3D printing service is a manufacturing technology that turns a computer model file into a physical product. The method works by building up a whole thing layer by layer of material.

Rapid prototyping is made possible by 3D printing. Designers and engineers can build and analyze their digital ideas in hours with 3D printing.

Most plastic products are made via injection molding, which involves injecting molten plastic into a metal mold and allowing it to cure in the desired shape.

While this procedure can take as little as a few seconds and is simple to duplicate, creating the first mold takes much longer and is only cost-effective if you’ve manufactured a large number of pieces.

How It Works

A digital file that directs the 3D printer where to print the material is required to make a 3D print. G-code files are the most frequent file type for this.

The X, Y, and Z axes, commonly known as the X, Y, and Z axes, are used to guide the printer’s movements horizontally and vertically. Layer height is a term used to describe how thick these layers can be printed on 3D printers.

More layers in a print, similar to pixels on a screen, will result in a greater ‘resolution.’ This will result in a better-looking final product, but it will take longer to print.

3D Printing Techniques

Sintering, melting, and stereolithography are the three main types of 3D printing techniques. Sintering is a technique for creating high-resolution products in which the material is heated but not to the point of melting.

For direct metal laser sintering, metal powder is used, while thermoplastic powders are used for selective laser sintering.

Powder bed fusion, electron beam melting, and direct energy deposition are 3D printing melting processes that employ lasers, electric arcs, or electron beams to melt materials together to create objects.

Photopolymerization is used in stereolithography to produce parts. This technology uses the right light source to selectively interact with the material, curing and solidifying a cross-section of the product in thin layers.

When Do You Need 3D Printing Services?

Companies that are working on a 3D printing project but cannot produce some or all of the work themselves use 3D printing components services.

People that need to use 3D printing but do not have access to one typically employ 3D printing components services.

They may get the parts they need without having to invest in their own hardware by outsourcing their job, and they can use the service as little or as much as they need.

This makes the services popular with companies that have 3D printers but need to outsource some of the work since they cannot handle the runs themselves.

The decision to employ 3D printing parts services is influenced by a number of criteria, including internal capacity, job size, and how quickly you need your part(s) back.

Here are some scenarios in which 3D printing parts services might be useful.

- You can outsource 3D printing if you just need a small or infrequent number of prototypes.

- A 3D model is even better than a thousand words if a picture is worth a thousand words. Using 3D printing to bring your models to life gives stakeholders a real picture of your concept and makes it easier to market.

- 3D printing part services can supplement in-house printing and fill production gaps. This is especially useful at peak production times and does not necessitate a long-term investment in new personnel or equipment.

- Despite the delivery time, 3D printing services can be faster than printing in-house in some cases.

Pros

- Traditional manufacturing technologies do not allow for the creation and printing of more complicated designs as 3D printing does. Traditional technologies impose design constraints that are no longer applicable when 3D printing is used.

- The prototyping process is sped up by 3D printing, which can produce parts in hours. This allows each stage to be completed more quickly. When compared to machining prototypes, 3D printing is less expensive and faster at generating parts because the item may be completed in hours, allowing for more frequent design modifications.

- When contrasted to alternative technologies that cut big chunks of non-recyclable materials, the creation of components only requires the materials needed for the part itself, with little or no waste. The procedure not only saves resources but also lowers the cost of the materials used.

- As a single-step production method, 3D printing saves time and, as a result, money compared to using several types of equipment. 3D printers may also be set up and left alone to do their work, eliminating the requirement for operators to be present at all times. As previously stated, this manufacturing process can cut material costs by only using the quantity of material required for the product, with little or no waste. While purchasing 3D printing equipment can be costly, outsourcing your project to a 3D printing service provider can save you money.

- With more local service providers offering outsourcing services for manufacturing jobs, 3D printers are becoming more accessible. In comparison to more traditional manufacturing procedures followed abroad, this process saves time and does not necessitate high transportation expenses.

- This procedure is inherently environmentally friendly because it decreases the quantity of material waste. When you include aspects like enhanced fuel efficiency from using lightweight 3D printed parts, the environmental benefits become much greater.

- Organs for the human body, such as livers, kidneys, and hearts, are printed using 3D printing in the medical field to help save lives. Further advancements and applications are being created in the healthcare sector, which will provide some of the most significant benefits from the usage of technology.

Cons

- While 3D printing can manufacture products out of a variety of polymers and metals, raw material availability is limited. This is because not all metals or polymers can be thermally regulated to enable 3D printing. Furthermore, many of these printing materials are not recyclable, and only a small percentage of them are food-safe.

- Small print chambers in 3D printers currently limit the size of parts that may be created. Anything larger will have to be printed in multiple parts and then put together afterward. Because the printer must produce more components before manual labor is employed to connect the parts together, this can raise costs and time for larger parts.

- Although big pieces require post-processing, most 3D printed items require some type of cleaning to remove support material from the build and smooth the surface to reach the desired finish, as indicated above. Water jetting, sanding, a chemical soak and rinse, air or heat drying, assembling, and other post-processing techniques were utilized. The quantity of post-processing required is determined by a variety of factors, including the size of the component being produced, the intended application, and the type of 3D printing technique employed. As a result, while 3D printing provides for quick part production, post-processing might slow down the manufacturing process.

- Unlike more traditional techniques like injection molding, where high volumes may be more cost-effective to produce, 3D printing has a fixed cost. While 3D printing has a lower initial investment than other manufacturing technologies, if scaled up to mass production numbers, the cost per unit does not decrease as much as injection molding.

- Parts are created layer by layer with 3D printing (also known as Additive Manufacturing). Although these layers attach to one another, they can delaminate when subjected to specific forces or orientations. This issue is more severe when utilizing fused deposition modeling (FDM), and polyjet and MultiJet parts are likewise more brittle. In some circumstances, injection molding may be preferable since it produces homogeneous pieces that do not separate or break.

- Another downside of 3D printing is the possible reduction in labor, as the majority of the manufacturing is mechanized and done by printers. Many third-world countries, on the other hand, rely on low-wage labor to keep their economies afloat, and this technology could jeopardize these manufacturing employments by eliminating the need for production abroad.

- Another issue with 3D printing is that it is directly tied to the type of machine or method utilized, with certain printers having lower tolerances, resulting in finished products that are not identical to the original design. This can be corrected in post-production, but keep in mind that this will add to the overall production time and expense.

- People will be able to produce phony and counterfeit things more easily as 3D printing becomes more widespread and accessible, and it will be nearly difficult to tell the difference. This has obvious implications for copyright as well as quality control.

Leading 3D Printing Companies Providing the Best 3D Printing Service

Beamler

Beamler is an on-demand 3D printing service available online. It assists engineers in determining which material is appropriate for their 3D printing project. Beamler was established in 2016 and is based in Amsterdam. It provides services all over the world.

Uses:

- Engineers may evaluate mechanical, chemical, and electrical properties of all 3D printing materials currently on the market using its comprehensive, up-to-date database of 3D printing materials.

- Engineers can rapidly learn about the cost of printing their parts with its automated quote tool.

- Silicone, tungsten, tungsten carbide, pure copper, aluminum alloys, and technical ceramics are among Beamler’s high-performance materials.

- Beamler is continuously on the search for new materials and 3D printing procedures to share with its clients.

- English, Dutch, German, French, and Italian are among the five languages available on the website.

- For SME and corporate, it targets the medical, shipping, automotive, and industrial industries, which are classified into Tier 1 and OEM. Online marketing for head innovation and engineers, as well as offline seeking direct contact with corporations to sell its products and services, are its target audiences.

- Engineers frequently struggle to gain the full benefits of 3D printing because they lack the knowledge and cash required to make the shift smoothly. By providing a plug-and-play cloud-based software solution for 3D printing, Beamler addresses both issues at once. The internet, as well as technology such as 3D printing, has made time to market a critical factor.

- A 3D printer service supporting post-processing

- Provides additional services like 3D printing material database

- Highly secure service providing IP protection and confidentiality

- Does not work with PLA

Autotiv

There is no better service than Autotiv for fast, economical, and convenient 3D printing. Autotiv has provided 3D printing services to over 1,000 businesses, as well as a variety of other services. Additive manufacturing, injection molding, and urethane casting are examples.

Uses:

- They create custom parts more effectively by combining excess manufacturing capacity from qualified vendors around the world with automated in-house manufacturing workflows.

- You can choose from five different 3D printing methods using Autotiv’s rapid online quoting tool. Plastics, elastomers, and metals are available.

- They also offer file preparation and repair, as well as materials consulting and project management.

- Supports traditional technologies such as CNC machining, urethane casting, and injection molding

- 1-50+ parts, shipped in 1 to 5 business days

- Provides quality checks

- Expensive

3D Systems on Demand

Customers wishing to accelerate product development can use 3D Systems on Demand facilities across the world to get quick design iterations, physical proof-of-concept, and scale models.

This 3D printing service’s Rapid Prototyping service enables real-time product design input and concept testing, allowing design and engineering teams to convert their ideas into reality fast and efficiently.

Uses:

- Shows how a product or part will appear and feel before investing in the more expensive components of production.

- With low-volume production and bridge manufacturing, you may save money on tooling, create customized goods, and get a product to market rapidly.

- It allows teams to evaluate issues such as usability, ergonomics, manufacturability, and materials testing in addition to the appearance and feel.

- Convert CAD files into physical components and assemblies that are highly realistic for aesthetic inspection, trade exhibitions, and sales presentations.

- 3D Systems on Demand has modern manufacturing facilities all over the world, as well as local support from our team of application engineers who have extensive industry and manufacturing knowledge.

- They provide a broad spectrum of additive and traditional manufacturing methods, materials, and processes, ranging from metal and plastic 3D printing to CNC machining, injection molding, and investment casting patterns, among other things.

- They provide quick and easy involvement, with engineers and project managers advising you from the outset.

- From prototyping and design iteration to pre-series or low-volume production, you may benefit from a single partner for the whole manufacturing value chain.

- 3D Systems is the inventor of 3D printing, and as such, it has a long history of expertise and a wide range of rapid prototyping options. Stereolithography (SLA), Selective Laser Sintering (SLS), Figure 4 ultra-fast technology, ColorJet Printing (CJP), and Direct Metal Printing are examples of this type of technology (DMP).

- They give you direct access to upload files, receive free online quotations, design verification, and all of your 3D printed prototype design files and order history 24 hours a day, 7 days a week.

- Works with polymers and metals

- Works with traditional technologies such as CNC machining, Injection Molding, Vacuum Casting, Metal Die Casting and Investment Casting

- Provides additional services such as 3D scanning, designing, manufacturing

- Only supports single STL file format

Xometry

Xometry, an on-demand manufacturing marketplace based in the United States, has launched its European fast quote service for 3D printing services.

Following an investment from Robert Bosch Venture Capital (RBVC) in its Series D funding round, the company set out to expand globally.

Uses:

- Xometry focuses on manufacturing methods that are low-cost to operate and maintain, allowing them to focus on nearly anyone who may want a small or medium production run of their products.

- Xometry’s online platform now includes subtractive manufacturing services in addition to its 3D printing services.

- Xometry, works on the web and also has a SolidWorks plug-in that will discover any faults in your part that are incompatible with the build process or material you’ve chosen.

- Protolabs is perhaps the most well-known and has the widest range of capabilities on the market.

- It employs the “hub” concept, in which a single resource is used to provide access to a variety of service providers, all of which are managed through a single interface.

- As you may anticipate, Xometry is focused on providing a web-based quoting service. After you have signed up for the service, you can begin uploading your geometry files and creating quotations.

- There is also a plug-in that runs within your property manager and offers you access to quotations directly from the SolidWorks UI if you are using SolidWorks.

- Xometry provides a best guess based on the geometry of your item, and the pricing updates when you narrow down your material or process options.

- The services provided by Xometry demonstrate the gap in economies of scale between most additive and CNC methods.

- A Ducati brake lever that they additively made is one of their test parts. While the one-time cost was roughly $600, multiplying it by multiples only resulted in a price reduction of roughly 50%.

- Supports post-processing including anodizing, metal plating, heat treatment, etc

- Provides additional services such as digital RFQ marketplace

- Does not provide CAD drafting services

- Delayed responses

Fast Radius

Fast Radius is a manufacturing company that specializes in both additive and traditional manufacturing technologies, ranging from application development to product design and testing, as well as production-grade manufacturing and global fulfillment.

This 3D printing service provides clients with a glimpse into the future of manufacturing and supply networks. Fast Radius can help with everything from completely new goods made possible by additive manufacturing to global supply chain solutions.

Uses:

- Produce parts wherever there is the capacity to avoid supply chain interruption.

- By storing parts in the cloud, you may avoid spending money on expensive equipment and cut your carrying expenses.

- Micro factories are designed to accurately regulate thousands of production factors, so expect high-quality products.

- They collaborate with global partners to deliver additional technologies and procedures in addition to their in-house solutions. Fast Radius is a company that specializes in producing industrial-grade metal and plastic parts for a variety of uses.

- They can scale at the speed you need using their network of factories, whether you are producing 100 pieces or 100,000.

- Consumer goods, medical devices, automotive, aircraft, industrial equipment, and electronics are among the industries that Fast Radius concentrates on.

- Processes, quality criteria, and order size all influence lead times. Many parts can be manufactured in as little as five business days.

- Provides post-processing services such as surface finishes, color options, chrome plating, etc

- Provides traditional technologies such as CNC machining, urethane casting, and injection molding

- Supports a multitude of file formats

- The company lacks a structural system

Sculpteo

Sculpteo is a 3D printing service based in France and was established in 2009. Professional online 3D printing services for prototypes, individual products, and short-run manufacturing are provided by the company with sophisticated controls for uploading and editing models, a decent selection of materials, enough information, and quick printing, Sculpteo provides a professional and consumer-friendly experience.

Uses:

- Polymers (PLA, Nylon 12), resins (from Carbon), and metals are all part of their material inventory (Aluminum, Stainless Steel, Titanium).

- BASF’s High-Performance 3D Printing Materials were recently added to their inventory.

- Sculpteo also provides design and consulting services. In Europe and California, the corporation maintains offices and production facilities (USA).

- A link to upload a 3D file is prominently displayed on the Sculpteo website. You can upload a file by selecting it or dragging it into your browser.

- You may use a viewer to look at your model from all angles and choose print settings.

- However, Sculpteo’s tool has its oddities, such as significant pricing swings once a model is merely shifted in the viewer.

- Sculpteo does a great job of providing material possibilities that you can click through to get relevant, detailed descriptions and obtain immediate price quotes.

- Sculpteo is designed to produce your items as rapidly as possible. Your object will be printed and mailed to you in 2–3 days after you place your purchase.

- With their automated examination of your models, Sculpteo makes this process a breeze.

- Sculpteo has almost every material or finishes imaginable for a 3D item. There are over 75 distinct material and finish combinations to pick from.

- You have three repair options: automatic, semi-automated, or manual. This allows all users, regardless of skill level, to prepare their models in a professional manner.

- Works with polymers, resins as well as metal and supports a variety of file formats

- Supports traditional techniques such as laser cutting

- Provides additional services such as consultation and 3D design

- Expensive

- Provides poor quality manufactures

CraftCloud

All3DP’s CraftCloud provides fast access to reliable 3D printing services. All of the service providers are fully vetted and are only accepted if they meet stringent criteria. You also do not have to deal directly with the providers; CraftCloud team serves as your exclusive service provider.

The goal of CraftCloud is to make the market more transparent. They compare multiple printing techniques, material names, finishes, and pricing from different providers in real-time to present you with the lowest and fastest solutions available, including local deals.

CraftCloud is the only stop you need to make on the way to achieving your ideas, with a constantly growing and improved array of features, functionalities, and offerings.

Uses:

- CraftCloud simplifies the process of ordering prints and removes the risk from your shoulders. It takes care of all aspects of managing 3D printing service providers and ensures that each one is trustworthy.

- CraftCloud not only helps you locate the best pricing for having your model produced, but it also provides helpful customer service.

- A complete inventory of available materials, technologies, and finishes, many shipping options, and even a design service to help you bring your ideas to life or enhance your pre-existing models to make them printable are all accessible as additional services.

- Supports traditional CNC machining technology

- Cheaper as compared to other services

- Less sturdy materials

- Results lack precision

Shapeways

One of the most popular web services for connecting with 3D artists and getting your creations produced is Shapeways. It is one of the most preferred options because of its popularity, but also because of its use of high-quality 3D printing.

Additionally, you can consult and engage a designer to create a unique and specific design. This strengthens the company’s offerings even further.

You can anticipate receiving your order. It has a variety of materials, surface finishes, product databases, and other options. It is a one-stop shop for everyone interested in the 3D printing service.

Uses:

- Shapeways is a fully functional e-commerce website that sells 3D printed items. In brief, when visiting Shapeways’ wide gallery, you can find a wide choice of objects like gift cards, lamps, and other products.

- You can sign up for a Shapeways storefront if you have good 3D design skills. Yes, it is entirely feasible.

- Makers may create their own stores and begin displaying their unique designs. You can even set prices for the 3D models and sell them to consumers online.

- You can also pay someone to come up with a 3D design for your assignment if you need to make a prototype using additive manufacturing.

- Provides painting post-processing service

- Ships around the globe

- Provision of expensive services

- Not a model marketplace

i.materialise

The 3D printing service provided by i.Materialise comes close to capturing all of the promise and excitement that 3D printing is meant to provide.

Its Web interface is simple, intuitive, and adaptable, removing the uncertainty and missteps from a complicated procedure.

Uses:

- Anyone can use the 3D printing service to simply submit their 3D models, have them assessed, and then produced them by the company.

- Once an object has been uploaded and successfully printed, a designer can sell it through the i.materalise online store’s gallery or by embedding it on their own website.

- I.materialise allows products to be printed in a variety of materials, including plastic, metal, ceramic, resin, and wood.

- They accept all major payment options, including credit cards and PayPal, and ship internationally by UPS.

- Provides additional 3D design service

- Ships worldwide with UPS or USPS

- Works with various hardcore technologies

- Supports material types such a resin, polymers, metal

- Does not offer silicon 3D prints or biocompatible 3D printing materialse globe

Materialise OnSite

Materialise’s online 3D printing service for industrial clients is called OnSite. OnSite is an ideal alternative for creating high-quality rapid prototypes in a short timescale, as it has one of Europe’s largest fleets of 3D printers.

As a result, you will have access to a wide selection of printing technologies, materials, and finishes. For a limited number of materials, rush services are offered, with lead times as low as one working day.

Uses:

- OnSite also offers its experience in selecting the proper technologies, materials, and finishes for the project, in addition to the online 3D printing service. Its in-house designers and engineers are also delighted to help you with 3D file optimization.

- It is the largest single-site 3D printing plant in Europe. Even the most time-sensitive projects can benefit from dedicated fast lane equipment, which ensures quick lead times.

- They have a variety of rapid prototyping methods at your disposal, including Laser Sintering, Multi Jet Fusion, Metal 3D Printing, Fused Deposition Modeling (FDM), Stereolithography, and PolyJet, with over 20 materials and 15 finishes.

- Works with several materials and provides additional services such as 3D design

- Ships worldwide with UPS or USPS

- Delivery within 15 days

- Do not allow the upload of multiple parts in a single 3D file

Stratasys Direct

Stratasys, one of the most well-known makers of industrial-grade 3D printers, now offers a high-quality 3D printing service. Stratasys Direct, appropriately, offers a fantastic array of materials from which its users might choose.

Engineers, doctors, and industrial designers will benefit from this online 3D printing service. Companies interested in switching to additive manufacturing can also benefit from Stratasys’ expertise.

Uses:

- The useful element of its online quotation page is the option to develop and change styles, which include printing methods, materials, finishing, and surface treatment that can be reused on subsequent projects.

- Solid Concepts is North America’s largest dedicated provider of additive manufacturing / 3D printing, fast prototyping, tooling, and injection molding services, built on a solid foundation of integrity.

- Solid Concepts is a project management and engineering firm with seven locations. With its wide range of technologies and materials, prototyping and low-volume manufacture of plastic and metal components straight from design data is simple.

- Solid Concepts’ additional skills in tooling and injection molding make it your one-stop-shop for taking your concept from prototype to market-ready completed product.

- Provides post-processing such as vapor polishing

- Provides additional services such as 3D designs

- Ships worldwide

- Only supports STL file formats

Beta Layout

Beta Layout’s price calculator can give an estimate for SLS 3D printers, but the company’s expertise is in complementary technologies for functioning prototypes employing PCBs and enclosures.

The company’s 3D mechatronic integrated devices, printed items with integrated circuitry, are perhaps the most enticing of its offerings.

Beta Layout is based in Germany and has offices all around the world, although some of their 3D printing services have yet to reach the United States.

Uses:

- According to the business, this is the first free electronic CAD software for creating electronic circuits on three-dimensional circuit carriers.

- Supports SLS technology

- Works with polymers, ceramics, resins as well as metals

- Supports PCB traditional technology

- Prepares material to ship within 4 days

- Expensive manufacturing

FacFox

FacFox is one of China’s major on-demand print businesses, offering a comprehensive range of manufacturing 3D printing services. The business caters to a variety of industries, including architecture, medicine, retail, and design.

You can rapidly upload models using a simple online interface, which will then be tested for printability (and instantly fixed if not) before payment.

The ability to follow the status of your print in real-time is a great addition, and competitive international delivery makes it a cost-effective option to some of the more well-known providers on this list.

Uses:

- Upload your model to obtain a quick quote, as well as a free printability inspection and mesh correction!

- Plastic, rubber, and metal are among the more than 50 industrial-grade materials available!

- Their cutting-edge printers and process guarantee a turnaround time of just 1-2 days!

- All of their equipment is of industrial quality, ensuring a consistent outcome for your project’s progress.

- Offers a quick turnaround time and a flexible delivery solution to help you accomplish your vision

- Supports material types such as polymers, resins, and metals

- provide post-processing facility such as polishing, primer coating, smoothing beautifier, etc

- Ships worldwide with 2 days as average delivery time

- Quite inexpensive

- Poor printing quality and post-processing

Fathom

Online 3D printing service situated in Oakland Fathom provides quick prototype, product realization, and batch production with a comprehensive range of 3D printing technologies and services.

The patent covers FATHOM’s internal and external platforms for creating pricing quotes for 3D objects with checkout options, such as unit selection, material selection, finish selection, and the amount of additively generated parts to be made.

Year after year, FATHOM’s proven ecosystem of dynamic advanced manufacturing technologies has received award-winning accolades.

Uses:

- Fathom began as a reseller of PolyJet machines (later Stratasys PolyJet), but as the company grew, it began to offer industrial-grade equipment from other manufacturers, increasing its service side to match.

- Fathom now employs a variety of fabrication techniques, including 3D printing, as well as design and engineering services, training programs, and staffing for in-house operations.

- Through STEP, IGES, and STL files can be uploaded to request a quote, Fathom’s On-Demand Digital Manufacturing platform is the website’s most comprehensive feature, allowing for the submission of a wide range of file formats and providing an easy overview of quotations and orders.

- Works with material types such as polymers

- Delivers the next day

- Provides additional services such as engineering & design support, consultancy, and training

- Expensive shipping and manufacturing

Protolabs

Since the early 2000s, Protolabs has served companies all over the world with 500 machines. Because you may request parts created with injection molding, this 3D printing service covers the entire gamut of rapid prototyping methods.

As a result, you will be able to create high-quality prototypes with properties that are similar to those of finished items. These components can be employed in advertising picture shoots and put through rigorous functional testing.

You will get a quick quote for how much the parts will cost based on the settings and materials you choose after uploading the 3D design files.

Uses:

- Supports DMLS, which employs a fiber laser technology to draw onto a surface of atomized metal powder, fusing the powder into fully dense metal objects

- SLA is compatible. Stereolithography (SLA) is a process that involves drawing thousands of thin layers on the surface of a liquid thermoset resin until the final component is created.

- A CO2 laser is used in selective laser sintering (SLS) to fuse nylon-based powder layer by layer until final thermoplastic parts are created.

- Metal, plastic, and nylon are among the materials that Protolabs can print with.

- Supports material types such as polymers, metal, silicon

- Supports post-processing of certain factors such as clear coating, plating, dyeing, etc

- Delivers within a day

- Turned or milled parts lack a reasonable level of quality

Fictiv

Fictiv is a multinational manufacturing company that also offers a 3D printing service. Fictive offers a low-cost 3D printing solution that comes in seven different materials.

You can create not only 3D printed parts but also subtractive prints and stunning final products. They can also put you in touch with a large-scale 3D printing company or an on-demand manufacturing company.

Uses:

- Fictiv is a professional service that can assist you in finding the right 3D printer and material for your prototypes and projects.

- Fictiv, based in San Francisco, employs its team’s knowledge of AM technologies and materials to locate idle professional 3D printers near you that best meet your needs, and then completes and delivers the prototype.

- Fictiv’s goal is to establish a network of 3D printing centers to assist more businesses and start-ups in bringing new goods to market faster.

- A modest local boutique and design company is one of their best examples.

- Supports traditional technologies such as CNC Machining, injection molding, etc

- Provides additional checks on the finished product

- Does not offer DFM review

- Only ships within the US

Kraftwurx

2020 marks Kraftwurx’s 16th year in the additive manufacturing business, having begun with the goal of putting greater power in the hands of designers and engineers.

The company is most recognized for its innovation of the Digital Factory, which allows any designer to reduce waste. Companies can use their Digital Factory software to create their own 3D model store. They also created a 3D printing service.

The company claims to manufacture locally in order to reduce transportation and shipping costs. The company’s efforts to reduce its carbon impact around the world are unusual.

Despite being only 16 years old, the company has grown to 110 production sites, with at least one of them located near you. The headquarters of Kraftwurx is located in Houston, Texas.

Uses:

- This is a platform, similar to Werkspot, which connects customers and producers. They provide options such as the ability to create your own shop and the ability to hire a professional designer to assist you with your design. They seek to make 3D printing more accessible to the public, and they believe that additive manufacturing is the future of manufacturing.

- Aside from producing, selling, and assisting, they attempted to develop a community by creating 12 subjects on which users can interact and discuss issues such as materials, 3D printing, the future of additive fabrication, and so on.

- Not only can you customize an object online and have it printed (from over 60 different materials), but you can also have it printed as close to you as feasible. Kraftwurx searches its network of suppliers (now 125, according to Norman), selects the one that is nearest to you, and has your thing printed.

- Furthermore, you can use the Kraftwurx site to interact with designers and have projects created at your request.

- Worldwide shipping

- Works with 85+ materials

- Provides additional services such as consulting

- Does not support any traditional technology

HK3DPrint

Online 3D printing service situated in Hong Kong HK3DPrint specializes in prototyping architectural models and exporting them all over the world. This 3D printing business also provides low-volume production at a low cost.

A rapid quote system and helpful documentation on 3D printing technology, in general, are also available on the website. On request, custom colors and finishes are available.

Keep an eye out for material deals on a regular basis. HK3DPrint offers a next-day 3D printing service, which is very useful for consumers in Hong Kong.

Uses:

- Architects and designers can use this 3D printing service to improve design creativity and quickly create 3D printed concepts and massing models with complicated surfaces and geometries for presentations.

- Reduce model production time to increase the design time.

- Reduce design processes, make project approval easier, and deliver projects faster.

- Build more precise models straight from 3D CAD files, avoiding mistakes made by hand.

- Full-color plaster composite, ABS-M30, PC, and Smooth Hi-res plastic materials are available, as well as white plastic (e.g., Nylon SLS).

- Offers SLS technology

- Works with material types such as polymers

- Ships worldwide

- Provides additional services such as Architectural Engineering and Construction Models

- Materials are not food safe and also must be kept away from dishwashers

JawsTec

JawsTec specializes in nylon 3D printing and CNC machining of steel and aluminum and provides a focused and professional 3D printing service.

Uses:

- Similarly, quality is prioritized across the company’s other products, with post-processing to order serving as a distinguishing feature between JawsTec and other services.

- CraftCloud can be used to access JawsTec’s 3D printing service.

- CNC Manufacturing, a Shop, and a Blog are all available through their 3D Design Service.

- It also supports HP Nylon PA 11.

- Supports SLS and MJF technology

- Includes polish post-processing

- Uses traditional technologies such as CNC machining

- Delivery within 5 days

- Does not print with resin

Treatstock

Treatstock is another website that brings together the best 3D printing services from across the world. Its rapid quote system is well-designed for novices, with options for prototype, jewelry, and dental applications, as well as specific materials (multi-color and metal). Each category features a variety of printing materials in a variety of colors.

Uses:

- Treatstock’s members also have access to a 3D model sale platform, which is a fantastic feature. Treatstock allows artists to set up shop and post their designs for buyers to buy and 3D print.

- Furthermore, Treatstock’s website includes a number of programs that allow users to create Braille labels and relief 3D pictures based on photos, making life easier for the visually handicapped.

- Metal, plastic, gypsum, paper, powder, resin, wax, and wood are just a few of the materials that Treatstock can work with. They take credit card payments and may send them anywhere in the world.

- Works with all types of technologies and material types

- Provides additional services such as 3D Design, 3D model shop

- Ships worldwide

- Subtly advertises website for personal profit on various platforms

SD3D

SD3D, an online 3D printing service business, offers a simple immediate quote tool for customers in need of 3D printed items.

From rough, low-resolution drawings to ultra-fine pieces with hardly discernible layer lines, parts can be obtained in four quality levels to fulfill the needs of every step in the design process.

The prints may also be used to cast parts, which is useful if you need to make prototypes on a small scale.

Uses:

- Sd3D’s delivery claims for most 3D print orders range from three to five days.

- Under the Services page of the website, there are four columns with product design, 3D printing, casting, and information.

- Volume orders, prototypes, and membership are all included.

- Supports various 3D printing technologies such as FDM, SLS, MJF, etc

- Supports post-processing such as Vapor Finish, Painting, and Coating

- Fast delivery and volume manufacturing

- Only provide the option to order a 3D print in 1 color and 1 material at a time

Star Rapid

For professionals and ambitious hobbyists, Star Rapid offers a wide range of prototyping 3D printing services. The website provides comprehensive information on the various additive manufacturing methods and finishing services offered.

Uses:

- If your needs expand beyond rapid prototyping, rapid tooling, and low-volume manufacturing are all possibilities, this company is a good fit.

- The case studies are also worth reading because they show what this company is capable of.

- To support your product development needs, they offer high-quality prototypes, quick tooling, and low-volume manufacturing services.

- Through manufacturing methods such as metal 3D printing, vacuum casting, CNC machining, plastic injection molding, and a variety of finishing services, its multinational team of engineers collaborates with you to bring your product ideas to life.

- Low-volume manufacturing is a great way to manage inventories and test the market before creating greater numbers because they can accomplish things faster.

- Works with DMLS technology

- Supports post-processing

- Provides high-quality prototyping services

- Ships to limited countries

- Does not provide design services

Trinckle 3D

Trinckle, a prominent online consumer and prosumer 3D printing service based in Berlin, debuted in early 2013.

The service, which includes an online marketplace with a variety of 3D printable designer 3D models to choose from, has expanded significantly and now includes even more technologies and materials (including alumite via sintering and silver casting).

The most significant innovation, though, is the recently launched online 3D file repair service.

Uses:

- SLS, FMD, and inkjet 3D printing processes, as well as materials ranging from ABS to Nylon, are all available.

- The service has developed significantly and now offers even more technologies and materials, as well as an online marketplace of 3D printable designer 3D models to choose from.

- The new Trinckle system is browser-based and fully free to use, which sets it apart from other similar applications.

- The Trinckle automated repair service is built on algorithms that have been fine-tuned to make 3D printing as accessible as possible to any online user, even if it is doing so for the first time.

- Trinckle says that its program can repair up to 95% of erroneous designs, and it presently supports STL, 3DS, and PLY file formats (with a 32 MB size limit)

- Treats data with absolute confidentiality

- Checks every CAD model for technical feasibility

- Ships only to a limited terrain

- Does not offer 3D scanning

3D Print AU

Online 3D printing service located in Australia. Customers in Australia and New Zealand can take advantage of 3D Print-3D Au‘s printers. It claims to be able to beat the competition’s bids due to its pricing structure (pay for the bounding box rather than the material utilized).

Uses:

- 3DPrint-AU employs industrial SLS production machines to deliver the highest quality printing service at the most affordable pricing.

- 3DPrint-AU employs industrial SLS production machines to deliver the highest quality printing service at the most affordable pricing.

- We can 3D print one or a few hundred items for you quickly with our new additive manufacturing 3D print service center.

- Every submitted model is verified before being sent to the 3D printer; therefore this 3D printing service guarantees to deliver exceptional quality. 3D Print-Au also accepts orders for low-volume production.

- Uses SLS, FDM, and Polyjet technologies

- Fast 3D printing

- Does not work with traditional technologies

- Only supports STL file format and only works with nylon material

- Only ships to Australia and New Zealand

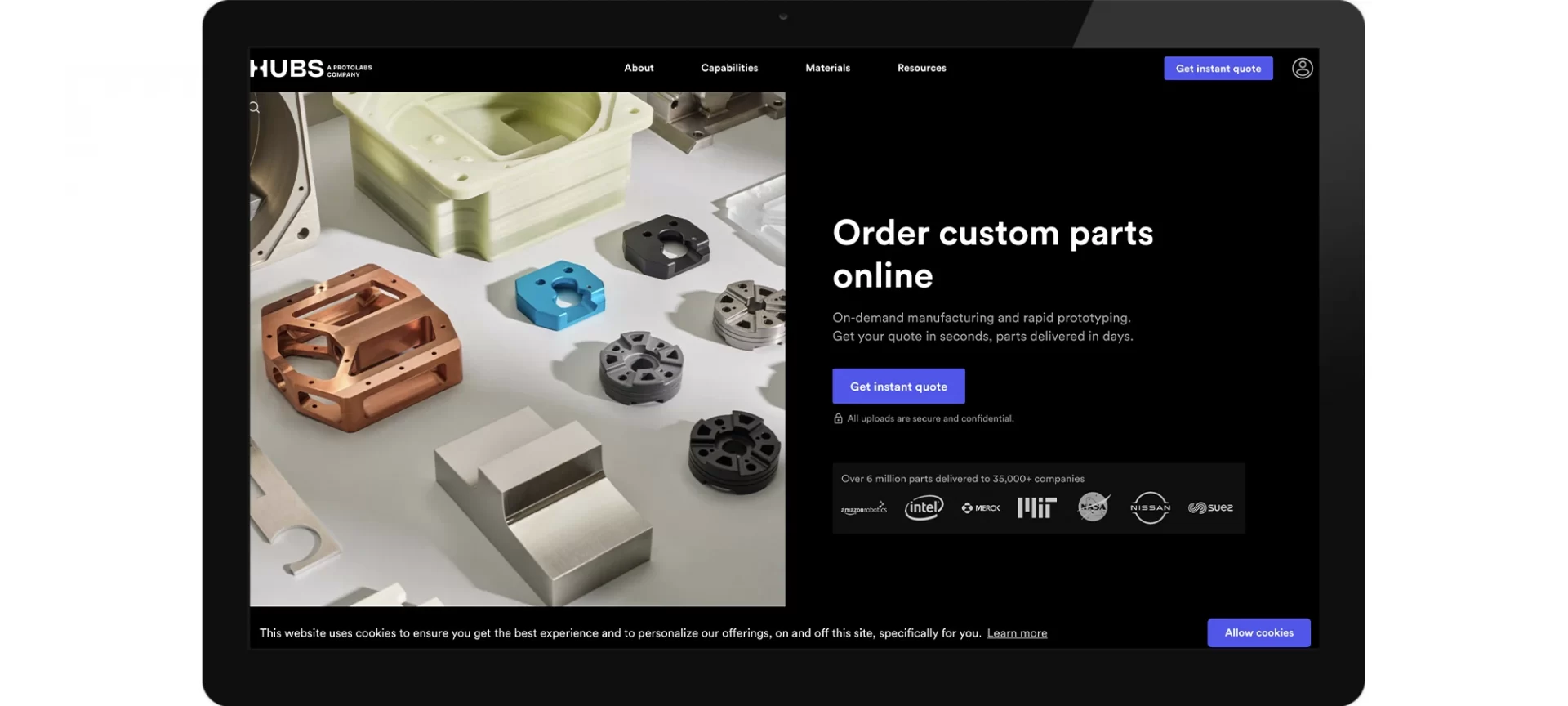

3D Hubs

3D Hubs differs from traditional 3D printing services in that the printing is done by individuals all around the world rather than by a single firm. This is a new technique for purchasing 3D printed items, but it works and gives the user more options.

Uses:

- It works in a straightforward manner.

- You upload your 3D drawings to 3D Hubs, choose the material you desire, and a list of Hubs in your chosen area appears. Hubs might be large corporations or individuals who will handle all of your 3D printing needs.

- Traditional 3D printing services differ from 3D Hubs in that the printing is done by individuals all around the world rather than by a single company. This is a new way to buy 3D printed objects, but it works and gives the user additional choices.

- It operates in a rather simple manner. You upload your 3D drawings to 3D Hubs, select your desired material, and a list of Hubs in your chosen area emerges.

- Large organizations or individuals may act as hubs, handling all of your 3D printing needs.

- Provides post-processing and additional services

- Ships in 4 business days

- Meets a large number of manufacturing needs

- Does not ship worldwide

3Diligent

3Diligent is a professional manufacturing network that allows organizations to publish jobs and requirements once they have signed up.

3Diligent then bids and completes the contract using its extensive network of partners (which includes manufacturing processes and technologies other than 3D printing service).

Uses:

- They take care of this for you by keeping a database of “vetted” part print service providers. Simply submit your materials for a quote, and 3Diligent will find a suitable service provider for you.

- When you request a quote, you provide your budget, the material, the method, and any other project needs. The vendors can help you select which material or procedure is best for your design if you are unsure.

- 3Diligent also has a knowledge center with quick guides to printing methods and materials, as well as a series of films that walk you through the ordering process.

- Works with traditional technologies such as CNC Machining, Casting, Injection molding

- Provides additional services such as consultation

- Manufactures products on time and provides flexibility for client’s ease

- Expensive

3D Printing Ally

3D Printing Ally, based in Eden Prairie, takes pride in being the birthplace of additive manufacturing in the 1980s. As a result of its founder’s background in aerospace production, the company is well-versed in the field.

Although 3D printing Ally has a wide range of additive manufacturing machines encompassing a variety of technologies and materials at its disposal, it is ideally positioned to meet the needs of a variety of sectors.

The website for the 3D printing service features an easy-to-use rapid quote system as well as relevant information on the various printing technologies and materials.

Uses:

- It provides custom parts and has a 24-hour turnaround time.

- By uploading your .stl file, they can also provide a fast 3D printing quote. If you have a CAD design but are not sure what material to use, the site includes a model uploading option that can help.

- Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), Stereolithography (SLA), MultiJet Printing (MJP), and ColorJet Printing are some of the technologies used on this site (CJP).

- It also has a variety of materials, including DuraForm PA, ABS-M30, Polycarbonate, Ultem 9085, VisiJet SL Clear, VisiJet Crystal, and Ceramic, that may be used to create any 3D printed object.

- Works with materials such as polymers

- Provides additional services such as 3D scanning and 3D modeling

- Supports FDM, SLA, and SLS technology

- Does not support traditional technologies

WhiteClouds

With its 3DyourPLAN, 3DyourMAP, and 3DyourSCAN service fronts, WhiteClouds is very probably the largest full-color 3D printing service in the world, with a strong concentration on B2B.

For experts and customers alike, it collaborates with stores and brands to produce bespoke action figures, medical models, and topological and architectural settings.

Uses:

- WhiteClouds 3D prints architectural models in monochrome and full color, and their models are stunning.

- It will take roughly five hours to print a model that is 5 inches tall.

- WhiteClouds has released 3DPlusMe, a new software solution that enables the company to offer 3D-scan-to-print services for fully customizable, full-color 3D printed products.

- It uses 3D Systems and Stratasys printers to make its high-quality prints. WhiteClouds has also created 3DPedia, a lexicon of 3D printing words.

- Provides painting post-processing

- Supports traditional technologies such as laser cutting

- Provides additional services such as 3D designs

- Provides worldwide shipping

- Discontented employees due to unrealistic deadlines

Frequently Asked Questions (FAQs)

What Are The Benefits Of Working With A 3D Printing Service Provider?

It can offer you quick turnaround times, clear communication, and the capacity to respond to any questions you may have without having to wait. It also provides a high-quality completed product and the capacity to quickly comprehend your needs.

What Information Do I Need To Get A Quote/3D Print?

For each part for which you require a quote, we would prefer 3D CAD. Estimates can be provided based on sketches or pictures of existing parts.

If you are sending images, we will need the total dimensions as well. If CAD data is not available, do not panic; we can develop it from your sketches or arrange for laser scanning of existing parts.

What Kinds Of Materials Are You Able To Print On?

3D printing may be done using a wide variety of materials. The Onyx One, Onyx Pro, and Mark Two desktop 3D printers from Markforged can print parts made of Onyx, Carbon Fiber, Fiberglass, Kevlar, and HSHT Fiberglass (High-Strength High-Temperature Fiberglass).

Markforged’s Metal 3D printer (Metal X) can print parts out of Stainless Steel, Aluminum, Tool Steel, Inconel, and Titanium. PLA, PVA (Polyvinyl Alcohol), Nylon, CPE, ABS, Polycarbonate, Polypropylene, and more materials can be printed on Ultimaker 3D printers.

Is There A Limit To The Types Of Objects You Can 3D Print?

Molds and cutting technologies are used in traditional manufacturing to create the necessary shapes. Using these approaches, creating complex and complicated shapes can be challenging and costly.

This problem is readily solved with 3D printing because it allows you to produce any form of geometries you can think of, depending on the size.

When combined with cutting-edge technologies like Generative Design, the possibilities are endless.

Is The Quality Of 3D Printed Goods Comparable To That Of “Traditionally” Created Goods?

This varies depending on the product. A 3D printed Japanese kitchen knife may not be as sharp as a genuine, painstakingly crafted steel blade or keep its edge as well.

On the other hand, 3D printing has allowed certain items, such as jet engine components, to be upgraded beyond the capability of traditional manufacturing procedures.

However, implying that a particular 3D printed product is better or worse than its traditional counterpart would be a subjective remark.

In terms of cost, 3D printing is on its way to becoming a very efficient, resourceful, and cost-effective means of production, and it will most likely surpass traditional manufacturing processes in the future.

3D Printing Service Guide

When comparing print services, there are a variety of aspects to consider. The major points to keep in mind while deciding which 3D printing service to use are listed below to help you focus on what important.

Price

There are numerous elements that influence the final cost of a 3D-printed part. You have a little amount of control over the pricing of the components you purchase, whether it is by using a 3D printing service that is close to where you need the printed item or being flexible with the materials you use.

Volume

The capacity to manage batch production is another element that will restrict the amount of useful 3D print services you can use. Finding a print service with the correct stuff is great, but if it cannot manage 1,000 copies of that thing by next week, it is pointless.

Time

This is an easy one. You needed your part yesterday, and the only thing that comes close to a time machine is an additively made component on the express train to tomorrow.

Fortunately, if you are not too particular about the material it prints in, several 3D printing service providers provide rush jobs. Therefore, time is an important factor to consider.

Privacy

The company’s privacy policy, terms, and conditions, as well as any certifications they may have, are less obvious factors to consider when picking a 3D printing service.

Printing Materials

ABS

ABS is a low-cost polymer that can be used to print robust, long-lasting objects that can tolerate high temperatures.

Flexible

Flexible filaments, also known as TPE or TPU, are noted for their elasticity, which allows them to stretch and bend effortlessly.

PLA

Because of its simplicity of usage, dimensional correctness, and inexpensive cost, PLA is the preferred material for most users.

HIP

HIP is a lightweight material that is frequently used as a dissolvable support structure for ABS sculptures.

PETG

PET and PETG filaments are well-known for their printability, excellent surface finish, and resistance to water.

Nylon

Nylon is a durable, semi-flexible material with great abrasion and impact resistance. It is an excellent choice for printing long-lasting parts.

ASA

Because of its strong UV, temperature, and impact resistance, ASA is a popular alternative to ABS for outdoor applications.

Polycarbonate

Polycarbonate is a strong and long-lasting material. Its strong heat and impact resistance make it an excellent choice for use in harsh conditions.

Polypropylene

Polypropylene’s fatigue resistance, semi-flexibility, and lightweight properties make it ideal for high-cycle, low-strength applications.

Metal Filled

Metal-filled filaments are created by combining a thin metal powder with a base material to provide a distinct metallic gloss and additional weight.

PVA

PVA is widely used as a support material for intricate designs because of its tendency to dissolve in water.

Conclusion

3D printing is a game-changing technology that is rapidly gaining traction. Aside from industries, end users can enjoy the benefits of technology. With the rise of print-on-demand services, things are becoming even easier. As the number of such services grows, so does the adoption of this fantastic technology.

Accessibility is improving, providing people more alternatives for printing the 3D creations they want to see come to life. In addition, 3D printing businesses are not making any concessions when it comes to providing the finest experience to their customers.

Companies are gaining customers’ trust and finding their way into the lives of both enterprises and cons thanks to better and innovative web interfaces.