The world of designing has been taken onto a fancy ever since the invention of 3D printing. Something that was initially understood to be impossible has become a reality because of 3D printing technologies.

After its invention, 3D printing technologies have undergone many transformations, one after the other and we can now solidify materials into 3D objects, using computers, those that we couldn’t before.

3D printing technology involves adding together materials that are present either in the form of powder grains or they are present in the form of liquid molecules layer by layer for creating a final solid object in three dimensions.

Curiosity has been generated into people’s minds and there lie many questions unanswered. Amongst those many, in this article we are going to try to answer one i.e. Can we 3D print rubber?

Amongst many other characteristics that rubber possesses, it is an organic material, its properties cannot be influenced by external factors. So, the fact that rubber undergoes vulcanization for improving its elasticity and strength means that it can never exist in a fluid state.

It is the process of vulcanization that makes rubber solid, ensuring that it holds its shape. And that doing any other process on it which involves reheating will cause it to burn. So, it is this fact that rubber cannot be in a fluid state is also a reason why 3D printing of rubber isn’t possible.

However, there are alternative i.e. rubber-like 3D materials with which we can 3D print. Which are those and how do we 3D print using them? Is something that we will discuss in this article! Although primarily they are filaments, we will also look at resins.

Rubber-like Filaments with Which you Can 3D Print

The best part about these materials is that, when an object would be 3D printed using them, it would give a similar feel as you get when you will be able to 3D print rubber. One of the most common filaments with which you can 3D print and get a very similar feel as when you get when you 3D print rubber is called TPE i.e. Thermoplastic elastomers.

There are several applications of how Thermoplastic elastomers are used like shoe soles, flip-flops, and industrial applications like sealing rings. TPE, just like rubber is a flexible filament and when you are not much familiar with 3D printing, you find it troublesome to print with them.

It is observed in every extruder which was made to meet with a filament that had almost no rigidity that the filament would bend or twist because of the softness it possessed.

This is something that is called a pushing string effect. It is after the introduction of direct drive extruders that made possible printing of flexible filaments.

3D Printing with Flexible Filaments

When you are printing using flexible filaments, the success and failure are primarily dependent on printer setup and calibration of your printer.

You may now know it for sure that the printer with which you are planning to print, must have a direct drive extruder because flexible filaments try and escape with the smallest gap that they find in the path.

So, you do not want the TPEs to push through and mess your print up. For ensuring that, you need a direct drive extruder.

Although they have such weird demands, flexible filament’s popularity continues to grow. 3D designers continue to experiment and find out new ways of dealing with this technique and it is a result of the same that today filaments are used in many things.

Some of the applications of this are grips, RC tires, robotic parts, and a wide range of other things that require the same feel or friction which rubber produces.

The point that one needs to take care of before printing with flexible filaments

You can promise by using these filaments that you will get the same feel as you get when you 3D print rubber. But, remember there are conditions.

And these conditions are somethings that you need to take care of in the 3D printer that you are planning to print with. Because 3D printers have a simple rule i.e. the more elastic the material is, the more difficult it is to use. So the first thing that you need to keep in mind is you need to print slowly.

It is observed that these filaments don’t do as well as they do under slow speeds, as under high speeds. In fact, they take a much longer time for 3D printing compared to other filaments. So, a recommended print speed while you are 3D printing using flexible filaments is 20-40 mm per second.

This print speed is for most of the flexible materials with 3D printers because not all of them have a specialized extruder. Secondly, you need to find the correct temperature at which you need to stop.

For achieving that, what you need to do is, start with a temperature that is recommended and go around that temperature. You need to do that until you achieve a print quality that you did determine to achieve.

Whenever you feel the environment is too hot or too cold, remember you will get poor print quality.

With this, you also need to ensure that the extruder that is present within the model walls should not travel in the open air and the oozing is within the model walls. You may have noticed that good slicers already have an option for this which you can utilize.

Lastly, please ensure that the retraction of your printer has been turned off. Otherwise, it is going to cause bending of the filament or result in causing jams.

Rubber-like Resins that you Can 3D Print With

As mentioned above, flexible resins can also be used for producing parts and functional prototypes that have the same quality if you would have 3D print rubber.

When it comes to quality, resins are more useful than filaments in generating parts that require intricate detailing like gaskets, custom grips, stamps, and wearables, especially when you wish to add ergonomic features in part assemblies.

Although after printing the complete part or functional prototype, a resin would just feel like rubber and usually compress and bounce back to their original form.

The only drawback they have is that the resins are usually designed, not for every printer. If you want to print with flexible resins, you need to first check the compatibility of that resin with that printer.

3 Examples of Flexible Resin that Feels Like Rubber

Formlabs Flexible Resin

This resin is made for Form 2 printer and is generally having the record to perform well under stress and testing conditions. Shore hardness of Formlabs Flexibler Resin is 80A and it is used for producing bendable and compressible parts and functional prototypes having resolution range between 50 to 100 microns.

XYZPrinting Flexible Resin

Tested by professionals guaranteeing superior quality print and resilience, this resin is particularly designed for the Nobel 1.0A printer. It is the flexibility of XYZPrinting Flexible resin that makes the prints bendable whenever they are subjected to forces.

The solid structures printed by this resin are impact resistant.

Type D Pro Flex

Can be used with DLP/UV light printers, this resin is epoxy-based and is designed by DruckWege. Not only this resin has flexibility, but also it has improved properties that can be and should be used for producing bedding resistant parts and creating impact strength.

If you are doing printing with flexible resin or flexible filament for the first time and need some assurance with the print quality, you might as well use 3D printing services that are available online.

There is i.Materialise, Shapeways which make use of high-end printers that let you use the parts and functional prototypes developed by professionals.

A high-quality print using flexible resin or filament with 3D printing service can end saving time as well as money along with the headache that might be caused by efforts that go into making of a part or functional prototype using flexible resin or filament. Some of the examples of using this service are listed below.

3 of The Best Flexible Filaments

NinjaTek

Claiming itself to be the world leader in producing parts or functional prototypes using flexible filament, NinjaTek has many varieties to offer.

An example displaying its variety offering is the SemiFlex filament which is a tough, semi-hard flexible filament that combines not only print resolution but also shock absorption with strength. It has a 98A Shore hardness and also comes with a wide range of colors.

On its website, it shows how Ninjatek has partnered with colorFabb, which is also a brand that has been active for five years in the field of the 3D printing business.

Specializing in the development and production of high-end quality 3D filaments, ColorFabb is a Dutch company. And by this partnership, Ninjatek would be allowed to distribute filaments produced by its partner in the geography os North America while ColorFabb will distribute Ninjatek’s range of filament in Europe.

Matter Hackers Soft PLA

MatterHackers offers a material that is highly flexible, enough to give you a feel exactly as rubber called Soft PLA. To 3D print rubber and to 3D print Soft PLA is almost the same.

If you as a user want your printed parts and functional prototypes to bend just like rubber, go for it. Some of the examples of parts and functional prototypes manufactured by this material are tires, phone cases, springs, machine parts, and toys.

This material is chemically a biopolymer that is created with natural materials. Not only does it not have the same elongation as co-polymer flexible materials, but also it is better than the standard, brittle PLA. The shore hardness of Soft PLA is 92A.

Matter Hackers has its headquarters in Southern California where in its dedicates staff committed to providing good service works. They claim to offer the highest quality materials, machines, and accessories that range from industrial-grade 3D printers to DIY laser cutters.

All of these, they claim to have been tested and approved by in-house experts. They also have an amazing team that helps you out with customer service with anything you may need, from finding the right machine to package your specific product. Or whether it be discussing which filament is best for classrooms.

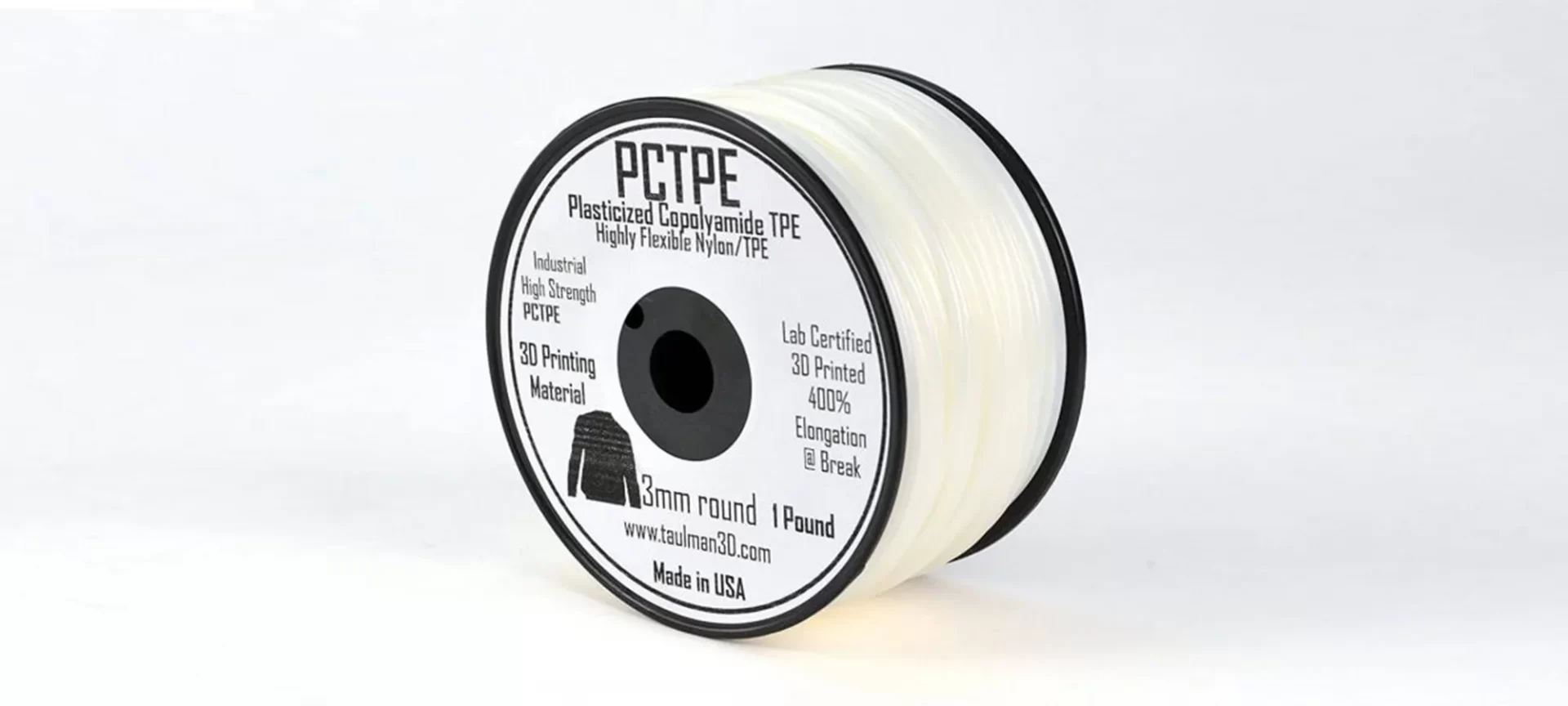

Taulman PCTPE

Taulman plasticized copolyamide TPE (PCTPE) is a material that has unique characteristics. Users of this material can enable printing any part with high flexibility.

Some examples of parts and functional prototype that can be printed using this filament are cell phone covers and cosplay wearables which can be made by users with FDM 3D printers. PCTPE is unique because any part or functional prototype will possess high durability and smooth texture which is nylon-like. To 3D print rubber and to 3D print with PCTPE is almost similar.

Chemically, PCTPE is a mashup of TPE and a chemical co-polymer of highly flexible nylon.

When you need a print that has to be similar to and more flexible than Nylon, you can use PCTPE. Because, not only it is easy to print, but also quick and less elastic than TPE. Although not proven, the Shore hardness of Taulman PCTPE is estimated to be over 100A.

The Conclusion

Although it isn’t possible currently to 3D print rubber which is clear from the discussion above. But it is also obvious that you can achieve rubber-like feel on 3D prints.

And this can be done possibly by using readily available rubber-like 3D printing materials. Not only has a list of these materials included flexible filaments, but also flexible resins.

So, you should not despair on your quest to achieving rubber-like 3D prints when you can find the right materials to give you the results that you desire. But do not miss on the settings and right procedure otherwise you may end up messing with your prints completely.