When it comes to manufacturing complex parts and functional prototypes, nothing helps as much as CNC Milling Machine. No other fabrication methods such as laser or plasma cutting can get equivalent results.

These two might be cheaper processes than CNC Milling, but they are not on the same level when it comes to achieving intricacies in the geometry of a part.

So, isn’t it obvious to get curious enough and ask yourself a simple question: How does a CNC Milling Machine manufacture part with such complexity that other processes cannot? And now that you asked yourself this question, allow us to answer your doubts right away.

Overview

It is important to understand the meaning of “CNC Milling” before getting into details. Many times, you will find people asking for CNC machining while what they essentially need is CNC milling. So, coming to machining and milling; the latter is one of the subsets of the former.

By machining, one must be able to visualize a mechanical cutting technology that utilizes physical contact for removing material by employing different types of tools. Well, milling is a more profound and extensive process.

Milling

The process of Milling can be divided into three essential parts:

- Designing the parts in CAD: This has got to deal with creating a virtual representation of the final product in CAD software. And when it comes to choosing one, you can find many available online. The real duty of any CAD software is to permit the creation of G-codes that are necessary for machining. The other way to write G-codes is manual and hence consumes a lot of time and energy.

- Setting up the machine: Fixing the workpiece on a work table, attaching milling tools to the spindle of the machine are the two chief jobs to be done while setting up any machine for the milling process. Modern milling machines do have an automatic process for this, but there are few steps that one needs to ensure to get the initial setup done.

- Production: The main production work in a milling machine is to cut. This is done in two ways: a) Conventional milling. B) Climb milling. Both of them are different in the way they shorten a material.

There are two categories of milling machines available in the market:

Horizontal Milling machines

In these machines the position of the tool is horizontal. The cutting tool joins onto the arbor, whenever the change is necessary, you can remove the arbor bracket and the spacers for replacing tools.

There may be several spindles working with a wide range of tools enabling you a quicker production time. The table along with the tools can move in various directions as well as the rotational axes.

Vertical Milling machines

You may have guessed from the description provided in the previous type of milling machine, how this type has derived its name. It’s because of the tool position.

Although a few differences between both, the main components remain similar. For example, the machine head is present at the end of the ram, the spindle used for cutting tools is joined to the head.

Apart from moving in three directions, modern five-axis vertical mills let you rotate the parts with a little more access for faster production times. The most common types of milling machines are as follows; bed-type, knee-type, ram-type, and planer-type.

One more thing that needs to be cleared is how a three-axis milling machine will be able to move in two directions, the same applies to the four, five, and six-axis milling machine. The more axis it can move into, the faster it can produce.

Now that the later part of these two words “CNC Milling” has gained some light, it’s time to remove darkness from the first word. Most of you might know its full form i.e. Computer Numeric Control.

The definition is as simple as the meaning of those three words coming by expanding an abbreviated term. One more thing that needs to be cleared here is that every CNC machining uses CNC machines, but it is not true the other way round. The list of CNC machines includes laser cutters, plasma cutters, press brakes, and a lot more.

Finally, CNC Milling is a subtractive process of fabrication that uses computer numerical controls for automating the milling process. And below mentioned are the operations that will permit you to produce different features over your parts.

What are the Operations Performed on Milling Machine?

What allows a CNC milling machine to produce intricate designs with unmatchable accuracy on parts and functional prototypes are different features such as threading, chamfering, slotting, etc.

And what gives these features support are different operations that you can do on a CNC milling machine, such as:

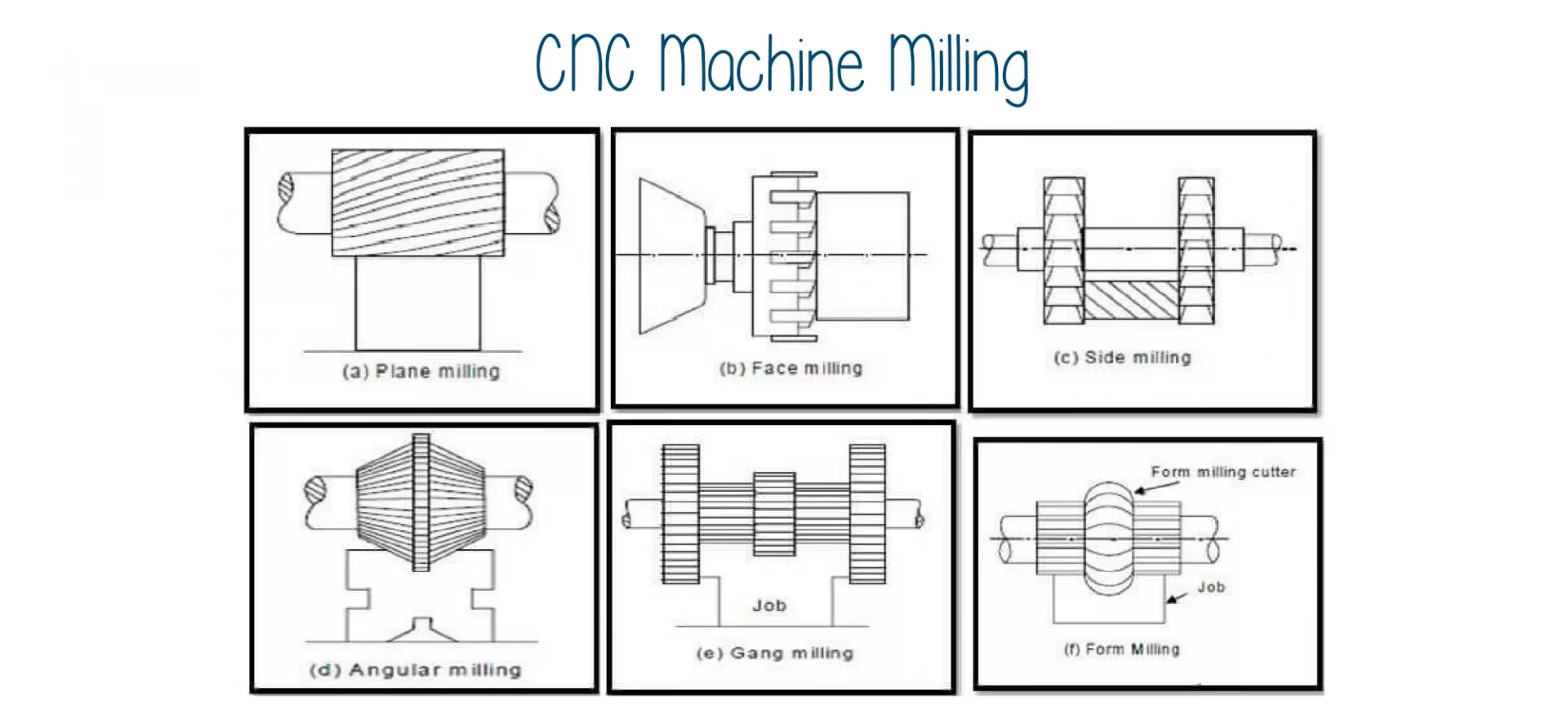

Surface Milling

It is also known as plain milling. This type of milling uses a horizontal milling machine in which the cutting tool’s rotational axis is parallel to the cutting surface. You can use different types of cutters while performing this operation.

Using a wide cutter will result in fast material removal, but will not be able to meet the quality requirements. Hence you will need a second step i.e. changing tools for using finer teeth.

The feed rate of the former one is faster than the latter. At the same time, the final finish of the former is not as good as the latter one. A good choice would be a mixture of these two.

Face Milling

This operation utilizes a cutting tool having teeth not only on the sides but also on the end. The tool’s axis is held ninety degrees to the machined part. This operation is done usually after plain or surface filling.

Doing face milling introduces even more intricate contours and leaves the surface of the part with a nice finish.

The function of the teeth on the sides is to do most of the cutting work, whereas the function of the teeth on the tip is to take care of the surface finish.

Angular Milling

If you want to create chamfers, grooves, etc on your part, you can do that by Angular milling. This operation can be done in more than one way.

If you have a regular three-axis mill, using different cutters makes sense. Dovetail cutters can be used for producing angled grooves. A conical cutting head can be used for chamfering.

These two can be termed as the exact opposite of each other. While this operation is taking place on the milling machine, the axis of the cutter can be perpendicular or in line with the surface.

Form Milling

You will need special tools for performing this operation on the milling machine. It can be used for creating even more complex contours than angular milling. You will have to use convex and concave cutters as tools for this operation. Using these tools and doing form milling will help you create surface contours in a single cut. You can create round recesses, edges using Form milling. Under this milling, type falls another complex milling operation called Gang milling. In which, you can use several cutters at the same time for creating a pattern. One thing is for sure i.e. the tools used in this milling must have the right parameters for achieving the desired outcome.

Profile Milling

The process of profile milling is conducted in three steps i.e. roughing, semi-finishing and finishing. Normally profile milling is used for producing convex or concave parts.

The first step, Roughing involves using round inserts for doing the starting work for removing the most parts from the material. Whereas the ball-nose end mills are used for semi-finishing and finishing work.

This operation will largely benefit from CNC milling machines with four or five-axis technology. They will not only produce parts quickly but also provide better quality.

Gear Milling

After undergoing the process of gear milling, they will have to undergo a heat treatment process for hardening the surface. And then the CNC turning would produce the final outcome.

But before both of these processes, there’d be gear milling. A golden rule to remember for gear milling is that: the material softness enables the creation of the part with more ease while achieving great tolerances.

After having explored the mechanism behind the CNC Milling machine, we’d not take you through some of the most famous CNC Milling machine brands.

What are the Best Milling Machine Brands?

One thing to notice is the universal use of CNC milling machines. Be it for any job you want to manufacture.

And because of this universality, many brands have jumped into manufacturing various types of these machines. But we present to you with the experts in this industry.

Mazak

Although this company is a leading manufacturer of every machine that comes out of their production facility, CNC Milling is what they do in a large-variety.

Something that’s tremendously noteworthy is their five-axis milling machines. Apart from that, their multi-tasking machines that can do turning, milling, boring, and a lot more in a single machine are also very popular in the market. But there are chances that you’ll fall back because of the budget.

DMG Mori

Another company producing incredible five-axis milling in competition with Mazak is DMG Mori. Apart from manufacturing some of the finest known CNC milling machines, they are also known for providing excellent customer service 24*7.

Their CMX series is very well-known for blending precision with user-friendliness. Also worth noting is how you get any spare part of the machine delivered to you within 24 hours of your order.

HAAS

The company has been active in this field since the 1980s. After making a splash, the company is very well-known for spreading in all levels of machine expertise. Also, HAAS’ products are available at a relatively affordable price.

Their constant effort to make work easy for their customers is visible in the way they keep video tutorials online as well as deliver high-quality products that can rival their Japanese or Korean competitors easily.

Okuma

Having more than a century of experience, Okuma has the largest distribution network all across America. It would not be wrong to say how this company holds the most market share of this industry.

Okuma is also the only company to provide customers with CNC machines, drives, motors, encoders, spindles as well as CNC control, all of that manufactured in-house.

Whatever they develop, be it a CNC milling machine or anything else, they take strict measures of quality.

Recently they have also put in front a mobile application that functions to any of the online stores. The only specificity of this application that is got to do anything and everything related to CNC machines.

We hope this would give you a glimpse of the enormous nature of this company and how its experience is getting converted into useful tools that you can enjoy.

Look around the complex parts that are present in your world, chances are that Okuma is somehow or the other related to those parts or functional prototypes.

The Conclusion

One of the chief advantages of CNC milling is that it can be used with a variety of materials. Be it metals or plastics, the huge list of materials this method can fabricate goes like, Mild Steel, Stainless Steel, Tool Steel, Aluminum, Brass, ABS, Nylon, Polycarbonate, POM, PTFE, HDPE, and PEEK.

CNC Milling Machines are produced by dozens of manufacturers worldwide. So, before buying one you should make sure you should understand what are you not buying? And only then you’d be able to reason out with yourself, why are you not buying that?

There are also manufacturing-specific CNC milling machines available in the market. The brands mentioned in this article are anybody’s go-to brands when it comes to buying these machines.

And hardly these brands can go wrong with their quality or their customer service. If they have to be in a market of producing the most universal machine, they need to do so, what do you say?