What is 3D prototyping? Also, popularly known as rapid prototyping, 3D prototyping refers to the iterative design process carried to achieve the desired results.

The process requires making edits to the various steps of prototyping to finally improve the end part. Not many people know, but rapid prototyping isn’t just limited to 3D printing.

There are many other traditional methods that could help create desired parts and components.

While manufacturing prototypes of products could result in huge time consumption and efforts, the rapid prototyping intends to fasten the complete process with precise outcome.

We have been using quite a handful of prototyping techniques such as laser cutting, injection molding. But these options aren’t as fast as 3D printing.

Plus, digital printing has given us more flexibility in terms of material, and the number of changes made to the part before it perfecting the design.

The fact that we are still not able to completely eliminate the old technologies does make us think twice about the capabilities of 3D printing.

However, like every other technology, this digital fabrication technology does have few limitations. Such as size and initial expense. But without spending much attention on these points, let’s stick to the topic here.

Why not find out the different ways to accomplish 3D prototyping and the contribution of 3D printing in the creation of prototypes.

How do you Make a 3D Prototype?

As discussed above, there are certain traditional methods as well apart from 3D printing with a varying use case that caters to the need for rapid prototyping.

And, it does make sense to find out the details of these technologies to better understand the importance of each of these techniques.

3D Printing

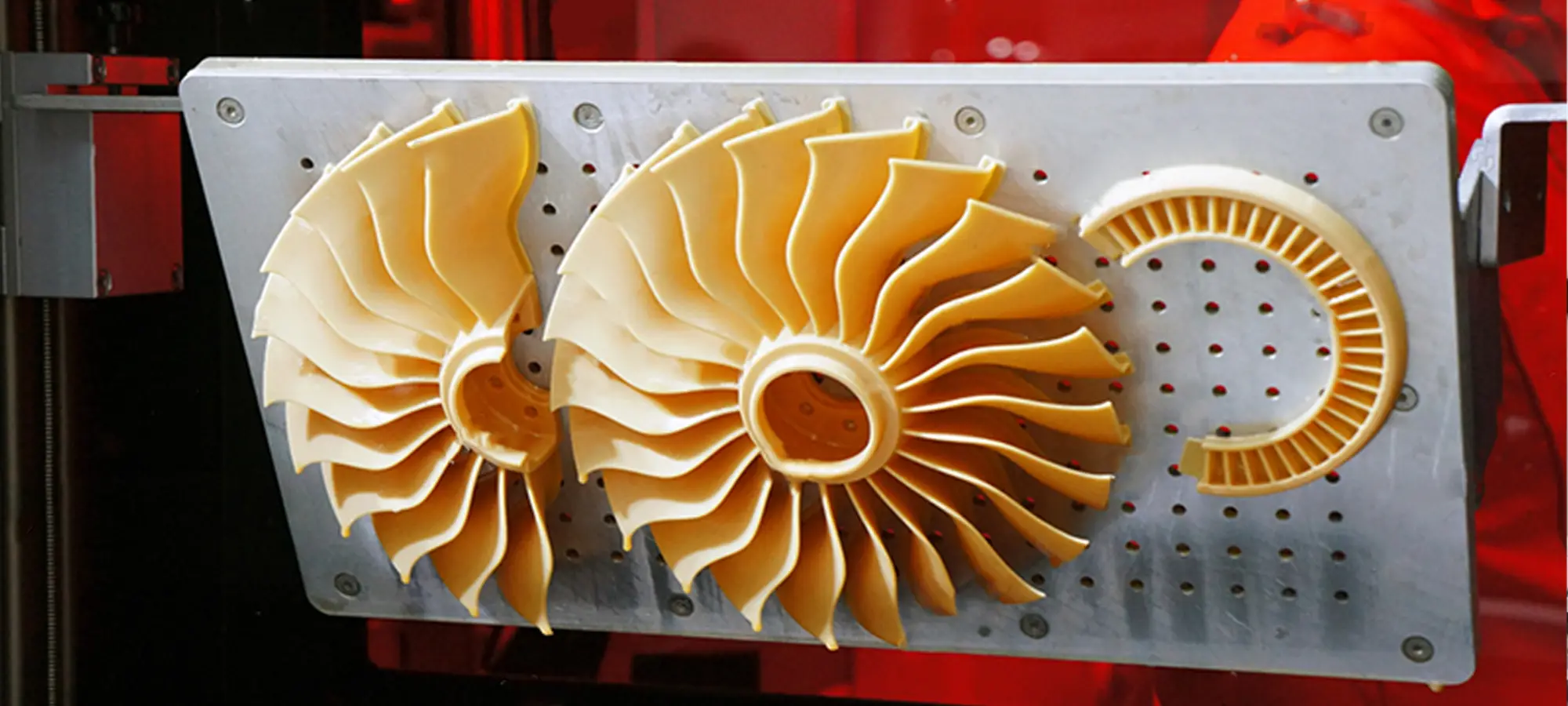

3D printing prototypes have become very common these days. With newer and powerful 3D printers, companies can now create functional prototypes apart from just replicating the cosmetic appearance of the end product.

Understand the need of time, there are many businesses that have started offering 3D prototyping service. You can just upload your designs and the company will ship the prototype to your doorstep.

Using this technology, one can achieve the results in less time and with a wider selection of materials. However, the unavailability of mass production is one of the major limitations that still restricts its integration to every application.

With the help of 3D printing, users can achieve complex geometries by decreasing the overall weight of the product.

There are many processes that come under this technology. And, each of these 3D printing processes offers varying results in terms of accuracy.

For instance, FDM 3D printers are a good option for first-run prototypes. The machines are comparatively cheaper and easy to handle.

However, they cannot offer high-end resolution as compared to the SLA 3D printers. Hence, if you wish to create highly detailed and isotropic prototypes, you must go with SLA 3D printers. However, these machines and their overall operation is expensive when compared to FDM printers.

Also, we do have SLS 3D printers that are highly precise and used for creating solid parts. Mostly used for industrial-grade prototypes, these are expensive than the former two.

3D printing is utilized for various applications within different niches such as architecture, jewelry designing, engineering, and many others.

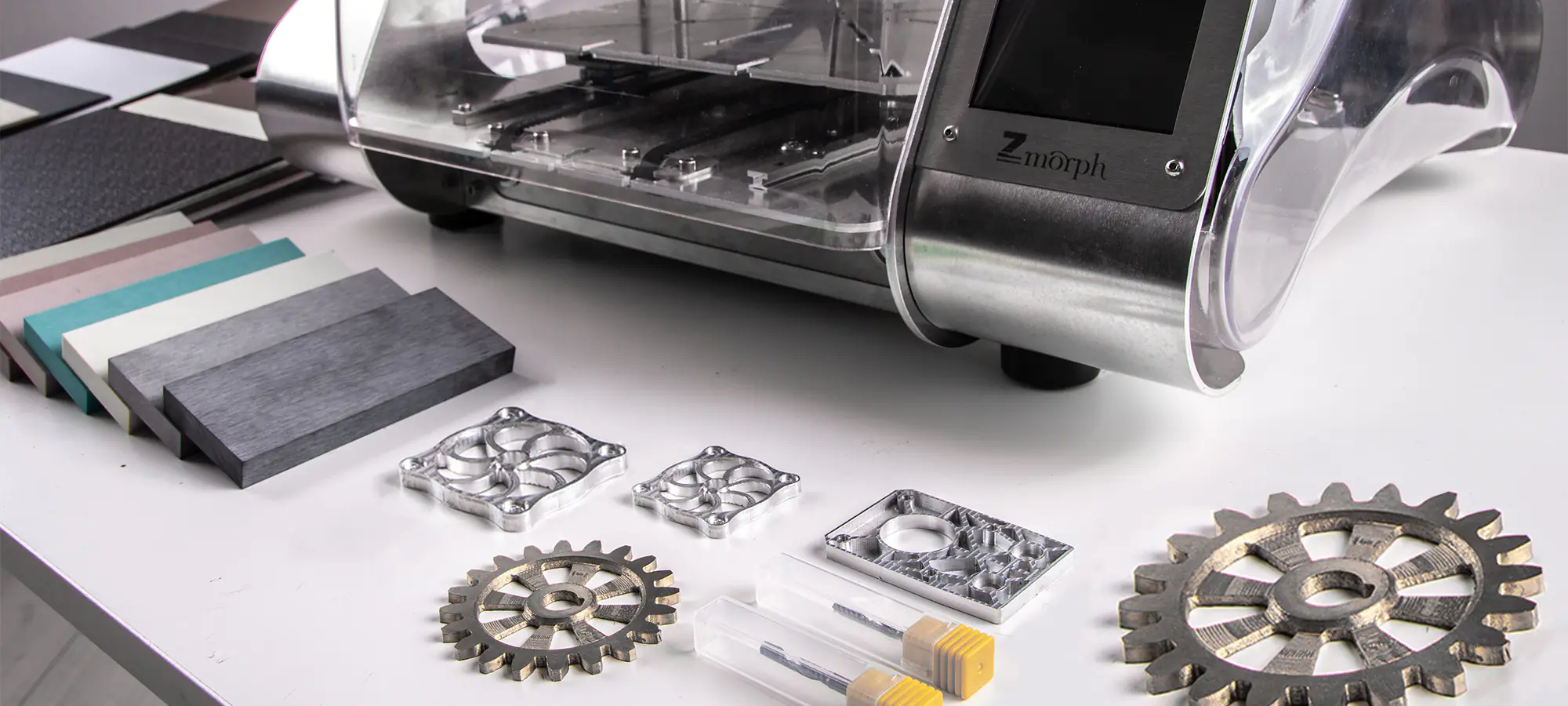

CNC Milling

Unlike 3D printing which is an additive manufacturing process, CNC milling works on subtractive technique. This technology can help in gaining great results for 3D prototyping.

Using a CNC mill, you can work with almost every type of material. Either it’s as soft as foam, or as hard as metal, the tool can cut almost everything, irrespective of its internal bonding and strength. It is used for plastic, wood, glass, and various other materials.

As it goes with 3D printing, to operate the CNC Mill, you must create the 2D or 3D digital models. These are then fed to the software for exporting it to a format compatible with CNC.

Later, you need to add the raw material or clamp to be more precise, to the work table. From here on, the CNC mill will take care of the rest process.

When 3D prototyping, you may need to achieve various results within the same project. For the same case, you just need to change the milling head with other ends.

It could be a polishing, grinding, or even slotting tool. This way, this technology provides highly flexible and versatile results.

Being able to work with varying materials, CNC milling is mostly seen working within industries for high-end prototypes. It includes automotive, aerospace, medical and aviation niches. There are other applications too.

Laser Cutting

Another subtractive method for 3D prototyping. Laser cutting helps in achieving precise results and are very popular. The laser cutters make use of laser beams for cutting the material into pieces of varying thickness. And, it’s pretty fast.

Like CNC milling, the tool can work with a variety of materials with different strengths and rigidity. For instance, you can cut acrylic as well as metal sheets. Along with that, you can even include wood, plastic, and other materials to your workspace.

The method usually works along with laser engraving. This further adds accuracy and preciseness to the prototypes. You can include details, such as logos, texts, and various other finer designs to perfect the prototype design.

When using the services of the companies offering laser cutting, you can also enjoy getting prototypes done in difficult materials as well. From stainless steel to carbon steel, you can ask for a variety of options.

With its flexibility to work with a variety of materials, and offering huge capabilities, laser cutting is utilized within the automobile, military, as well as aerospace industries and various others.

How Does 3D Prototyping Work?

By using 3D printing, one can achieve better design results for 3D prototyping. But how does it work? Find the standard steps involved in creating the final design.

Create a 3D Digital File: Starting with a digital file, one must make sure that all the requirements are well explored and included in the 3D model. From size to density to a lot of other factors concerning the function of the prototype, if the design is meant for functional testing. In case, one wants to test the cosmetic looks, the surface finish, and detailed finish is what one should concentrate on.

Choose the 3D Printing Method: Depending on the accuracy, one must pick the material and the 3D printing process. As mentioned before, for non-functional testing, an FDM printer with PLA could help achieve the desired outcome. However, for more precise requirements, especially for functional prototypes, one must go for SLS or SLA.

3D Print and Test: In the third step, one must 3D print the prototype and check for its usability. This step usually requires one to check the capability of the prototype and see if it suits the specs required. If the results aren’t very close to the required output, one must move to the next step. Or else, the process would finish here itself.

Make Changes to the 3D File: After tests, depending on the changes needed, one must make edits to the digital file and repeat the entire step again. If the results are perfect, the job completes. If not, the process must be repeated unless the desired specs are achieved.

Benefits of Using 3D Printing

With the introduction of 3D printing, a lot has changed across the globe within manufacturing industries. And, rapid prototyping is the most affected process of all. From greater accuracy to affordable parts, the technology has moved the industries many steps ahead.

Precise Designs

Regarding the use of prototypes, nothing has changed in terms of their utility. Today as well, prototypes are created for testing purposes. It helps perfect the end product design and functionality before it goes for the final production.

While the traditional methods and techniques required users to go through a number of steps, 3D printing can be concluded in lesser time and steps.

And, the entire stage of 3D printing depends on the 3D file, completing the prototyping through digital fabrication. With less human interference, which isn’t possible to separate from the old techniques, 3D printing happens to be more precise and accurate.

Moreover, one can create prototypes using the same material as needed for the final part. This way, functional testing becomes more accurate and overall, more predictive.

Environmentally Friendly

The manufacturing industry has been blamed for long being the major contributor to waste materials. Hence, increasing the entire carbon footprint to an unmanageable level.

However, with 3D printing, one can substantially reduce the wastage. Apart from reducing the waste material consumed for production, the technology is effectively contributing to reducing carbon emission as well.

Hence, there is no running away from the fact that 3D printing does create a safer place for us to reside. Based on the additive manufacturing process, most of the material is consumed while creating prototypes.

Maximum Utilization

Manufacturing operations aren’t very high when it comes to utilizing the material or other resources. At most, the USA accounts for 75% manufacturing utilization which is too far from being sustainable.

In other words, the companies are unable to utilize one-fourth of the materials along with processes efficiently. With injection molding and old techniques such as die-casting, efficiency seems to be a farfetched dream.

These processes fail at providing the versatility available with 3D printing. And, most of these techniques depend on subtractive methods.

When talking about 3D printing, things become a lot simpler. These machines could print a variety of different parts one after another, without needing to switch between different methods or systems.

Hence, 3D Printing is able to enhance and surge the overall utilization percentage with a huge difference. And, it seems to be a huge progress for the entire manufacturing industry.

Impossible Designs

While you may think that certain designs aren’t possible to manufacture, even being practically fit, think again. 3D printing can help realize imaginations that aren’t very easy to accomplish with other methods.

Or even the designs that are impossible to create with laser cutting or CNC milling, 3D printing can get that done for us.

Either its highly detailed designs or the complex geometries, 3D printing can make space for designs that are too difficult to create using traditional methods.

If you do not know, 3D printers are very precise as well. Making hollow parts or products with lighter weight seems so easy with 3D printing.

Thanks to the technology that one can now innovate without limitation. Instead of worrying about how to manufacture, one just needs to focus on what to manufacture. This is a huge shift. And, everyone should embrace it to achieve better results.

The Conclusion

We do know that 3D printing has become very popular and getting into mainstream hastily. And, the results are too good to seem true.

But the good news is that the manufacturing sector is able to gain huge perks with the introduction of 3D printing into rapid prototyping.

However, there are certain limitations that still remain. With an increase in demand, we do are expecting huge changes to the restrictions though. But it would take some time until we could say that 3D printing is the answer to all prototyping needs.

Because of the increased cost of equipment and material with a huge initial investment that one must make, the technology isn’t able to showcase its full throttle.

But it’s so intriguing, that despite the high cost, it still is making itself comfortable within industrial applications.

People and businesses around the world are making use of 3D Printing for creating prototypes as well as end products. There are cheaper home 3D printers, although lacking features, have made a great deal for beginners and experts alike.

Today, you can buy a home 3D printer and start working on your prototypes for at least testing its appearance and style.

Many 3D prototypes are being created at home and even small businesses are offering manufacturing as a Service to create prototypes on demand.