|

Metal DesignLab and X1F advanced furnace form a complete metal 3D printing system that operates with the ease of an entry-level plastic printer. It utilizes a nozzle for building designs in Hydrofuse – an innovative water-based paste containing metal or ceramic powders.

ExOne’s two-step method of 3D printing and sintering water-bound metal parts allows printed parts to land directly into a furnace. It skips all the long chemical or thermal debinding steps that can take up to three to five days for delivering the final parts.

The efficiency of Metal DesignLab is because of Hydrofuse, which does not require debinding before final sintering.

Although currently, the printing system allows 3D printing with only two parts, 17-4PH and 316L Stainless Steel, metals and ceramics will soon be available. Moreover, the newly advanced X1F advanced furnace with about 10 liters of usable volume also accompanies the printing system.

So, let’s check the detailed review of Metal DesignLab by ExOne – the professional-grade metal 3D printer.

Features

Unlike parts made with other bound metal systems, DesignLab requires no chemical or lengthy thermal debinding. Therefore, the need for a debinding unit is completely eliminated.

Not only that but also the sintering time is reduced by days. The complete 3D printing system is well-packed with many such exciting features. Let’s explore them one after the other.

Reduced Print Times

The original two-step bound metal 3D printing process eliminates the need for any chemical or lengthy thermal debinding process. Thereby, limiting the final part delivery time to a simple one-night sintering.

For building this printing system, ExOne had partnered with Rapidia to enhance the printing technology. And the successful collaboration led to the development of a uniquely original shorter 3D printing process.

Rapidia was the first to permit water-bound metals and ceramic parts to go directly from the printer to the furnace without debinding. The company calls it a truly “Print Today, Parts Tomorrow” innovation.

Print Any Part Thickness

The three-step process that included debinding, limited the thickness of 100 percent solid parts. Thanks to ExOne and Rapidia, Metal DesignLab does not make users go through the chemical or thermal debinding and limits printing of parts with certain thicknesses only.

The printing system permits you to print any kind of part thickness without infill. Such a condition is beneficial while printing certain solid metals that restricts the use of infill. Hence, printing with Metal DesignLab means the ability to print more in-strength solid parts for end-use applications.

Innovative Hydrofuse

Once an object has been printed there is no requirement to debind before carrying out sintering. Printed parts with conventional three-stage processes are required to debound from the polymer binder.

Doing so can take up to fifty hours and also boiling of part in a chemical solvent, which is not a safe process to carry out in offices. But that’s not the case with Metal DesignLab.

All the credits to the printer’s high efficiency are given to its Hydrofuse – an innovative water-based paste that contains metal or ceramic powders.

It replaces 98 percent of the binder with water thereby providing an environmentally friendly solution that easily evaporates while printing. Moreover, it allows parts to get directly into the furnace.

Office-friendly

Metal DesignLab is built by not only eliminating 98 percent of the binders but is also odor-free. Therefore, it can easily team up with the office environment. Also, the printing system utilizes no solvents and there is no need of disposing of waste polymer.

Needs Limited Hydrogen or Forming Gas

The printer sinters common metals such as 316L without using any hydrogen or forming gas. All that’s needed is a little bit of Argon and that can be availed from anywhere at a fraction of cost. So, there are two benefits of these features: safe to operate and decrease the overall cost of the 3D printing process.

Capable of Creating Complex Parts

Rapidia is the only system that lets operators print objects with complex internal structures. It is enabled by proprietary evaporative polymer or ceramic supports.

The printing system reduces metal waste by up to 90 percent because the same evaporative support can also be utilized as a separation layer when users need meal support.

Metal DesignLab lets owners print with hand removable supports that can easily be removed, thereby decreasing post-processing time.

The printing system also lets you do water-bonding by which it’s easy to join unsintered parts. Doing so enables users to make complex assemblies by simply wetting both parts and pressing them with each other.

Efficient Furnace

X1F is an advanced furnace by Rapidia that’s fully automated, secured, and easy to install. It’s powered using a 60 Ampere single-phase receptacle and fits office door size. In fact, the printer manufacturer claims how the printing system is truly designed from scratch to make it more office-friendly.

The furnace software is pre-loaded with sintering profiles. So, all the user needs to do is select a material and start printing. A wall of commendable thickness will ensure thermal uniformity over the entire temperature range with a peak temperature of 1400 degrees Celsius.

Specifications

Metal DesignLab offers a massive build envelope of 200 mm * 280 mm * 150 mm. Currently, users can print parts with materials such as 316L, and 17-4PH. However, the printer manufacturer promises to add more metals and ceramics to this list.

The printing system provides a maximum build rate of 40 cubic centimeters per hour and a print accuracy of one percent. Therefore, you can print large parts with an excellent surface finish in minimal time. Its external dimensions are 178 cm * 70 cm * 157 cm. Metal DesignLab is delivered to manufacturers with two independent heads.

X1F sintering furnace is an easy-to-install and automated machine. It features a 10-inch-long touch screen interface. The sintering gas employed for heating stainless steel is Argon.

The furnace has a maximum heat load of 14000 BTU per hour and can withstand a maximum temperature of 1400 degrees Celsius. It hosts two standard trays and a special tray with configurations.

Moreover, the furnace has single 0.75 inches long plastic tubing vented to the outside with a push-to-connect fitting feature.

Price

For the price of Metal DesignLab, please request a quote from ExOne.

First Impression

Metal DesignLab’s printing system consists of a Printer and a Sintering furnace. Both of which have a solid build-up and are almost equal in height. Their compact width and height make them office-friendly.

The printer has an open mechanism on its top face for processing the material with a lower compartment. Whereas, the furnace features a touch screen interface that lets users control different functions on it.

Setup

ExOne provides on-site technical assistance with the Metal DesignLab printing system. Although the setup process is a little complex, the printer’s software succeeds in easing it out.

The software’s process is similar to that of 3D printing plastics. It comes pre-loaded with sintering profiles, so all the user has to do is select a material and press start.

Print Type/Cost

Metal DesignLab and Rapidia’s proprietary two-step technology involves 3D printing directly on a mildly-heated glass bed with a water-based metal or ceramic paste called ‘Hydrofuse.’ The method is beneficial as the resulting parts don’t need debinding before sintering.

Therefore, the old three-step process is converted into two processes of 3D printing. Because of such advancement, the step that was not only messy and dangerous but also required time as long as 50 hours is no longer needed.

Naturally, the cost of 3D printing a part with a two-step process is lesser than that of three-step processes. However, the cost depends on many factors. For instance, part geometry, the material used, support structures, etc.

Print Quality

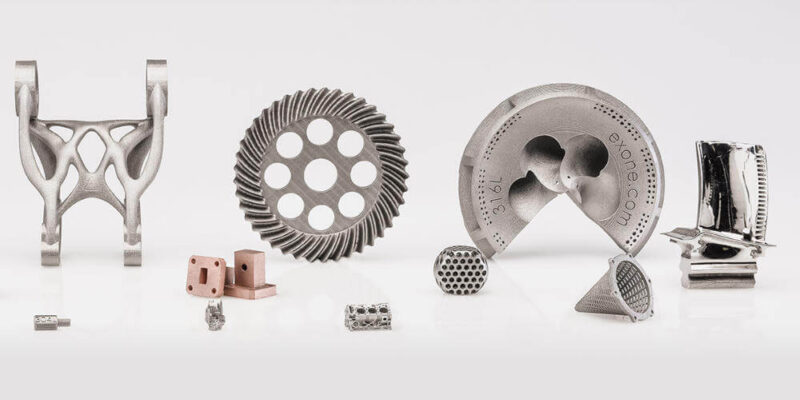

Credit: exone.com

Credit: exone.com

Metal parts produced on Metal DesignLab possess around one percent dimensional accuracy. Therefore, 3D printed objects will closely represent the geometry that’s fed into the system.

DesignLab can print 100 percent solid metal of any thickness by delivering maximum strength parts that befit a wide range of demanding pre-production and end-use applications.

Additionally, users of the printing system can print parts of any thickness without infill. Hence, 3D printing solids parts with DesignLab is easily possible.

Software

The application that’s compatible with Metal DesignLab is straightforward. It isn’t complicated and similar to many other similar applications that you may have come across in the past.

The furnace software supplies for integration of furnace or binder jetting platforms. It comes pre-loaded with sintering profiles, so all the user needs to do is select a material to start.

Its user-friendly interface and advanced controls allow users to easily handle the 3D files.

Customer Support

ExOne’s support is exemplary. To offer users easy setup, with minimal assistance, the company provides a lot of quick videos and manuals. Whether your doubts relate to 3D printer installation, maintenance, or support, ExOne’s Adoption Center offers you all.

Apart from this, if there are any doubts, users of the printing system can reach out to ExOne via filling the contact form, via call, or email.

On-site assistance is also available for the users.

Parameters Influencing Buying Decision

Metal DesignLab’s chief factors are mentioned below in brief.

3D Printer Cost: It is an industrial 3D Printer and is expensive.

3D Print Speed: The printing system offers 40 cubic centimeters per hour which is a pretty good print speed for similar metal 3D printers to which DesignLab belongs.

3D Print Quality: Metal DesignLab holds the capacity to build the most complex parts. Thanks to the evaporative and hand-removable support that not only provides all that the part geometry demands, but also reduces the post-processing time. Also, the water bonding enables joining unsintered parts with each other for making complex assemblies simply by wetting parts and pressing them together.

3D Printer Capability: Currently, the printing system can build parts using 17-4PH and 316L stainless steel, but soon ExOne is planning to launch other metal and ceramics as well.

3D Printer Practicality: Metal part manufacturers can utilize the system to develop complex geometries with ease. The credit for which goes to DesignLab’s two-step 3D printing process.

3D Printer User Expectations: Hydrofuse – the innovative water-based paste containing metal or ceramic parts, is responsible for expediting the entire 3D printing process. It replaces 98 percent binder with water, allowing parts to go directly into the furnace. Hence, satisfying users with its unparalleled operation.

The Verdict

Unlike other industrial metal 3D printers, Metal DesignLab utilizes simple 3D printing without any chemical or lengthy thermal debinding. The printing system comes in two parts, the printer, and the efficiently heating furnace. Both of which contribute to shortening the sintering times not only by hours but by days. It’s truly a very capable machine with many features to awe the users.

Additionally, Metal DesignLab allows building parts without any infill. Therefore, manufacturers can print solid parts for end-use applications with ease. The printing system’s software is a breeze, it is as efficient and simple as other software’s used with plastics 3D printing. Moreover, DesignLab does not utilize hydrogen or forming gas, instead, it uses Argon.

Metal DesignLab is an office-friendly printing system with two compact-sized machines. It does not spread any harmful odor into the surroundings where installed. Dimensionally accurate metal parts and functional prototypes created using it finds application in numerous industries.