If there has to be a period that has to be rated as the fastest-growing period for 3D printing services, it has to be now.

A lot of people know what it is, in a lot more depth than they did before.

In this article, we are going to talk about 3D printing services in the UK.

Looking at some of the top-rated 3D printing services and their websites, how they function, what they need apart from the STL file, how do they offer the quoting option, and how quick they are in replying, etc.

A sort of general idea of 3D printing Services UK is what you can get by reading this article which you can then use to think on, before ordering 3D printing of part or a functional prototype.

It is to be observed that in many cases, all of these 3D printing service providers produce and deliver desired parts with a wide range of options and professional quality.

But the following are some of the introductions to some of the largest 3D printing services in the UK, and we are going to be discussing their techniques, prices, materials, and other useful details.

You as a reader are expected to keep in mind that the services presented here are made up of those actually based in the UK. So, if you are expecting to see any large name services that deliver to but aren’t based in the UK, you would be disappointed.

3D Print Direct

When you land on the homepage of their website you are able to see lots of small square or rectangular pictures, presumably of 3D printed parts and functional prototypes.

Beneath the text 3D PRINTING ON DEMAND. The first option that you have is the Upload 3D model and print.

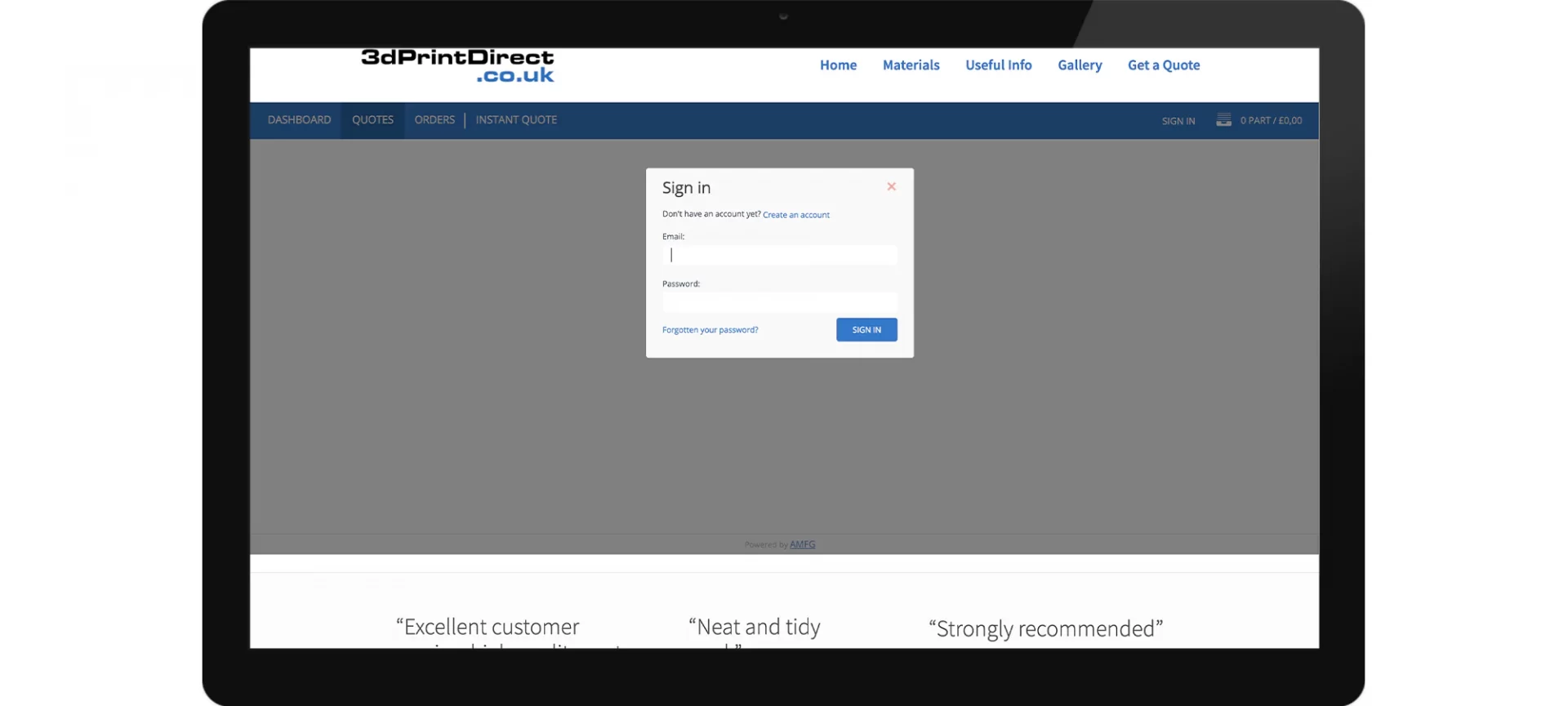

Clicking on it leads you to the GET A QUOTE page. Wherein you have the option to upload your STL file.

Going back to the home page and scrolling a little bit down, you have the option of finding out more about printing your own COVID-19 virus protection tool.

How does it work with this 3D printing service in the UK?

There are five different steps in which work happens on this website, you have to first upload your 3D design file which is for printing a part or functional prototype.

Then you need to select the material with which you wish to 3D print, thereafter you are going to get an instant quote, and if you give a go-ahead the company is going to print your design and deliver it to your doorstep.

There are all sorts of write-ups that the company has got in place if you are the first-timer and need help in knowing what all can you 3D print or what is the best material, everything is stereotyped.

Material that this company offers to 3D print with

There are four materials that the company offers you 3D printing with, their names and descriptions are as mentioned below.

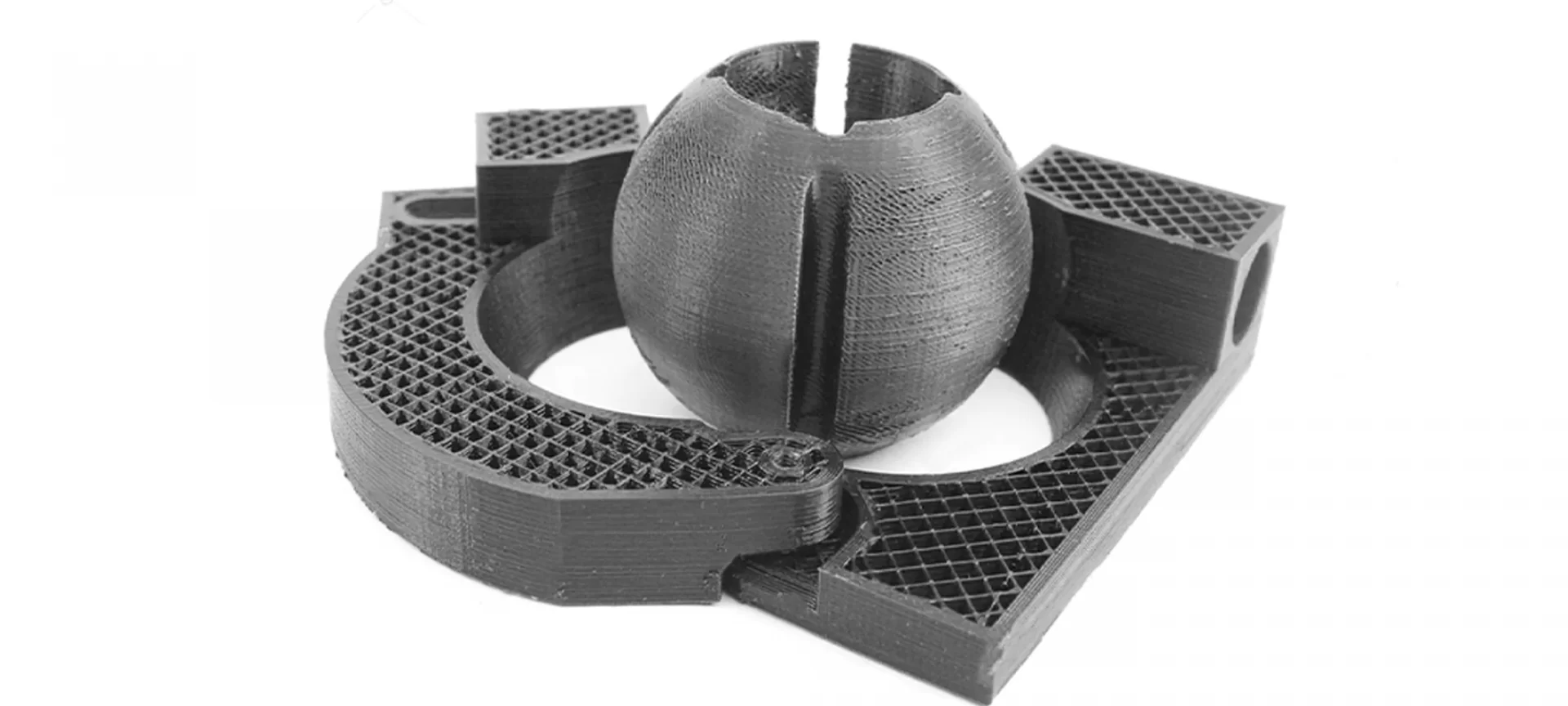

Graphite G4

This is a cost-effective reinforced PA12 material that has an excellent black surface finish and mechanical properties.

The material is lighter than comparable glass-filled nylon materials. It has a temperature resistance: 176 degrees Celsius, a density of 1.10 grams per cubic centimeter.

The Impact strength of this material is 37 joule per meter. Whilst its Tensile strength 58 megapascals.

The material has a Tensile modulus of 4,240 megapascals.

Carbon C6

This material is a specialized carbon-fiber filled with PA12. It is ideal for functional components that need to be light and strong.

And has the highest strength-to-weight, also stiffness-to-weight ratios than seen in any 3D printed SLS plastic.

The Temperature resistance of this material is 176 degrees Celsius, its Density 1.09 grams per cubic centimeter.

The Impact strength of this material is 53 joule per meter, whilst its Tensile strength 76 megapascals and its Tensile modulus 7,100 megapascals.

PA 12

This is a robust thermoplastic that produces high-density parts with balanced property profiles and strong structures. Its Temperature resistance is 175 degrees Celcius, a density of 1.01 gram per cubic centimeter. The material’s Impact strength is 35 joule per meter and the Tensile strength is 48 megapascal, whereas its Tensile modulus is 1,800 megapascal.

Perform

Has high accuracy, low shrinkage, stable, and temperature resistant epoxy.

Perform is a material that can also give an exceptionally smooth surface finish when sanded.

The Temperature resistance of this material is 132 degrees Celsius and density is 1.61 gramd per cubic centimeter.

The Impact strength of which is 17 joule per meter, while its Tensile strength and tensile modulus are 70 and 10,500 megapascals.

The first, second, and fourth materials are used for SLS 3D printing, whilst the third one is used for multi-jet fusion 3D printing.

All of them are rare materials, and asking an intermediate or expert in the field of 3D printing will tell you, exactly how rare they are!

Essence 3D print

There are multiple slides going behind the text i.e. Delivering your projects fast ESSENCE 3D PRINT, all of them in background white color.

There are seven tabs that are visible when you land on the homepage of this website.

But under the Services tab, you only have two options i.e. 3D printing service and CAD Service.

About this 3D printing service

The company claims many things but starting with what they are proud of i.e. each and every one of the 3D prints that they have done to date.

And the company also shares this pride on their social media pages.

If you’d like to see what they’ve been up to lately, you can join them on one of their social media accounts.

Essence 3D Printing is there in the 3D printing market for helping you bring your projects to life by either printing your already designed models or by creating customized models which you to complete your need.

The company claims to enjoy working closely with their clients and keeping them updated on the progress.

Isn’t that the general responsibility of the company? Each project that the company does is unique to them and they have a personalized approach for each of their customer.

The company claims to be on a constant journey to providing you with the best experience and products.

For every order that the company gets, they provide you with personalized consultancy and the best 3D printing solutions.

The company claims to constantly deliver your models in the shortest time possible.

They have also researched and offered the best designing and 3D printing solutions for meeting your needs, whether you are looking for color scale models or detachable or movable parts.

You name it, they have got it! The team of Essence only uses environmentally safe materials, such as PLA and PETG.

So, you would not get any other material as an option to 3D print. Isn’t this something the company should have marketed on?

The materials that are used by the company are biodegradable, they are made from natural resources, and hence they are fully recyclable.

On top of that, they do not produce any toxic fumes during the 3D printing processes.

The company minimizes the amount of plastic used by working with the best 3D printers, although which ones?

They do not mention it. All these printers have a very low print fail rate.

Currently, the company claims to be working on using at least 50% of their 3D printing filament from providers who create them using recycled material

How Does the 3D Printing Service of this Company Work?

You need to contact the company by sending them a product request or print file in either STL or OBJ format by email or by using the company’s contact form.

The company guarantees to reply to you within 24 hours of your email, be it a Sunday or a Saturday that you are sending the email to the company on.

The company can ask for further information if they think, it’s needed.

Then the company would ask you to choose from the best materials that they have in the kitty for you.

The company also gives you the freedom to tell them the color that you wish to 3D print with.

And after you approve it’s the printing and the delivery.

Protolabs

Protolabs is a 3D printing service UK company in operation since 1999.

Their 20 years of experience includes apart from 3D printing and additive manufacturing, technologies like injection molding, and CNC machining.

Protolabs’s 3D printing service in the UK is mostly used by professionals who need rapid prototype production or small manufacturing runs.

As a customer of Protolabs, you are given five options to choose from, these five options are the five technologies that you can print with Protolabs i.e. SLA, SLS, DMLS, Multi Jet Fusion, and PolyJet.

On the website of this company, you have a fast and easy-to-use quote generator.

It is also one of the very rare companies to openly discuss pricing in the field of 3D printing service UK. So, for comparison purposes, when you compare Protolabs’ quotes with Sculpteo’s by uploading the same file and selecting the same 3D printing technology (SLS) and material (PA12 White Nylon). Protolabs’ quote you around £86.66 and Sculpteo quotes you around €32.56.

If you too are wondering about the huge difference in the price, it’s because of the number of parts and prototypes.

If it is single Protolabs charges you more than Sculpteo, if it is more than once, it’s vice versa.

The thing is, Protolabs charges more when you request the manufacturing of a single part but when you add up the number of parts too, for example, 5 samples, the price suddenly becomes competitive, with £165.26 from Protolabs compared to €157.92 from Sculpteo.

Already at this scale, the price range is pretty similar. Finally, with efficient 3D printers and fast delivery, Protolabs’s customers get their parts to their doorstep in a matter of days.

Being on the website of this 3D printing service the UK

There are five tabs that you notice as soon as you land on their website.

When you click on the Services tab, you encounter plenty of new options under the three titles i.e. injection molding, CNC machining, and 3D printing.

Under 3D printing, as mentioned above, there is mention of five different technologies that Protolabs offers you 3D printing with!

Under the materials tab, you have the list of the materials and comparison guides. A comparison guide is something that not every website offers.

So, when we clicked on it, it opened a webpage wherein there is a short description under the title manufacturing materials that you have.

Under this, you have three general types, plastic, metal, and elastomer.

And just when you scroll down you realize the immense variety of materials that this company offers.

There is a data sheet that you can access every material listed on this list.

The industries that Protolabs serves are medical, aerospace, industrial equipment, automotive, and consumer electronics.

Protolabs was founded in 1999 by Larry Lukis, who was a successful entrepreneur at that time.

The guy was a computer geek who wanted to radically reduce the time it took to get injection-molded plastic prototype parts.

And the solution that he recommended for doing so was to automate the traditional manufacturing process by developing complex software that communicated with a network of mills and presses.

Protolabs is a result of 20 years of his and his teammate’s hard work.

The Conclusion

There are many 3D printing services in the UK, which are based in the UK.

However with the advancement in technology one thing which is clear is, you do not necessarily search for a 3D printing service based in the UK if you are living in the UK.

There might be a 3D printing service provider that is better than one in your locality, both, in serving parts of high quality as well as charging you something more affordable than your local one.

So, good luck to you and hope this article let you decide from the 3D printing service the UK mentioned in the article with one name that you wish to 3D print your part or a functional prototype.