Copper isn’t a new name within the manufacturing industry. It has been in use in abundance for various applications. However, a few years back, the metal was limited for traditional manufacturing methods. But that is not the case anymore.

Currently, metal is gaining popularity among additive manufacturing processes as well. There have been great developments concerning Copper 3D Printing. And, these new innovations have led us to many possibilities that weren’t available before.

Copper 3D Printing – An Overview

As we know, Copper is popular for its unique and extremely fascinating properties as a manufacturing material. It is highly conductive and malleable. However, these same properties make it difficult for users to tame the metal for usage within additive manufacturing technology. Thanks to the recent development that the metal is now available for 3D Printing as well.

Among the many Copper 3D Printing processes, the most popular technique is Powder Bed Fusion. Using this technique, the machines make use of electron beams for melting powdered material and further glue the particles together. With dropping temperature, the particles join together to form solid models.

However, the results weren’t as easily accomplished as it sounds. Going back to the properties of copper, it was not an easy task for experts to include copper among the metals used within 3D printing.

Because of the conductive property of the metal, the electronic beams weren’t absorbed by the powdered material but reflected. In addition, with a sudden temperature drop or increase, the parts would break.

Therefore, the experts came up with the green laser solution. By replacing the electronic beams with a green laser, the problem with absorption of energy source by Copper was eliminated.

However, cracking due to sudden temperature change was still daunting. Therefore, pre-heating of the material came into the picture. And, the innovation kept growing.

Today, there are many ways you can accomplish copper 3D printing. Care to know how? Keep reading!

Additive Manufacturing Process for Copper 3D Printing

The time has gone by when thinking about Copper 3D Printing would have created a fair tension among experts. Knowing the potential of the material, but not able to use it with the best existing technology for manufacturing was certainly annoying.

However, currently, after a lot of experiments (one stated above), we have been able to come up with an array of solutions for printing with Copper.

FDM 3D Printing

Yes, we know! Copper 3D Printing with FDM machines isn’t sounding very doable. But it is. However, there are limitations to the same though.

When working with FDM printers, you cannot have pure metal filament for the same. On the other hand, you get to use copper-infused filaments.

There are a number of companies offering such materials that consist of a few percentages of metal powder mixed in the PLA Material. Therefore, the parts produces aren’t completely made of Copper. Instead, they are a bit heavier than usual plastic parts and exhibit metal texture.

If you still wish to accomplish 100% Copper 3D printing using FDM machines, there is one filament you can use. The Copper-infused filament by The Virtual Foundry (TVF), which is pushing every boundary and has been successfully able to reach up to 90% metal with PLA combination. It does include an extra step that is not necessary for other part printing using FDM printers.

Once the part is printed using TVF’s Copper-infused material, it must be heated inside a kiln. The part then melts into a 100% copper model. While using the technique, you must consider the shrinkage that happens during heating. And, compensate for the same when designing the 3D file for the model.

Cost for Copper 3D Printing with FDM Machine

As you can expect, the Copper Infused filament won’t come cheap. You must be ready to pay almost $121 for 1 kg of the spool. The expensive rate is due to the higher density of copper included in the TVF filaments.

You can also choose to print with a lower percentage of Copper-infused filaments. However, those would also be costly when compared to the standard PLA.

Just remember, when you are printing with this filament, remember to pre-heat it before use. And, start the print operation at a slow pace. Following the guidelines offered by the filament manufacturer, you will easily be able to create parts with Copper 3D Printing on FDM machines. Isn’t that fascinating?

When it comes to print performance, users can achieve a minimum layer height of 100 microns.

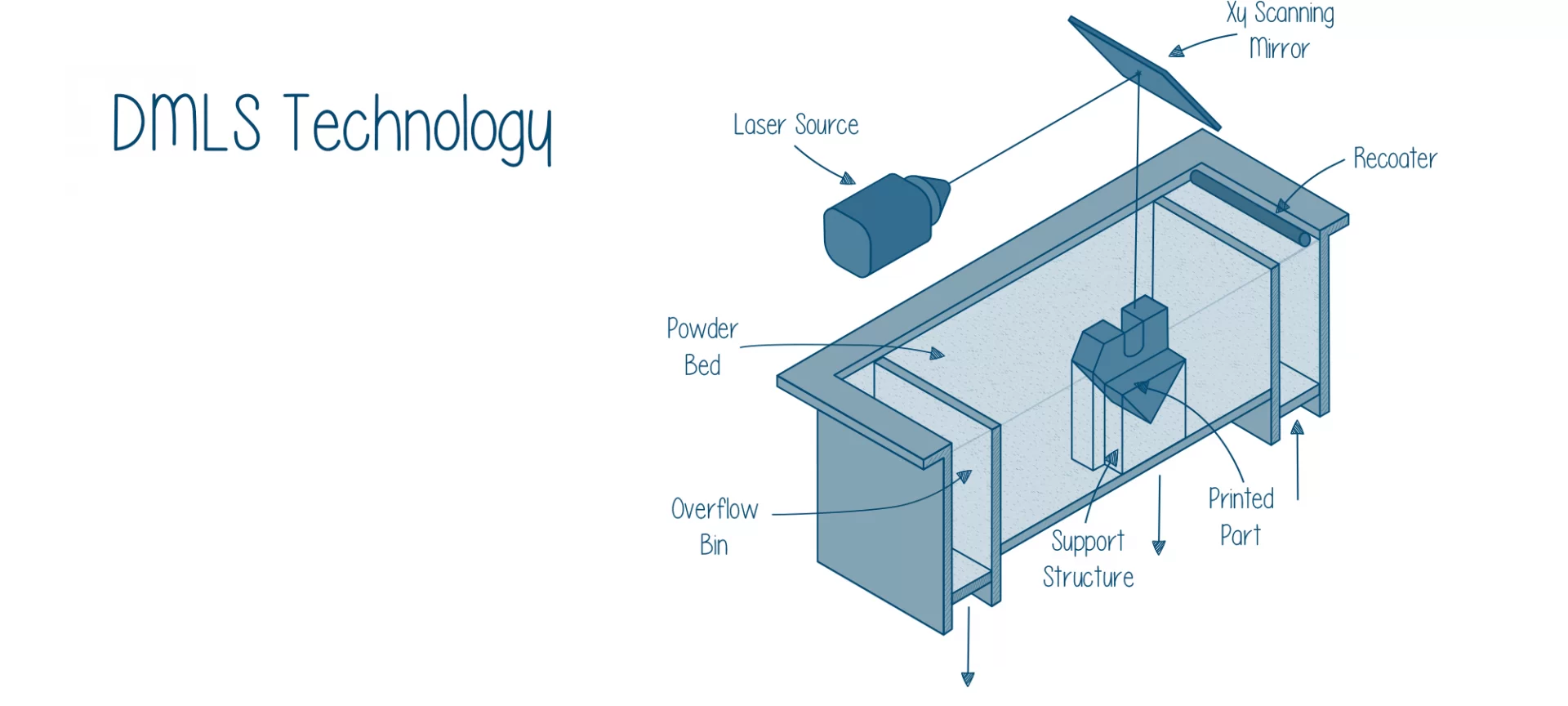

Direct Metal Laser Sintering (DMLS)

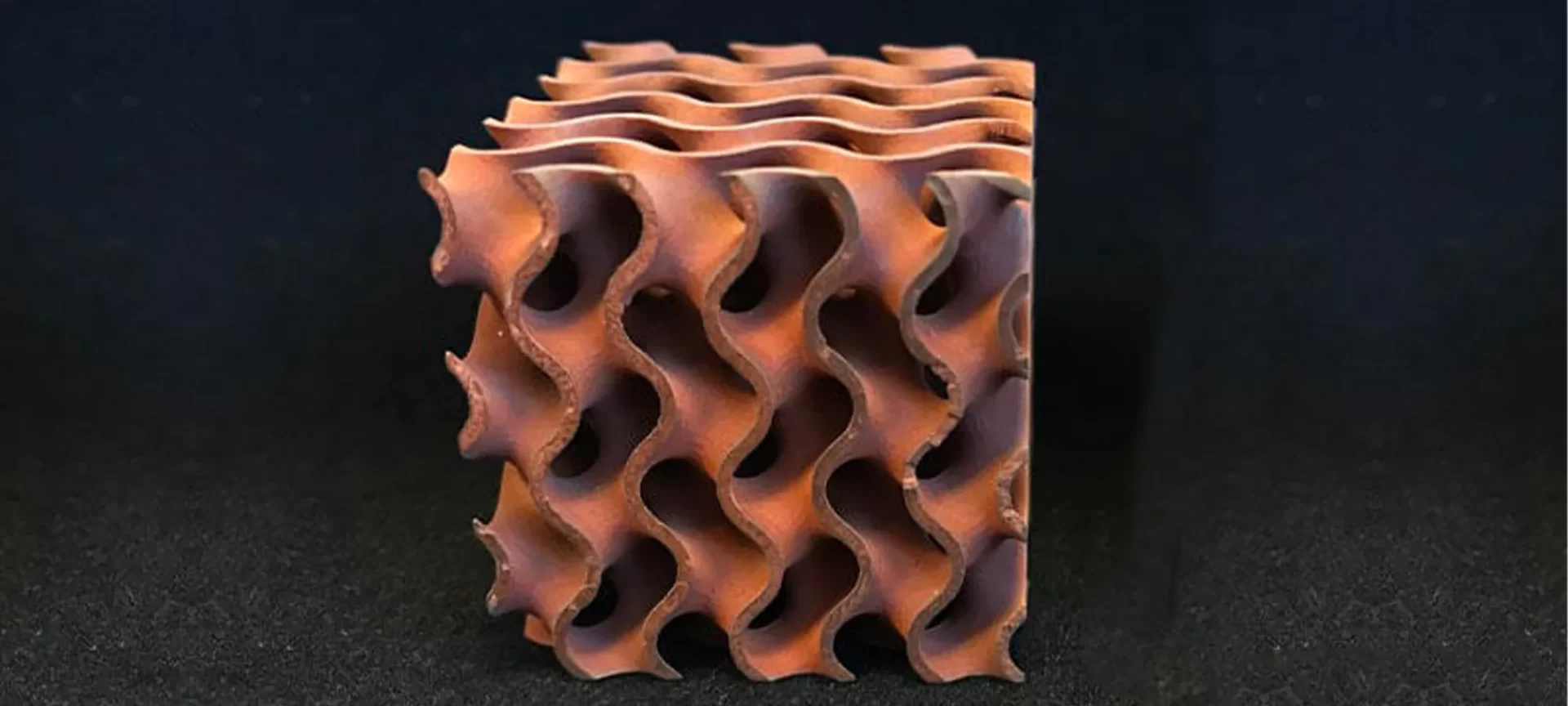

Similar to SLM, or the powder bed fusion methods, DMLS involves powdered Copper material and fuse it together using the laser source for creating one layer at a time. The process can help accomplish fully functional 3D models with the highest precision.

To start the process, users must deposit the Copper powder, layer by layer. And, let the laser do its job. Once the part completes, you must take away the excess powder with the help of compressed air inside a closed chamber.

Just note, the 3D Printing process is not for home use. It requires a lot of expensive and heavy tools. Similar to the one needed during the sandblasting process. In addition, it is important to avoid inhalation of copper particles. Or else, it may cause serious health issues.

As mentioned before, the process is costly. And, only the machine would cost over $100,000. Usually, Copper 3D Printing using DMLS machines is solely for industrial use. However, if you still wish to print parts using the process, do not shy away from choosing an online 3D printing service you prefer.

Cost for Copper 3D Printing Using DMLS Machine

We have already talked about the price of the machine which is highly expensive, the same goes with the material cost. One kg of metal powder will cost almost $1000. But the best part is the results that it offers.

You can easily achieve a minimum layer thickness of 38 microns when printing with this process. Moreover, the parts would retain the properties of objects created using the Copper casting method. Interesting, isn’t it?

Lost PLA Casting

The process is similar to lost wax casting. So, what is it actually? Well, in Lost wax casting, the model is initially created using wax that works as the mold for the final object. Using the casting methods, the wax is melted and the Copper parts are created.

With similar steps, Lost PLA casting happens. The first object is made of PLA using 3D Printing technology. Later, the plaster when poured around the wax acts as the mold for the Copper part.

To melt away the wax, all you need to do is heat the part inside the kiln. This will melt away the wax leaving the plaster mold for Copper casting.

Remember, the complete process will lead to shrinkage when heated in the kiln. Therefore, you must design the parts considering around 15 to 20 percent shrinkage. In addition, the tiny details may get lost in the process of Lost PLA casting. Therefore, it is recommended not to create parts with too many small details.

Or, if your parts must retain high precision, you can choose among the other alternatives for Copper 3D printing.

Cost for Copper 3D Printing Using Lost PLA Casting

While the process is cheaper than DMLS 3D printing, it still isn’t cheap. Especially, if you do not have the proper tools to complete the job. For instance, the Kiln comes for at least $500. And, it gets even more expensive depending on the quality and the size of the same.

In addition, you will have to pay for Copper, PLA, and plaster for carrying the complete process. But the results will definitely be highly rewarding if you are not creating parts with minute details.

The Conclusion

Knowing that you can use Copper for 3D printing is in itself great news. For years, researchers have been trying to couple copper manufacturing with 3D printing to achieve remarkable results.

While there still needs to be more developments to perfect the process, the journey has begun. With many new machines coming out in the market and materials that provide precise results, users are already excited about future endeavors.

And yes, there is no doubt that we have come a long way to be able to tame such notorious metal, Copper. The unlikely properties that make it great as a manufacturing material also create difficulty for users who wish to 3D Print with it. Thankfully, the days are gone when Copper was a complete ‘NO’ within additive manufacturing.

With growing demands and the rise of better solutions, Copper 3D Printing is taking a high road. Not only the materials are available for industrial use, but filaments from TVF and other companies are letting home users take advantage of Copper 3D Printing. And, the journey will keep progressing as we proceed to the future. Sooner, the accessibility and ease will surge, making the task even simpler than it is now.