Look at the past century, if there is one material that has played a vital role in many industries, it is stainless steel.

Ranging from nuclear energy and healthcare, to several domestic appliances, stainless steel is some material that has found application everywhere.

In recent times, stainless steel manufacturers are looking to increase the potential of this metal by incorporating 3D printing technology during production.

So here is the complete guide for 3D printing Stainless Steel.

What is 3D printing? It is a method of manufacturing three-dimensional solid materials through the use of a digital model that prints the final product through the use of a printer that features this specialized digital technology.

Unlike conventional machining techniques that remove material by cutting and drilling procedures, 3D printing instead operates by additive processes that deposit successive layers of the desired material to create a final product.

By Which Methods can the Stainless Steel be Printed?

3D printing technology works on many mechanisms. These mechanisms are called techniques. Every part can be printed using various techniques.

One such common technique used by stainless steel 3D printers to print it is binder jetting. This technique involves 3D printing of stainless steel powder with the assistance of a bonding agent.

Here the stainless steel powder has to be deposited at the bottom of a build box, where a print head moves across the box and selectively sprays a binder solution.

A heating lamp is then used to dry the layer of the model as outlined by the binding agent.

To create another layer, a new coating of powder is spread, and the process is repeated.

The 3D model is built layer by layer until completion before it is dried in an oven to strengthen the binder.

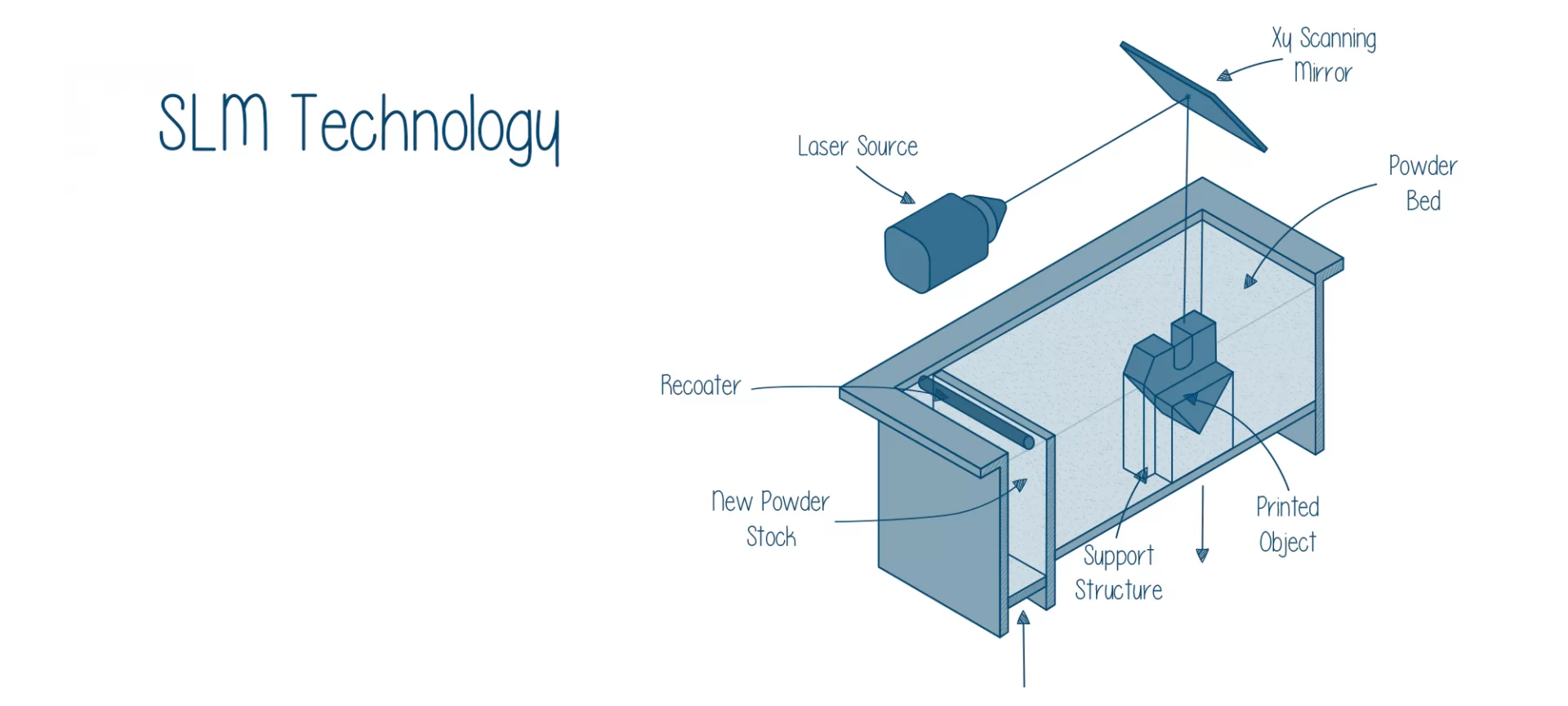

Other methods that are not as common as mentioned above, but they exist, are selective laser sintering (SLS), and direct metal laser sintering (DMLS), selective laser melting (SLM).

With all these methods too you can do 3D printing stainless less. SLS and DMLS entail selectively sintering (heating and fusing) powdered stainless steel.

This is achieved with a high-power laser, which fuses the granules of the deposited stainless steel powder.

SLM is essentially the same thing as SLS or DMLS, apart from the fact that powder is fully melted instead of sintered.

According to AZO materials, thin layers of stainless steel powder can be fused with the help of a ytterbium laser.

For answering your question of “ What all do you need for 3D printing Stainless Steel?” read the next section out.

What 3D Printers can Print Stainless Steel?

Two of these printers, unveiled in 2017, are the Studio System and the Production System.

Both printers are manufactured by Massachusetts-based 3D printing startup Desktop Metal, a company that has already received corporate approval from BMW, Lowe’s, GE, and Techtronic Industries, among others.

The Studio System, from Desktop Metal, makes use of bound metal deposition (BMD) extrusion and utilizes metal injection molding (MIM).

On the other hand, the Production System employs single pass jetting, whereby layers of metal powder are fused with a binding agent.

Even though both printers promise to make metal additive manufacturing faster, they are very costly: The full package of the Studio System retails for slightly over $100,000, while a complete Production System is over $400,000.

Both printers are stainless steel 3D printers that can print stainless steel 17-4 PH and 316L (austenitic), among other types.

After reading about the machines that do 3D printing Stainless Steel, let’s look at manufacturing in a little more detail.

How to 3D Print Stainless Steel?

Stainless steel is a material that offers a low-cost form of metal printing. This is an ideal material for 3D printing large objects as a result of its exceptional physical strength.

Similar to titanium and aluminum, stainless steel can also be used as a metal 3D printing material for complex designs, which is not currently possible when traditional manufacturing methods are used.

For producing stainless steel using the old method, conventional steel material, which is a combination of both iron and carbon elements, is melted and eventually combined with chromium and molybdenum elements to prevent rust and corrosion to the final product.

The melted material is then processed through a series of cooling, reheating, and rolling steps that allow the final microscopic structure of stainless steel that accounts for some high strength properties by tightly packing alloy grains with thin boundaries

As mentioned above the main method used for 3D printing stainless steel requires binding the layers of stainless steel powder together with a bonding agent.

While 3D printing stainless steel powder layer is laid in a build box and a print head is allowed to move across the box to spray a binder solution.

The heating lamp is then used to dry the layer which is laid with binding agents. After this is done, a new powder layer is spread and the process is repeated.

Once the final object is completed, it is then dried in an oven to cure the binder completely.

Sadly, the traditional method of 3D printing for stainless steel products has often left the final products to be highly porous and subsequently susceptible to fracture.

For addressing this manufacturing issue, several alternative methods for 3D printing stainless steel have been investigated.

Stainless Steel 316L

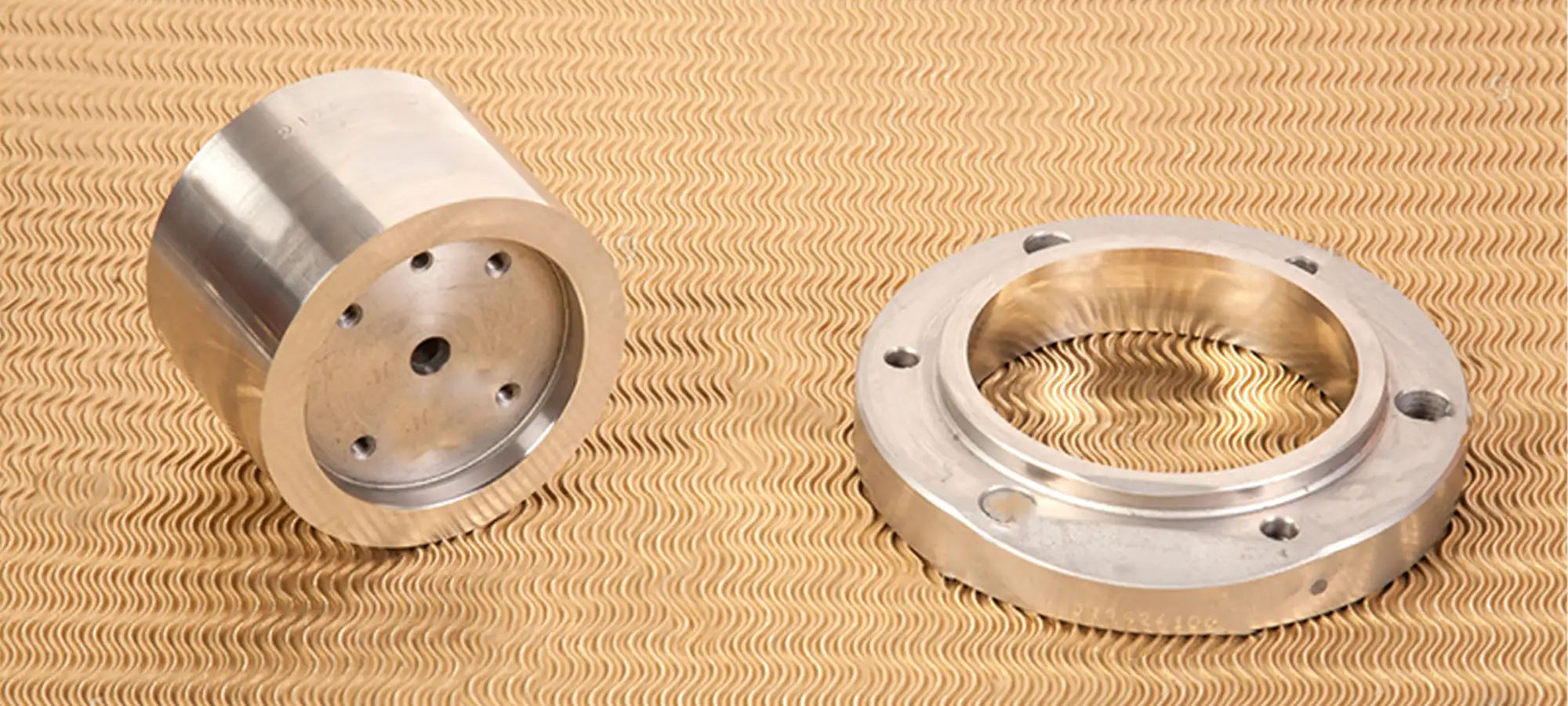

Objects printed in 316L stainless steel are made from fine metallic powder primarily composed of iron (66-70%), enriched with chrome (16-18%), nickel (11-14%), and molybdenum (2-3%).

Stainless Steel 316L provides strong resistance against corrosion and is distinguished for its high ductility.

These types of features make it a great candidate for implementation in several industries, such as the medical field for surgical assistance, endoscopic surgery, or orthopedics; in the aerospace industry for creating mechanical parts; in the automobile industry for corrosion-resistant parts; but also for making watches and jewelry.

The printing of this material is done very accurately because of the fine coating resolution (30-40 µm) and the laser’s accuracy.

Unlike polymer powder sintering, stainless steel printing through DMLS requires adding base structures to attach the part to the board and to strengthen distinctive geometries like overhangs.

The bases themselves are made from the same powder as the piece and will be taken off afterward.

Even without any particular finishing, the material gives off a granular and coarse appearance, though suiting most applications.

But after you have done 3D printing of Stainless Steel 316 L, smooth and shiny surfaces can be acquired after printing through finishing steps.

Pieces can be machined, drilled, welded, electro-eroded, granulated, polished, and coated.

When this material is compared to the other metal 3D printing materials, stainless steel is the smoothest material. Now let us look at the applications of this material.

Applications of 3D Printed Stainless Steel 316 L

Since the stainless steel is melded at a very high temperature, the additive metallic production process requires vast technical mastery for the initial studying of thermal and mechanical effects before 3D printing.

It also requires excellent knowledge of finishing techniques for the object’s completion.

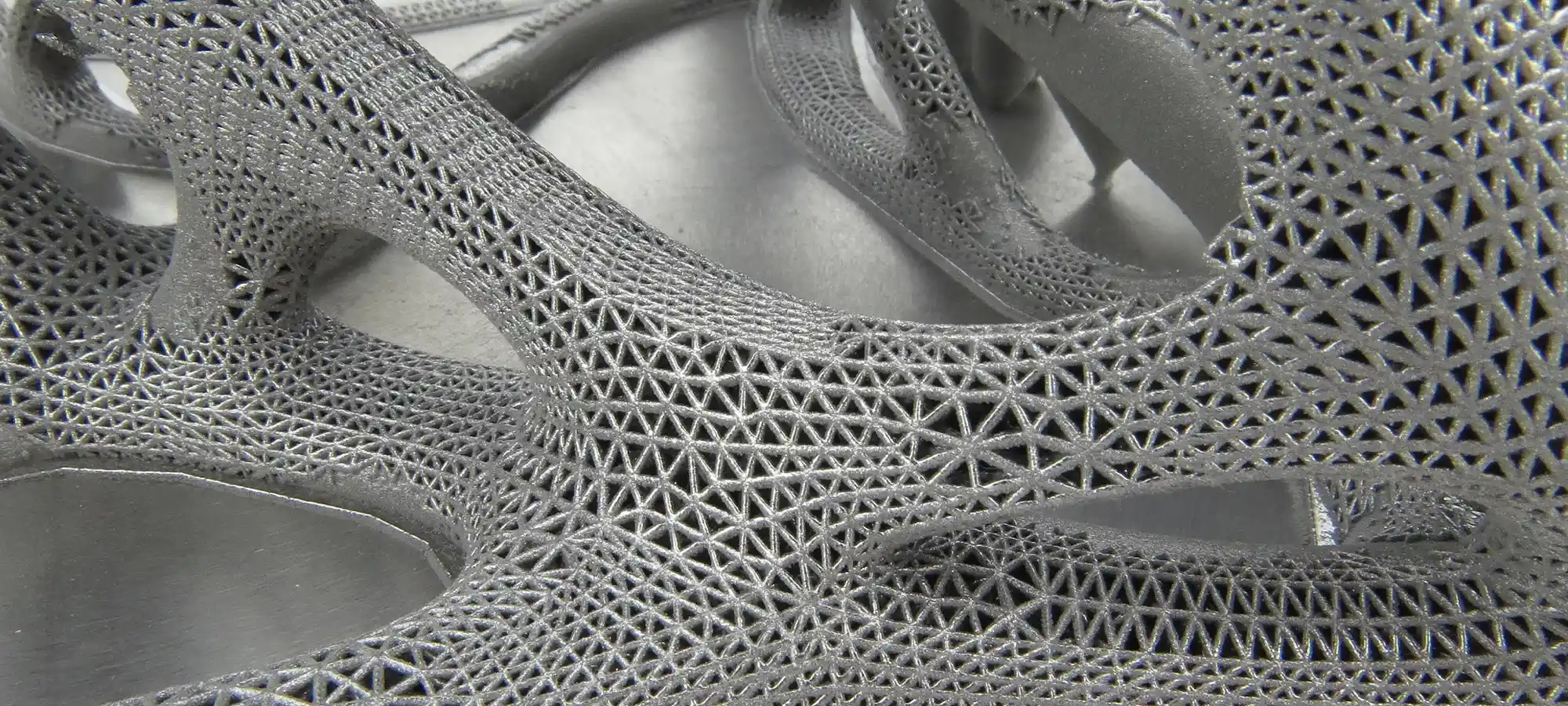

Successful additive production of stainless steel parts often constitutes projects in which 3D printing is wholly justified given it is the best alternative when compared to other production methods (foundry, machining, cutting).

Something that we have observed is that these benefits to 3D printing are often found in: Complex design or Wired Geometries or Fixed Mechanisms Speed, shortening assembly time, Topology Optimization, or Reduction, in Small-Volume Production and Mass Customization, also in Remote Production.

Now let us look at the methods that make such materials.

Description of Alternative Methods used for 3D Printing Stainless Steel

The first alternative technology that you can use for manufacturing Stainless Steel is Selective Laser Sintering.

What this method does, involves selective sintering, which is more simply understood as heating and fusion, of a powdered material that allows layers of stainless steel powder to be laid down.

These structures of stainless steel are then fused through the use of a laser.

Secondly, Selective Laser Melting. This method uses metallic powders to build functional 3D parts.

While SLM printing of parts, thin layers of metal powder are laid down and then fused through the use of a ytterbium laser.

Once the part is complete, it is removed from the bed and goes through any finishing processes that are required for the given object.

Thirdly, Direct Metal Laser Sintering. This method uses a laser source to bind a powdered material together used with metal powders. Similar to DMLS there is Laser Powder-Bed Fusion.

This is based on a recent study conducted by Lawrence Livermore National Laboratory in California that utilized an approach known as laser powder-bed fusion to produce 3D printed stainless material that maintains a tightly packed microscopic structure upon completion.

By this method, the researchers use a series of lasers combined with a rapid cooling process that fuses metal alloy particles.

Additionally, the researchers also designed a computer-controlled process that allows the user to create densely packed stainless steel layers by manipulating the structure of the material at the nano-level8.

It is by the use of both of these procedures, the researchers found that their final stainless steel product exhibited a much smaller quantity of fractures as compared to stainless steel that was produced through more commonly used 3D printing techniques.

To ensure the successful production of your piece, having to modify your initial design is commonplace.

Even if we must be repetitive, we prefer to warn you: if you wish to create a stainless steel piece just for curiosity, you risk being disappointed when confronting the necessary effort and cost of undertaking the project!

This material is good for printing both functional and spare parts in 3D.

Also, it is easy to maintain because it attracts little dirt and the presence of chrome gives it the added benefit of never rusting.

316L Stainless Steel is used to offer solid pieces and essential hygienic in several industries such as the medical, aeronautical, automobile, and domestic products industries.

3D Printing Services that offer 3D Printing Stainless Steel

In case you don’t want to get your hands dirty, several 3D printing services will deliver to your door.

After all, you might think that owning a stainless steel 3D printer rather costly. i.materialise, Sculpteo, and Shapeways are some of the biggest services offering 3D printing.

Based on your demands, you can pick from any of them if you want a solid, smooth 3D printed stainless steel part.

i.Materialise

Their high-detail stainless steel makes the perfect material for bolts, miniatures, dog tags, watch parts, board game pieces, jewelry, key chains, and an array of other items.

For pricing, i.materialise considers the amount of space your design takes, and they call it the “imaginary box around your model”.

Also, a startup cost is charged to your model’s price. This is a fixed cost independent of the quality or features of your model.

Sculpteo

Sculpteo maintains that a customer should always expect modification of their initial design to ensure a successful production.

Their 316L is easy to maintain because it attracts less dirt, and having chrome as one of its components gives it the benefit of not rusting.

Shapeways

It is a European 3D printing service that partners with ExOne to 3D print steel.

Their process involves sintering powdered 420 Stainless Steel together with glue in whatever shape your design takes.

The Conclusion

3D Printing Stainless Steel is looking very positive at the moment. Researchers manufacturers all over the world are taking a notice of it and showing interest in developing this technology.

They have managed to study Stainless Steel 316 L in detail and are looking forward to it.

However, there are some issues like stainless steel is porous and therefore prone to fracture.

But now, as Science Magazine notes, researchers have developed a computer-controlled procedure that controls the structure of stainless steel from the nanoscale to micron scale.