With time, the number of possibilities in terms of diverse filament choices is surging within the 3D Printing industry. And, one such example is TPE.

Using TPE Filament you can manufacture parts possessing non-slip characteristics and flexibility. The most common example of TPE application is the flexible phone cases.

The other application in which you can find TPE is, dampeners, medical prosthetics, and industrial applications wherein you need functional prototypes to counter loads. Apart from making objects extremely flexible, TPE also makes them intensely durable.

TPE stands for Thermoplastic Elastomers that do not specifically refer to one material, but a varied range of elastic thermoplastics. While buying TPE filament you’ll often observe it being associated with TPU.

Although there are many differences between these two and in the way they are used to make parts, the best way to differentiate is by noting their technical hardness ratings.

Any material of hardness 90A or below is termed to be TPEs even if the base material of the resulting elastomer is TPU.

So, let’s discuss the many properties of TPE that make it unique and one of its kind. We will learn about the various facts related to the printing and storage conditions that you need to take care of when working with TPE.

Remember, TPE is a flexible filament. Therefore, you need to take more precautions while 3D printing it than you used to while using ABS or PLA or any other choice.

You will also face some challenges, but if dealt with patience and correct settings, the resulting objects will turn out to inherit rubber-like qualities. And that’s something only achievable with this material.

So, let’s start diving into this special material TPE by looking at its printer settings and storage conditions.

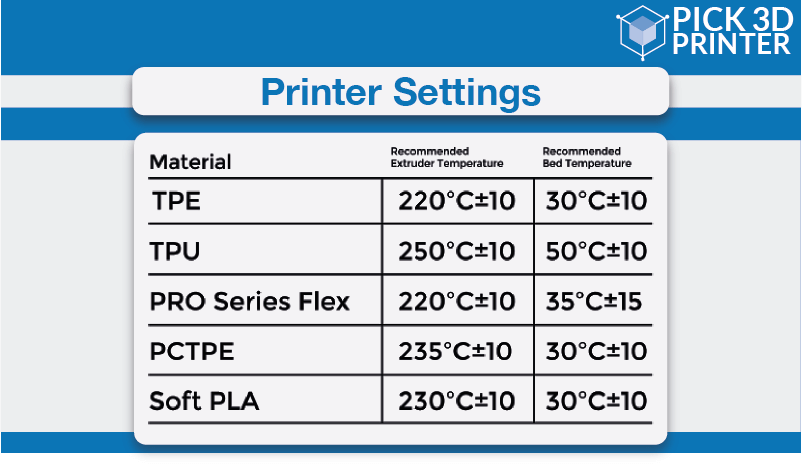

Printer Settings

Buckling or squeezing through gaps in the filament pathway are two of the most general problems while 3D printing TPE. So, make sure your path does not have any gaps or obstacles.

You are recommended to use a direct drive extruder, not a Bowden one. The other part you need to be keen on is retraction.

As TPE is stretchable and can be compressed, retraction is usually disabled while 3D printing the material. The other issue is with adhesion.

Generally, while printing with TPE advice is to use a painter’s tape, glue stick, or hairspray.

While TPE 3D printing, ensure the nozzle temperature ranges between 190 to 250 degrees Celsius as per the brand you use.

Similarly, keep the bed temperatures ranging between 0 to 70 degrees Celsius as per the brand of TPE filament you are using.

Experts advise the print speed range to be around 5 to 50 millimeters per second.

Storage Conditions

TPE filaments are hygroscopic, meaning that they absorb moisture from the air. So, if you keep storing the filament in an open atmosphere, they would not be able to produce good quality prints.

Instead, the material should be stored in a low-humidity environment like an air-tight container or bag with desiccant packs.

Having gone through the printer settings and storage conditions it’s time now to go through different brands of TPE filaments that are very well-known and reliable.

Top-Quality TPE filament Brands

Below mentioned are a few handpicked brands of TPE filament that are tried, tested, and proven to provide excellent results.

Colorfabb Varioshore

Available in two colors, black well as natural, Varioshore is a variant of TPE i.e. TPU. You can buy the complete spool, either in 700 gms, 2000 gms, or 4200 gms.

The diameters in which this filament is available are 1.75 mm and 2.85 mm. Varioshore TPU is made using foaming technology that Colorfabb calls by the name LW-PLA.

This brand has its own set of special features like varying shore hardness, lightweight, light density, and softness when touched.

You can vary the density of this material by adjusting temperature as well as material throughput. It is observed this filament starts to expand between temperature ranges of 200 to 250 degrees Celsius by 1.4 to 1.6 times its original volume respectively.

The filament has been developed with Lubrizol and hence is suitable for printing insoles and cosplay parts. You are advised to print this filament at a print speed ranging between 20 to 40 degrees Celsius. Its flow ranges anywhere from 60 to 100 percent.

Colorfabb was founded in 2012 by Rudd Rouleaux, CEO of Helian Polymers. The company is based in Belfield, Netherlands. Helian Polymers is a trading company in the field of bioplastics.

Ninjatek Ninjaflex

With a shore hardness of 85A, Ninjaflex is a truly flexible brand of filament that allows 660 percent elongation without any sort of wearing or cracking.

Made from specially formulated TPU material, the patented technology takes pride in coming up with a low-tack, easy-to-feed texture.

It’s uniquely flexible and prints strongly. These qualities make the filament ideal for direct-drive extruders.

This brand of TPE filament is available in 1.75 mm and 3 mm diameter in 0.5 kg, 1 and 2 kg spools.

According to Ninjatek, their filament finds application in seals, gaskets, plugs, leveling feet, and protective applications.

You can get this filament in nine different color options namely, fire, midnight, water, lava, sapphire, snow, sun, grass, and silver.

The specialty in this brand lies in its patented low friction exterior that permits smoother feeding than others.

The composition of polyurethane in this filament authorizes it to have characteristics such as excellent vibration reduction.

The recommended nozzle and bed temperature ranges for Ninjaflex are 210 to 235 degrees Celsius, 20 to 50 degrees Celsius respectively.

While the advised print speed range for the same is 10 to 30 millimeters per second.

Fenner Drives additive manufacturing company sells their filament by brand name Ninjatek.

They are very actively producing filaments for end-users in industrial space. Based in Pennsylvania, USA, Fenner’s products are well-known in the market for their unique characteristics and consistent product quality.

3D Jake Filaflex

Accessible in 1.75 as well as 2.85 mm, Filaflex has a shore hardness of 82A. It’s obtainable in two weight options, 250 grams, and 500 grams.

The filament is extremely elastic in nature, has high adhesion to the printing bed, and is odorless and solvent-proof.

The colors in which this brand of TPE filament is available are; black, transparent, white, orange, fluor, green, yellow, skin 1, aquamarine, silver, blue, gold, red, magenta, skin 2, and clear blue.

The endorsed print speed range for printing with this filament is 30 to 110 millimeters per second.

The manufacturer advises you to print this brand of TPE filament at processing temperatures ranging between 220 and 260 degrees Celsius. Its diameter-related tolerance is 0.05 mm.

The material in which Filaflex is made consists of TPE and other additives. Parts such as your own shoes can be created using this brand of filament. And it’s compatible with almost any 3D printer.

In your printer, you are suggested to use a direct drive extruder, no retraction for successful 3D printing of the filament. The flow of this material can be increased up to 105 to 115 percent.

3D Jake is a part of online shops owned by Niceshop groups, an Austrian company specializing in the development of online shops for various product segments in European markets. They deliver in more than 90 countries.

NinjaTek EEL

With a shore hardness of 90A, Ninjatek EEL is a truly flexible conductive material that allows for a whopping elongation of 355 percent without any wear or cracking.

It has a consistent diameter and reliable material properties that permit high-quality print of parts or functional prototypes. The filament is also chemically resistant to various materials.

According to the manufacturer, you can use Ninjatek EEL for making electronic traces, integrated flexible wire, anti-static grippers, and conductive wearable products.

This TPE filament is available in two diameters: a) 1.75 mm, b) 3 mm. It’s accessible in 0.5-, 1- and 2-kilogram spools and midnight color.

For printing with this filament, you need to ensure your printer’s extruder temperature ranges from 220 to 230 degrees Celsius.

The platform temperature of your printer needs is somewhere around 45 degrees Celsius. And you are advised to use glue or blue painters’ tape in case you are not using a heated bed.

For the top and bottom layers of the print, you are recommended to keep the print speed around 15 to 20 millimeters per second. Whereas, for infill, you can use anywhere from 45 to 60 millimeters per second!

Recreus Filaflex Ultrasoft

Used for making insoles, prostheses, and models of organs, flexible objects and parts for the automotive industry such as stoppers, joints, tires, grippers, etc., this brand of TPE filament is non-toxic.

You can also use it for creating parts such as textile garments, fabrics, prints on garments, bags, earrings, footwear like sandals, shoes, slippers, etc.

For printing with Filaflex Ultrasoft, you will need a print temperature ranging from 215 to 235 degrees Celsius. The print speed should be around 20 to 40 millimeters per second.

It has a diameter tolerance of 0.04 mm. The filament needs a retraction speed ranging from 35 to 50 millimeters per second at a distance of 2.5 to 6 millimeters per second.

The travel speed of your print head should be around 160 to 200 millimeters per second.

Filaflex Ultrasoft is available in 1.75 as well as 2.85 mm diameter, 500 grams, and 3 kilograms.

The filament shows excellent resistance to acetone, solvent, and gasoline. You do not need a heated bed for printing with this filament.

eSun Elastic Natural

It’s non-toxic, highly flexible, and elastic in nature and can be obtained in 1.75 as well as 3 mm diameter.

Elastic Natural can be used for making sports equipment, industrial parts, shoe material supplies, daily necessities, auto parts, etc. You get this brand of TPE filament in one kg spool. A complete container of this filament contains twelve spools.

You are recommended to keep the extruder temperature ranging between 210 to 230 degrees Celsius.

The extruding speed range can be anywhere from 15 to 30 millimeters per second, whereas the traveling speed range should be from 90 to 150 millimeters per second.

The shore hardness of this filament is 85A and its tensile strength is 30MPa. The number of shells can be ranging from 3 to 5.

eSun was founded in Shenzhen in the year 2002. It’s a company that does research and development in the area of biodegradable polymers such as PLA and PCL.

Since its inception, the company is known to have good relationships with 3D printer manufacturers, distributors, and resellers all over the world.

Elastic Natural is an outcome of consistent research of eSun since the year 2007 in various unexplored areas of filament.

The Conclusion

The world of 3D printer filaments is very dynamic. A new 3D printing material is developed very rapidly and hence it is also exciting.

So, while buying TPE, you are advised to correctly check some of the most basic requirements such as extruder temperature range, heated bed temperature range, print speed and shore hardness.

Noting all of that would mean lesser mistakes and help in facing challenges while printing using TPE filament.

Moreover, check with recommended retraction settings which will decide the stringing nature of your TPE 3D printed part.

Objects printed using TPE filament will have flexibility as well as durability. But also ensure that the filament you are buying does not turn out to be extra soft or flexible.

Otherwise, it will be extremely difficult to load its spool in your printer’s spool holder. Also, with the increasing popularity of the material, more and more brands are into manufacturing of the same.

So, it’s highly advisable to be a little choosy while you are buying. Look keenly for brands that offer easy storing conditions and printer settings that are suitable for your 3D printer.

If all goes well, you’d be able to manufacture some of the most delicate parts that will exhibit rubber-like qualities.