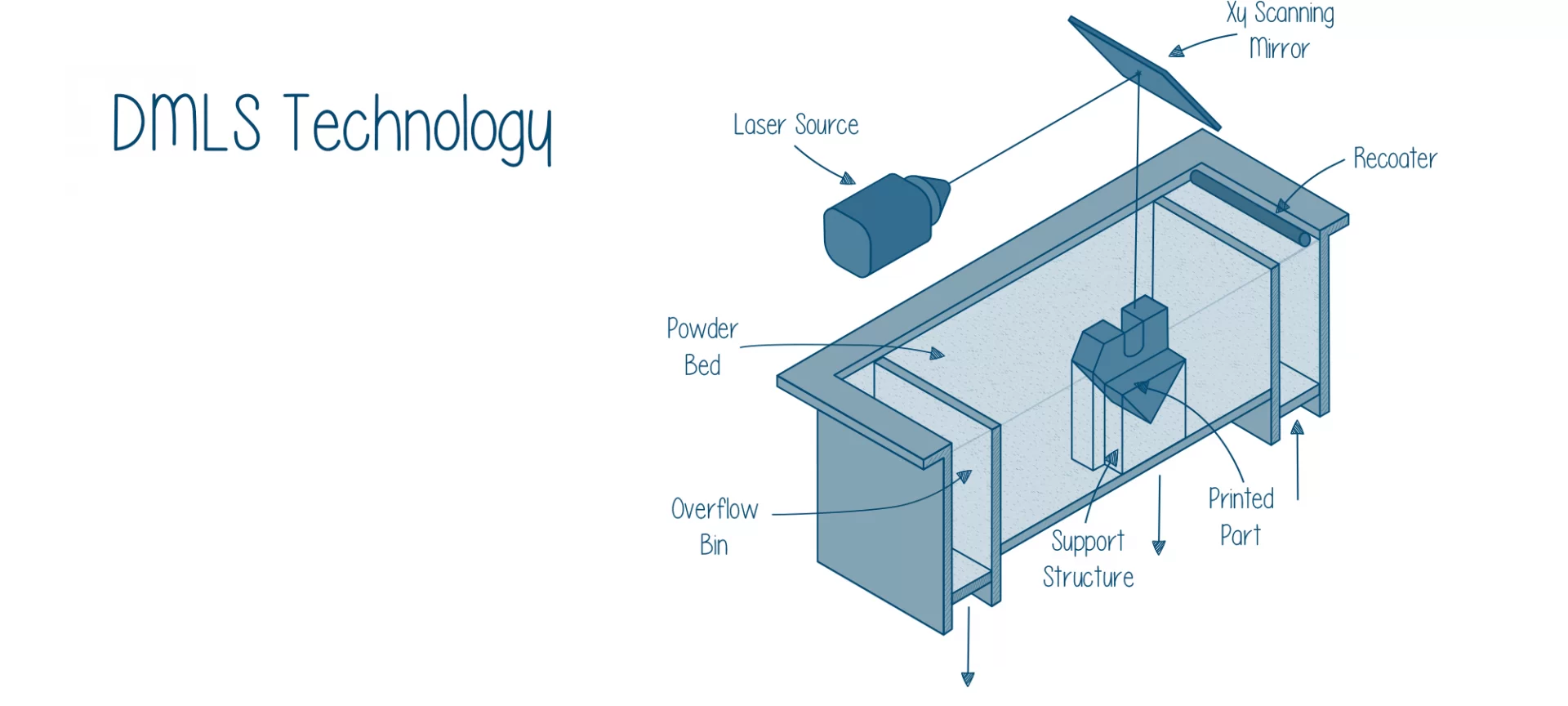

Direct Metal Laser Sintering follows the basic process sequence for most 3D printing technologies. You have to have a model which you then slice, and print layer-by-layer into a part or functional prototype.

After a 3D model is created and sliced with the appropriate slicing software, the code needed for the printer to make the part or functional prototype is then supplied to the printer.

This is actually when 3D printing titanium’s physical process begins. The first step happens with a filling of the DMLS printer hopper with the desired metal powder.

Here the printer’s heaters bring the powder to a temperature that is near the sintering range of the alloy. What the printer uses for protecting the heated powder is the inert gas, this gas also protects the part as it is built.

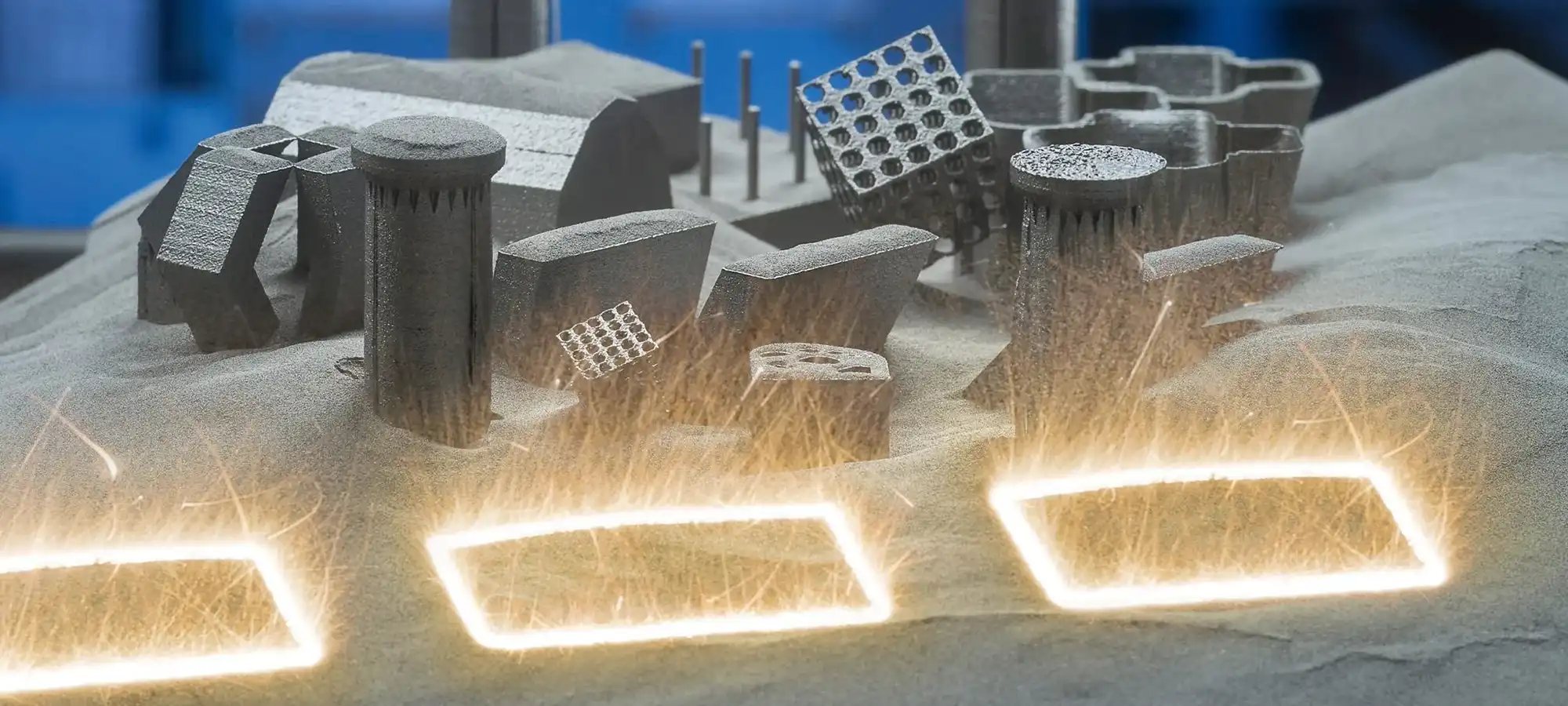

The step of building 3D printing titanium begins with dispensing a thin layer of metal powder onto the build platform.

Once that is done, the laser then begins its path for this layer, one by one selectively sintering the powder into a solid part or functional prototype.

The sequence of dispensing a layer and sintering continues until part completion. After the part is left to cool, the surrounding loose metal powder is removed from the printer.

The last steps include support removal as well as any post-processing needed. DMLS parts can be treated like metal parts produced by conventional metal working for further processing.

This may include machining, heat treatment, or surface finishing. These process steps are shared with SLM, just with the laser’s power turned up to “melt”.

Why 3D Printing Titanium is Different than 3D Printing with Other Materials?

Considerations and preparations required for 3D printing titanium are more in the amount than other metal alloys because of its strength and other physical properties.

Every other metal or its alloys, especially the most popular ones can be spun onto spools of filaments and used like traditional 3D printing materials such as PLA or ABS, but not titanium.

What titanium requires is completely different 3D printing equipment. Specifically, lasers. Arguably, titanium is metal in more than the literal sense.

For wrangling Titanium into your 3D printing projects, you have to utilize an additive metal fabrication process called direct metal sintering which we have already seen above.

The design process is not different than with your usual computer-aided drafting program. In fact, you can use whatever 3D design program suits your fancy as long as it’s compatible with the titanium 3D printer – and most of them are.

Most printers that 3D print titanium accepts the same design file extensions as standard 3D printers, so the only part you have to worry about here is making your design fit your imagination.

Is there Another Method Apart from DMLS with which 3D Printing Titanium can Take Place?

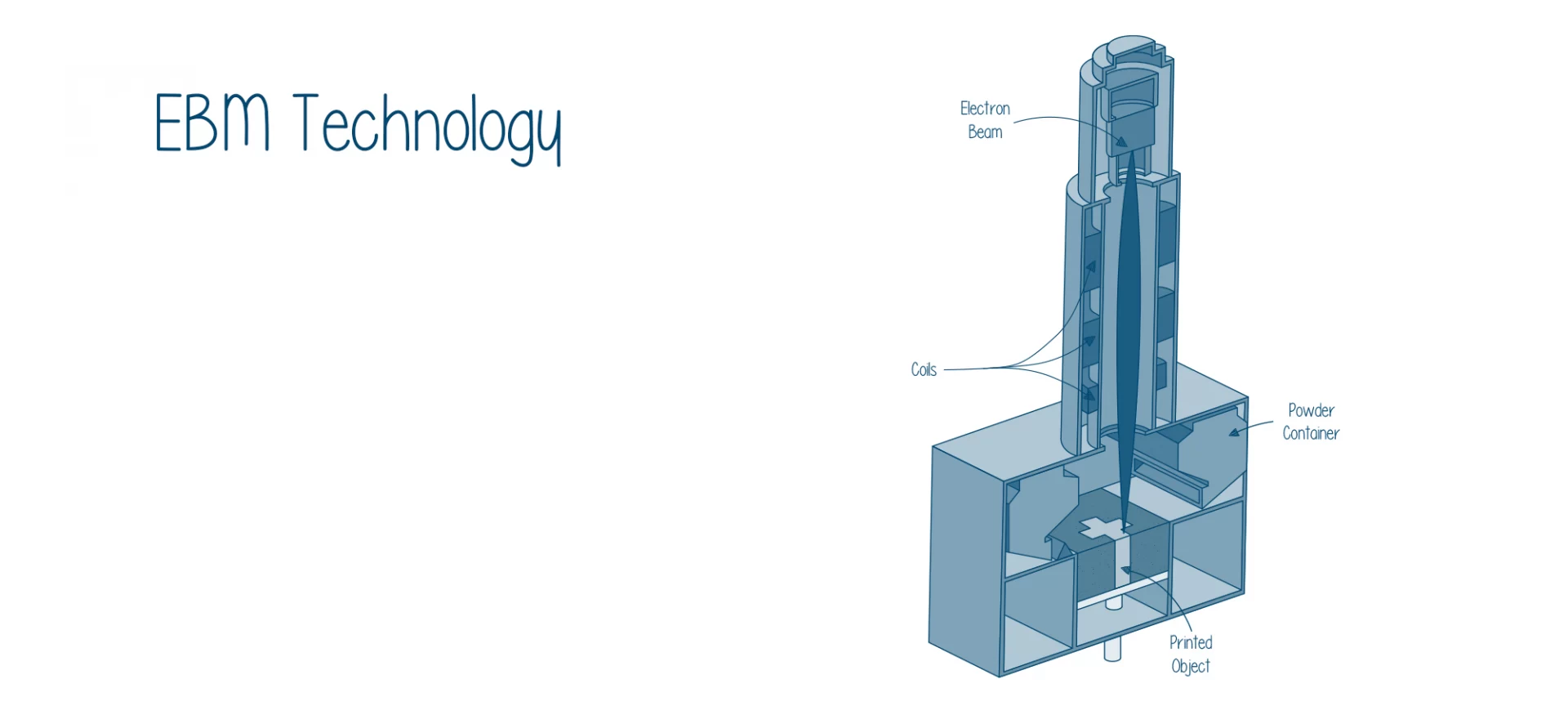

More recently, a technique called electron beam melting (EBM) has been gaining ground. One of its pioneers and main developers is Arcam, which is part of GE Additive.

You can tell by the name that the principal difference between DMLS and EBM is the power source: lasers vs electron beams, i.e. photons vs electrons. Otherwise, it’s still capable of titanium 3D printing. Typically, the energy output through the EBM process is higher than that of DMLS.

EBM offers several advantages:

- Fewer internal defects, resulting in Good material properties.

- Notably better fatigue properties and minimal residual stresses due to high process temperature.

- Little waste material, with virtually all excess powder being recyclable.

The main advantage of DMLS lies in its finer layer thickness (typically 20–40 μm, compared to 50–70 μm for EBM). This results in a smoother finish, which can be of relevance for both aesthetics and function.

EBM has recently been in the news for breaking the record of the largest ever titanium 3D printed part.

A little over 1200 cm across, the object in question was a dome for capping a fuel tank and set the aerospace giant Lockheed Martin to take the prize.

Pros of 3D Printing Titanium

Specific, but complete

For all those who term the process of printing Titanium to be very particular than other metals because it requires a specific machine, a DMLS machine does everything except design your product for you.

This is some facility that you don’t necessarily have with other metals. This quality makes 3D printing with titanium ideal for producing prototypes and test parts.

Anyone who has experience with prototyping and test parts knows how much time they can save you in the long run. Apart from this, DMLS machines produce 3D printed objects without any special tooling requirements.

So unlike other printers, you don’t have to worry about additional equipment or processes when you’re getting your printing done. This is not only a time saver but also saves you on maintenance as well a lot more.

Detailing is served in the print

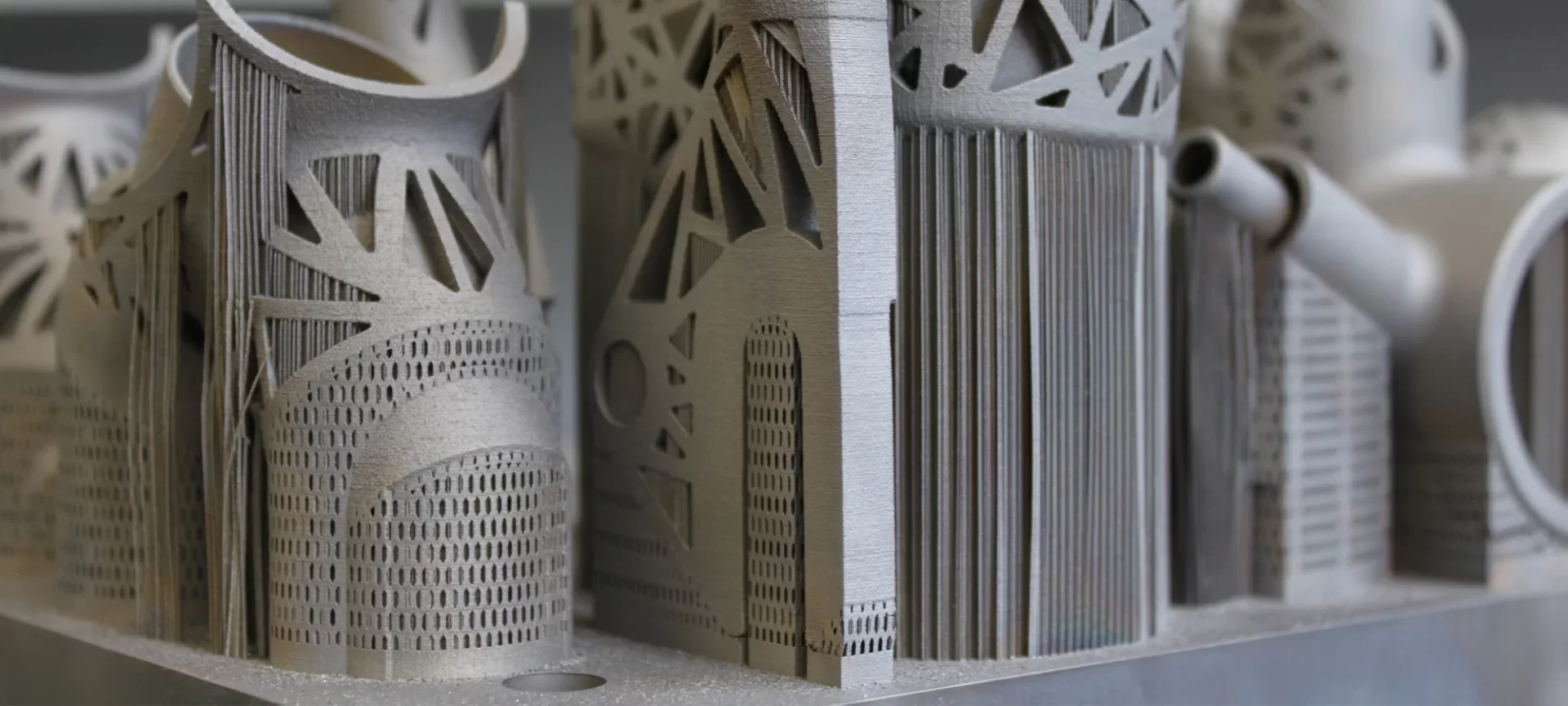

The process of DMLS guarantees to serve you with the best details you’ll ever get from any other 3D printing process. All the layers are easily arranged one over the other and the laser or electron beam cutting is much more precise than traditional 3D printing extruders.

This is what accounts for any tiny detailing that otherwise requires a lot of finesse. Flourishes to your design can be easily added, which could have been impossible to add otherwise been without supporting it with some sort of structure.

This is also great news for industries that rely on small to medium-sized parts and demand them to be readily available and accurate. Some examples of these industries are dental, medical, and aerospace constructions.

Prototypes can be easily manufactured

The benefits of doing 3D printing of Titanium are easily available. And the best part is editing any model or any sort of replication to try and tear to shreds, is not done in a cost-effective as in other technologies.

But that is exactly where prototypes come into play. Arguably, you won’t be able to print Titanium parts on an industrial scale, but what you can print will be exactly what you need to see if anything needs adjusting before you print the real part or functional prototype.

And this will save you so much time and money that you’ll wonder why you didn’t add this step to your routine earlier.

Cons of 3D Printing with Titanium

Expensive compared to other techniques

The expensive tag does not go into buying this metal or the printing cost of it. What it more suitably goes in for is buying a DMLS machine that is needed for 3D printing Titanium.

A DMLS machine will cost you more than a mid-level car as their market price– starts around $25,000 for a beginner. So, arguably 3D printing of Titanium is not advisable for a newbie into 3D printing or someone who is still trying hard to experiment with 3D printing ideas.

All it is advisable for is someone who is so sure about the technology and is willing to build a long-term business with it.

There is also a bright side to this is: DMLS machines are self-contained, so once you buy the initial setup, you’re good until you need more titanium material to print with.

Specific mistakes on the Z-axis of the DMLS printer have to be taken into account

This problem arises because DMLS machines manipulate layers, so it’s easier for you as a user to make mistakes to show up in the Z-axis than with traditional 3D printer extruders.

The technology is otherwise great at keeping attention to details on the X-axis and Y-axis. But there is a little uncertainty on layer height movement and the way it obviously manifests itself.

Fixing this problem can be done by carefully designing and keeping an eye on the DMLS machine as it prints. So, as the rule goes with another 3D printing process, if you’re seeing something start to go bad, stop the printer and readjust.

Imperfections related to surface smoothness

We know by now that titanium is a smooth alloy to work with. But because DMLS machines print with precision, it may be difficult to notice a tiny surface imperfection.

Although this won’t cause problems later on down the chain if you’re 3D printing titanium as the first step. But it also doesn’t necessarily mean you have to reprint because the imperfection is small enough in the area. And that is arguably negligible.

The Conclusion

The other way of 3D printing Titanium is by ordering 3D printing services online. Yes, it is possible, simple, and very affordable.

All you have to know here is the design file of the part or functional prototype that you are willing to print, that you wish to print with Titanium and the infill percentage for minimum layer visibility.

And you are done. Because these are all the details that any website would ask you before you place your order on them.

3D printing Titanium is a 3D printing service that not every website is going to offer you because it is a rare and expensive metal. Although there are companies that manufacture their own metal powders and provide 3D printing service as well.

For these companies, it is easy to offer their consumer this facility. Otherwise normal 3D printing service providers provide 3D printing with other common materials but not Titanium. All the best for the 3D printing of your Titanium parts or functional prototypes.