Imagine you have an idea in your head to build an object. And there are all sorts of ways in which you can bring that idea into reality. There are a whole lot of traditional methods, there are advanced manufacturing methods.

Which method would you want to choose for bringing that idea into reality? Wouldn’t it be a manufacturing method that comes with an assurance of being the most flexible one?

Flexible to the extent that all you need to build that object is a single design file. Flexible to the extent that you can build that object online.

Flexible to an extent that the industry’s best machine would be made available for you, no matter you wish to batch produce it or make it in a small volume.

This type of flexibility is possible with 3D printing manufacturing technology. And this article, we are going to talk about service providers of 3D printing in Houston.

Before going through the list of best service providers, let’s talk a little more about this unique method. How does it work? What kind of mechanism does it imply?

To understand it better and in a shorter way, you can imagine the two-dimensional print that you get from a shop and if you can understand the mechanism behind that printing, it’s the same mechanism.

The difference being, in the former there is only one layer and in the latter, you have a bunch of layers over each other. Let’s start by seeing where is 3D printing useful?

What is 3D Printing and Its Applications?

The basic idea behind this technology is flexibility. It enables people like you and me to easily manufacture complex objects from the comfort of our own homes.

If it were not for 3D printing, you imagine the world of manufacturing and it’d be frightening for you.

Imagine those huge machines that are installed in factories, compared to the $100 machines which are easy to operate and can be kept at a table in your home! Compare those two and you will get the answer yourself.

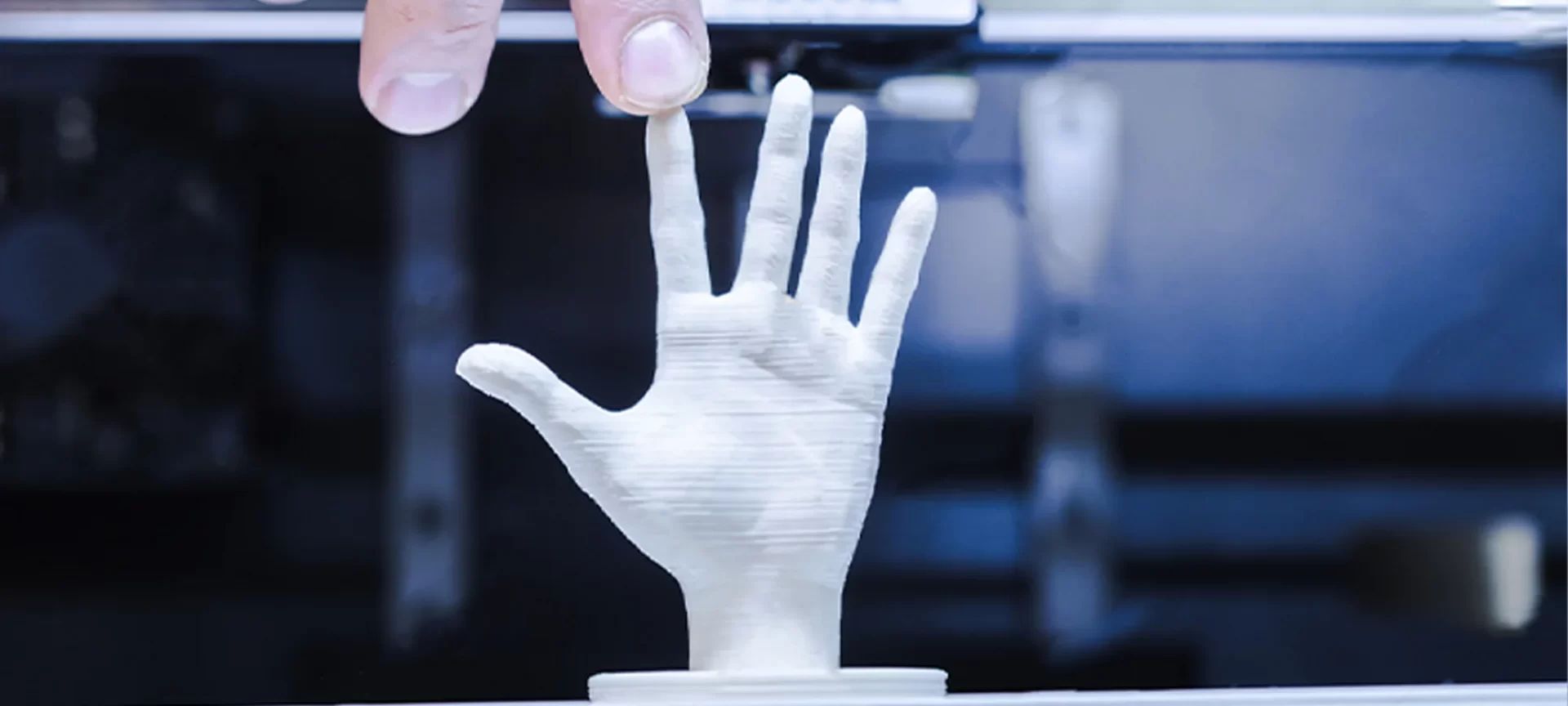

The latter i.e. $100 machine, is a desktop 3D printer that easily fits on a study table. What these 3D printers let you do is 3D print parts and functional prototypes at your home.

Imagine all those parts and functional prototypes that are very easy to manufacture, like the toy which your kid is demanding, or may the handle of your door that has been broken, or maybe something else that your partner is demanding. Every and any of these things is what you can 3D print at your home if you have this machine.

The other benefit of 3D printing and owning a 3D printer is that you can custom design essentials. A lot of times, when you go out to buy something or there is a gift that you wish to purchase for someone, you want it to be customized so that no one has ever seen it anywhere else.

3D printing lets you do this. If you wish to custom design, say a teacup, you could do that. Often you get it for a cheaper price, faster with a 3D printer, rather than buying it from the nearby store.

Customizable things are often not available and if they are, they cost a lot more than the standard ones in the store. Well here is a device that can get you a customizable thing for a very affordable cost and you don’t have to wait much either.

Steps to 3D Print an Object

Like we have in any manufacturing process, you need to have an idea. Here too you need an idea but in a more viable form. In the sense, you do not just need to have it in your head, but also on paper.

You need a design file for starting to think any further in this 3D printing process. And that is the first step.

Designing

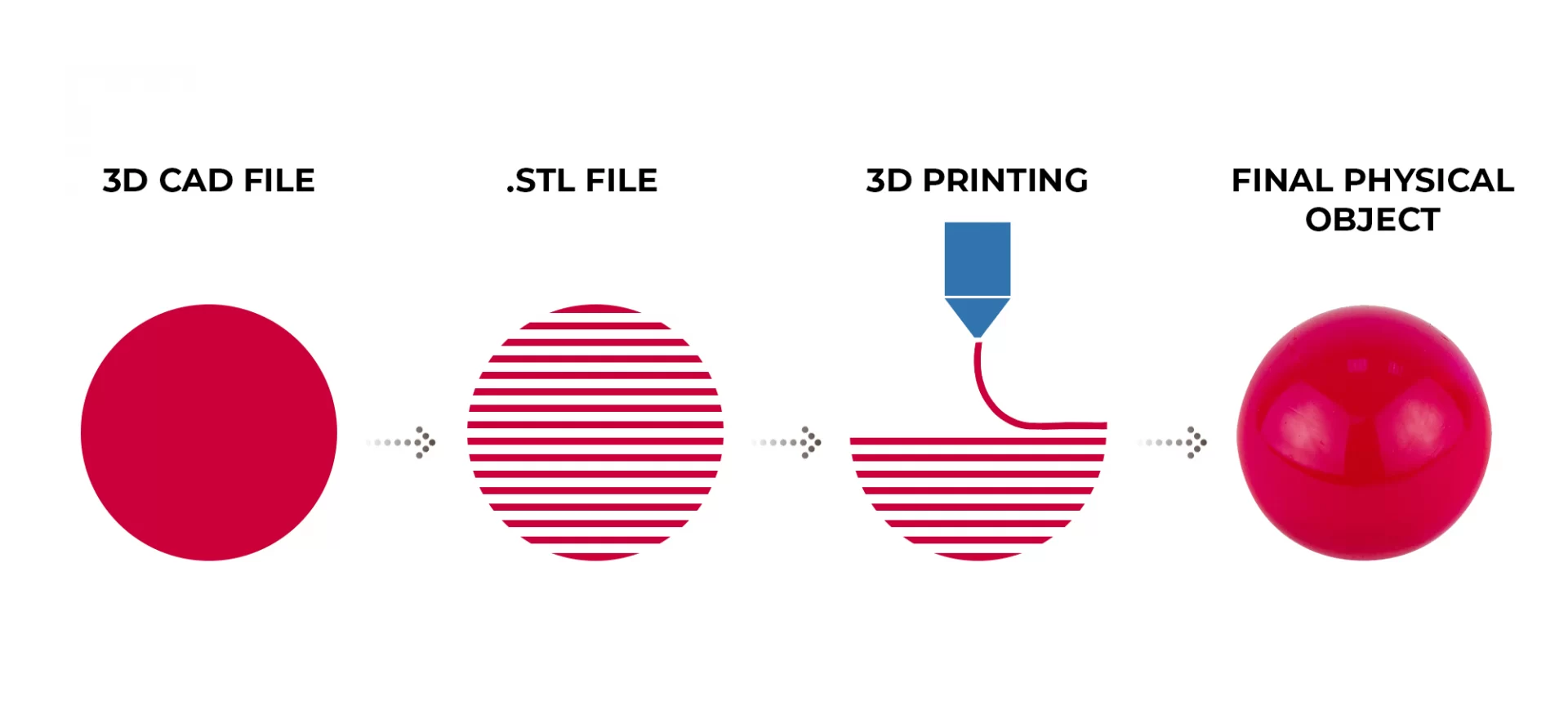

For 3D printing any object, you need a digital design file encoding the three-dimensional geometry of the object. The question, now is, where to get this 3D design file from? Do you need to draw it yourself or do some kind of a major in this subject? What do you exactly need to do?

Well, the flexibility in this technology lets you design 3D file, without being too technical about it. Anyone can design 3D objects because there is no drawing or sketching involved in it at all.

All you have to do is learn to use CAD (Computer-Aided Design) software, the tools, and shapes available in the software, and that’s it, you build up your 3D object.

This software is just like working with MS Paint, GIMP, Inkscape, Illustrator, or Photoshop. They all feature the same click, select, drag, and drop interfaces.

Slicing

Now you have the file that has the design or your idea encrypted in it. What you need is language. And by language, we mean, the language that a 3D printer can understand.

Here comes the role of a dedicated slicing software, which converts your design file into a language that a 3D printer will understand.

3D Slicing software is called Slicer, the job of which is to process the 3D design and create a file that contains instructions for a 3D printer to print your file.

It is not something that cannot be controlled, if you wish to change the settings of this software, you can do that by controlling various aspects of the printing process.

The name of this software is given Slicer seeing its work i.e. to break down the object that you wish to 3D print into layers. Just like a chopper or a vegetable slicer at your home would do, break down vegetables or chop them down into pieces.

3D printing technology is also called the technology of reverse engineering objects.

Unlike subtractive methods of engineering that work by the removal of parts to make the final object, 3D printing is an additive method of engineering that works by adding one layer to the other for making the final object.

Slicing software tells a printer’s head where to move when to move upwards after the layer has been finished, create the second slice. In a way, it plans the best route for the printer which is the optimized one. The language in which Slicing software converts your design is also called G-code.

Printing

This is more than an order which is given to the 3D printer, rather than a step. Because if you have a 3D printer that is plugged into electricity, this is simply hitting the print button after getting the design, the slicing, and the material in place.

What gives this order does to your printer is, it simply opens up the gate of communication between your printer and the slicer. As soon as this opens up, the printer is able to read the G-codes that are essential for the object to be 3D printed.

Now that you know a lot about this technology, below mentioned are top service providers of this technology in Houston. So, if you are in that locality, why don’t you check their website out and visit them if possible to get your first 3D part printed?

Top Service Providers of 3D Printing Houston

That’s right! You can get all the three steps mentioned in the working section of 3D printing done online. There are these amazing companies that provide you these 3D printing services. Let’s see which ones are top in the Houston locality.

Xometry

What they’ve done at Xometry is, they’ve created a proprietary software platform that enables product designers and engineers to instantly access the capacity of a network of manufacturing facilities.

Xometry makes it possible for you to receive instant pricing, expected lead times, and manufacturability feedback. So all you need to have is a design file and this service provider of 3D printing Houston is going to be able to tell,” you know what? You can 3D print your design at this much dollars.”

This goes for all customers, whether you are a startup or a Fortune 100 companies which are trying to access manufacturing on demand by providing the most efficient way to source high-quality custom parts.

Launched in 2014, Xometry has grown rapidly, because of its instant quoting platform, manufacturing expertise, and relentless devotion to helping customers with their project engineering needs.

In 2018, the company acquired MakeTime, and since then it is the single largest manufacturing partner network in the industry.

Xometry’s capabilities include CNC Machining, Sheet Metal Fabrication, Direct Metal Laser Sintering (DMLS), Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), HP Multi Jet Fusion, PolyJet 3D, Die Casting, Metal Stamping, Extrusion, Urethane Casting, and Injection Molding.

3D Hubs

You see a photograph of a pair of legs running in what seems to be a race. One of these legs is natural, the other one is artificial, on the home page of the company’s website.

The photograph is behind the text “At 3D hubs, we empower engineers to create revolutionary products.” This service provider of 3D printing Houston was founded in 2013 and has since then produced more than 4,000,000 parts, as per the claims on their websites.

The other claim by the website is that they’ve raised over $30M from the people behind the world’s most successful online platforms, such as Uber, Spotify, and Booking.com. 3D Hubs’ headquarters are located in Amsterdam, The Netherlands.

3D Print Texas

The Company is a service provider of 3D Printing Houston. On their website, they claim to be Service Bureau which uses the latest technology in polymer 3D Printing to serve industries like Healthcare, Sports, Manufacturing, and Oil & Gas.

3D Print Texas claims to strive to continuously improve in order to innovate, refine, and expand our services and expertise, year after year. This they do by understanding customer needs and how can their customers achieve their objectives on time and within budget.

Re3D

This Company consists of a group of explorers who are committed to decimating the cost & scale barriers to industrial 3D printing. Re3D claims to have pioneered the world’s first and most affordable, human-scale industrial 3D printer.

They are creating large scale, affordable 3D printers printing from pellets, regrind, and flake plastic waste.

Beyond just creating 3D printers for customers in more than 50 countries, the company also offers 3D printing contract services, consulting, design, and education services of 3D printing.

This service provider of 3D printing Houston is someone whom you can contact for learning 3D printing, designing your first object, getting help for your complete project on 3D printing, and a lot more.

The Conclusion

3D Printing as a technology has matured from the state of growing technology but is yet growing. There are methods in 3D printing technology that have been able to achieve the type of quality that you do get in any other traditional manufacturing techniques.

If you are a newbie to this 3D printing technology, something that you should also know about 3D printing is the type of technology that you can 3D print your object with. This would let you go into a little more specifics about this technology and select the 3D printer that you wish to 3D print with.

And then you can search for a service provider of 3D printing in Houston which has this 3D printer and continue with it.

Some of the names that we mentioned in the list of top service providers of 3D printing Houston are global providers of 3D printing services.

The quality of their products and timely delivery of the same has enabled them to grow more than just a nation or state, and become what they are.

So, starting your 3D experience with such a partner would be really worth a good experience which is worth striving.