3D printing allows you to manufacture unique and complex structures with high precision and accuracy. With a 3D printer, you can manufacture any model as the printing technique is now growing fast. It is used in many niches, including jewelry, medical, dental, manufacturing, and so on.

While previously, 3D printers remained largely limited in their technology, nowadays you can easily buy any type of printer that you desire.

If you are looking for SLM 3D printers that meet your needs, this guide rounds up 10 of the best SLM 3D printers. Each printer has been tried and tested by our experts. Check them out below:

What Is SLM 3D Printing And How Does It Work?

SLM stands for selection laser melting. This technology makes use of lasers to help print our different models and prototypes. SLM is used to fully melt the powder, which is why it requires high-temperature settings to work with.

An SLM printer has a build chamber that is usually filled with an inert gas that can be either argon or nitrogen. This helps create an ideal condition for the melting and printing process.

For SLM, the laser is used to fully melt the metal, which allows it to form a homogenous block that has good resistance. This technique is ideal for pure metals like titanium or aluminum. These specific metals require high temperatures to fully melt.

The SLM process also makes use of the support that helps reinforce and define small angles. This support can be removed manually once the printing is done and the model has been cooled. The SLM makes use of various finishing techniques such as milling, thermal treatment, or touring as well.

What Are the Benefits and Uses of SLM 3D Printing?

When it comes to SLM 3D printing, there are many advantages. One advantage of SLM 3D printing is that it offers high-quality results with smooth surface finishes.

This allows for great detailing on the model and allows you to print out intricate to highly complex geometries. There are also no design limitations. These printers are often the only way to get fine details on your models.

In addition, the SLM 3D printers eliminate manufacturing issues, like inefficient workflows, while maintaining print quality and print speed.

Not to forget that SLM printing is the best solution if you need to produce custom-made objects. With so many benefits of having an SLM 3D printer, you really should invest in one.

Comparison Chart

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| SLM 125 | Editor’s Pick | 9.9 | |

| ProtoFab SLM 150 | Extraordinarily Efficient | 9.8 | |

| SLM 500 | Innovative Design | 9.6 | |

| ZRapid Tech iSLM 100 | Highly Reliable | 9.5 | |

| SLM 800 | Most Consistent Performance | 9.3 | |

| TRUMPF TruPrint 5000 | Made for Professional Use | 9.2 | |

| Concept Laser XLine 1000R | Extremely Office Friendly | 9.1 | |

| SLM 280 Production Series | Most Advanced | 9.0 | |

| DMG Mori LASERTEC 65 3D | Reliable Printing | 8.9 | |

| SLM 300 | Most Effective | 8.7 |

List of Top 10 SLM 3D Printers

SLM 125

|

The SLM 125 offers an impressive combination of speed and high printing quality. When it comes to exceptional results, this SLM 3D printer comes to mind.

With its advanced technology and functional features, the printer offers detailed printing and produces intricate geometrical designs with ease.

The machine comes in a compact size, making it travel-friendly and easy to handle. It offers a build volume of 125 mm x 125 mm x 125 mm, which can also be reduced to 50 mm x 50 mm x 50 mm if you use it with a 400 W fiber laser.

Precise in its function, this printer is ideal for printing functional prototypes. The printer has an open frame design, which makes monitoring easy and accessible.

The printer is able to print at a fast speed. The printer uses an internal re-circulation of inert gas along with a laminar flow. This allows for safe as well as cost-effective consumption of gas.

This SLM 3D printer has been equipped with software that allows greater control over the printing process. With flexible and open software, you can print a wide variety of models.

The printer processes metal powders through its very effective closed-loop powder-handling unit. This helps save power and lower production cost.

The SLM 125 is truly one of the best SLM printers available in the market.

Uses:

- Ideal for research and development

- Can be used in small-scale production areas

- Suitable for professionals in the fields of medicine, tooling, aerospace, automotive, and so much more

- Offers a dynamic interface where the users can interact and view precise tool paths

- User-friendly touchscreen interface

- Functional hardware-software duo

- Layer thickness can be adjusted accordingly

- Reliable printing

- Ideal for mass production

- Printing technology can be very complex for some people

ProtoFab SLM 150

|

With an immense build volume of 150 mm x 150 mm x 100 mm, you can depend on this impressive printer for producing the best possible printing results without any hassle.

Featuring many innovative features, the ProtoFab SLM 150 is one of the best SLM printers available today.

This 3D printer can work on its own as you can connect it to multiple devices over Wi-Fi and Ethernet. The printer also includes a user-friendly LCD interface, which makes it easy to navigate through the printing process.

This entry-level printer is compatible with a wide variety of materials including steel, cobalt, chrome, bronze, aluminum, and much more. With a broad choice of material, you are able to print anything that you require.

The SLM 150 also offers patented layer applying technology that allows for detailed printing of intricate designs. Offering high-quality printing, this printer is a printer you should consider when buying SLM printers.

The SLM 150 has a low carbon footprint as it helps reduce waste. The printer also offers high production speed, even while printing complex designs.

Delivered as fully assembled, this printer is easy to set up and operate while remaining one of the best SLM 3D printers.

Uses:

- This versatile machine also allows you to work with a variety of materials and produces all kinds of models and prototypes

- Capable of printing building parts or spare parts

- Used in industries such as art, fashion, and footwear

- Affordable price

- Offers fast production

- Compatible with advanced metals

- Does not require many post-processing adjustments

- Needs improvement for material changing

SLM 500

|

Rich in advanced features, SLM 500 offers the best printing experience for manufacturing high-quality parts and functional prototypes. Offering an impressive build volume around 500 mm x 280 mm x 365 mm, this SLM 3D printer is ideal for large-scale production.

This printer took the initiative for offering a quad-laser system in the market. It also offers additive manufacturing, which allows for the production of high-volume parts and prototypes.

With an SLM Build Processor and open software architecture, the SLM 500 is able to meet all your printing needs. The printer has two or four overlapping lasers that have power ratings of 800 W or 2800 W, respectively.

The printer consists of quad laser optics that help increase build rate while the process chamber allows for easy gas flow.

With its patented closed-loop transport of metal powder, SLM 500 reduces the preparation time required to manually fill in the printing material. The automatic powder sieving procedure also does its own job while not interfering.

Among other features, you also get a user-friendly interface with its color touchscreen. The screen allows you to customize your designs or change the printer settings easily. The screen also allows you to monitor the printing process as it allows you to see how much printing material you used.

This SLM 3D printer offers exceptional printing quality and precision.

Uses:

- The innovative technology provides greater control over geometry and makes it ideal for use in industries such as Aerospace, tooling, automotive

- Popular in the education sector due to its unique and easy to use features

- Creates high-resolution models and intricate geometry designs for medical and energy industries

- Offers a large build volume

- Super-fast, thus making it ideal for producing high-quality models

- Comes completely assembled

- Safe and easy to use

- Offers separate section for cooling

- Pricey option for an SLM 3D printer

ZRapid Tech iSLM 100

|

Known for creating complex internal geometries and impossible designs, this SLM 3D printer is an ideal option if you want high print quality.

The SLM 100 comes with some advanced features, which allow it to function efficiently and effectively.

With a build volume of 110 mm x 110 mm x 110 mm, this machine is considered one of the best SLM printers. The printer makes use of a fiber laser that has a wavelength of 1064 nanometer and uses 200 Watts of power.

The printer also comes with a recoating system that uses scraper paving and offers precision between 0.02 mm to 0.03mm.

The SLM 100 has many desirable features that increase its reliability. The printer has a simple and smooth operating system, which is easy to maintain.

Offering reliable printing, this SLM 3D printer is a choice for many.

Uses:

- Ideal for dental modeling

- Recommended for use in professional settings such as the automotive industry

- Works well in small-scale industries as well

- Does not require much assembly

- Can be monitored remotely

- Capable of printing accurately and precisely

- Offers multiple material support

- Offers small build volume

SLM 800

|

If you are looking for a printer that consistently produces superb quality, this SLM 3D printer is your best option. Featuring a building envelope of 500 mm x 280 mm x 850 mm, the SLM 800 allows for large-scale print production.

This printer has a lot to offer in terms of its features. It comes with a quad-laser configuration that offers lasers in either 400 W or 700 W of power. The printer is capable of working efficiently, therefore offering a print speed that can go up to 171 cm3/h.

There are also many features that are unique to this printer such as its integrated powder handling and design freedom, which opens up the possibilities of creating something new every time. With this printer, the sky’s the limit.

The SLM 800 comes with a sintered chamber wall through which there is a continuous stream of enhanced gas flow. This creates ideal conditions for the printer to work. The enclosed design also prevents the entry of any contamination so that the printing process is not hindered.

This printer also features a Permanent Filter Module that helps clean the chamber and get rid of any impurity. Together, these features ensure that optimal build quality is offered.

Uses:

- This printer is suitable for printing a range of models and prototypes in the fields of Medicine, Tooling, Metal, and so on

- Ideal for professional use in the Aerospace and Automotive industry

- Practical and compact design

- Produces large parts without any hiccups

- Has a permanent filter

- Can connect to other devices over the internet

- Print cores maintain their temperature

- Expensive option

TRUMPF TruPrint 5000

Known for their highly capable 3D printers, TRUMPF offers the best SLM in 3D printers. The TruPrint 5000 comes with numerous features that make it the best choice for SLM 3D printers.

This highly productive printer is ideal for industrial use. It features full field multi lasers that have 500-Watt fiber lasers. The printer is equipped to tackle any heavy-duty task. The printer is also capable of pre-heating to 500 degrees Celsius.

The TruPrint 5000 is a reliable machine that is compatible with a wide range of metal materials. The machine carried out the entire printing process within its shielded gas atmosphere.

It is capable of sieving, printing, cooling, and de-powdering. The machine also helps you save time with its automatic process starting feature.

This SLM 3D printer also offers a high utilization rate as its supply cylinders can easily be exchanged for parallel production.

The machine can be set up in no time with its zero-point clamping system that allows for downstream processes such as sawing, milling, or grinding.

The printer is also capable of remote monitoring as you can connect it to other devices over Wi-Fi. The printer is extremely easy to set up and even easier to operate due to its user-friendly interface. The 3D printer also has a print bed that levels itself semi-automatically.

Uses:

- Efficient production in fields of medicine and automotive

- Easy operation makes it ideal for educational use

- Time-saving printing

- Resume print function

- Compact footprint

- Reliable printing

- Design can be improved

Concept Laser XLine 1000R

|

Concept is a renowned name when it comes to SLM 3D printers, its Laser X Line 1000R offers the most advanced features for an ideal printing experience. The printer comes fully assembled and has a plug-and-play design.

With a stable body, this 3D printer also offers noiseless operation. You can connect the printer to multiple devices over Wi-Fi. With a user-friendly interface, the 1000 R is extremely easy to operate.

The printer also has some sensors, which alert the user if any error occurs. The printer also reduces the amount of waste by reusing the printing material.

The Concept Laser Xline 1000R is compatible with a wide range of metal powders, which allows you to be more creative with your designs. The printer comes with a huge build, which accommodates large-scale printing with ease.

Offering high-quality and reliable printing, this printer has many impressive features. It offers a layer resolution between 20 and 200 microns, allowing for the printing of highly complex and intricate designs.

The machine offers an impressive build volume of 630 mm x 400 mm x 500 mm and it exhibits 1000 Watt laser strength.

Uses:

- The printer features pre-installed software, which makes it easy to use for jewelry production

- Fit industrial needs for medicine

- Limited footprint

- Simple operation

- Reliable prints

- Removable plate

- Heavy in size which does not make it ideal for moving around

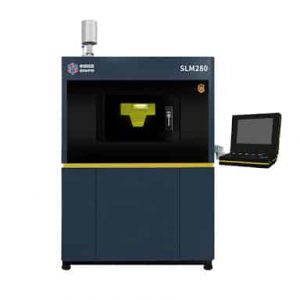

SLM 280 Production Series

If you require 3D metal modeling, then you need to get your hands on the best SLM printers. The SLM 280 is a top contender in this regard owing to its high production capabilities.

This printer comes with upgraded features that make it a strong contender for the best SLM 3D printers. Built with a 280 mm x 280 mm x 365 mm build envelope, the printer can meet most of your production needs.

The SLM 280 comes with an automated system to handle printing powders that allow the user to remove the excess powder easily.

Unlike other dual laser printers, the SLM 280 is equipped with multiple laser optics which help increase its printing speed and allow it to work at higher power. This printer also allows you to optimize parameters easily.

Uses:

- The advanced technology produces parts with complex geometry that require little or no post-processing

- Ideal for use in professional industries such as aerospace and medicine

- Supports free prints

- Remote operation

- Compatible with a wide range of print materials

- Large printing space

- Might not be beginner-friendly

- Pricier option

DMG Mori LASERTEC 65

If you are looking for an SLM 3D printer that offers numerous advanced features, the Lasertec 65 is an option that you should consider. Offering an impressive build volume, this printer is also capable of effortless printing.

The 65 3D printer makes use of integrated laser additive manufacturing technology which has a 5-axis milling machine. The printer is capable of applying the precision of conventional millers.

The 65 SLM printer uses Directed Energy Deposition technology which printers every model layer by layer. This allows for the detailed printing of intricate designs. The printer offers 10x greater speed than its competitors.

Fast printing speed is done by melting the metal directly on the future 3D part. The printer also allows for easy switching between its laser and miller operations for the best possible results.

The printer is compatible with a wide range of printing metal materials. You can connect it to various devices over the internet, which allows for remote operation. The widescreen is not only intuitive but also user-friendly.

Uses:

- Ideal future design and development

- You can use this printer for printing out models efficiently

- Consistent printing

- Simple operating process

- Offers support for multiple metals

- Industry competitive speed

- High in terms of price

ReaLizer SLM 300

With the ability to deliver the best performance possible, the SLM 300 comes highly recommended as one of the best SLM 3D printers.

Offering an impressive build volume, this 3D printer is able to accommodate large-scale production.

The SLM 300 comes with a wide range of material compatibility, which lets you be more creative with your designs. This industrial printer offers precise and accurate results.

Offering a reliable printer, the printer is also upgradeable, which means that you keep on improving technology without having to buy a new printer.

The printer also offers an ideal user experience with its breezy operation. Designed for excellence, this machine offers one of the best SLM technologies.

Uses:

- Support for multiple materials allow you to be creative with your designs

- Ideal for industries that require medium build volume

- High-quality printing

- High resolution

- Safe and simple process

- Can be expensive

Buyer’s Guide

Buying a 3D printer is a heavy investment, which is why you need to be smart about your choice.

Before investing in an SLM 3D printer, it is important to keep certain important factors in mind so you can choose the right model. Here is what you should consider:

- Accuracy and Print Quality: For a high printing quality, select a printer that offers a high resolution. Every machine specifies its layer resolution that can help you make the correct decision.

- Ease of Use: Even with advanced features, a printer should be user-friendly and allow you to print your parts with ease while ensuring that the printing operation is smooth and steady. A user-friendly interface can guide the user through every step and make design customization easier.

- Size and Build Volume: SLM 3D printers come in various shapes and sizes. If you are working in a small space, go for a compact and lightweight printer. However, if you require a printer for industrial use, opt for a model that offers the maximum build volume.

- Material Compatibility: An important factor to consider when buying a 3D printer is its material compatibility. Your printing material should have the required properties to meet the designed specifications. Therefore, choosing the technology that offers printing in materials similar to your application is crucial.

- Speed: For industrial use, look for high-speed printers. A high-speed printer is able to save time. It should also be capable of printing high-quality prints.

Frequently Asked Questions (FAQS)

What Materials Can Be Used In SLM 3D Printing?

SLM printers are compatible with different materials. Most printers use metal powders such as aluminum, chrome, and so on. Before buying a printer, check the metal compatibility and get one that best suits your needs.

Where is SLM 3D Printing Mostly Used?

SLM 3D printing has uses in a vast number of fields, including aerospace, automotive, medical, jewelry, or even home use. The technology is mostly put to use in industries and professional settings.

Are 3D Printers Too Expensive?

Yes, most of these printers can only be afforded by industries. However, you can see the price range of each printer and see which one meets your budget the best.

Conclusion

Within the market, you will find different options for SLM 3D printers and each of these printers offers a unique feature.

From the SLM 3D printers reviewed above, all these SLM 3D printers are the best of the best. This article provides the ultimate buyer’s guide to help you make an informed decision.