As evident by its name, a sand 3D printer utilizes sand for 3D printing parts and functional prototypes. It could be silica sand, ceramics, or even metal particles.

Among all the types of 3D printers, the Sand 3D printer occupies a special place in 3D printing. So, let’s discuss this unique 3D printer, how was it founded, how does it work, and a lot more.

How Was Sand 3D Printer Invented?

The history of sand 3D printing starts in the late 1990s. A German company, named Generis, in collaboration with MIT, Massachusetts Institute of Technology in the United States is credited for its invention.

The company focused on sand 3D printing for metal casting molds while the university developed and patented the 3DP metal binder jet technology.

In coordination, their work led to the first-ever commercially available printers which came into the market from the mid-2000s.

VoxelJet and ExOne, the current leaders in the same technology are said to be two divisions of Generis over the course of time.

A sand 3D printer is based on binder jetting, which uses a binder polymer to bind the particles together into a physical 3D model.

This arrangement can then be used to produce finished products or molds for an alternative material that is to be poured into.

Ultimately, a sand 3D printer shares many of the functional attributes of other 3D printing methods as it uses a layer-by-layer printing process allowing the creation of parts with complex internal and external geometries.

These layers are recognized by slicing the computer part models into thin sections. The sand particles are stuck with each other by a binder glue that solidifies the particles into a 3D shape. The average particle size over here ranges from 140–200 micrometers.

How is Working With Eccentric Sand 3D Printer?

Most 3D printing technologies are known to use heat for processing material into final parts. It may be laser energy that melts or sinters the material, or it can be just electrical heaters that melt plastic to dispense it in a thin molten stream.

But the core logic remains the same. In contrast to these 3D printing technologies, a sand 3D printer does not use heat.

It works like a typical inkjet printer, the only difference being, instead of ink onto a piece of paper, a sand 3D printer prints binder onto a sand layer. So, here the binding agent is also allowed to include pigment to print in color.

The very significant advantage of a sand 3D printer is that it requires no heat. So, the energy consumed is very very less comported to other 3D printer technologies and despite that it can be easily built to form very large parts.

On the other hand, the huge industrial 3D printers that use heat in their process require added energy and insulation, which limit also at times limit their size. Or maybe require a proper ventilation providing workspace!

Currently, build volumes up to 13.1 ft x 6.6 ft x 3.3 ft are commercially available in sand 3D printers.

Even with these large build volumes, sand 3D printers are known to provide resolutions of 600 DPI and layer thicknesses of 0.3 mm are printable. Isn’t that great?

The stepwise procedure of 3D printing parts via sand 3D printing

- Sand 3D printing begins like any other 3D printing process, with leveling the first thin layer of sand onto the build platform. The sand printer’s head traverses the sand layer while extruding the binder in the pattern that’s needed for that layer.

- The sequence of a) dispensing, b) leveling, and c) binder extruding continues until the complete part formation. After that is done, the additional sand in the build platform remains as the support material and is utilized in the coming layers, meaning that no additional supports are needed.

- As soon as the part is finished, any loose sand is carefully removed from the build platform. Post-processing of the part manufactured may include further cleaning, impregnating the part for increased strength, or sintering and binder removal for metal powder parts.

After having gone through the working of sand 3D printers, let’s look at the typical advances that have happened over time.

What Are The Advantages Of Sand 3D Printing?

Although sand 3D printers are very versatile, they can be useful not only for creating intermediates but also for construction.

Additionally, they are used for parts that need a higher strength or different material than typical sand 3D printing can offer. Moreover, it also can be used with materials other than sand.

Currently, metal sand casting, sand 3D printing of concrete forms, and direct printing of metal parts are the three most important areas where the technology is utilized in the most efficient manner.

Metal Sand Casting

Being an ancient metal working technology, Metal Sand Casting is known to have originated in China in 700 BC. Since then, it has continuously been a major aspect of metal working to date.

So you might want to question, how did 3D printing revolutionize such an old technology? And it right for you to carry such a question. Let’s look at the basics of sand casting to find an answer to this question.

The first step in sand casting is making an exact model of the final part. The materials used in this step are made of wood, wax, or clay.

Overall, this first step is a time-consuming process and requires a very skilled craftsman to create each part of the pattern perfectly.

Not only that, but also while doing so, the craftsman should be able to understand how the molten metal will react, flow, shrink, and solidify in a mold.

The second step is packing the casting sand around the patterns inside a holding box for creating the mold. In case the model was made of wax, it can be left in the mold for burning when the molten metal is poured in.

However, it should be noted that the mold has to be constructed in parts. If that is not done, a wooden or clay pattern used in this should be allowed in the pattern to be removed before casting the metal.

Sand 3D printing transforms the traditional sand casting process by creating a mold directly with all of its complexity and multiple parts in one shot. Also, it has reproducibility and is easily adjusted even if the finished mold isn’t quite right.

Additionally, the large print bed volume available in the 3D printer permits bigger molds to be made. Hence saving you the time, not requiring any skilled labor, and still giving you a better quality! Revolutionary, isn’t it?

3D Printing Sand in concrete forms

This is a very recently developed new and exciting application for sand 3D printing. It allows you to 3D print complex shapes for architectural design.

The researcher’s team at ETH Zurich has been researching on the subject of “how to use a sand 3D printer to create molds for concrete?”

As concrete can make up as much as 80% of commercial structures today, with such a material demand, architects and engineers are always looking for a way to reduce material consumption but not at the cost of strength.

Dealing with conventional flat concrete forms is not easy, but by 3D printing forms on a sand 3D printer, the concrete is known to be sculpted to just the right shape and thickness.

Using a sand 3D printer, if you are an architect, you can freely design the shapes and artistic elements for enhancing your design.

3D printing concrete forms opens new horizons to design structures with never before created shapes, sizes, and features. Also, it is next to impossible to achieve the same with other construction methods.

Direct printing of metal parts

In this type of advancement, the sand is replaced by metal powder. In this technique, a sand 3D printer is used to 3D print metal parts directly.

The case of metal 3D printing is especially interesting for industries because there is often a need for replacing large metal parts no longer manufactured.

Instead of making an expensive replacement design, it is easy to use a large metal part that can be 3D scanned and computer-modeled.

Then that model can be directly printed on a sand 3D printer with metal particles instead of using sand as a raw material.

It’s important to observe that the finished part will not be strong enough is used straight off the printer. This is because the metal particles are just glued together; only after doing post-processing can you achieve the desired strength.

Typical post-processing may include impregnating the part with molten metal, pressing and sintering the part.

Through direct printing of metal parts using a sand 3D printer, a completely usable replacement metal component can be made in a straightforward way.

Not only does this process saves time and money, but also does it lets you print the large print volume of a sand 3D printer buildable in one piece.

What are The Best Sand 3D Printers by Voxeljet and Exone?

As mentioned above, the company that founded Sand 3D printing with MIT was divided into Voxeljet and ExOne. Both of these companies are leading sand 3D printers in the 3D printing market currently.

And below mentioned are two of their best 3D printers that print using sand. So, let’s have a look at their features and specifications.

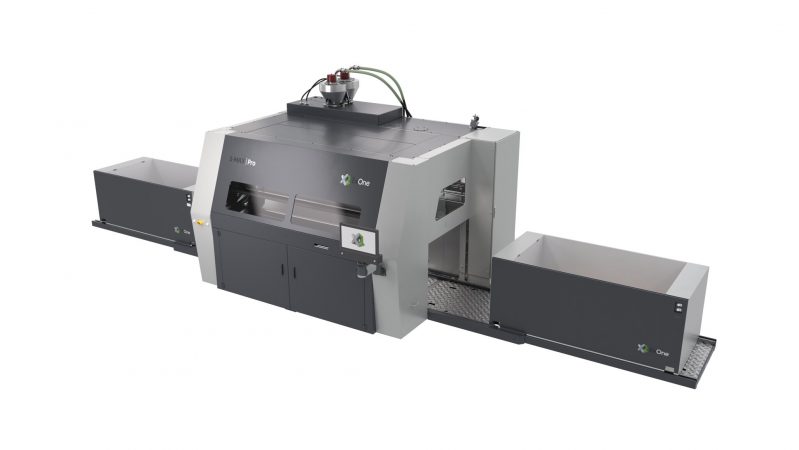

ExOne S-Max Pro

Based on the latest generation of industrial 3D printing technology, S Max Pro impresses with its speed, reliability, and precision. The printer is an excellent choice for both prototyping and industrial series production.

It can achieve printing speeds of up to 125 l/h (20 s/layer) and can therefore 3D print two full 1800 mm X 1.000 mm X 700 mm/400H job boxes, each with a volume of 1260 L. Isn’t that amazing?

S Max Pro by ExOne is equipped with a fully automated print head. It has an optional recoater that automatically adjusts for easy printing with different materials.

The 3D printer has an optional box-in-box system that enables you to immediately remove and post-process any job after printing.

It comes with an Intuitive Siemens control system with Industry 4.0 integration, cloud connectivity, and recipe control. Above all, you can real-time process control the printer.

Voxeljet VX 4000

Claiming itself as the largest 3D printing system for sand molds in the world, VX 4000 comes with a contiguous footprint of 4 meters x 2 meters x 1 meter. The 3D printer is unrivaled in terms of build volume.

Unlike other smaller 3D printing systems from the company, the VX4000 uses an innovative and patented layer construction process ensuring consistent shift times, maximum precision, and component quality.

This holds true even for high-volume production orders and smaller component series.

VX 4000 is smart to operate and can do many things. The complete process of operation remains simple because of the well-thought-out ergonomic concept.

It offers seamless integration by making use of foundry-standard materials that can be processed quickly.

Offering you a resolution of 200 dpi, VX 4000 can image even the finest details in the highest precision with large format components up to 4 meters long.

Being a robust 3D printing system the printer remains unmatched in terms of the reliability offered in industrial multi-shift operation.

|

The Conclusion

Sand 3D printers have already found applications in numerous industries and their scope is increasing with time. By allowing you to print large 3D parts and functional prototypes, without any support structures, and 3D printing offers you immensely in terms of freedom.

Additionally, the materials used for 3D printing sand parts are cheap and have been proven over all these years.

However, the parts printed using sand 3D printing are relatively weaker and require post-processing to achieve the desired strength. Also, the cost of metal 3D printing is very high because of the material and post-processing methods involved in the same.