Thermoplastic Polyamide is one of the three Thermoplastic elastomers of varying shore hardness value. The other two beings, TPU – Thermoplastic Polyurethane, and TPC being Thermoplastic co-polyester!

So, if you try searching for TPE filaments, you may get confused and a little annoyed at the options that appear. The reason for this confusion would be because TPE is a wide category of materials that several other types mentioned above. So, searching by TPA filament will yield quick results.

Now that we have got this confusion of yours cleared out, here’s something that makes TPA filament more special than its competitors.

To start with, it’s flexible and soft. The filament has excellent fatigue resistance and amazing electrical properties. Its vibration damping capability makes it immensely favorable for mechanical applications of parts that have to bear sudden impacts after regular durations.

TPA filament shows excellent resistance to chemicals and weathering. Stating about resistance, the filament also gives a strong fight to tear and abrasion. Above all, it’s completely recyclable and hence does not harm the environment.

So, wouldn’t you be interested to know, about the printing requirements of TPA filament, its application, various kinds of brands available in the market, and their specifications? Well, this article is meant for catering to all of that.

Coming to the end of this article, you’ll be sure in your mind, about what points to take care of while buying this filament and also which brands to rely more on upon. Excited? Let’s get started.

What is TPA filament?

Thermoplastic polyamide (TPA) is a chemical co-polymer of two very different materials, namely, TPE and highly flexible nylon.

When both materials are mixed in a certain proportion, the result is a combination of a smooth, lustrous texture, coming from nylon, and the flexibility quality coming from TPE. But what are TPEs?

TPE

Thermoplastic elastomers (TPEs) are polymers exhibiting equivalent to that of a cross-linked rubber. The degree of elasticity in the material depends on the type of TPE and its chemical structure.

Additionally, this grade of elastomers comes with the processing advantages of thermoplastics, which is extremely beneficial for 3D printing!

TPE is the only group of materials capable to produce rubber-like 3D printed parts. But it has its own issues.

TPEs have the problem of being poorly handled by extruders owing to their softness. As TPEs are hygroscopic, they absorb moisture and hence need to be stored in a correct atmospheric condition.

Otherwise, their prints will pop up and sizzle if the filament isn’t stored properly. TPEs are also particularly sensitive to quick movements.

So, if you are not completely careful the filament might buckle when pushed through the extruder. After going through TPE, it’s important to know about the other material that makes TPA i.e. Nylon.

Nylon

Nylon aka polyamide is a repeating molecule linked by amide bonds. It is another niche of filament that belongs to high-end engineering thermoplastic.

The material has extreme toughness and durability, but requires excessive fine-tuning and care to produce successful prints. For the same reason, it’s best suited for experts wanting to print small machine parts like gears.

The filament made of nylon is strong and flexible. At the same time, it’s light and resilient to wear and tear that is faced by parts when they are generally associated with continual use.

To understand its use in a better sense, the weed whacker trimmer line is made with Nylon filament. Because of its increased strength and elasticity over PLA and ABS, Nylon is especially utilized in industrial applications, such as machine parts or tools, even in the replacement of automobile parts.

A special property of Nylon is to bond to itself very well. Meaning that Nylon is a great filament for making parts and functional prototypes that can be either drilled, tapped or screwed.

For adding versatility to the nature of Nylon, its filament can also be dyed any number of colors by users, provided it should be done prior to printing.

After going through both the materials that constitute TPA, it’s time now to see the exact features of TPA and its print settings!

What Are The Features and Print Settings of TPA Filament

Because of the mixing done between TPE and Nylon, TPA gains a high amount of flexibility. TPA is one of those rare filament materials that have elasticity in the range of 370–497% Shore hardness of various brands of TPA filament ranges anywhere between 75 and 63A.

The filament is exceptionally durable, it has good printability. TPA is known for resisting a good amount of heat and for offering extraordinarily good layer adhesion.

Print Settings

- For printing with TPA, you need to take care that your 3D printer’s extruder temperature ranges anywhere between 220 degrees Celsius to 230 degrees Celsius.

- Coming to the bed temperature range that you need in your 3D printer while printing with TPA filament, you are allowed to go as low as 30 degrees Celsius, and as high as 60 degrees Celsius.

- The most important part while printing with TPA filament is the print speed. The temperature can be a little more or less, both the print head as well as the extruder’s but if the print speed is a little more or less, it will cause troubles. Please note that experts recommended the print speed while printing parts and functional prototypes with TPA to be around 5 millimeters per second while printing complex geometries or geometries with support structures. Whereas for simplest geometries you are allowed to go till 30 millimeters per second.

- For receiving good bed adhesion, you need to follow the same guideline that you follow for PVA-based materials.

- The recommended extruder system for printing with TPA filament is either direct drive or Bowden.

Tips

As is the case with any filament, please ensure before printing with TPA filament that you’re using the right printing temperatures. Also, check the extrusion temperature and start in the middle of the range.

In case your TPA filament is under extruding, turn the temperature up a little, and in case it’s over extruding and oozing all over your print, you are advised to turn it down a little.

Stating about another common problem of oozing, ensure that you’re using the correct retraction settings.

Doing so might need to be a little more than standard filament retraction as TPA being a flexible filament can leak a little more between extruding points.

In case you’re getting excess material than needed, or wispy thin strands adjust by increasing your retraction in the Slicer.

Another benefit of increasing retraction is that it prevents the pressure from building and causing the material to expand and clog in the hot end which is usually caused by excess friction.

Soft filaments are known to typically adhere well to 3D printer’s print beds. Often you won’t need a heated bed at all, because they don’t tend to warp.

But we do recommend heated beds for those first layers of the prints at least. For ensuring the safety of these layers forgets the hairspray, either the blue painters’ tape or thin (dry) coating of glue stick should give great results.

Some surfaces such as PEI can stick a little too well, so be wary of that otherwise they will cause trouble while removing the part or functional prototype.

You can also print faster than the above-mentioned speeds, but you will need specialist extruders, that will either have lower friction linings or reduced space for the pushing string effect.

Particularly, direct-drive extruders are known to work more effectively, as opposed to Bowden tubes that can cause extra friction.

Who Makes the Best TPA Filament?

Below is a list of few reliable brands that are known to manufacture high-quality TPA filaments.

NinjaTek

Ninjaflex’s TPA filament is a great flexible material, that’s very soft. Although it’s very demanding and needs much care, it produces excellent results. The filament has a Shore Hardness of 85A.

Unlike other filaments’ settings, that you are able to print the NinjaTek at up to around 85mm/s, typically TPA filament is softer materials so it is advisable to print at around 30-55mm/s depending on your printer.

The benefits of this filament are:

- Low friction

- Higher stiffness

- Easier to print

- Adheres to most regular print surfaces

This filament is only available on 0.5KG spools and is very expensive – especially if you need a larger quantity. It needs print settings ranging between 225 degrees Celsius to 235 degrees Celsius.

Polymaker

The filament’s Shore A hardness is rated around 90A – 95A which is comparable to most other TPA-based filaments.

At first, you will find it confusing that the filament doesn’t seem to commit to a specific hardness rating, so it can be subjected to conditions such as temperature, humidity etc.

Generally this TPA filament prints well also the brand’s customer support is good. Its single spool weighs only 750-gram.

The brand’s color range is very limited. You need to ensure that the printing temperature ranges between 220 degrees Celsius to 235 degrees Celsius.

Recreus

This filament has the lowest shore hardness on the list i.e. 82A. Although the filament is flexible, it prints well. The 3D printer filament is worth considering using a specialist extruder with a thermal insulator and low friction PTFE lining.

Even the elongation level of 700% would not be able to break the filament. This TPA filament is useful if you need something with even more stretch.

The filament is also available in a healthy range of colors and weights 250g and 500g spools. You need to print this filament in temperatures ranging between 210 degrees Celsius to 230 degrees Celsius.

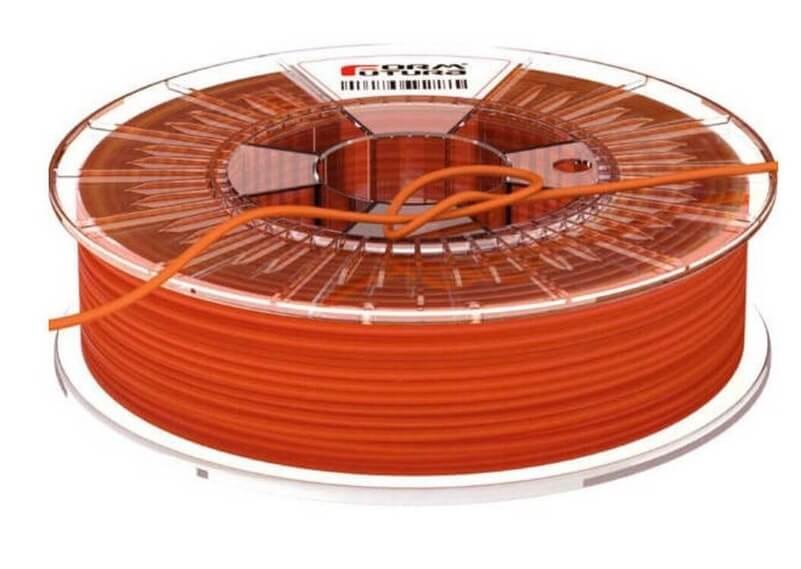

FormFutura

Here’s an interesting material that is a Co-Polyester Flexible 3D Printer Filament partially made from bio-oils. FormFutura uses a different scale to measure hardness, other than the A scale, this printer manufacturer uses the Shore D scale.

Converting the rating that they give i.e. 45D it means somewhere around 92-94A. The filament is only sold on 0.5KG spools.

Their recommended printing temperature range for printing with this filament is around 220 degrees Celsius to 260 degrees Celsius.

It’s worth considering that this TPA filament must be printed very slowly in the print speed range between 10 millimeters per second to 20 millimeters per second.

Experts recommend adding a tiny amount of WD-40 to get aid in extrusion. The most important highlight for this material is that it is environmentally friendly. The second most important highlight being, excellent quality prints.

MatterHackers

This filament is a biopolymer. Meaning that it’s created from one or more types of natural materials. The printer is a great advancement over regular, often brittle PLA.

It needs an extrusion temperature range of around 220 degrees Celsius to 235 degrees Celsius. For printing speed, you will have to follow the slower trend somewhere around 10 millimeters per second. If you try printing higher, you will end up with the problem of jams.

Also, it is a common problem while printing with flexible materials too fast can cause them to expand too quickly in the nozzle, this can lead to reduced extrusion or even blocking.

The Shore hardness of this printer filament is 92A. It comes in 0.75KG spools, both in 1.75mm diameter as well as 3.00mm diameters.

The Conclusion

Overall, TPA filament leads to the printing of varied parts and functional prototypes that cannot be printed with any other 3D printer filament. But to achieve those parts, you need to take an extreme amount of care.

Because this filament is a part of a very delicate group of 3D printer filaments i.e. flexible filaments. So, you will have to take care of the extrusion temperature range, the heated bed temperature range, print speed range, and also retraction settings in some cases.

Various brands of TPA filaments come at various costs, colors, price, and shore hardnesses. You need to decide based upon the application of the part or functional prototype that you need to print with the filament and match it with your printer settings.