Every 3D printing material has its own characteristics which makes it different from the other. There is a specific way in which it needs to be treated, not only before but also while it’s being processed.

Doing so ensures the good print quality of parts or functional prototypes. And when it comes to finding a guide that tells you how to print with a 3D printer filament, there are plenty available for ABS and PLA. But, rarely to the point of being negligible tips for PVA 3D printing.

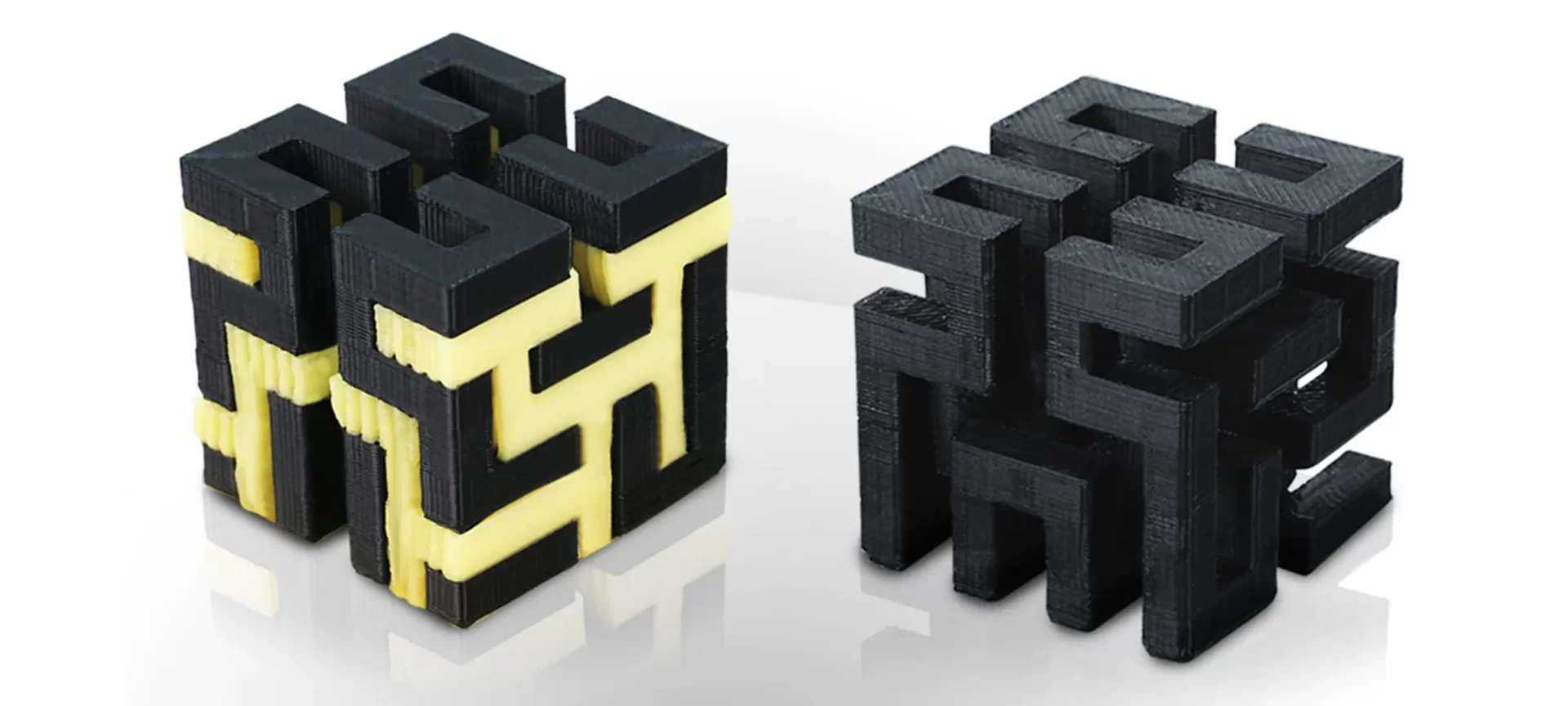

PVA finds its application in various industries because of possessing some very eccentric properties that are not even seen in ABS or PLA. Although best known in the 3D printing community as a support material, PVA is also used in making health products like contact lens solutions. But mainly PVA is utilized while making complex geometries like partially enclosed cavities.

So, let’s explore this unique 3D printing material before knowing expert recommendations or general tips while PVA 3D printing.

General Properties of PVA Material

PVA’s full form is Polyvinyl Alcohol. It is a soft and biodegradable polymer that is extremely sensitive to moisture. A special property of PVA is that, when the material is exposed to water, it actually dissolves and because of this reason PVA is utilized for making water-soluble support structures. The material is especially used when making parts with complex geometries, the ones with enclosed cavities.

PVA filament is made from a synthetic polymer created by polymerizing vinyl acetate that is then hydrolyzed into PVA. It has a translucent white appearance that is resistant to oil, grease as well as solvents. The filament possesses excellent adhesive properties and high tensile strength with flexibility.

Note that, do not confuse PVA with PVAc i.e., polyvinyl acetate – a water-soluble white glue. PVA material is colorless, and odorless synthetic polymer that has impressive biocompatibility. It has lower toxicity compared to other materials used for making filaments.

After getting to know PVA material in general, let’s get to know how suiting it is with different types of FDM 3D printers. Check out our list of Best FDM 3D Printers.

Is PVA Compatible with FDM 3D Printers?

As mentioned above, PVA is very much preferred as a support material. Mostly, support materials are utilized with multi-extruder hosting FDM 3D printers. It is to note that generally FDM printers are known to have only one extruder in which the printed part, as well as support structures, are to be created using the same material.

In such printers, it becomes a difficult task to remove the supports after 3D printing, and also, they leave ugly marks when taken away from the part. On the other hand, dual extrusion FDM 3D printers permit the use of various materials for parts and supports, which is exactly where PVA material is extremely useful.

Because PVA filament easily dissolves in water, so if you print support structures using PVA, they can be easily removed by simply keeping the printed part in water.

Not only does doing so makes easy removal of support possible, but also decreases the need for post-processing processes such as sanding and painting. Specifically, PVA is known to work extremely well with PLA filaments as it uses similar printing conditions including temperature.

The latter is a hydrophobic material, therefore if a part is printed using it with supports made from PVA, the supports will dissolve in water leaving the part in an ideal condition.

After going through the basics of PVA 3D printing with FDM 3D printers, it’s time now to explore those points that you need to take into account while PVA 3D printing. So, let’s get started.

How To 3D Print PVA Filament?

Below mentioned are the expert-recommended points to keep in mind while PVA 3D printing. Following them is ensuring good quality prints even while printing complex geometries and small shapes.

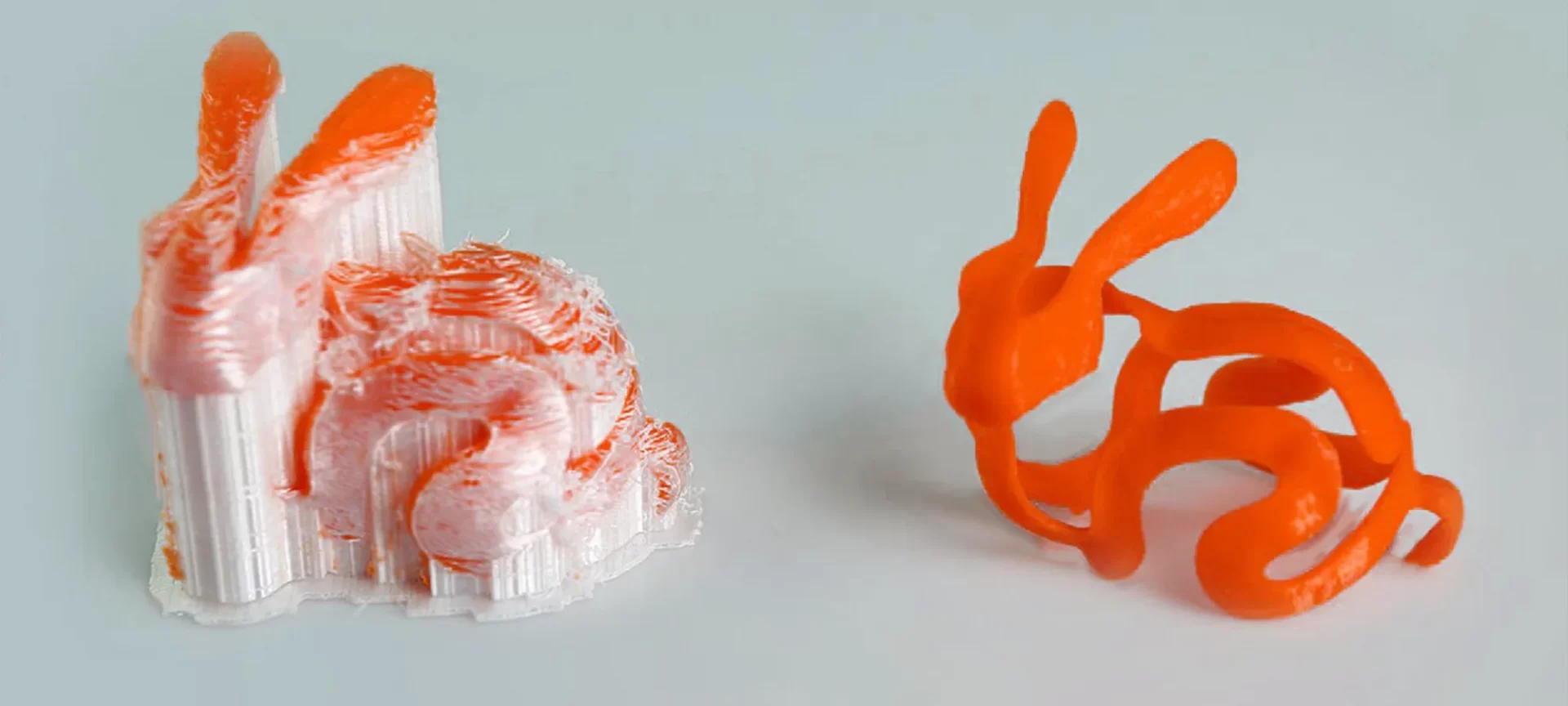

Safeguarding the filament while storage

PVA is highly reactive to water, hence storing its filament in a moisture-free container is a must. Note that, any PVA that has absorbed water from the air will be inclined towards forming bubbling and even cracking during printing and will end up ruining the overall quality and strength of the finished part.

Also, when you are done printing with a PVA filament spool keep in mind to remove it from your printer, place them in an air-tight container with a desiccant for removing any sort of moisture that’s accumulated in it.

In case you feel, the filament has absorbed too much moisture, don’t worry, it can still be dried using a commercial dehydrator or an oven set at its lowest temperature for a short span of time, say a few hours. Doing so will draw the water from the filament without melting it after which it will allow users to print smoothly without bubbles.

Employing an Ooze shield

This point should be considered especially while 3D printing with PLA material. Experts advise using an ooze shield with at least two outlines. This will benefit users while priming the PVA extruder after every tool change making sure that the extruder is ready for 3D printing at the start of that particular layer.

Moreover, the ooze shield will also catch any sort of oozing from nozzles thereby preventing the deposited plastic from reaching your part.

Don’t worry about its removal as the ooze shield can be easily discarded. But in case you find the ooze shield too weak or tending to separate easily, do consider adding an additional one for thickening the protective shield.

Apply dense support layers

PVA 3D printing can be expensive compared to 3D printing other filaments. So, it’s better to minimize the total amount of PVA used in your part’s support structure.

To make sure this task can be easily put into application, some open-source software offers a feature by the name Dense Supports. This feature allows users to reduce the use of PVA material limiting it only to the interface layers present between the part and the supports.

Doing so offers a material saving advantage of at least 90 percent or more. Moreover, Dense Supports creating a solid interface layer that enhances the overall surface quality on the underside of the print.

Print at any temperature falling in the optimal nozzle temperature range

Although brand to brand the optimal nozzle temperature range needed for PVA filaments will vary, all the variants fall between 180 to 200 degrees Celsius.

In case of any confusion, always consider the temperature referred by your 3D printer manufacturer. Having stated so, always keep in mind that high-temperature 3D printing rapidly degrades PVA thereby causing the nozzle to clog.

Optimum print bed temperature for PVA 3D printing

To ensure an ideal bed adhesion, experts recommend a building temperature ranging between 45 and 60 degrees Celsius not only for PVA but also for PLA.

The most basic tips for improving adhesion such as using Aluminum, Stainless Steel, Glass BuildTak, Kapton Tape, PET Tape, or PEI film do while PVA 3D printing. Moreover, a cooling fan is required only if you can manage it to not overcool the PVA otherwise you may end up making the part brittle.

Summing up, Ideal printer settings for PVA 3D printing:

- Keep the nozzle temperature ranging between 180 to 200 degrees Celsius.

- The ideal print bed temperature should be as low as 45 degrees Celsius and as high as 60 degrees Celsius.

- After PVA 3D printing, a part fan cooling up to 50 percent is recommended.

- Most importantly, PVA is soluble in water so before post-processing, for removing support you can dip the 3D printed part in it.

- Manage your slicer’s infill settings: typically use a low infill percentage throughout the PVA support structures and only use higher numbers when the supports are supposed to come in contact with the print.

Having discussed the points to keep in mind while PVA 3D printing, let’s look at the practical applications of the material.

What Are The Applications of PVA 3D Printing?

PVA material is most commonly used for making paper, adhesives, dissolvable packaging like those seen in single-time use detergent capsules, printing, eye drops as well as textiles.

Also, fishermen use PVA dissolving bags for disposing of bait around their hook for attracting and catching more fish. Moreover, the material is used for making putty or slime for child’s play. And as we have already mentioned a lot of time till now, it is used as supports while printing intricate geometries.

After having looked at the most common applications of PVA 3D printing, let’s look at its advantages and disadvantages.

What Are The Benefits of Printing with PVA Filament?

- Being a completely water-soluble material, PVA permits users to use it as a dissolvable support material. Most importantly when it dissolves, it leaves no blemishes on the final print.

- PVA is biodegradable and environment-friendly material, hence it’s completely harmless to the environment.

- Can be used with FDM 3D printers with dual extruders for providing support to a 3D print without warping issues.

What Are The Disadvantages of Printing with PVA Filament?

- PVA filament requires careful storage. In case you are not storing it in an air-tight container, it will have strong reactions and create a bubble or crack in the final 3D printed part thereby degrading its final quality and strength.

- The cost of filament is more expensive than ABS or PLA filament.

- You’d have to be too particular while PVA 3D printing in terms of maintaining the printer bed and extruder temperature range. In case the temperature is set higher; you’d end up oozing the PVA filament. In scenarios wherein it’s set lower than the needed temperature, it will lead to the problem of clogging.

- Most experts recommend using an ooze shield when PVA 3D printing which increases the overall technicality of the process.

Who Makes The Best PVA Filament?

After looking at PVA’s advantages and disadvantages, let’s look at some of the best PVA filaments available in the market.

- MatterHackers: Offering 0.5 and 1 kg spool, MatterHackers PVA is available in two diameters i.e., 1.75 mm and 2.85 mm. Its filament does not require a heating bed and dissolves in water naturally. It requires a nozzle temperature range of 175 to 200 degrees Celsius.

- eSUN: Available in 500 grams spool, eSUN PVA recommends a nozzle temperature ranging between 190 to 200 degrees Celsius and a bed temperature ranging between 60 to 80 degrees Celsius.

- Ultimaker: Claiming that its filament is the most eccentric one in the market, Ultimaker designs its PVA to work with Nylon as well as CPE filaments. The Dutch manufacturer’s PVA filament is 100 percent biodegradable. Its also lesser sensitive to moisture than other PVA filament brands. Ultimaker PVA requires a nozzle temperature and bed temperature ranging between 215 to 255 degrees Celsius, 60 degrees Celsius respectively.

- Gizmo Dorks: Providing 1.75 as well as 2.85 mm PVA in a 500-gram spool, Gizmo Dorks makes its filament available in Natural color. It requires a nozzle temperature ranging from 160 to 190 degrees Celsius. Whereas, the filament needs a bed temperature of 60 degrees Celsius.

- SainSmart: Sainsmart’s PVA is the cheapest among the mentioned five. Its filament requires a nozzle temperature ranging from 160 to 180 degrees Celsius. The filament is available in 1.75 mm diameter weighing 500 grams.

The Conclusion

PVA 3D printing makes it possible for parts to exhibit intriguing features such as water solubility, incomprehensible and heat resistance, low elongation and flexibility, high modulus, and durability. Also, the objects printed using filament have an improved layer hardness and are non-toxic in nature.

For the same reason, parts made from PVA 3D printing find application in areas where aesthetics are given importance. Some typical examples of the same are paper adhesives, thickener, packaging film, reinforced rubber hoses, rollers, and the fishing industry.

Overall, printing with PVA does has its own challenges but the benefits outdo them. Also, its compatibility with PLA eases the work of the designer in creating parts with intricate support structures. Above all, the material is biodegradable thereby providing no risks to the environment at all.