Speaking about the materials a user of 3D printing technology can 3D print with, Nylon is a material that standouts. Not only is Nylon one of the most popular materials for professional 3D printing, but also it has a wide range of applications.

A credit to both the things mentioned above goes to unique properties that it possesses. To 3D print, Nylon is to make parts and functional prototypes easily and inexpensively.

In this article, we will talk about how Nylon can be used as a material that can be 3D printed. It is said that Nylon can be printing using many different 3D printing technologies such as Fused Deposition Melting, Selective Laser Sintering, and Multijet Fusion.

Chemically, Nylon is a polyamide that is found in variants PA 11 and PA12. It is a very strong and durable material that offers flexibility to an extent amongst the thin walls.

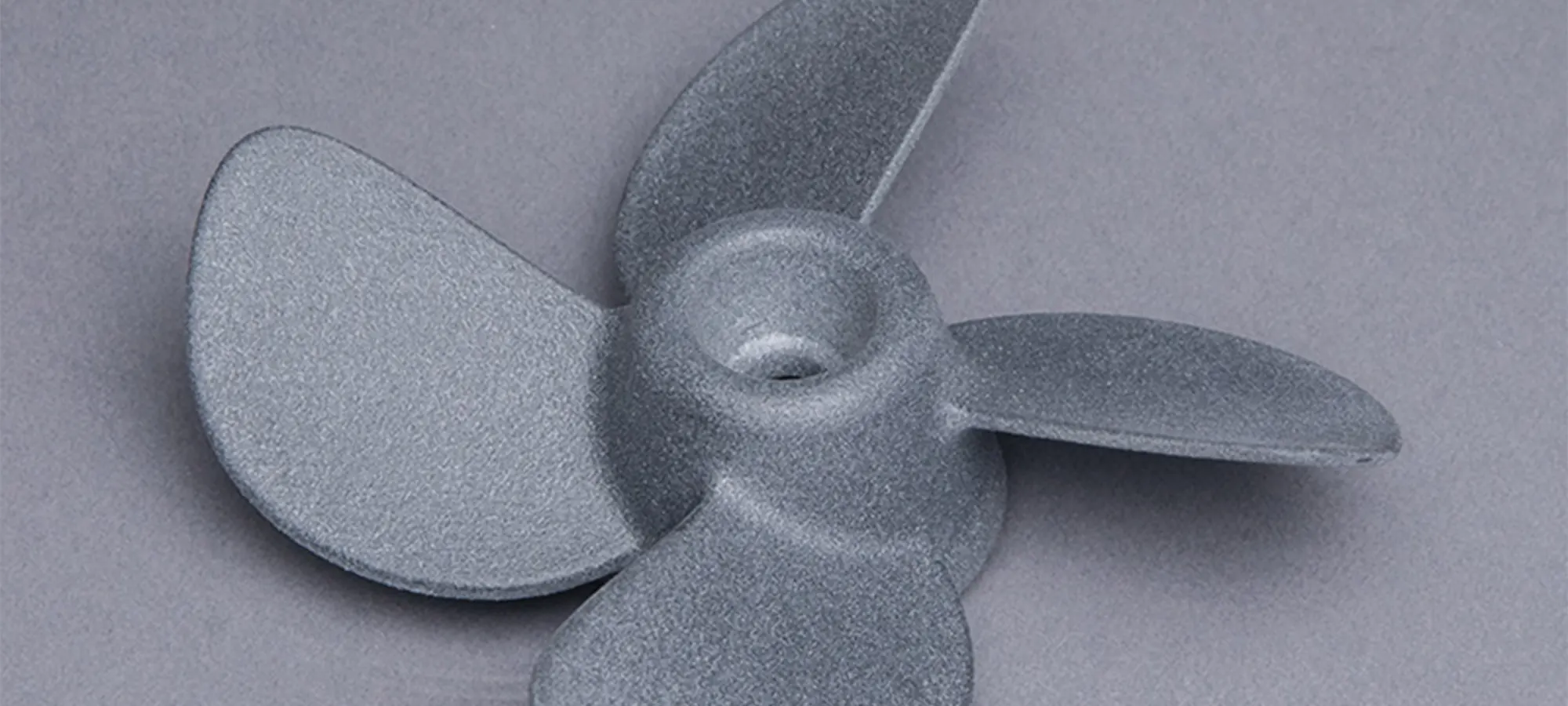

Another characteristic of Nylon is that it has a high melting point and a very low coefficient of friction, because of which it is used in 3D printing of functional gears.

A property of Nylon that helps it to be one of the most popular materials to be 3D printed with is that it is hygroscopic i.e. it absorbs moisture.

It is easier to 3D print parts and functional prototypes with fabric dyes and spray prints for altering aesthetics of the final part or prototype.

On the other hand, this same feature which makes Nylon popular is also one that makes it prone to absorbing moisture from the air and affects its overall performance.

Let’s start by looking at printer settings that you need while printing with Nylon in various 3D printing technologies.

How to 3D Print Nylon Using FDM Technology?

Before reading about how to print Nylon with FDM technology, let’s have a little brief about how printing with FDM technology is possible. Amongst the very many methods used for 3D printing of materials, Fused Deposition is the most popular.

Fused Deposition Modeling

Parts and functional prototypes that are created using a printer based on FDM technology are merely CAD files. To print using a CAD file, the modeling file must have an extension which is usually.STL.

While printing a part or functional prototype using FDM technology you don’t just need to design the exact part or functional prototype that you need to print.

You need to design something extra i.e. the support structure which is something that holds the object while it is being 3D printed.

As the printing process starts, materials with which part or functional prototype is to be printed are present in the form of plastic threads that are generally called filaments.

They unwind from a coil and are then fed through an extrusion nozzle. What the nozzle does is that it melts the filaments and then extrudes them to a base which is called the build platform.

During this process, the nozzle and the base of the printer are controlled by a computer that instructs it based on the dimensions of the object that is to be printed into X, Y, and Z coordinates for the nozzle and base to follow during printing.

It is the extrusion nozzle that moves over the build platform in X and Y direction which leads to the drawing of a line of a cross-section of the object that is to be printed on the platform.

This line which is a layer of plastic, then cools and hardens immediately and binds itself to the layer beneath it. After one layer is completed, the base is then lowered, making room for the next layer of plastic. Here are the Best FDM 3D Printers.

Printer Settings while using Nylon in FDM 3D printing

As mentioned above, Nylon is hygroscopic, meaning that, it can absorb moisture from the air. So, Nylon should be stored in a dry place with silica gel. It is seen in practice that Nylon absorbs around 10 percent of its weight in water.

So, when Nylon is heated i.e. during the printing process, the moisture inside it bursts and affects the bed and layer adhesion, generating a rough surface finish.

Because of this condition, Nylon should be dried before it is 3D printed. And the best precaution for ensuring you get a successful print is Oven drying.

Another issue with Nylon is about warping. For solving this problem to a little bit of extent, a heating bed is needed for 3D printing Nylon.

You will have to apply glue to the surface of the heating bed and this would ensure a print without any warping issues.

You are also recommended to not use cooling fans. The easiest way of drying the filament, not just Nylon, but any filament, is to bake it in a convection oven.

Here too, the oven must be preheated before inserting a spool for drying. After setting a preheat temperature for the oven and inserting filaments after it is reached, ensure the temperature is properly set.

To 3D print Nylon the preheat temperature required is 70 to 80 degrees Celsius and for doing this the time required is four to six hours.

After doing this procedure, the filament of Nylon must be removed and stored in an airtight container.

Temperature setting is one of the most important things because otherwise, you end up burning your entire spool.

How to 3D Print Nylon Using SLS Technology?

Selective Laser Sintering, as the name suggests uses Laser for fulfilling a purpose. Before knowing the general print setting that should be taken into consideration while printing Nylon with it, let’s get to know about the technology in brief.

Selective Laser Sintering

As mentioned above in the section of Fused Deposition Melting, the process starts with a computer-aided design file which has to be converted in the.STL format so is the case with SLS technology as well.

Amongst the very many objects that are printed using SLS technology are powder materials, which are mostly plastics such as Nylon, etc. These powdered materials are dispersed making a thin layer on top of the build platform of printers.

Once the dispersing is done, then comes the part play of the laser. A computer-controlled Laser tells it what object is to be printed, after which the first layer of the object is traced down onto the printer bed.

Here, the role of the laser is to heat the powder just below the boiling point or above it. Doing this fuses the particles of the powder with which you are willing to 3D print into the part of a functional prototype.

As soon as the initial layer of the part or functional prototype is formed, the print platform of the SLS 3D printer drops usually by measurement less than 0.1 mm.

This exposes the laser to a new layer of powder which is then to be traced and fused. It is this process that is continued again and again until the entire object has been printed.

Printer Settings while using Nylon in SLS 3D printing

If FDM was the most used technology for 3D printing, SLS is the most suitable one. To 3D print Nylon, you need to use its PA 11, PA 12, or as composite materials like carbon-fiber-filled and glass-filled Nylon.

However, according to the reports, Nylon PA 11 is more flexible than PA 12. The benefit that the latter has than the former is that it has all-around mechanical properties which are ideal for making functional prototypes.

While printing using the SLS 3D printing technique, Nylon is used as an input powder for producing great prints with excellent material properties.

The reference tolerance for SLS printers is 0.3 mm plus or minus. Wall thickness should be 0.7 mm and the layer height in the range of 80 to 120 micrometers.

How to 3D Print Nylon Using Multi Jet Fusion?

Before reading about the recommended settings that are needed to 3D print Nylon in Multijet Fusion technology, you should know a little bit about the technology, so we will explain it to you in brief.

MultiJet Fusion Technology

This technology is a powder-bed 3D printing process developed by HP. In this technology, there is an agent that bonds itself with powder in a process similar to binder jetting.

Although this is not done similarly to point-by-point laser-based powder-bed fusion systems. In this technique, there is the selective distribution of fusing and detailing agents all across the print bed of powder.

Afterward, layers are fused using infrared light. The complete system includes exchanging build units that can be moved between the multijet fusion 3D printers and the post-processing stations.

This is done for rapid cooldown and powder removal. The modular system allows the printer and postprocessing stations to run continuously while build units cycle through, speeding part production.

The printhead of the multi-jet fusion printer deposits droplets of binding agent and detailing agent all across the layer of polymer powder in a preheated bed.

The binding agent serves as a heat-absorbing ink by making the powder it binds, a little more prone to melting. In this technique, every layer is fused using infrared light for melting the areas held by the binding agent all at once.

In the meantime, at the place where the detailing agent has been deposited, a cooling effect provides crisp edges around the melted area. This prevents the melt pool from bleeding into the loose powder.

The powder is distributed on top of each solid layer. The same process is repeated until the part is complete. The point to note here is that the powder supports parts as they grow; so support structures are not necessary.

Because of this users can have greater design freedom and it also enables them to produce larger quantities at once.

Printer Settings while using Nylon in Multijet fusion

The Multi JetFusion technique offers many nylon 3D printing materials. Starting with HP 3D High Reusability PA 12. This material is used ideally for producing strong, and quality parts at the lowest cost per part using the multi-jet fusion technique.

Secondly, HP 3D High Reusability PA 12 Glass Beads is a material that is ideally used for producing stiff, low cost, and quality parts.

Followed by, HP 3D High Reusability PA 11 which is a material that’s ideally used for producing ductile, quality parts at the lowest cost per part.

Second, lastly, we have, HP 3D High Reusability PA 12 which is claimed to REACH i.e. Registration, Evaluation, Authorization, and Restriction of Chemicals compliant.

REACH is a regulation of the European Union that works on improvement and the protection of human health and the environment from risks posed by chemicals. And lastly, we have HP 3D High Reusability PA 12 which is biocompatible and RoHS compliant.

The Conclusion

It is to be noted over here that for printing a part or functional prototype using Nylon, you don’t necessarily need the equipment i.e. printer and Nylon.

To 3D print Nylon, you can also use the online services that are available on various websites i.e. to print any material using any technique and any printer. Online platforms like Shapeways, Sculpteo, or I. Materialize can let you do so.

And don’t be in any doubts about the quality or reliability of these online platforms. Some of these platforms are owned by companies that manufacture 3D printers in the market.

And with that, they have opened these platforms to ensure that the user of this material can 3D print without any boundaries i.e. he or she does not necessarily need to have a 3D printer to use a 3D printed part.

If you want to 3D print Nylon and you don’t know where to get the material from, there are some options such as MatterHackers Nylon, Ultimaker Nylon, and Nexeo Nylon as far as Nylon printing with FDM is concerned.

For SLS, you can get resins of Nylon from Alibaba and for Multijet Fusion, you can get Nylon from HP, which also holds the patent of the printing technology.

Nylon is a well-suited material for parts and functional prototypes that have higher tensile strength compared to PLA which is one of the most popular materials for 3D printing.