|

Here is a 3D printer that claims to offer three different manufacturing methods, namely, 3D printing, laser engraving, and CNC carving.

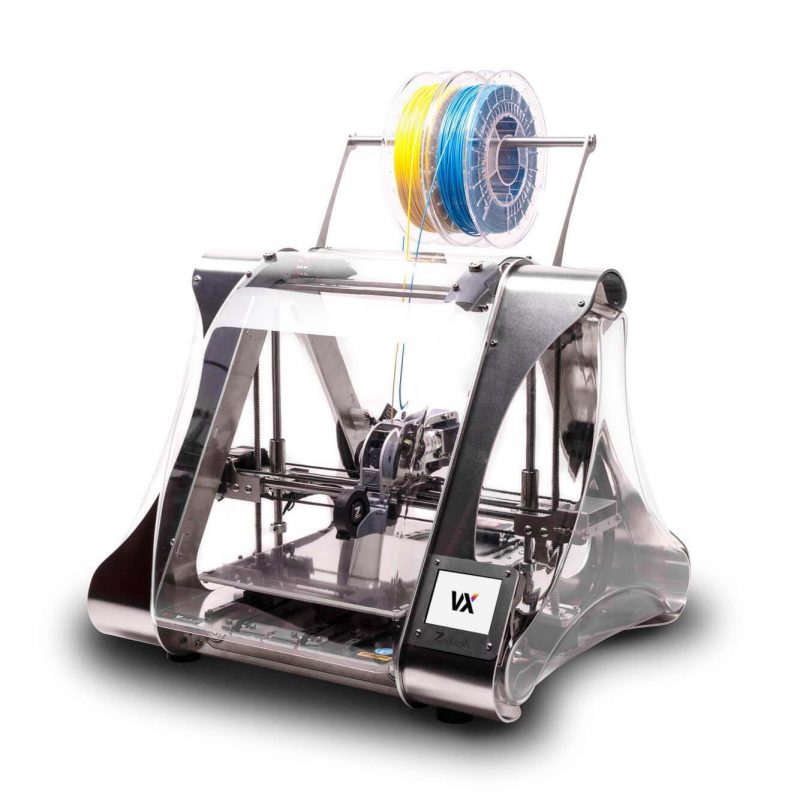

Z Morph VX is a product of a Polish manufacturer that is multiple functions providing a desktop system created in 2017.

Overall Z Morph VX is a useful 3D printer that has enhanced features as well as multiple functions and everything to be a robust solution to all your creative design needs.

There are a lot of printers that you will find are big-budgeted than this one, but Z Morph VX can provide you features that they provide at a lesser cost.

In this article, we are going to be reviewing the printer in-depth to give you insights about its amazing features, specifications, print quality, price, and a lot more.

This model boasts of advanced solutions in its print quality and machine reliability.

The manufacturing company of this printer promises that the machine is easier to set up and operate than ever before, and, while we’re inclined to agree, the process is not without its small wrinkles.

Let’s get started with our journey that promises to provide you with insights about the printer’s features.

Features

Featuring robust and sturdy construction, the Z Morph VX is meant for prolonged use.

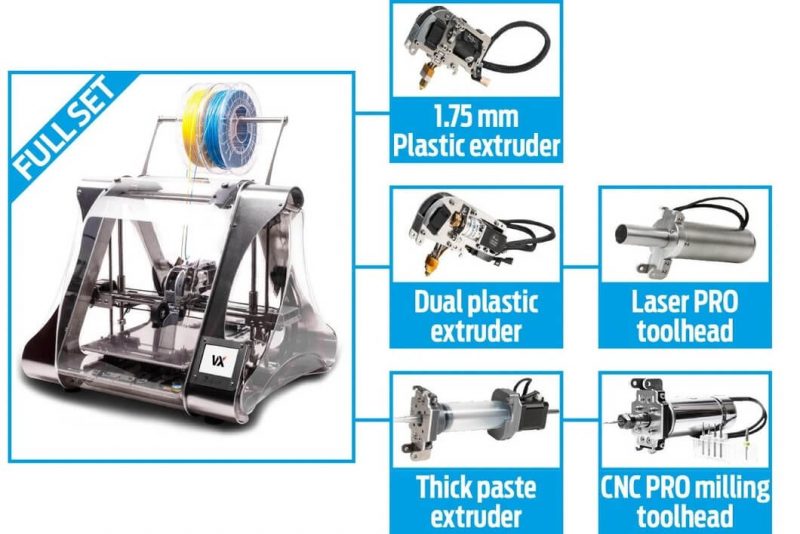

The printer has multiple interchangeable tool heads, a paste extruder, and a dual extruder that enables users to do more dynamic and versatile printing. The interchangeable tool heads can be transferred easily.

Users who wish to learn more about this can do a free ZMorph Academy course that allows them to learn how to operate them correctly.

Overall, the ZMorph VX is a multi-tool machine with Laser PRO, CNC Pro tool heads, and unmatched FFF 3D printing quality, as per the claims made by the company.

This printer works with all the printing materials available in the market.

If you are someone who would not like to specialize in the 3D printing market but keep your hands in the other techniques as well, ZMorph is the printer that will enable you to do so.

Let’s start seeing the amazing list of features that this printer has one by one.

Dual Extrusion System

The Dual Pro tool head is the printer’s answer to multi-tone printing.

This feature allows you to print two filaments binarily, or, crucially, with a mixture of the two.

This allows users to use extra different print effects that are powered by the filters provided in the Voxeliser software.

These options include the ability to have a gradual gradient transition between the two colors or apply dual extrusion to ordinarily mono-material prints using texture mapping and an image of your choice.

When you as a user switch from the Single to Dual Pro extruder, you need not worry about the difficult because overall it is a smooth process.

You will simply have to unplug a couple of easily accessible cables, loosen one bolt, and then slide the tool head out of its mounting.

Repeating this process in reverse will enable you to attach the new tool head, and you’re ready to print again.

In seconds you will be able to exemplify VX’s versatility as a multi-tool solution.

The efficient Spool Holder design

The printer offers its users an efficient design that can hold up to four rolls of filaments at one time.

So, you do not need to worry about the material getting over while the printing process is on. You can easily switch from one build to the next quickly.

The dual extruders would let you extrude only two spools at a time, but you can line up two backups if you think you may run out.

You can also queue up your next print job, so you don’t have to change the spools out later.

This feature is extremely useful during the mass printing of the same object.

The dual extruder of this printer has two feeders, two inlets, and a single nozzle.

Open feeders on the nozzle make it easy for spot clogging and so you can resolve the issue and get back to printing more quickly.

There is also a modular heating element that can heat up the area when experiencing a clog so you can clean it easier.

The built-in Touch screen interface

The printer has a built-in touch screen interface that gives every user an interface from which they can interact, operate, and monitor the print process.

This is extremely useful because you can monitor the complete print process using this feature, you do not need to peek into where the printing process is actually happening.

Also, if there is a feature that would like to decrease, increase or completely shut up during the print process, you can do that by clicking on the screen rather than going to that region of the printer manually.

Auto-calibration can be done via this feature, rather than manually going to the print bed.

Laser Engraving as well as CNC carving

As mentioned above, the printer enables its user to print using more than one manufacturing technique.

In order to switch to CNC carving from 3D printing, you need to switch out the print bed for the CNC router work table.

Thanks to the magnetic design of the print bed as well as the work table that makes them easy to exchange whenever needed.

The simple design of the printer allows it for easy planar aligning and calibration.

And for easing out this complete procedure, there is a tutorial that is available on the website of the manufacturer.

ZMorph also gives five different types of cutter tips that are needed for CNC carving and easy to mount on the tool head.

Specifications

Credit: wow3dprinter.com

Credit: wow3dprinter.com

The build volume of this printer is 250 mm * 235 mm * 165 mm and the layer resolution offered by this printer is in the range of 25 to 400 microns.

The printer enables you to print using technologies such as FDM/FFM, CNC Mill, Laser Engraving, and Thick Paste Syringe.

The material diameter of the tool head is 1.75mm and 2.85 mm.

Whereas the nozzle diameter that you can use in this printer is in the range of 0.2 mm to 0.4mm.

Platform leveling can be done in this printer automatically and the printer can be operated using single as well as dual extruders.

The print platform of Z Morph VX is made of glass when you are making parts as well as functional prototypes with 3D printing and when you are making parts and functional prototypes using CNC or Laser, the print bed that you can use is made up of Aluminium.

You can connect to this printer using the USB cord as well as the SD card.

If we try to list down materials with which you can 3D print, it will take a lot of time because there are plenty of materials with which this printer allows you to print.

The maximum temperature this printer’s extruder can withstand is 250 degrees Celsius whereas the minimum platform temperature is 100 degrees Celsius.

First Impression

Credit: wow3dprinter.com

Credit: wow3dprinter.com

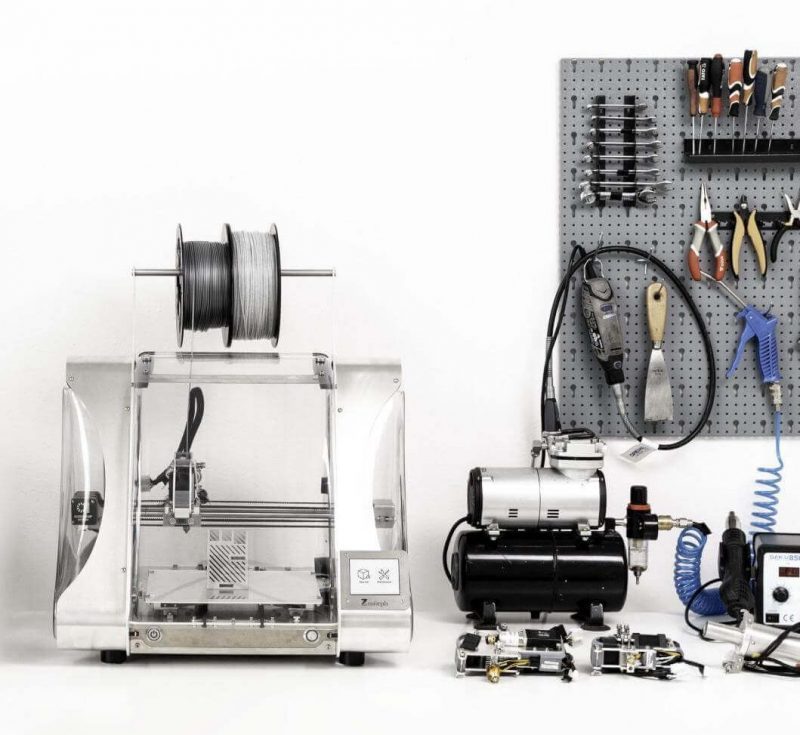

Among the few multi-tool 3D printing systems out there, the ZMorph VX builds on a legacy of modular multi-function machines.

The printer keeps the squat aluminum frame, trapezoid shape, and distinctive swappable tool heads of its predecessors.

The ZMorph VX is a machine flagship that exists today as the VX.

This printer is a highly polished system that is available not only as a dedicated 3D printer, a complete all-in-one solution but also as something in-between.

The dual extruder of this printer has two feeders, two inlets, and a single nozzle.

The ZMorph VX has open feeders on the nozzle which makes it easy to spot clogging.

This enables users to resolve this issue and get back to printing more quickly.

The modular heating element inside this printer can heat up the area when experiencing a clog so you can clean it easier.

Each tool head of this printer is mounted by a single screw. Doing so makes it easy to change them out quickly, and also make the printer more versatile and quick to manipulate.

These tool heads can be changed in less than a minute, making it easy to switch between print jobs.

Setup

For unpacking the ZMorph VX and attaching the spool holder, it takes about 5 and 3 minutes respectively.

So, summing them up, in 8 minutes, your new 3D printer can be ready to go.

The setup guide that comes with the printer is quick but comprehensive in giving you a detailed explanation of each of the five operational modes that the printer works in.

For calibrating your print bed, you can use either the manual or the automatic calibration that can be done using the touch screen which is attached to the printer.

Additional tutorials can be found on the website as well as the free ZMorph Academy, which is a huge benefit over other printer manufacturers.

Printing Type/Cost

The printer operates in an eccentric way compared to other printers.

Because it gives an option for users to print with more than one manufacturing technique!

You can manufacture a part or functional prototype using 3D printing, laser engraving or cutting, CNC engraving, and cutting.

So, the printing type differs with the option that you choose and so does the printing cost.

Print Quality

Credit: zmorph3d.com

Credit: zmorph3d.com

Gears that are seen in the picture that is posted on the website of this printer depicts accuracy that you cannot get to see anywhere else.

Using this printer’s pyramid sample print in PLA silver, you can run a test of newly purchased ZMorph VX for analyzing its performance.

Running the test will show you how the printer handles angles, edges, spaces, and designs.

The sample design has delicate features, which makes it a challenging object to print, which will put your 3D printer to the test. The ZMorph VX handles benches flawlessly.

So, you will be able to print many different shapes and sizes using different types of filaments without experiencing stringing across any difficult areas like windows.

However, there isn’t a condition wherein stringing does not happen at all. It may happen sometimes when objects are very small.

Software

Credit: zmorph3d.com

Credit: zmorph3d.com

Other slicing software takes a 3D model, and then in one step slices it into layer-specific tool paths and instructions.

Voxeliser, ZMorph VX’s software, instead introduces an intermediate step named “voxelization.”

This step transmogrifies the 3D model into an equivalent representation that is comprised of voxels.

This tool treats the 3D model as three-dimensional pixels and allows Voxeliser to apply filters and modifiers to your model without destructing it completely.

Customer Service

ZMorph Academy is the course that is offered by the company for free.

In this course, you can learn about your new printer and how to use it to print anything you want.

Apart from this ZMorph provides comprehensive instructions with your 3D printer purchase and more tools.

Overall efforts are made in the direction to make work easier for you.

Parameters Influencing Buying Decision

Factors that will matter to you while purchasing this printer are mentioned below in brief.

3D Printer Cost: Compared to its competitors in the field, the printer is expensive.

3D Print Quality: Compared to the competitors in the same price range, it is above average.

3D Print Speed: Industry-average.

3D Printer Capability: Printing with limited materials is possible using this printer.

3D Printer Practicality: This printer is practically a small manufacturing unit.

3D Printer User Expectations: 3D Printing, Laser Engraving as well as CNC milling is possible with this printer.

The Verdict

If you are someone who is fond of various manufacturing techniques and always was in search of a machine that can perform more than one, this is your go-printer.