Roll down a few years back and it would have been difficult to assume that PEEK 3D Printers can also exist. Given the mechanical and chemical characteristics of the PEEK filament, it is obvious to turn and say – How?

The good news is that the technology has taken a huge leap and 3D printing with PEEK is no more limited to the conventional manufacturing methods. Moreover, there are not just a few limited manufacturers who offer such machines. On the contrary, you may find a lot of alternatives in the market.

This brings us to one of the most important points – Can we trust every other 3D printer promising high-quality results with PEEK. Yes, it is important to give this concern a thought before you buy a PEEK 3D Printer.

That is why we have come up with some of the key points for buying PEEK 3D Printers along with a few recommendations.

How to Select a PEEK 3D Printer?

PEEK is one of the most difficult materials to print with. However, it still is one of the most popular ones when it comes to obtaining professional print qualities.

It is derived from polyaryletherketone, abbreviated as PEEK. And, so is the name of the filament. PEEK is a semicrystalline thermoplastic and boasts a variety of amazing attributes.

For instance, it carries great mechanical strength are is resistant when exposed to extreme temperature. Not only that, but PEEK is also resistant to many of the chemicals while also being extremely lightweight.

Well, that sums it all. So, if you too think that the material could help with your manufacturing needs, why not find the right 3D printer to make that possible. And, for that, you must look for some of the most important features that these printers must possess.

Heated Print Bed

That’s what we thought too. For handling professional-grade material, 3D printers must have a heated bed. Not only it enables for proper first layer adhesion but will also count in for the overall print results. And, if you are planning to 3D print with PEEK, you will need a heated bed that can reach at least to 120 degrees Celsius.

Extruder Resistant to High Temperature

Do you know that the PEEK materials have a higher melting point? Yes, it melts over 343 degrees Celsius. So, if you are looking to extrude PEEK filament, your extruder must withstand that kind of extreme temperature. Please we warned, not every FDM 3D printer can accomplish such task, depending on the strength of its extruder.

One more point to note when checking the extruder – the hotend must be all metal as well as able to reach a temperature above 343 degrees Celsius. This will allow the printer to work seamlessly and keep the extruder away from abrasion.

Enclosed Printing Chamber

Most of the professional-grade materials are highly prone to problems like warpage or shrinkage. And, the same case is with PEEK as well. But you won’t like your 3D models to deform.

This is why you need a heated and enclosed chamber to sustain a consistent temperature around the 3D parts. This will avoid these problems discussed before and would help you attain the best print results.

When 3D printing with PEEK, in case of larger parts mostly, your enclosed chamber must be able to reach a temperature of 143 degrees Celsius. This is the glass transition temperature of PEEK.

What Else?

While these are some of the most basic features, you must also look at other aspects when printing with PEEK filament.

The foremost requirement is to maintain a consistent temperature throughout the printing process.

Controlling fluctuations could help achieve best outputs with PEEK 3D Printers. Along with this, post-processing and treatment occupies most of the hard work.

You must also take care of consistent cooling. The layers must be cooled gradually to offer the part stability and strength as well as in order for PEEK to crystalise properly.

Also, when you are done printing, you must wait for the PEEK part to come down to the room temperature. Or else, you may end up disturbing the process of crystallization already in effect.

Apart from these tips, there is a lot that you would learn once you start printing with PEEK. So, let us move to a few recommendations that offer amazing control over the temperature. And, allows printing efficiently with PEEK.

Recommendations for PEEK 3D Printers

Here are a few 3D printers that could help you print with PEEK effortlessly by offering favourable printing conditions.

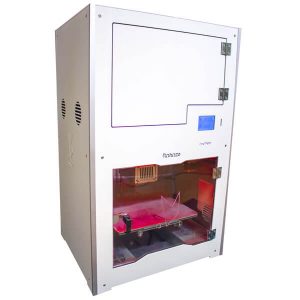

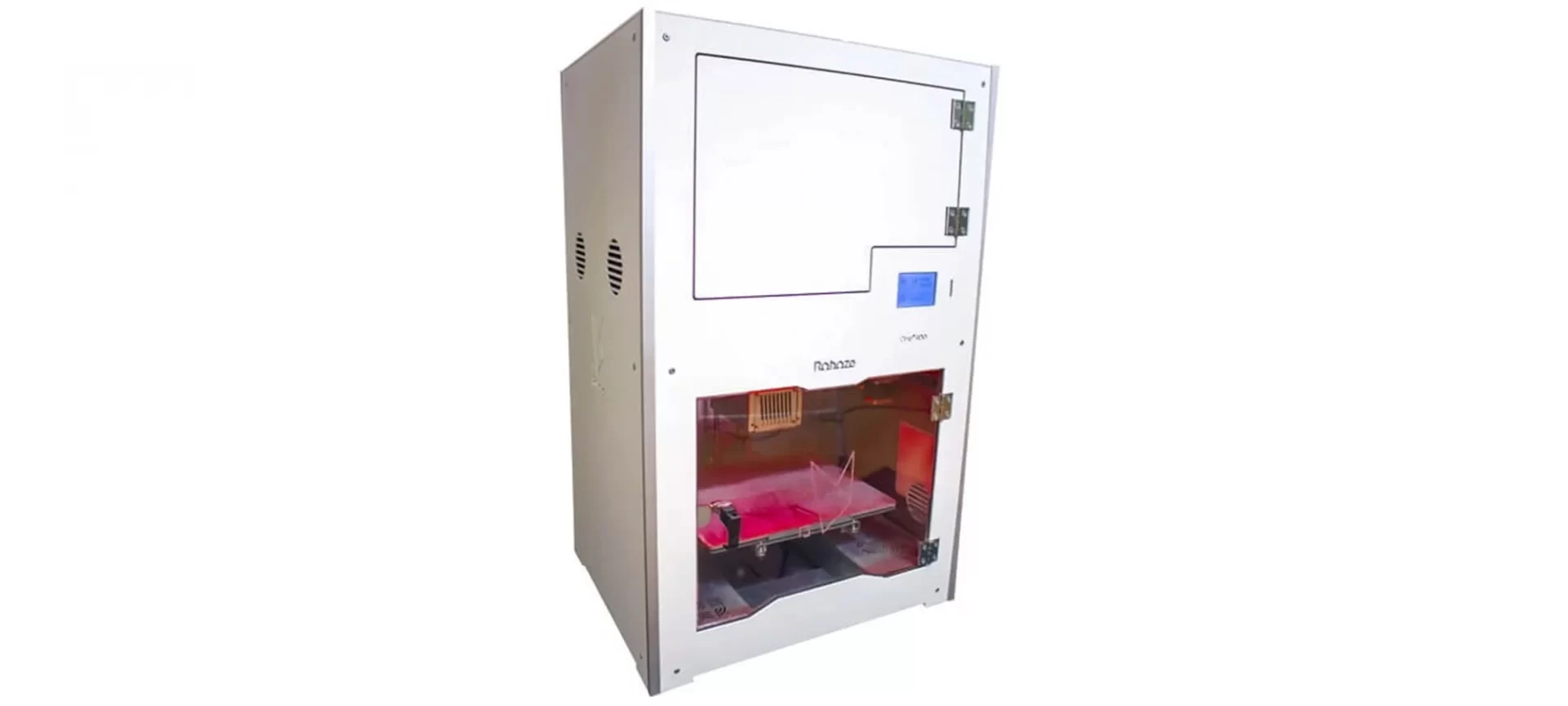

Funmat HT by Intamsys

Intamsys is a Chinese manufacturer of 3D printers and Funmat HT is a professional 3D printer by the company that can print with PEEK.

The printer is equipped with many advanced features that you may find with more advanced alternatives.

The machine exhibits a high-temperature extruder that can reach a maximum temperature of 430 degrees Celsius. Also, the heated bed has a maximum limit to reach 140 degrees Celsius.

Along with this, the 3D printer comes in an enclosed frame. All these features make this 3D printer suitable for printing with PEEK as well as PEI.

Apart from these features, this PEEK 3D Printer also has the filament run-out sensor, a built-in camera, remote monitoring facility and more. It offers a build size of 260 x 260 x 260 mm.

With all these benefits, if you wish to buy this 3D printer, you must be ready to spend somewhere around $6000. However, it would certainly be worth that amount.

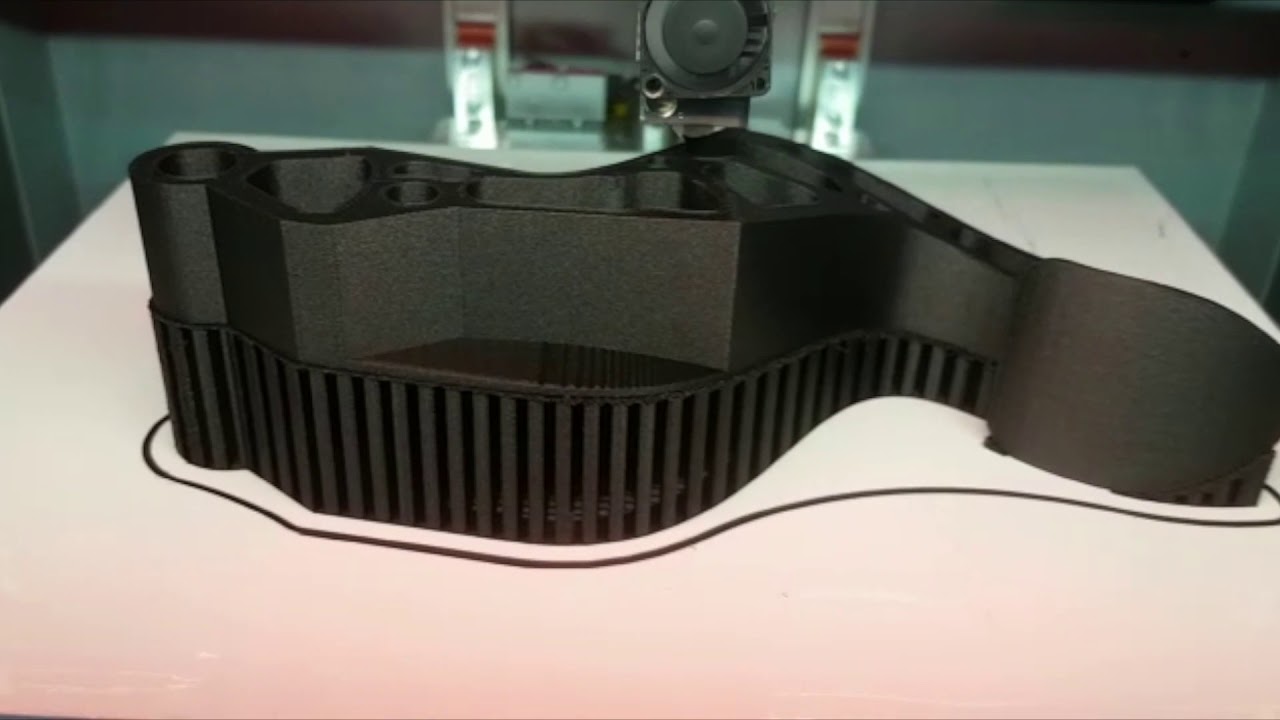

F420 by 3DGence

3DGence is a polish manufacturer and has been busy releasing wonderful 3D printers to help professionals better their production requirements.

The company claims to be the first manufacturer of the 3D printer to bring soluble material with PEEK printing.

This means, that users can print with dual extrusion system using its F420 3D printer that can easily cater to the needs of PEEK printing.

You would be astonished to listen to the different perks the 3D printer offers to its users.

Not to forget, you can easily tame PEEK with the high-temperature extruder that can reach a maximum temperature of 500 degrees Celsius.

Yes, you have heard it right. To attain such high temperature, the company has really stretched its arms a little further than where it was during the release of its predecessor.

This particular 3D Printer makes use of interchangeable modules for printing. Hence, you can change the module depending on which filament you use for printing.

For different industrial-grade material, the printer has a separate printing module. This makes it easy for users to take care of versatile needs just with one 3D printer.

More to the perks, the 3D printer has dual extruders. So, you can easily print highly complex geometries using industrial-grade material and soluble material. This helps in achieving amazing finer results with a smoother surface finish.

The maximum heated bed temperature is 180 degrees Celsius and an enclosed chamber to make printing suitable for PEEK. You can also enjoy the smart material manager inclusion in the printer.

This allows the printer to identify the filament in use and tweak the settings accordingly.

Given all the different features, the 3D printer seems pretty suitable for a number of applications.

From automotive to prototypes to the production process, users can make use of this printer for an array of needs.

M2 2020 by Aon3D

With a build volume of 454 x 454 x 640 mm, M2 2020 is a large format 3D Printer from Aon3D.

The manufacturer is based out of Canada and has expertise in creating industrial-grade 3D printers.

This particular release aims at offering production solution for tooling, end-use parts, jigs, prototypes and more.

M2 2020 can print with PEEK and many other industrial-grade filaments including PEKK and ULTEM. It can also work with polycarbonate.

The company has also ensured the flexibility of material choice. So, users can even print with third-party filaments.

The best part is that the printer already has saved profiles for many of the filament brands.

You can enjoy printing with dual tool head that runs independently. So, you can use PEEK along with the support materials for printing models.

The extruder can reach a maximum temperature of 500 degrees Celsius and the print bed reaches up to 200 degrees Celsius.

Though being bigger in size, the machine takes not more than 15 minutes to heat up. There are various other perks of working with this PEEK 3D printer. And, you can easily explore that once you get hands-on experience with this machine.

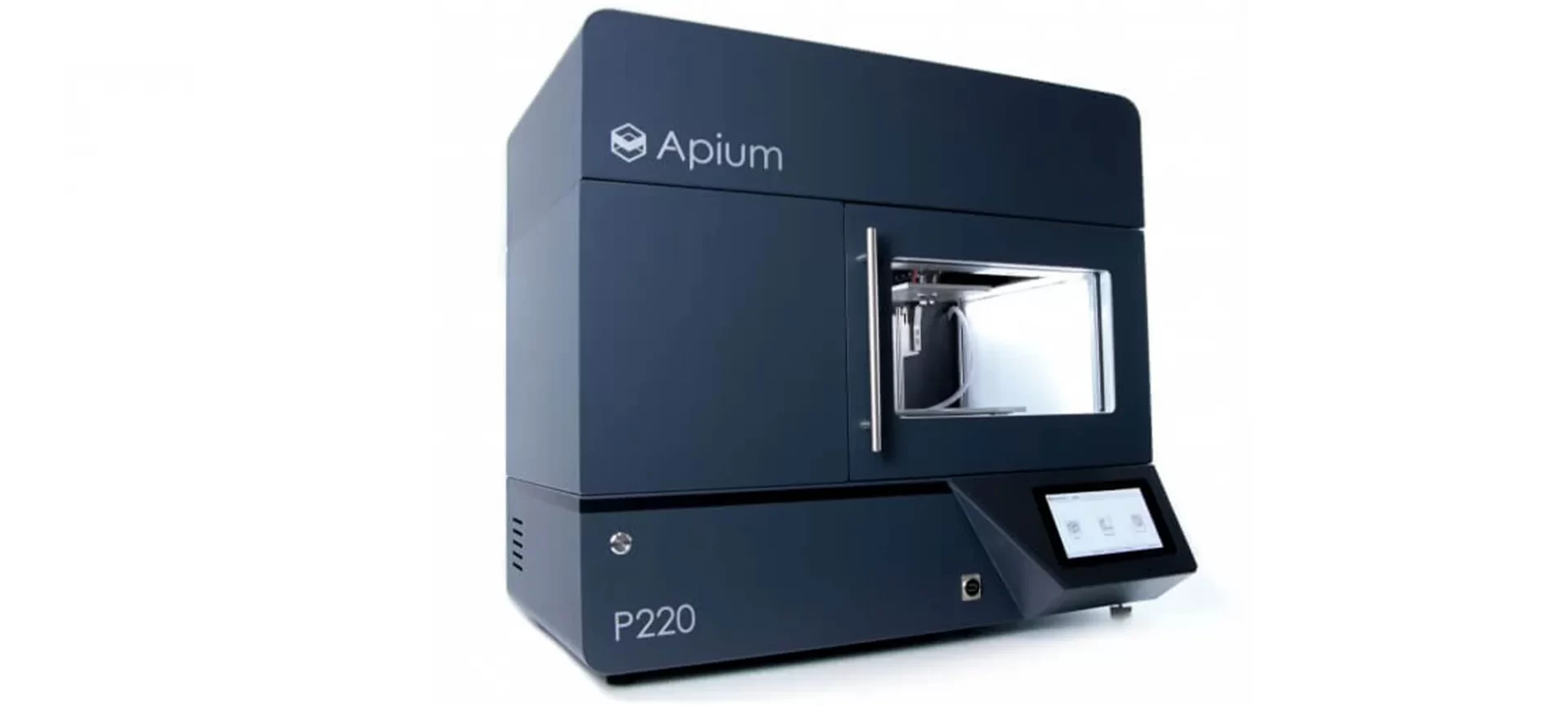

P220 by Apium

A great professional solution by Apium, a German manufacturer to help create PEEK models with ease.

P220 is an industrial-grade 3D printer that offers high-quality prints while able to handle different flexible materials.

The 3D printer is capable of producing high-end functional prototypes for businesses as well as creating end-user parts.

However, it just offers a build volume of 205 x 155 x 150 mm. Looking at the brighter side, the size is manageable and best fit for small business setups.

To offer compatibility with PEEK filament, the printer comes fully enclosed. Not just that, the extruder can reach a high temperature of 540 degrees Celsius.

Alongside, the heated bed has the capacity to touch a temperature of 160 degrees Celsius.

These attributes bring the 3D printer closer to the expensive and large-format 3D printers.

Users can print with carbon fibre as well as glass-reinforced PEEK. What makes it even a better choice for small offices is its low operating noise. Plus, it’s blessed with simple filament change arrangement and interchangeable nozzle.

Stratasys F900

Let’s not leave behind this large-format PEEK 3D Printer when talking about the best recommendation in this segment.

F900 by Stratasys, a pioneer of additive manufacturing technology, is capable of printing with PEEK and various other industrial-grade filaments.

The machine could allow for best printing results if properly used to its highest capabilities.

What amazes us most is its very large build volume of 914 x 609 x 914 mm. The F900 comes with an acceleration kit.

This further allows the professionals to expedite the print operation and scale up their production with time.

Plus, you can always count on its customized software that provides detailed previews for 3D Parts.

There is a built-in camera for remote monitoring and various other benefits for users.

The 3D printer has three different variations. Apart from F900, there are F900 AICS, and the F900 Pro. While the prior is designed for aircraft solutions, the later uses ULTEM resin for production.

Roboze One+ 400

Designed specifically for professionals, the 3D printer allows for printing with PEEK along with various other flexible materials.

It features a compressed air-cooling system that boasts gradual cooling for best results with PEEK printing.

Roboze One+ 400 has a high-temperature resistant extruder that can withstand a temperature up to 500 degrees Celsius.

The print bed can also manage to reach the highest temperature of 130 degrees Celsius.

Along with all these favourable attributes, the 3D printer offers a vacuum plate system.

This is included for offering the stability of prints for large models as well along with the smaller ones.

The build volume is sufficient enough to offer enough room for creativity. It has 300 x 200 x 200 mm volume of space for printing.

Ensuring efficient heat exchange of extruder, this PEEK 3D printer is highly reliable and very efficient.

|

The Takeaway

Nothing beats the passion of going a step further with creativity. Businesses keep looking for better and advanced options to give their production goal, wings.

To summarize it, 3D printing is one of the most trusted technologies that could allow companies to attain the highest level of satisfaction.

Along with amazing results, not possible otherwise, PEEK 3D printers could turn the production goals of small as well as large scale businesses into reality. So, if you wish to give this a thought, do not forget to look for reliable options.