CNC stands for Computer Numerical Control. It offers a manufacturing process that uses computer software to design a model and translate all the instructions and coordinates into Gcode commands that the machine can understand to produce the desired output.

All CNC machines, including the CNC mills, use software to control the whole process that starts from designing to producing the model. We can broadly classify the process into four stages:

- Design a model (2D or 3D)

- Generate the G- Code

- Process the G- Code

- Drives stepper motor to create the desired results

Whether you are a beginner or expert, choosing the right software that is intuitive and user-friendly is very crucial. Most software can automate the whole process; offering greater efficiency, consistency, and accuracy. In this article, we will focus on the top software for the whole CNC process that includes modeling, controlling, and simulation.

List of Best CNC Router Software

LinuxCNC

If you are looking for free CNC software that is best for beginners, LinuxCNC is a great option. It is open-source software that has been around since 1993. It is the most trusted one that offers many advanced control features and has a large community.

The software runs under Linux with a real-time extension that enables it to generate the pulses required through a parallel port. It is suitable with multiple cards and setup. Using Mesa cards and Ethernet is also possible. Some have even tested running on Raspberry Pis.

You can easily install it on Ubuntu and Debian, or via Linux’s live/USB images/install DVD. It can be used to drive your 3D printer, CNC milling machines, robot arms, laser cutters, plasma cutters etc.

Salient Features:

- Offers several GUIs, e.g. touch screen

- Enables rapid tapping, and cutter compensation

- It has a forum on its webpage for any queries

- Provides full source code under the term ‘GNU GPLv2’

- Active user community

- Highly Customizable

- Mature software

- Simple to install

- Supports many CNC machines

- All in one

- Requires manual updating

Machine kit

Machine kit is open-source software that runs on various hardware platforms such as mill machines, lathes, robots, and other CNC machines. It is an advanced version of LinuxCNC that focuses on the modernization of older systems. It offers great performance at a very low cost.

The software has an active user community that supports when an issue arises. It is licensed under the Lesser GNU General Public License (LGPL) and GNU General Public License (GPL).

Salient Features:

- It has a HAL component architecture that includes 150 building blocks for control loops, signal processing, motion, digital logic, and hardware drivers.

- Can easily build real-time Linux applications.

- Supports GUI remote control features.

- Offers an interpreter for ‘G-code’.

- Provides a real-time motion planning system.

- Offers several interfaces including a graphical user interface.

- Easy installation

- Open software

- Supports a wide range of interfaces

- Easy to use

- Promises future

- Growing community

- No drawing (CAD – Computer-Aided Design) and G-code generation from the drawing (CAM – Computer Automated Manufacturing) features.

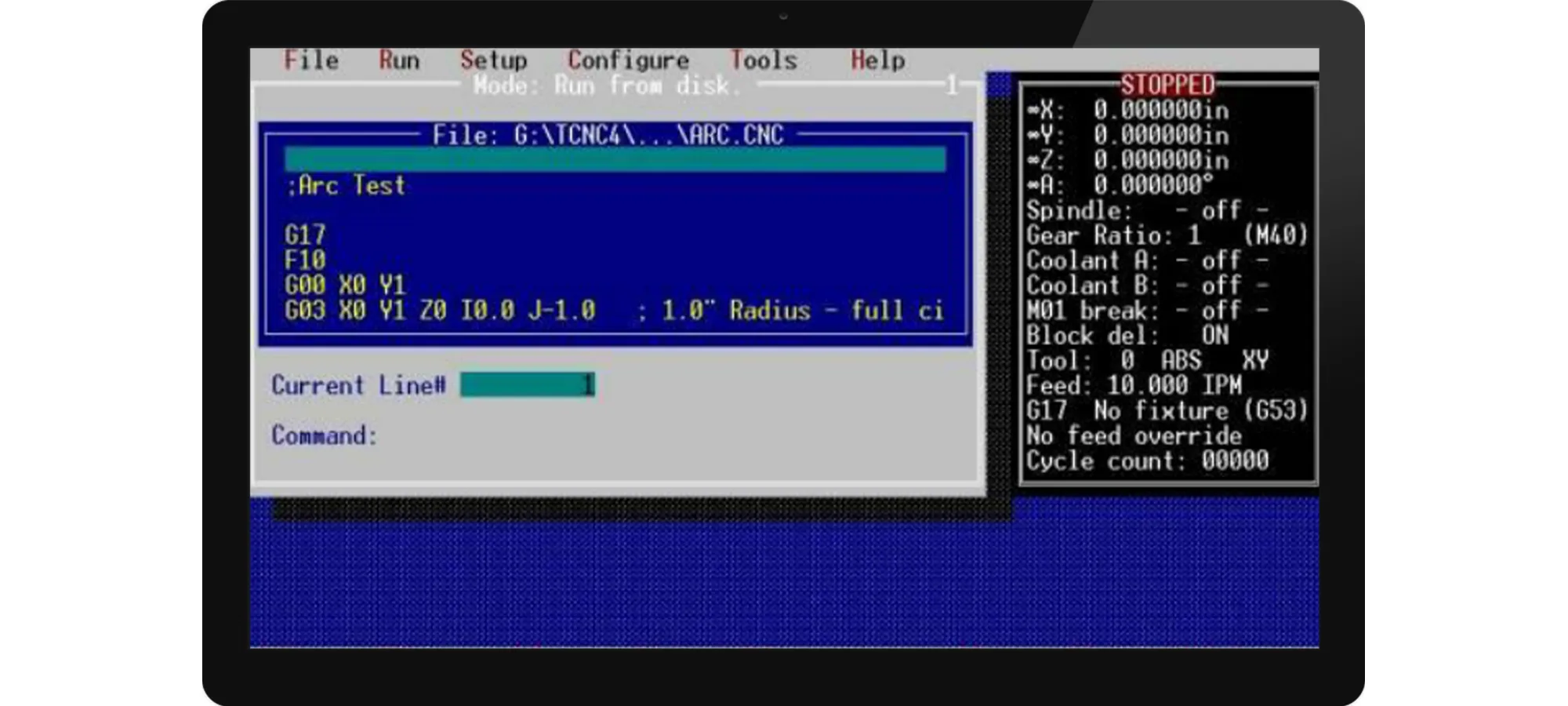

Turbo CNC

Offered by Dak Engineering, Turbo CNC runs on Ms. Dos with precise timing. As mentioned by the developer, it is quality software with no-nonsense. Like LinuxCNC, it is old software with great popularity among CNC enthusiasts. It has a wide active users’ community.

It can drive machines with up to 8 axes of motion. It offers free support to its users at a very low registration fee of $60. It requires a 486-66 PC or better with a math coprocessor, DOS or DOS-based operating system, and a parallel port for IO.

Salient Features:

- Has a built-in code editor that enables you to stop and restart anywhere in the program.

- Offers configurable IO for E-stop, home, reversible, and speed control spindles, clamps, digitizing probe, jog encoder, and PLCs.

- Enables fully parametric programming (variables, expressions, and subroutines) and multiple axis threading capabilities (tapered and multi-start).

- Circular, linear and helical interpolation using R or IJ notation.

- 60 offset tools.

- Cheap

- Active community support

- Precise

- Reliable

- Supports unlimited files

- Stop and restart options

- Non-customizable

Mach 3

Mash 3 is rich in features and provides great value for money. It is old software that offers customization. It can drive CNC machines with up to 6 axes motors. It is also suitable for controlling milling, plasma, engravers, gear cutting, and laser equipment.

The low price of Mash 3, customization feature, and compatibility with various boards make it an idol choice for many users. It can be set up in many ways either by using a parallel port or an external board such as SmoothStepper.

Mash 3 costs around $175.

Salient Features:

- Converts a computer into a featured rich, 6 axes CNC controller.

- Enables direct import of BMP, DXF, HPGL, and JPG files through LazyCam.

- Visual G Code display.

- Generates codes via Wizard or LazyCam.

- Offers full screen, touchscreen, customizable M Codes and Macros using VBscript, multiple relay control, and spindle speed control.

- High quality

- Precise

- Versatile

- Customizable interface

- Intuitive

- Updates available

- Offers technical supports

- No real-time, causing potential lags.

Mach 4

Developed by Newfangled Solutions, Mach 4 is the reboot version of Mach 3. It addressed many issues that were faced using Mash 3. It offers great speed and quality performance making it capable for industrial use also.

There are two variants of Mach 4 software. One is for hobbyists that costs $200 and another is an industrial version that costs $1400. The industrial one offers various advanced features such as tool life management, Macro B G-code programming, advanced GUI editing, and screw mapping tools.

The program is highly intuitive with various customization and remote control options. It is flexible, expandable, and highly responsive software. It does not use a parallel port. Instead, it uses its ingenious core for calculations.

Salient Features:

- Can control CNC machinery, robotics, and PLC equipment.

- Easy and quick GUI customization.

- Can link data between other programs, such as Excel.

- All motion control calculations are done at the core.

- Improved anti-gouging.

- Track the operation of the equipment.

- Modular

- Flexible

- Free demo available

- Supports large files

- Expensive

- Mostly geared towards industrial projects

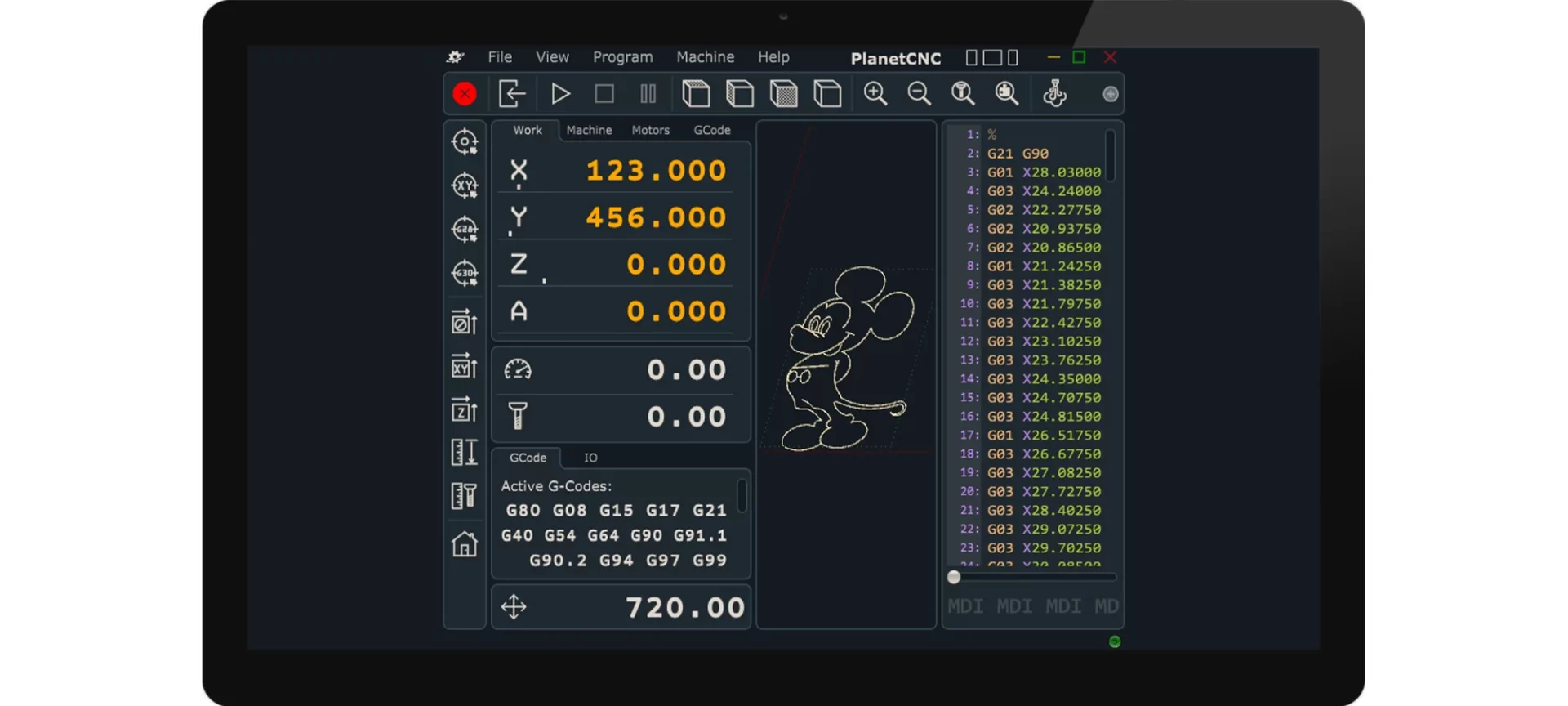

Planet CNC

Looking for a full hardware and software solution? PlanetCNC is a great choice. It is one of the well-developed CNC software available in the market. It uses modern techniques that include G code manipulation.

The software is highly intuitive with flexible configuration and simulation features. It is known for its stability and robustness. It is free to use and drives multiple CNC machines. These include milling machines, plasma, laser cutting, engraving, and foam cutting tools.

Planet CNC has a wide active community with great support for its users. There is a blog with various tutorials and a support tab on its webpage.

Salient Features:

- Supports spindle synchronization, measuring, probing, relay control, video display, and canned cycles.

- Compatible with Mac, Windows, Raspberry Pi, and Linux operating systems

- Can import a wide range of file types, including DXF, Gerber, NC, and HPGL/PLT

- It uses USB for transfer instead of parallel ports.

- Provides an API, which enables users to create other applications

- Fully-configurable tool.

- Flexible.

- A modern take on systems.

- Allows you to change the language.

- Tutorials are available.

- Need to buy a separate license.

- Closed firmware/software environment.

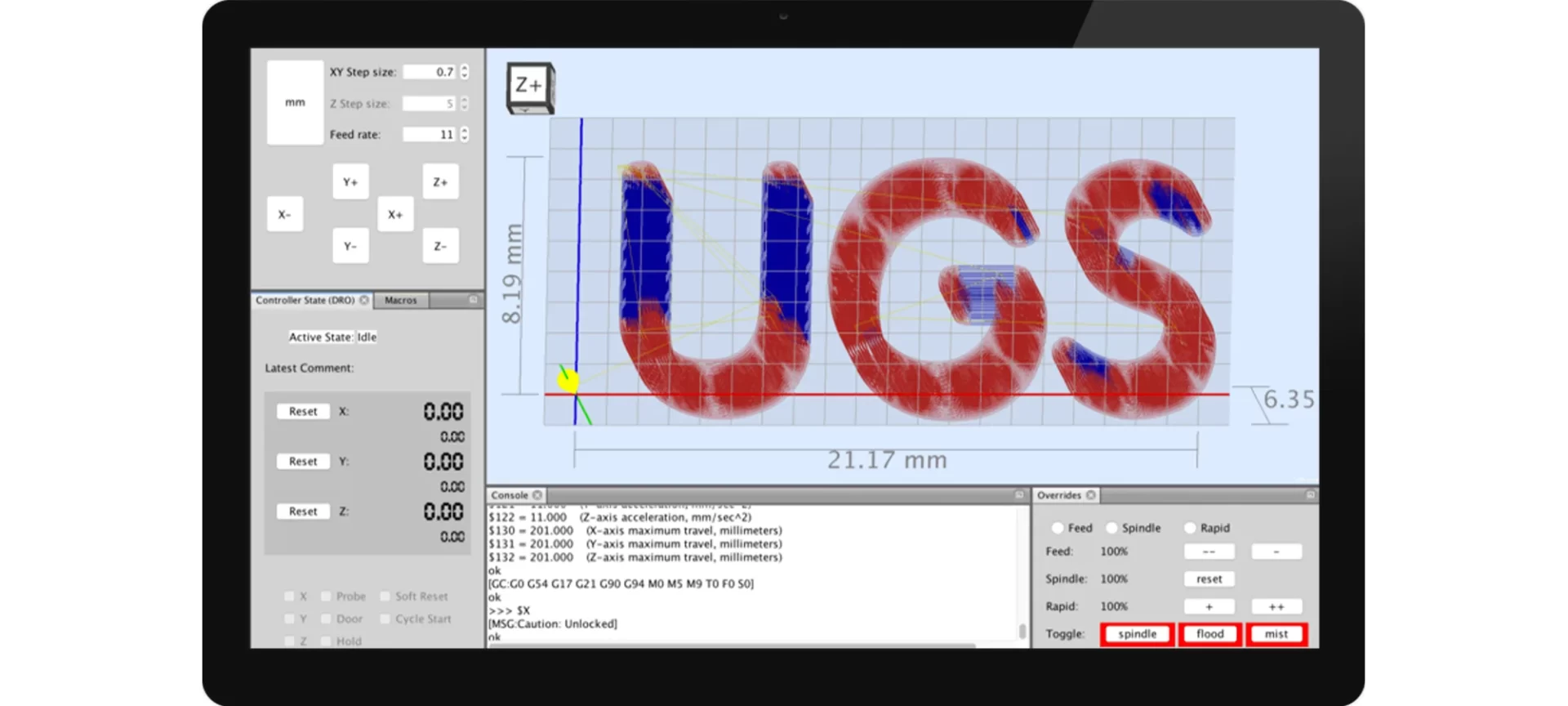

Universal G Code Sender

Another free CNC software on our list is the Universal G code Sender. It is a user-friendly, open-source, and straightforward program that is written in JavaScript. It is compatible with multiple operating systems. These include Windows, Mac, Raspberry Pi, and Linux. It also works great with custom setups.

The software is great for beginners and hobbyists with various advanced features and G code manipulation. It works great for various advanced controllers. These include TinyG, GRBL, and G2core.

For beginners, there is a Github page support as well as unofficial support available to guide through its usage.

Salient Features:

- 3D G Code Visualizer with color-coded line segments.

- Real-time tool position feedback.

- Duration estimates.

- Support for Joysticks and Gamepads.

- Web pendant interface.

- Over 3,000 lines of unit test code and 1,000 lines of comments documenting the tests.

- Configurable g code optimization truncates decimal precision to the configurable amount, removes comments, converts arcs to line segments, and removes white spaces.

- Layer-by-layer visualization of the complete process.

- Real-time position.

- Free.

- Requires zero installation.

- Needs to pair with firmware that accepts g-codes.

Marlin

You will be familiar with Marlin if you have ever searched for software for your 3D printer or used a 3D printer. It is a well-known software for almost all sorts of 3D printers.

It was created in 2011 by Erik van der Zalm for RapRep and Ultimaker 3D printers. It has tons of features that also enable CNC configuration.

Marlin offers a comprehensive G-code with 150 commands. It supports 5 multiple extruders. It is licensed under GPLv3 and is free for all applications.

It is available in two different versions, one for 8 bits microcontroller and the other for 32 bits board. The 32 bits version offers more advanced and better features. It enables you to customize almost everything.

Salient Features:

- Supports Cartesian, SCARA, Delta, and Core Kinematics.

- Smartmotion system with linear acceleration, interrupt-based movements, and lookahead features.

- Complete G-code movement, including arcs, lines, and curves.

- Heater power control with thermal protection, auto-tuning, and cut-off and is useful for monitoring PID.

- Controls LCD that supports 30 languages.

- Supports SD Card with folders and long filenames.

- Supports auto bed leveling with or without bed probe.

- Linear advance extrusion.

- Supports volumetric, mixing, and multi extruders.

- Supports Filament width/ runout sensors.

- Print counter and print job timer.

- Large community support

- Open-source

- Highly compatible

- Frequently updated

- Versatile

- Causes a lot of memory issues when upgrading to Marlin 2.0

- Issues with Marlin build

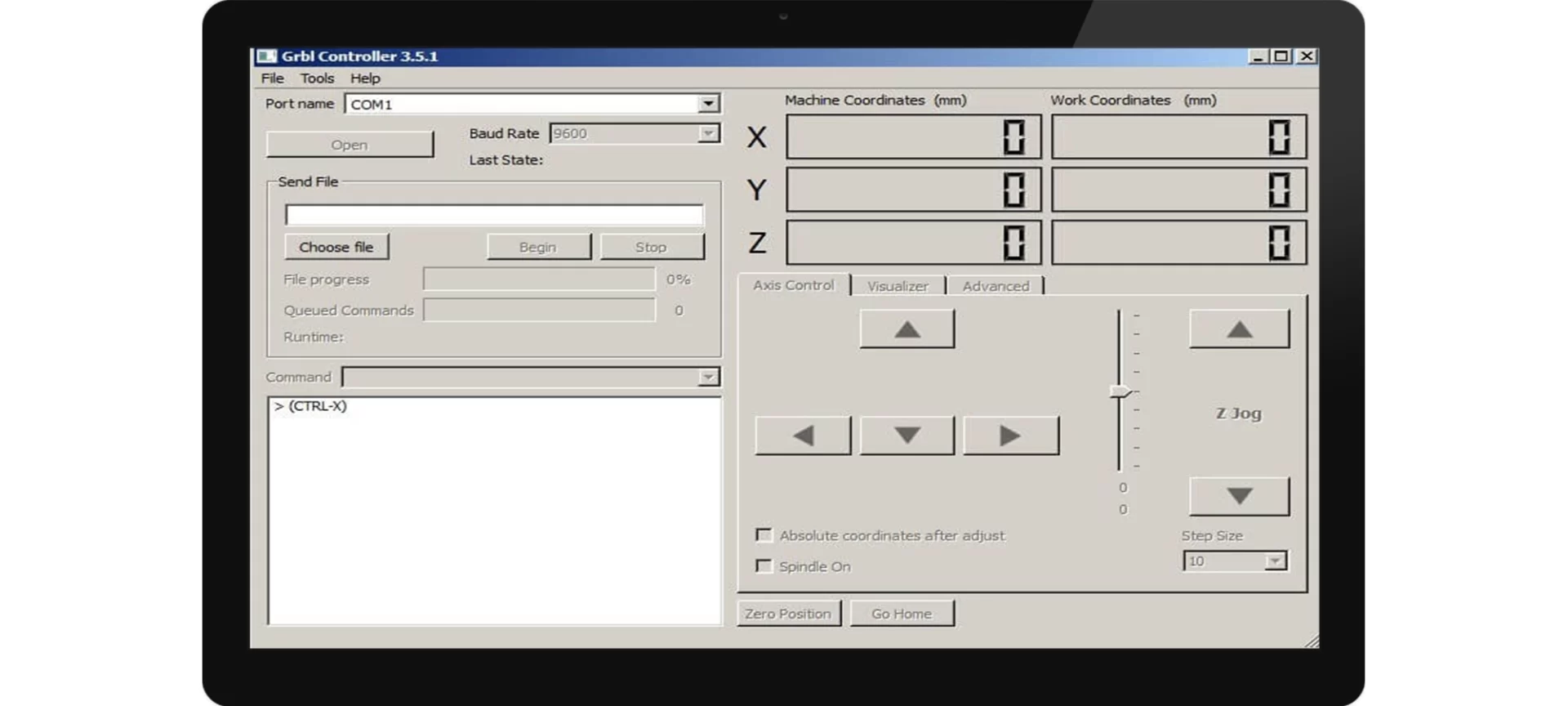

GRBL

Grbl is a high-performance and low-cost firmware with no compromise. It is a substitute for parallel port-based movement control for CNC milling.

It operates on a vanilla Arduino (Duemillanove/Uno) until it runs on Atmega 328. It is written in modular C and uses all great features of the AVR chips for simultaneous operation and precise timing.

The firmware accepts standard g-code and has undergone several tests with several CAM tool’ outputs without any problem. It was licensed under the GPLv3.

Salient Features:

- Supports Arcs, circles, and helical motion, and all other primary g-code commands.

- Full acceleration management with a look ahead.

- Smooth acceleration.

- Jerk-free cornering.

- Great performance

- Low cost

- Precise operation

- Does not support macro variables, functions, and most canned cycles

- Does not require a parallel port

- Does not control extruders

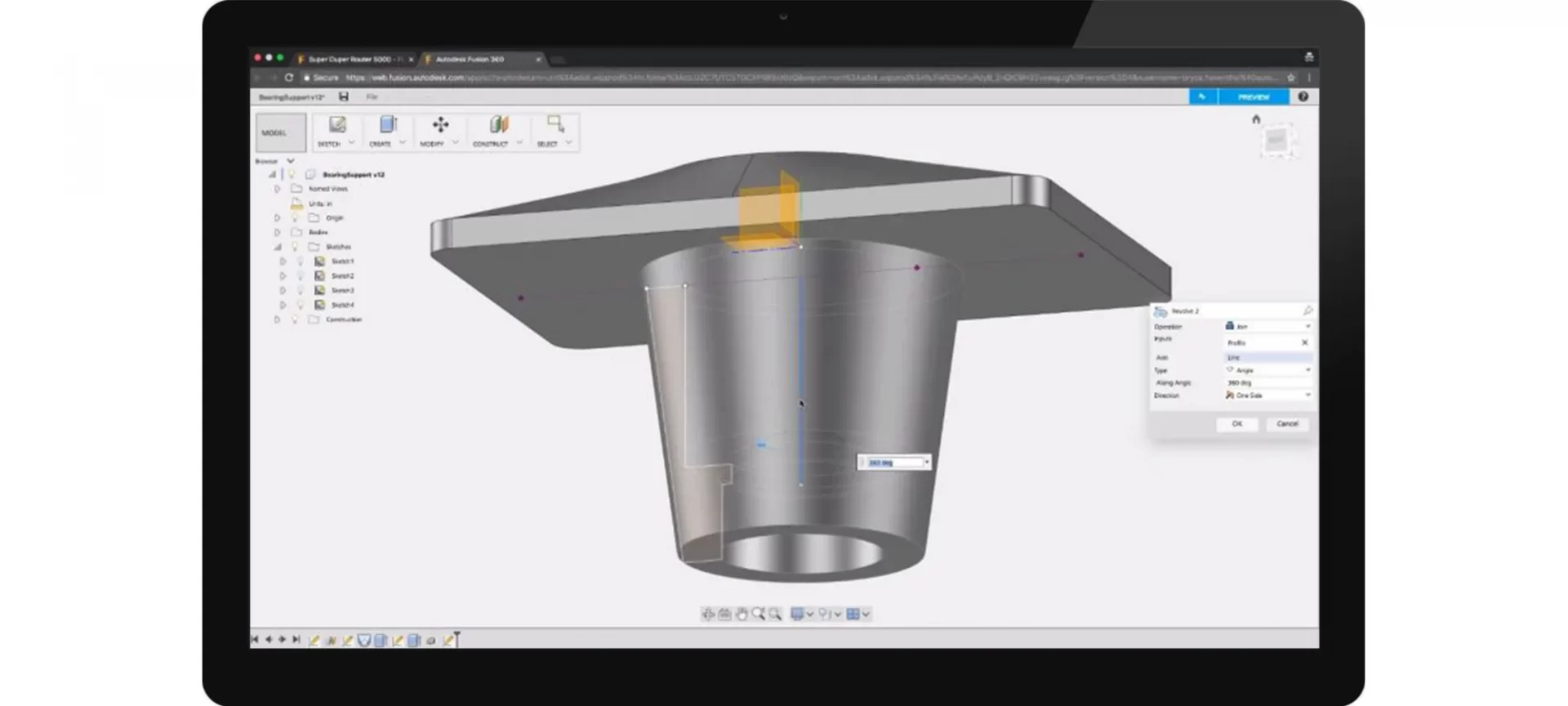

Fusion 360

Fusion 360 is one of the most popular CAD/CAM software with professional features. It is user-friendly and includes planning, testing, and executing 3D designs.

It is available as a free version for hobbyists and a paid version for commercial and industrial use. You can even download for academic purposes using an educational license owned by your institute.

There are tutorials available for users over YouTube along with official and unofficial support for users.

Salient Features:

- It offers both 2D and 3D modeling.

- Supports CAM process with an intuitive interface.

- Enables assembling, simulation, and G-code editing.

- Compatible with Windows and MacOS.

- Simple visualization

- Easy to use

- Tutorials available

- Use vast mobile memory

- Becomes laggy when there is slow internet

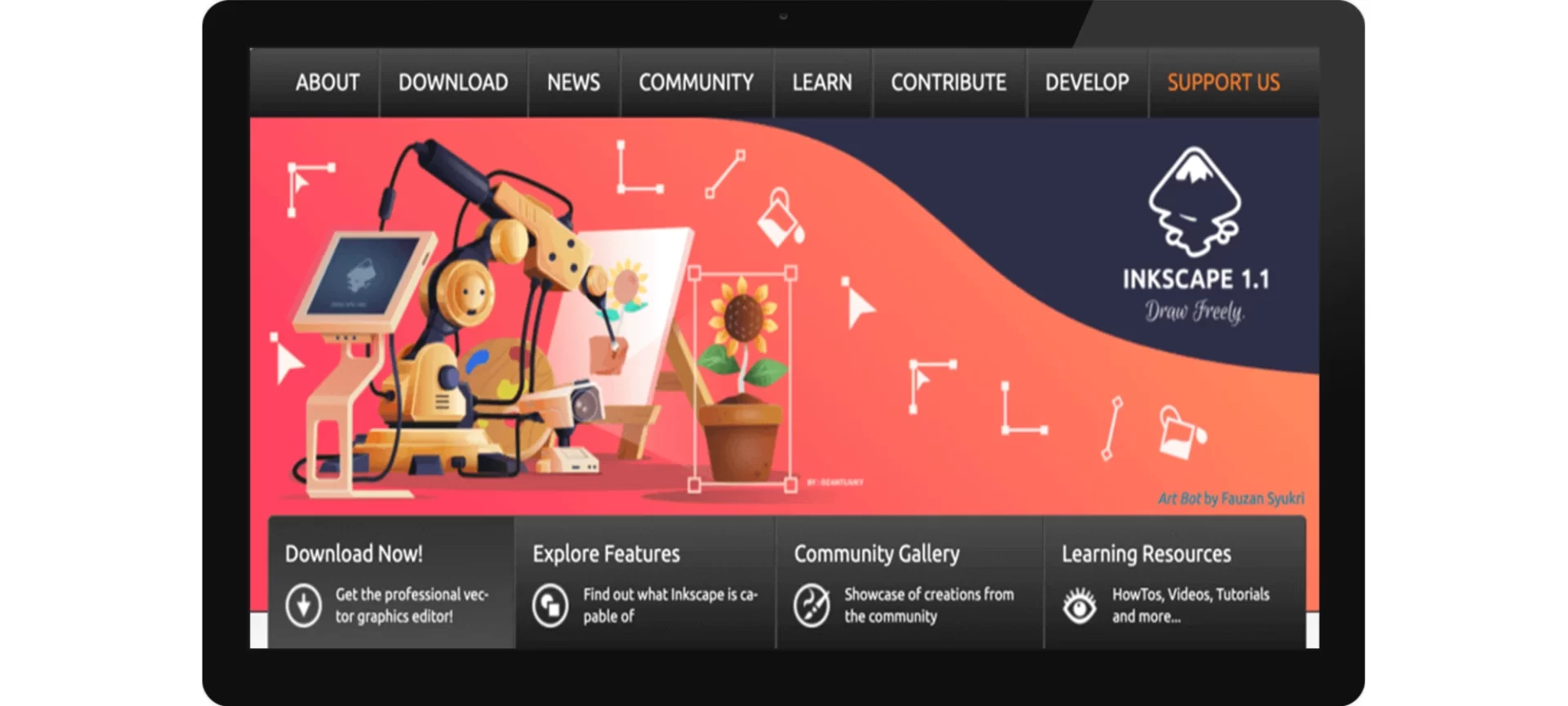

Inkscape

Looking for vector drawing software? Inkscape is one of the popular ones among the CNC community for 2D modeling. It is a free and open-source program. Whether you are a designer, illustrator, or web designer, Inscape is for you!

Vector digital drawing is preferred over rasters (bitmaps) as it uses mathematical functions indicating the start and finish points of a shape and their coordinates. They are not dependent on resolution and can easily be mashed for cutting.

Salient Features:

- Enables third-party plug-ins

- Supports multiple file formats such as ODF, Sk1, DXF, PDF, Adobe PostScript, and EPS for exporting.

- Tutorials available on their webpage

- G-code visualization

- Free

- Open-source

- Easy to use

- Powerful text tool

- Flexible

- No 3D modeling

SolidWorks

SolidWorks is a cloud-enabled simulation tool used by many professionals and engineers in an industrial setting. It is a paid program. However, you can freely access it if your institute or academic center has purchased its academic license.

It automatically updates unless you are using an academic version. The company offers great support to its users. In addition, there are many official and unofficial tutorials available online.

Salient Features:

- Enables modeling, simulation, CAM, computer-aided engineering (CAE), blueprint drawings, assemblies, and motion study.

- Ability to assign materials.

- Allow users to access recent features via the FeatureManager’s history folder.

- Compatible with Windows only.

- Extensive program

- Cloud-based software

- Increased productivity

- Integration possible

- No free version

- Heavy to download and use

User’s Guide

There are numerous CNC router software available in the market. Each one has its pros and cons. It is difficult to choose the best one for your CNC machine. One should consider always consider these words when selecting a CNC router software:

- Positive reviews and users experiences

- Wide range of features

- Adaptability

- Strong and active community support

- Customization

- Purpose of use

- Your technical skills

- Paid or free version

Frequently Asked Questions (FAQs)

How many types of CNC software are there?

There are three types of CNC router software. These include CAD drawing software, CAM software, and CNC control software.

Is it difficult to learn CNC router software?

If you are good at basic mathematics and know how the program works, a basic CNC router software is easy to learn. Whereas, for the intermediate and advanced CNC router software, it might take you some time, even a year, to excel those.

Most of the CNC router software listed above has a user-friendly interface and is simple to learn and use. Thus, even beginners can learn how to use these software in a short span of time.

Conclusion

Choosing the best software for your CNC machine might be challenging. By reading this guide, we hope you were able to choose one that best fits your goals.