Chemically, Nylon is a synthetic polymer formed from polyamides. For those of you who do not know what polyamides are, they are polymers linked with amide bonds.

When it comes to 3D printing, nylon is often considered an advanced material than ABS or PLA. When it comes to printing the latter two, you have plenty of information available online, but not for Nylon.

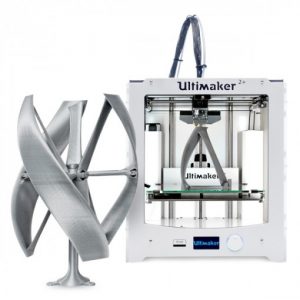

Printing Nylon requires some skill and specialized machinery. And one of the perfect combinations is Ultimaker Nylon!

Don’t get us wrong we are not talking about the brand that produces Nylon filament. In this article, we are more interested in taking you through tips that you need to take care of while printing with Nylon filament on 3D printers manufactured by Ultimaker.

There’ll hardly be anyone associated with the 3D printing community who must have not heard the name Ultimaker. The company has been in the field since 2010 after building its first Rep Rap project.

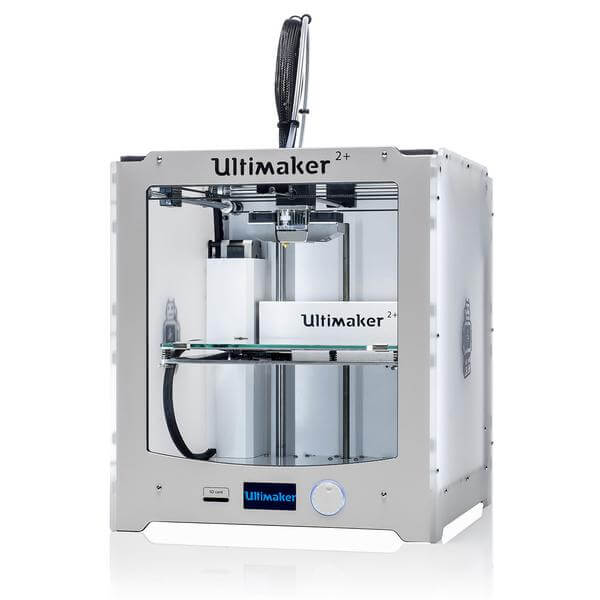

Since then they have given us some of the most renowned 3D printers days. Starting from, Ultimaker 2+, Ultimaker S3, Ultimaker S5, and Ultimaker S5 Pro Bundle.

And this is one of the most asked questions also in the community that whether Ultimaker printers can print with Nylon or not? So, we would want to end the confusion to this question by answering it.

Yes! Ultimaker printers have all that it takes to print with this eccentric filament. How to succeed in Ultimaker Nylon 3D printing? Well, let’s find out! But first, let’s go through some standard features of Ultimaker 2+

Standard Features of Ultimaker 2 Plus

When the printer released in the 3D printing market, it was termed as an evolution of an important brand in the fused deposition modeling (FDM) printer space. And it was very easy to miss the factors making up this evolution.

A series of small but critical refinements did make the machine more of a pleasure to use than ever before. The Ultimaker 2+ is highly recommended to you as a beginner in the field of 3D printing.

- The white, plastic acrylic-framed Ultimaker 2+ measures 15.3 inches x 13.5 inches x 14 inches. It has a semi-open frame, meaning that it’s partially enclosed on four sides but has no door, or top cover. Its build area is 8.8 inches x 8.8 inches x 8.1 inches.

- Resolution of parts or functional prototypes manufactured from Ultimaker 2+ ranges from 600 microns down to 20 microns, where a micron is 0.001mm.

- The print bed present in Ultimaker 2+ is a heated plate of glass material. Both, the print bed and extruder assembly are positioned on moveable, motorized carriages. The former moves on the Z (vertical) axis, while the latter moves on the X and Y (horizontal) axes.

- The extruder assembly of Ultimaker 2+ has a redesigned cooling fan attached to it, which is noticeably flatter, with the fans attached adjacent to the extruder rather than at an angle.

- The printer supports wood-filled filaments, bronze- and copper-filled filaments, polycarbonate, nylon, conductive PLA and ABS, and UV luminescent filaments.

After having looked at the standard features of Ultimaker 2+, let’s look at the printing tips needed for Ultimaker Nylon 3D printing.

|

How to Successfully Print Ultimaker Nylon?

Nylon is a different material than PLA and ABS. It is both stronger, as well as durable than both of them. Nylon has a high impact and abrasion resistance and very low friction.

It’s flexible and bends when printed in thin geometries. Having stated so, the material is robust and solid when printed in thick geometries. Perhaps its best characteristic of Nylon is its impressive dimensional stability!

It maintains its shape even when exposed to the high temperatures that are needed to 3D print it, like those in the range of 240 degrees Celsius.

You can use nylon for creating parts like living hinges, bearings, gears, and most other parts that will then be put to mechanical use.

In fact, most 3D-printed parts printed with nylon are for industrial use. And this is because of its material’s fatigue resistance.

It is to be noted how no known thermoplastic on the market can match Nylon’s durability.

Hot-end Temperature Range

Nylon is known to be easily 3D printed between the temperature of 240°C to 260°C. A hot-end temperature lower than the mentioned range would not melt the material down to a suitable viscosity!

For, a temperature higher than this holds the capacity to burn the material and will most certainly cause warping. So, experts suggest using a heated bed for 3D printing Nylon.

But you should note how all-metal hot-ends don’t have plastic elements near the melt zone, though standard hot-ends do. And they are also known to print elements melt above 240°C.

In case you are starting out, a temperature of 245°C is good for Ultimaker Nylon. A general rule of thumb here is that the faster the speed you print at, the higher the temperature you require for keeping the nylon in liquid form.

Print-bed Temperature Range

Ultimaker Nylon 3D printing will require a heated print bed temperature of 75°C. This is the optimal temperature on glass which the print bed surface material on Ultimaker 2+. But 55°C – 65°C also does often work with high-quality nylon filament, depending on the brand of Nylon you’ve got.

In scenarios wherein you are printing Nylon on a cool print bed, it will warp and lose stability as it cools rapidly. Also recommended is to use PVA glue on the print bed.

This is especially for cases when your print bed operates at between 55°C – 65°C. The glue will help the nylon to adhere to your Ultimaker’s build plate and also makes removing the part easier once it’s printed.

Print Speed and Other Settings

Note that Nylon is known to print at a 30-60 mm/s print speed and can only typically support a layer height of 0.2 to 0.4mm.

So with your Ultimaker, if you try to print the infill too fast, its extruder may not be able to keep up with the speed which will result in an under-extrusion.

Also to note that because nylon is susceptible to warping it is believed to be a good practice to keep the cooling fan on at a low, constant speed.

In case you wish to turn it off, you can do that as well. The heated chamber always needs to be kept warm and if possible at a consistent temperature.

Finishing

Please remember that Nylon cannot be polished like PLA or ABS as it is rougher in texture and even with sanding remains. However, if you use a very fine grit wet and dry sandpaper that can smooth away layer lines and make the surface good for painting.

Because nylon is strong, lightweight, and weight-bearing, it is also prone to be attacked by strong acids. The moisture acts as a plasticizer for Nylon and therefore reduces its strength and stiffness while increasing toughness and elongation.

Storing

It is a commonly known fact that Nylon filament is incredibly hygroscopic; meaning it readily absorbs water from the air.

From studies, it is observed how Nylon can absorb more than 10% of its weight in water in less than 24 hours. This is the reason why you should not leave it in the open.

When you 3D print with nylon filament that isn’t dry, what happens technically is that the water in the filament explodes causing air bubbles during the 3D printing process ultimately preventing good layer adhesion to happen.

Because it greatly weakens the part and ruins the surfaces finish. So there are no two opinions about successful Ultimaker Nylon 3D printing requires a dry filament.

Dry nylon will provide you with 3D prints that are buttery smooth and has a glossy finish. One way to dry nylon filament apart from using desiccant is by placing it in an oven at 160°F – 180°F for 6 to 8 hours.

After this process is completed, either immediately print it using your Ultimaker in a room that isn’t cold or drafty or stores it in an airtight container with desiccant to use for later.

The Conclusion

Overall, Ultimaker Nylon 3D printing can be said to be lesser foolproof than ABS or PLA, but it offers parts and functional prototypes that you can never make up with the former two so it’s worth it.

Also, the points that you need to take care of while 3D printing with Nylon on your Ultimaker is not much. All the Ultimaker printers use parts that are compatible with Nylon and a lot of other 3D printer filaments.

These are parts with high quality and reliability. Be it 2+, S3, S5, or any other, printing Nylon on them is not much of a hassle as it can be with other printers. So, follow the above-mentioned steps to get Nylon 3D printed parts for various applications.