Leapfrog is a Netherlands-based manufacturer of 3D printing-related products. Founded in 2012, Leapfrog holds the history of being the first manufacturer to ship 3D printers to its customers.

Not only that but also it is the first company that started offering plug-and-play machines, easing out the effort that the customer had to put into setting up the 3D printer.

Their solutions are reliable, easy to use, and beautiful in design. So, without much further ado, let’s start exploring Leapfrog 3D printers.

List of Leapfrog 3D Printers

Leapfrog is a company that does not necessarily cater to one class such as beginners, intermediates, or professional 3D printer users.

It tries to offer 3D printers keeping in mind the needs of all the audiences. So, you’d love to see how the 3D printers mentioned below have a balance in terms of the build volume they offer.

Moreover, in terms of the print speed, layer height, and layer resolution they offer while 3D printing parts and functional prototypes.

After making you wait long enough, we present to you the first Leapfrog 3D printer.

Bolt Pro

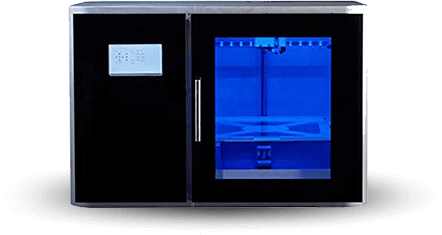

Here is a 3D printer based on FFF 3D printing technology, manufactured for helping professionals achieve high-quality prints. It comes with easy packing that can be easily unwrapped.

In fact, Leapfrog made history by becoming the first manufacturer to start shipping machines at the users’ place.

The first impression of this printer will be given to you by the printer’s sturdy body.

The printer is made of high precision laser cut Aluminum, while the parts are joined with the help of interlocked joints.

Bolt Pro offers a print volume of 330 mm * 320 mm * 205 mm. It is capable of creating objects in one shot.

Leapfrog’s Octoprint user interface plugin lets you monitor the entire print process remotely.

For doing so, there is a little procedure you need to go through. You’ll have to enter the printer’s IP address in the device you wish to monitor.

After you get this done, you will be able to pause as well as cancel the prints, provided the device should be sharing the Wi-fi with the Bolt Pro machine.

Due to the 3D printer’s dual extruders, you are allowed to print with two different materials or colors. Both of these extruders can print independently from each other.

Because of these features, you would never have issues such as oozing occurring in the printer.

When you are printing two identical parts or functional prototypes you can do that in half the time than taken by a printer that does not offer dual extruders.

Whereas, in the mirror mode you can 3D print either the right or the left part of the object by one extruder and let the other extruder print the other part.

This Leapfrog 3D printer is compatible with a broad range of 3D printing filaments. The reason for such a capability is the printer’s high-temperature hot-end. You can attain up to 260 degrees Celsius of temperature on Bolt Pro.

Apart from coming with a heated bed, the printer comes with an enclosed chamber that helps you maintain a constant temperature. And now let’s look at the pros and cons of this Leapfrog 3D printer.

- Independent dual extruders.

- Possesses a built-in camera with a custom Octoprint plugin for remote monitoring and control.

- Features a direct filament feeder.

- In-cooperated dual-head calibration.

- The cooling fan set up to decrease the temperature of the chamber instantly after the 3D printing process is over.

- A touch-screen interface easing your interaction with the printer.

- Preheating this printer takes more time than normal.

- You will have to get used to manual bed leveling as the printer does not have the facility of an automatic one.

- When printing with more than one filament, you have to take care that the filament spools do not get entangled with each other.

Why Volkswagen is using Bolt Pro?

Volkswagen was searching for a 3D printing solution that offered the capability to work with flexible materials and cooperate with their development department.

And they were satisfied with Bolt Pro because it is capable to print with sixteen different materials that are constantly burgeoning with time.

Also, the build volume of Bolt Pro suited the parts’ size that Volkswagen was looking to manufacture.

According to the company, this feature did not limit their imaginations of part design during the prototyping stage.

These benefits, combined with the independent dual extrusion system just give Volkswagen the exact amount of print speed they needed for manufacturing.

|

Xcel

This machine 3D prints parts and functional prototypes using FDM 3D printing technology. So, as you can guess it is one of the cheapest 3D printers available in the market.

Although coming at a very low price, the printer manages to offer some of the best build volumes.

As a user, you have 510 mm * 520 mm * 2320 mm for printing, with an accuracy of 18 microns * 18 microns * 10 microns and a layer height range from 10 to 600 microns.

Xcel utilizes the print speed of 80 millimeters per second and has a travel speed of 180 millimeters per second without putting any barriers on the print quality of parts and functional prototypes.

As mentioned about the previous Leapfrog 3D printer, Xcel too comes with a new Leapfrog software version.

It is also accessible using a Wi-fi connection, after which you can use it on smartphones, tablets along with PC.

One of the limitations of Bolt Pro, not present in Xcel, is the auto bed leveling feature. Yes! You would not have to manually level the bed every time after a print. This would lead to a decrease in overall print time while doing mass production.

Xcel will also let you automatically load the filament. And as this 3D printer too, like the previous Leapfrog 3D printer, comes with dual extruders, printing with them will become easier because of the above-mentioned feature.

When the printer would be shipped to your place, you would not have to work for hours for getting the machine installed for your first print.

All you will have to do is simply unpack the machine and install it at the place you wish to.

This 3D printer provides an excellent resolution range even while manufacturing the most complex parts and functional prototypes.

Apart from seeing its massive build volume, you’ll be able to notice its Aluminum frame that would ensure the printer does not vibrate even while printing the parts and functional prototypes with maximum build volume.

- The massive build volume that this printer lets you print with is a major advantage of this printer. Especially considering the price range this printer falls into.

- After the large build volume, the printer’s ability to print in various modes using its dual extruder is the second most important benefit. Because it decreases your overall print time like no other.

- Xcel is a very user-friendly printer. It has Leapfrog’s standard interface that will let you interact, control and monitor 3D prints very easily.

- The printer’s auto-calibration feature frees you from making lots of human effort and also increases the overall efficiency of the complete printing process.

- Lastly while mentioning the printer’s advantages, how can we forget the printer’s capability to print with a large number of 3D filaments!

- The printer is very less suited for home users. You’ll have to have a specific room dedicated to this printer if you are planning to get it at your place.

- Xcel has a bulky size. Due to which managing it gets difficult sometimes.

|

Xeed2.0

Need exceeds in terms of providing you with options for 3D printing materials.

Apart from offering 3D print parts and functional prototypes with nylon, polyethylene terephthalate, PLA, and ABS, you can also print with hybrid materials such as the ones made from flexible plastics that result by blending PLA and ABS.

With the printer, you are offered filaments in five different colors. And most importantly, Xeed 3D allows you to print with support materials such as HIPS and PVA. They will ensure you never have to undergo warping and sagging.

Similar to Xcel, Xeed too allows you to automatically level the machine for your next print. So, say within a minute after unwrapping this printer you are all set to 3D print.

With every part or functional prototype, you are able to print layers of varying thickness from as small as 10 microns to as big as 350 microns.

The overall resolution of these layers is 10 microns. This 3D printer is mainly used for making architectural models, medical prosthetic devices, and tiny gears.

Currently, there is already a university using this printer for making a novel drug delivery mouthguard.

Like the previous two Leapfrog 3D printers on the list, Xeed also comes with two extruders.

This lets you double the speed of 3D printing parts and functional prototypes on it. It is said that the print speed of this printer is around 180 millimeters per second.

Along with that, the printer’s capability to print in two different colors without stopping to change filaments is also something that is noteworthy.

Both of these extruders can work being independent of each other. The heated glass build platform of Xeed increases the consistency of the item.

The maximum build volume of part or functional prototype that Xeed can create is 11 inches * 8.7 inches * 9.1 inches.

This Leapfrog 3D printer has a horizontal design rather than being tall and narrow. You can easily fit this one on a shelf or a table.

Apart from the features mentioned above, there is one more that steals the show i.e. the 7.1 touch screen interface. If you look closely, the setup has an industrial look to it.

Not only can it show what’s being printed with which material and in which quality, but also the progress and preview of the complete printing process.

Xeed keeps a log of all communications for making sure if anything goes wrong, you are all covered.

- The printer comes with Simplify3D software that can automatically correct for design faults, add support to the part that you are 3D printing, and optimize a tray of small parts.

- Speed can be connected with a company’s LAN or wi-fi or wired Ethernet. You can also connect with the printer, an USB flash drive.

- The printer does not require much maintenance; all you have to do is keep the stage and the area around it neat and clean.

- You’d have to snap a screw or two after unwrapping the printer; it does not allow you to start the printing process straightway.

- If you are expecting a cart or stand for this printer, you’d be disappointed by the printer manufacturer.

- There are other 3D printers such as Z18 or the Stratasys Fortus 250mc that are priced similar to this one and offer even greater build volumes.

- Unlike other companies offering Customer Support 24*7, you would not have Leapfrog assistants ready for you anytime you call. The phone and chat window is open from 8 a.m. to 4:30 p.m. CT. And the other way to reach them is via email.

The Conclusion

If you notice the build volumes of these three Leapfrog 3D printers, they are all in a suitable range.

They are not typically starting from offering too small build volume to, particularly very large build volumes.

And this is the main reason that makes these 3D printers compatible with any class of 3D printing individuals.

Whether you are a beginner, an intermediate in the field, or an established expert, you can afford the printer.

Another notable benefit of these printers is their ability to print with different materials.

If you are someone who doesn’t like to stick with the most popular materials and experiment, you have the freedom to that.