Wish to use PVA for 3D printing? If yes, you must be aware of the PVA print temperature setting to perfect your parts. Mostly used for printing supports, PVA is a very common material within the additive manufacturing industry.

PVA stands for Polyvinyl alcohol which is known for its water-soluble property. This is the same reason why PVA is such an important part of the 3D printing regime, making it the best support material.

People often confuse PVA with PVAc (polyvinyl acetate). However, these two are completely different. PVAc is water-soluble glue. On the other hand, PVA is a synthetic polymer that is completely odourless and colourless.

It also carries huge biocompatibility properties. Moreover, the material exhibits very little toxicity. Therefore, PVA makes up for applications of health products. For instance, contact lens solution.

In short, PVA is a very common material, mostly used for support construction. Hence, it is difficult to skip its contribution within additive manufacturing.

In case, you want to try your hands printing PVA, do not forget to read about its properties and PVA print temperature settings.

And to make your task easier, we have included all the important details that will come in handy when working with this material with unique properties.

What is PVA in 3D Printing?

Unlike other known filaments such as PLA and ABS, PVA isn’t very popular for the production of final parts. However, it is more pronounced for its application as support material.

Usually printed with a machine with dual extruders, PVA enjoys its own fan following. Many users consider PVA the best filament for support. And, the reasons are too obvious.

When using the same material for printing support and the part, it becomes difficult to remove the support later.

This is because of the similar strength the support and actual part share. It becomes really daunting to remove supports from tricky spots. And, how can we forget the ugly scratches and marks that are too common to experience after removal of support using pressure?

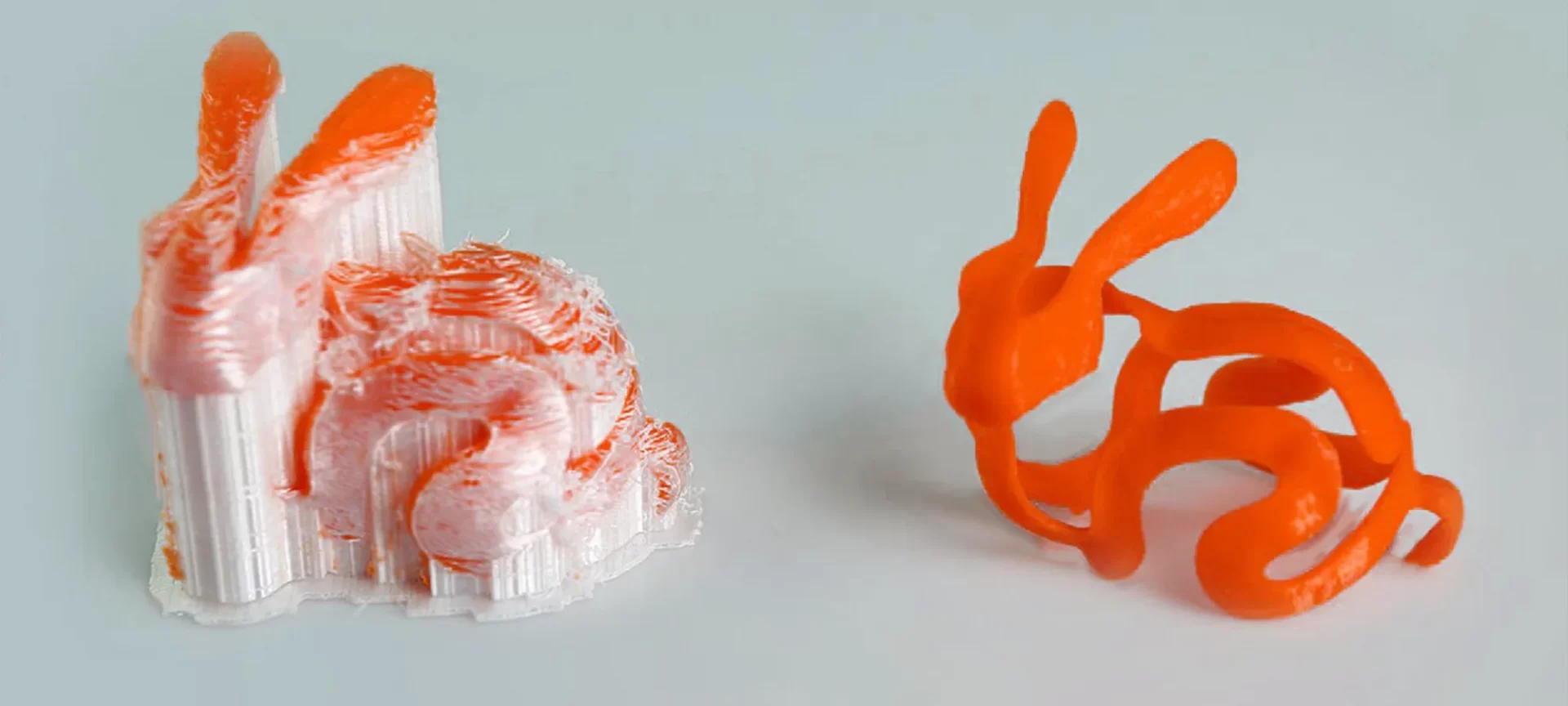

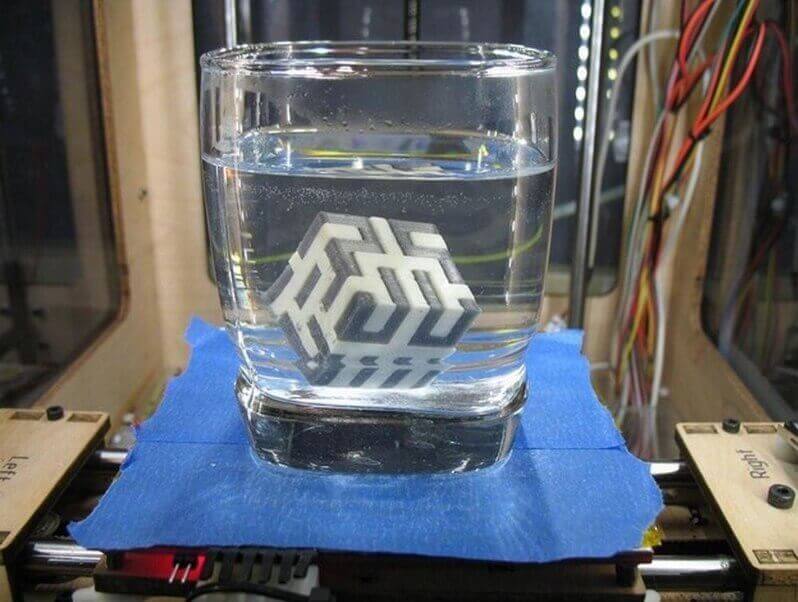

However, when using PVA, such instances are completely eliminated from the equation. Being able to dissolve in water, PVA does not require much effort for removal from the final part.

Once the parts complete printing, all you need to do is submerge them inside water. The support will dissolve and separate from the final print. Hence, summing up for a much effortless process.

This easy removal of support not only facilitates ease but also saves the prints from unwanted marks. The prints are smoother and do not require a minimum of post-processing steps. You can easily skip processes such as sanding and painting.

There is just one thing you must not forget. Printing support using a second material will require two extruders. Hence, PVA printing as support material is only possible with printers equipped for dual extrusion.

All of this must sound great. However, it is not very simple to operate dual extruder printers. From printer preparation to calibration to PVA print temperature setting, one must know all of it. Hence, why not check out the various properties and setting requirements for PVA?

PVA Features

With several unique and many common features, PVA stands as a very impressive addition to the filament family for 3D printing. Here is what you can expect from this material in terms of features:

- Water Soluble: The material easily dissolves in water. The same property makes this material the first choice for printing support. However, if you are printing end parts with PVA, ensure to keep it away from water as well as high temperature.

- Cannot be Compressed: Again, a very suitable feature for printing supports. Because the material does not compress at all, the final parts can be built along with it without worrying about deformation. PVA offers strong support to the building material.

- Colourless and Odourless: With no colour or odour, PVA happens to be a silent substitute for printing. Hence, when it comes to creating support, the material becomes highly preferable. Offering nothing but support.

- Durable: Yes, the material is durable. Hence, good for support when working with parts consisting of finer details.

- Non-toxic: Being non-toxic is a very friendly feature. With such attributes, it becomes easy to include PVA for almost every application, including health-related products.

PVA works best with PLA. This is because these two filaments work almost with similar settings, including PVA print temperature.

Moreover, PLA does not like water. Hence, when PLA is printed with PVA, only the support eliminates. PVA dissolves while PLA does not. Making these two the best match for each other.

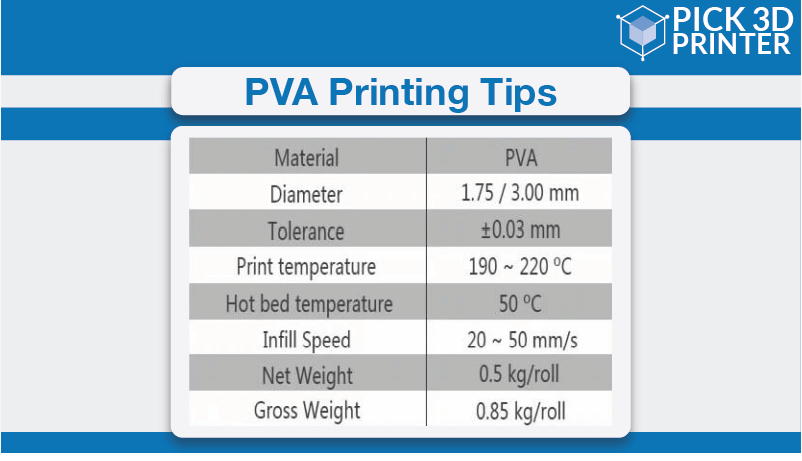

PVA Print Temperature – Tips for Printing

Learning about PVA and its properties make a lot of things lucid. However, the job is still incomplete unless we find out the perfect PVA print temperature setting for the best outcomes.

Nozzle Temperature

Not sure what temperature setting for the printer’s nozzle will allow for the proper extrusion of PVA? Well, the usual nozzle temperature requirements range between 180 degrees Celsius to 200 degrees Celsius.

However, the exact temperature depends on the PVA brand you choose to print. Also, in case you overheat the filament, it is very common to experience nozzle clogging. This is because PVA degrades at a high temperature, it isn’t able to withstand.

Print Bed Temperature

As it is with the nozzle temperature, print bed temperature will also depend largely on the brands that you select. However, typically the bed temperature ranges between 45 degrees Celsius and 60 degrees Celsius.

What Is The Best Temperature for PVA?

The precise PVA print temperature widely changes along with the different brands. Therefore, let us find out the various choices for PVA along with the recommended temperature of each of these brands.

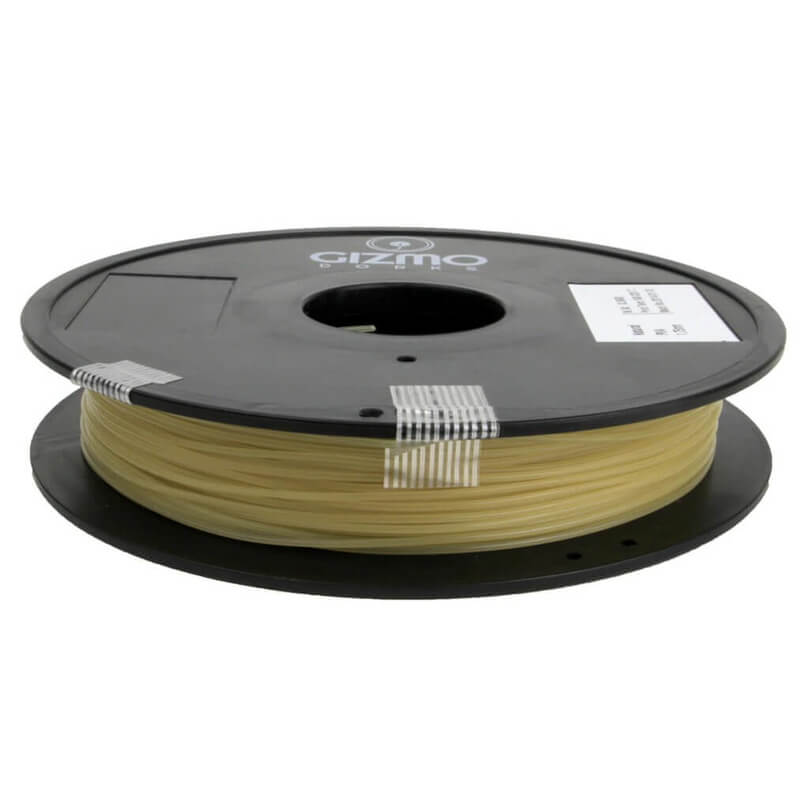

GizmoDorks

GizmoDorks is an American manufacturer offering PVA filament that’s designed to works in tandem with PLA. The manufacturer has 1.75 mm and 2.85 mm filament spools available in 500 g weight.

Checking the guidelines provided by the company, you will come to know that the PVA by GizmoDorks must not be exposed to a temperature of 200 degrees Celsius or more. Otherwise, the material will degrade, finally clogging the printer’s nozzle.

Therefore, the recommended PVA print temperature for the extruder lies between 160 degrees Celsius to 190 degrees Celsius. For bed temperature, the company recommends heating the print bed to 60 degrees Celsius. However, this is not a mandatory requirement.

MatterHackers

MatterHackers is a company from California supplying various 3D printing materials along with tools for printing. Also considered as the top manufacturer for filaments, MatterHackers include a wide variety of material choices to their list of offers.

And, it does include PVA filaments too. The company offers two 1.75 mm and 2.85 mm diameter spools in two different weight options: 0.5 and 1 kg spools.

What’s best about the material is that it does not require a heated bed to print. Moreover, the MatterHackers filament easily dissolves when put inside tap water.

The manufacturer recommends using the extruder temperature between 175 degrees Celsius and 200 degrees Celsius.

SainSmart

The company specializes in open-hardware manufacturing, especially for maker products. This also includes 3D printing material along with a PVA filament spool.

What separates SainSmart PVA from the competition is its really cheap market price. A 500 gm spool costs $33.

You can purchase a 1.75 mm diameter spool from SainSmart. And, as per the reviews, the PVA filament by this manufacturer is quite impressive in terms of performance. It can provide better results than most of the popular brands working for quite longer.

The PVA print temperature settings are also quite easily attainable. One can print the filament with nozzle temperature ranging between 160 degrees Celsius to 180 degrees Celsius. However, one does not need a heated bed to carry printing with SainSmart PVA.

Ultimaker

In the beginning, Ultimaker PVA was meant for their own 3D printers. However, later the filament was brought to use by other printers as well.

Currently, Ultimaker PVA is supported by an FDM 3D printer requiring 2.85 mm diameter spools. Unlike other brands, Ultimaker PVA showcases different properties and is very popular among industrial applications.

The best part is that the Ultimaker PVA works with difficult filaments such as Nylon and CPE. In addition, the manufacturer claims that their PVA filament is completely biodegradable along less prone to moisture absorption. Hence, very different from PVA filaments offered by other brands.

And, because of these properties, Ultimaker PVA needs a higher nozzle temperature compared to the usual range for printing PVA.

Hence, you must heat your nozzle to 220 °C for working with Ultimaker PVA. Also, you must have a heated bed to work with this filament. To be precise, it requires 60 degrees Celsius print bed temperature.

The PVA spools are available in 350 gm and 750 gm with their standard 2.85 mm diameter.

eSun

Being one of the most famous brands around for 3D printing filaments, eSun surely has a lot of choices for its users when it comes to printing. The company operates from Shenzhen, China.

Among its various choices for users, the company also offers PVA filament. eSun PVA is available in 500 gm spool. Also, they only have 1.75 mm diameter PVA spools.

Similar to Ultimaker, eSun recommends a higher print temperature for working with its PVA filament. And, it goes up to 220 degrees Celsius. The bed temperature requirement ranges between 60 degrees Celsius and 80 degrees Celsius.

What’s amazing is the fact that the filament is pronounced around the world for its quality and precise results. Hence, if you are seeking an accurate print job combining PVA with other materials, do not forget to check this alternative.

Additional 3D Printing Tips for PVA – How do I Print PVA support?

There are certain properties that make PVA a little difficult to handle. And, one must take care of the same when operating printers with PVA.

While PVA can be printed without an enclosed chamber, it is necessary to ensure that you meet the requirements for the accompanying filament.

For instance, if you are printing PVA with PLA, you may not need a closed chamber for printing. However, it’s completely the opposite in case you use PVA with Nylon.

Furthermore, PVA draws moisture and ends up creating failed prints. Therefore, it is very crucial to find out the correct measures to handle PVA when printing.

As already mentioned, right after you open the PVA filament, it will start absorbing moisture from the surroundings. Hence, printing must be done carefully.

In order to minimise the problem, try to create a favourable ambient temperature that stays below 28 degrees Celsius. Also, maintain a relative humidity staying below 50 per cent.

Once you are done printing, use the resealable bags or airtight containers to store PVA. You must also use a desiccant, usually supplied with the filament.

In addition, when not in use, store the material as per the recommended ambient condition as suggested by the manufacturer’s material storage guidelines.

Also, prefer drying the PVA if opened and not in use for some time. This will not only allow for a smoother extrusion but will also limit problems such as oozing and clogged nozzle.

The Conclusion

That was a lot of information for PVA printing, isn’t it? However, it isn’t that difficult to follow. Users often find it irritating when experiencing failed prints, especially because of the problem with the support material. So, why not take some time and find about the best practices and tips for printing PVA.

While it isn’t the only material out there. But when it comes to printing support using dual extrusion, it seems to be the most recommended one. Easy to dissolve and durable to support the final product, PVA has a lot of best properties backing its popularity.

Hence, you must read about the best PVA print temperature before you go on and create your first print including this filament. The results will definitely stun you if you follow the right guidelines. Moreover, you can stay away from the extra work of printing models over and over again.