Being the first of its kind, Bronzefill filament is made with actual metal in it. The 3D printer filament is as highly dosed as physically possible, for FDM/FFF 3D printing.

When working with bronzefill you feel as if you have a 3D printing filament in your hands that astonishes you with the surface quality that it’s able to put out in parts manufactured via it.

Not only does the filament change the look and feel of parts, which makes your print look as if art, but also its weight is extraordinary.

On average, Bronzefill filament’s weight is about three to four times heavier than regular PLA. Based on Colorfabb’s PLA/PHA formulation bronzefill has a matte, mostly laser sintered finished.

Only when polished, or by using another way of post-processing, you can make the parts made by this filament truly shine.

If archeologists are to be believed, the filament is meant to keep in a certain kind of museum. Let’s start looking in-depth at various aspects of the filament starting from its overview, followed by specifications.

Overview of Bronzefill Filament

Manufactured by ColorFabb, Bronzefill stands out as being one of the bronze filaments that has the highest amount of embedded bronze particles.

The filament has around 80% bronze composition; is uniquely heavy and used for producing distinctly good-looking finished prints. It is probably the most premium bronze filament that you can get in the market currently.

Arguably, a bit more on the expensive option but there’s nothing that can rival the heft and quality of finishes that it manages to put up in parts and functional prototypes manufactured using the filament.

Only with a little bit of sanding and polishing, the prints made using the bronzefill filament can look very close to the real thing.

You are even allowed to rub your print with some steel wool for getting that weathered bronze effect. An issue that you may need for anticipating is that the small amount of PLA in this filament makes the complete layer adhesion a bit of a challenge.

By printing the bronzefill filament at the upper end of the printing temperature range you’ll be able to ease up on the cooling.

As far as other filaments are concerned, it will take a bit of experimenting to get the best printer settings for the bronzefill. Why is that? Let’s find out the filament’s specifications.

Specifications of Bronzefill Filament

The ColorFabb bronzeFill filament is made from either PLA/PHA mixed with fine bronze powder.

It has a diameter tolerance of 0.05 mm, a density of 3.9 grams per cubic centimeter, and a glass transition temperature of 55 degrees Celsius.

At ColorFabb they have a well-equipped 3D printing studio with a lot of popular 3D printers which they use to know their materials that can give you excellent results and help you get to achieve those using tips and tricks.

- The advised 3D printing temperature for printing with Bronzefill filament ranges between 195 to 220 degrees Celsius.

- The recommended 3D print speed range for printing with the filament ranges between 40 to 100 millimeters per second.

- Stating about the heated bed temperature range, it ranges between 50 to 60 degrees Celsius.

- It is fine if your 3D printer does not have a cooling fan for cooling the part printed using Bronzefill filament.

Tips for printing using Bronzefill Filament

Depending on the set-up of your 3D printer and slicer software, you might see that bronzefill requires a bit more flow compared to your normal PLA settings.

Most plastics are known to show die swell when coming out of the nozzle tip, which is counteracted with specific slicer settings. But with bronzefill the case is different.

It doesn’t show a die swell such as PLA. So, you might need to increase the flow rate a bit, around 4-8% which is considered perfect for Colorfabb’s UM2. Whereas UM original does not generally need any adjustments!

Sanding and polishing the parts made with bronzefill makes the bronze particles shine. You are recommended to start sanding with grit ranging anywhere from 120-180.

This would make sure all the printed lines vanish! You’ll observe that because bronzefill is easy to sand down and if you do it carefully you won’t lose too much detail.

After some time, you can start working your way up by following with grit ranging anywhere between 240-320 and finishing off with grit of 600 – or even higher.

Finally, it is advised to use a clean soft cloth and some copper polish to really get all of the shine out from the bronze particles.

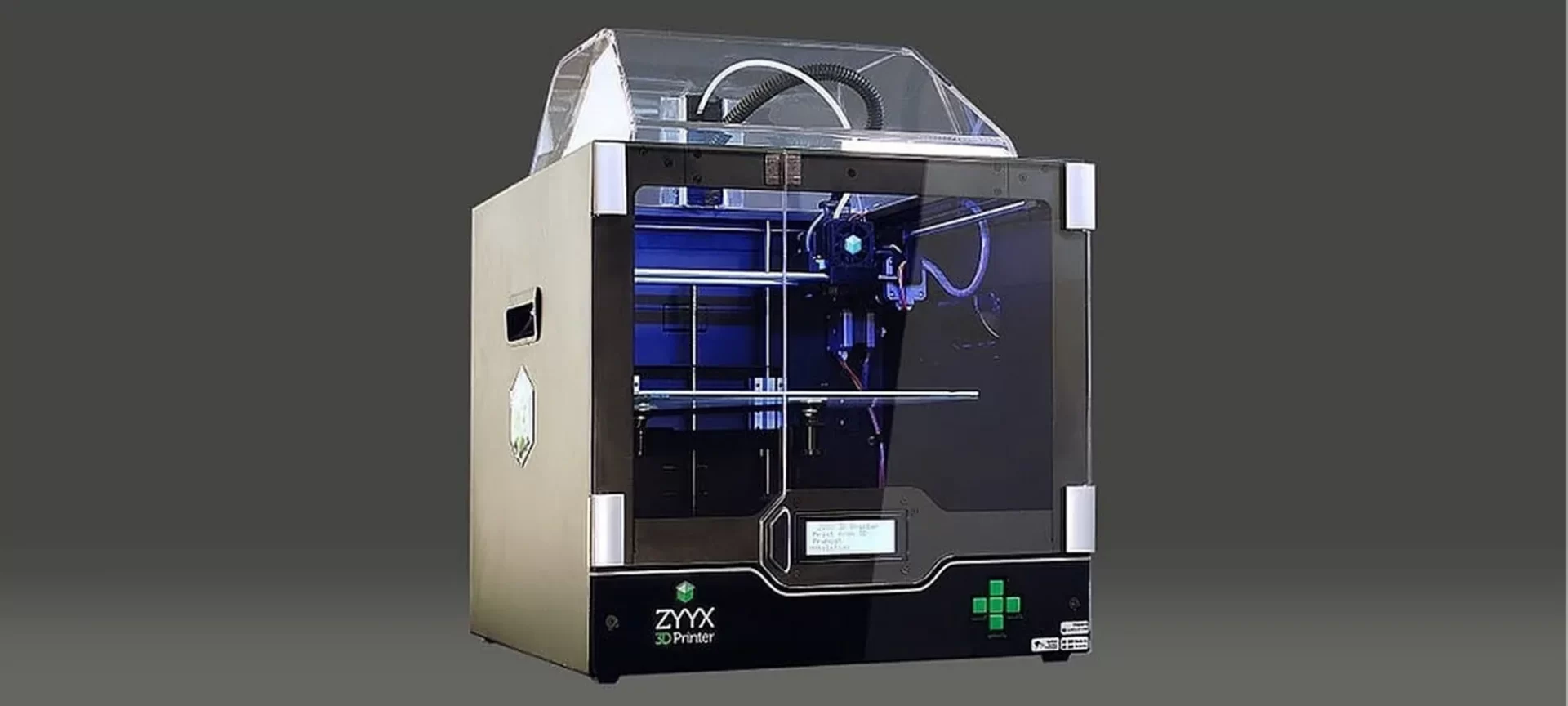

A Brief Review of Printing Bronzefill with ZYYX 3D Printer

For testing the print quality the was used for printing with this filament. Note that the printer has a direct drive extruder and no heated bed.

Feeding the filament into the extruder works without any problems, however, the only thing worth observing is that you’ll have to restrain yourself from your habit of pulling strings of filament away from the nozzle while purging it because the metal parts in this filament make it hot to touch it right away.

While 3D printing the filament at around 205 degrees Celsius, the metal particles make the recently-printed filament cool down very fast because of the active fan on the extruder.

This results in very clean printing lines and very layers. The metal particles in this filament lead to an increase in the upwards-traveling of heat from the hot end to the cold end, but you do not have any problems with this on the ZYYX.

Look and feel of parts

Objects printed with bronzefill filament are somewhat eccentric i.e. even without finishing. The credit for such characteristics is given to its heavyweight. You’ll like the standard brown-grey color and matte look and feel.

The fact here is that it’s three times heavier directly and sets it apart from any other 3D print you ever touched, so it obviously feels a lot more substantial.

Also, it will be the first time if you haven’t experienced a FFF 3D print as feeling like a cheap, plastic trinket. And, optionally you can make it even heavier by increasing the infill.

Online examples of Apple watch are available with the filament which actually feels like a metal watch and not like any normal smartwatch.

Apart from that, there are parts that are printed at as high as 200 percent scale and 160 microns that depict amazing surface finish.

Finishing of the 3D printed parts

The first thing you are probably recommended with bronzefill printed parts is sanding them with increasingly finer sandpaper.

It is advisable to do this exercise manually because a touch with a Dremel sanding bit goes way too fast! You’ll also find a tip on ColorFabb’s Learn website about how to use Steel Wool for making the bronze particles shine out.

You wouldn’t find the steel wool at the supermarket, but instead, you can bring Vileda Glitzi PowerInox sponges with stainless steel fibers.

They are known to work very well, without using a lot of force you will be able to let your statuette shine after 20 minutes of rubbing.

Although it’s surely not the same as actual polishing, it’s not messy and is able to provide a quick result. The pads used here are also cheap €2.50 for 2 but they can be reused often.

Pros of Printing with Bronzefill

There are some characteristics which this filament can offer in parts and functional prototypes printed using it. These aspects cannot be offered by any other filament and they are mentioned below.

Aesthetically superior

The topmost reason why anyone would print with this filament is that the prints simply look amazing, even before post-processing. Bronze is a metal that tends to have this rustic appearance that will make any display piece pop up and catch the attending eyes of just about anyone present in the same room.

All your dreams about having a customized figurine or display piece in a gorgeous bronze color displayed in your living room, 3D printing it with a spool of bronzefill filament would make your dream come true.

That too, a much cheaper and easier than having a professional metal craftsman do it for you. Superior visual appeal is something this filament will be able to create pretty much par for the course for all composite 3D printing filaments.

Amazing options for the finishing of printed parts

It is a fact that a finished 3D printed part made with bronzefill filament has bronze particles embedded in it. And this is something that opens up a whole new dimension of finishing opportunities for the object.

Knowing that the pure PLA can be sanded and finished until it has a smooth finish; a bronze-embedded PLA, just like bronzefill filament, can end up looking like real bronze with the same treatment.

Heavier parts

It is because of the presence of solid metal particles in bronze filament that the complete part is a lot heavier than usual parts of functional prototypes.

This aspect of the filament translates to the finished print, which gives it a certain heavy look making it feel more premium than prints made completely with plastic.

Cons of Printing with Bronzefill

Like every other filament, bronzefill has its own list of disadvantages that are mentioned below.

Costly filament than usual ones

This con should be a surprise for you if you have read that these bronze filaments come with real bronze particles.

So, it should be hardly surprising for you that they also cost much more than standard PLA filaments!

Stating about the market conditions, you can get a 1-kilogram spool of PLA for less than $20, whereas a spool of bronze filament of equal weight will probably cost you anywhere between the range of $60 to $100.

So, while buying bronze filament, it is better to keep in mind that the 1-kilogram spool of bronze filament will have a much shorter length compared to a 1-kilogram spool of PLA or any other similar plastic filament.

This is because of the fact that bronze filament is much heavier because the embedded particles, play a role in this. This is something to consider if your project requires you to be budget-conscious.

Brittleness

Bronzefill is basically bronze embedded in PLA, which makes it lose a lot of its elasticity. And this is something that makes bronze filament exceptionally rigid and brittle.

So, while handling bronze filament, you’ll have to be extra cautious and make sure that there are no sharp turns over its complete path starting from the spool to the extruder.

Wearing of the nozzle

Although not being the toughest metal around, Bronze is certainly abrasive enough to accelerate wear and tear on the parts of your 3D printer. This goes for every part that comes into contact with the bronzefill filament.

Mostly you will notice this phenomenon with the brass nozzles that come as stock in most desktop-scale 3D printers.

You must note that a worn-down nozzle can lead to poor detail quality on your prints which in turn leads to overall drop inconsistency.

So, if you plan on working with the filament, you would need to invest in a wear-resistant all-metal nozzle. But again that would mean increasing your budget.

It is advisable to get a nozzle with a wider diameter ranging anywhere between 0.5 and 0.6 mm. This would lead to a reduction in the abrasive forces of the metal particles and prevent them from clumping up at the orifice.

The Conclusion

Bronzefill filament is an eccentric material used for creating parts that look like real metal parts.

BY taking the precautions mentioned in the article you can fabricate 3D printed parts that can be put into application in various industries such as automotive, defense, jewelry, and a lot more.

With the pace at which this filament is getting noticed, it is obvious to conclude that it would be trending as the topmost preferred choice of experts in the near future.