|

The manufacturer of this printer is also the inventor of SLA 3D printing technology.

So, in this article, you will learn about what goods the company can provide you in terms of parts and functional prototypes, with its huge build volume, here is the industrial-grade 3D printer ProX 950.

Features

We will start with a list of points that this printer has and about which the manufacturer of this printer boasts about.

Strong large parts in one single piece

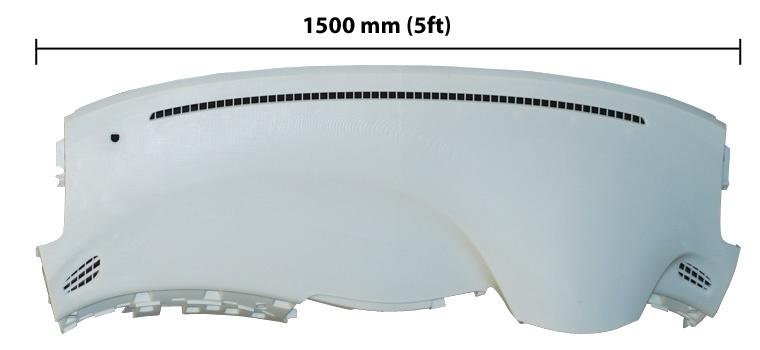

The ProX 950 offers a huge build volume that can let you build large parts up to 1500 mm in length.

All this in one single piece where there is no need for you to disassemble the parts or functional prototypes’ design files.

Instead, because you can build the complete part or functional prototype in one single go, it increases the part or functional prototype’s strength as the attachments always present a weakness in a part or functional prototype.

Additionally, building a part or functional prototype in one go also frees the additional resources that would otherwise occupy themselves while assembling the different segments.

This feature of the printer can be used for building parts such as dashboards, middle consoles, or stable and light or extra-light Quick Cast metal casting patterns.

The videos besides the text on the webpage dedicated to the printer on its manufacturer’s website claim a few more things by showing you a complete part is manufactured from the printer.

The first claim is about the printer delivering the largest SLA parts faster than ever.

The second one being “big huge parts from end to end.”

The third one being about the manufacturing speed of the printer which is 50 to 70 percent faster.

The fourth one follows up how the 3D Systems ProX 950 gives a choice to choose from the widest selection of 3D printing materials.

So, you can quickly produce large, precise tool-free casting patterns.

Integrated Printer, Material, and Software Solution

For expert application support on ProX 950 SLA 3D printer, there is a single point of contact.

This point of contact is the printer’s advanced manufacturing exclusive software.

You need to select the material with which you want to manufacture, and then optimize your 3D design file because the complete quality of a 3D part or functional prototype depends on this 3D design file.

So the manufacturer has paid extra attention to designing before starting to 3D print the part or functional prototype.

All your flaws during designing are exposed to you at the same stage, the tools to fix them are also highlighted to you so that you can quickly and efficiently change the flaws into actual design valuable points.

The company guarantees that you do not need any third party slicing software for correcting flaws in your design.

The proprietary software of the manufacturing company is enough to deliver extraordinary results in design.

With this, there is an assurance that you will have parts on your hand in which dimensional accuracy is the chief concern.

Reliable, from micro to macro

ProX 950, the manufacturing company claims to deliver with an equal amount of parts or functional prototypes whether they are micro in level or macro.

An exceptional amount of resolution and accuracy is guaranteed in all the parts and functional prototypes whether they are extra large in size or batches of highly detailed small parts.

Whether you are into batch production or printing part after part in the machine after machine, the parts or functional prototypes are accurate throughout the entire build platform.

A new level of management is provided by the company’s 3D Connect Service for production.

This is a secure cloud-based connection that professional designers can use to exchange their designs.

It has service teams that can provide proactive and support that can be well presented, enabling better service, improving uptime, and delivering production assurance for the complete system present at your workplace.

Low material waste and exchangeable material delivery modules for flexibility and changeovers

Being an SLA 3D printer, the ProX 950 guarantees that the amount of waste you find in this 3D printer will be lower than you find in other SLA 3D printers or FDM 3D printers.

Support structure management is where all of the waste majorly depends.

Since, in the ProX 950, everything is managed by the production management software as well as the software that is very intuitive.

When you are into batch production that’s when you realize the flexibility offered by the printer’s delivery modules.

After printing one part or functional prototype, when you need to print another part or functional prototype you can do that easily by changing the material with material delivery modules.

It will also take the printed part or functional prototype and put it safely aside.

All this is automated and hence it reduces the chances of human intervention, increasing the efficiency of the complete process.

Specifications

Credit: 3dsystems.com

Credit: 3dsystems.com

The ProX 950 printer is based on Stereolithography 3D printing technology.

It offers a build volume of 1500 mm x 750 mm x 550 mm.

For curing or solidifying one layer, two laser spot sizes are utilized, which increases its efficiency compared to other printers that utilize only one spot.

Even though the printer guarantees to offer more quality parts or functional prototypes than other printers, there is no compromise made in the speed at which this printer prints.

The complete management of the printer’s production is done on Cloud which is able to give its user a predictive as well as prompt service.

You are also able to print with a variety of different materials using this printer.

Price

You can get a quote for this printer; there is an option to get so from the webpage dedicated to this printer on the manufacturer’s website.

Like it is the case of most industrial 3D printers, so is it in the case of Pro X 950, the price of the printer is not explicitly mentioned on the printer’s website.

Instead, you need to Get A Quote for the same. For this, you need to fill down a form that will open to you when you click on the Get A Quote option, which will require you to fill in details about them yourself.

You can also speak to an expert in case you wish to.

First Impression

Credit: multistation.com

Credit: multistation.com

There are two pictures of the printer available on the webpage dedicated to it on its manufacturer’s website.

The front view of the printer is simple; the rectangular printer is divided into two parts, the left, and the right.

Both the parts have some part of the body which is black in color while the other is Grey in color.

The print bed of the printer is supposed to be just above the laser source wherein parts or functional prototype can be printed layer after the other and cured using the laser source as in the case of most SLA 3D printers.

Setup

Being an industrial 3D printer, it should come completely assembled.

All you have to ensure is you know about the detailing of every part and the way in which it functions.

After that, you are good to go. If you have already used SLA 3D printers, it won’t take you much time to get comfortable with this 3D printer as it must be a bigger scale version that you have used before.

But if you haven’t printed a part or functional prototype, you would have to download the resources about the printer and read from them about the parts of the printer and the way in which they operate to make sure you can make the most of the printer.

There are brochures as well as resources available on the webpage, you can download them and read about it and contact the company for any doubts.

Printing Type/Cost

SLA 3D printing technology utilizes a laser source to cure the parts and functional prototypes made in the printer.

ProX 950 claims to use two laser sources for the curing of layers that are printed.

It is extremely pleasant when the parts or functional prototypes are large and it is difficult to manage with one laser.

Because the laser source is a must to have in SLA 3D printers, the cost of printing one part or functional prototype in printers based on SLA 3D printing technology is more compared to FDM 3D printers.

The reason for this belief is the argument that most FDM 3D printers require exposing parts or functional prototypes in an ambient atmosphere or cooling it with the blowers.

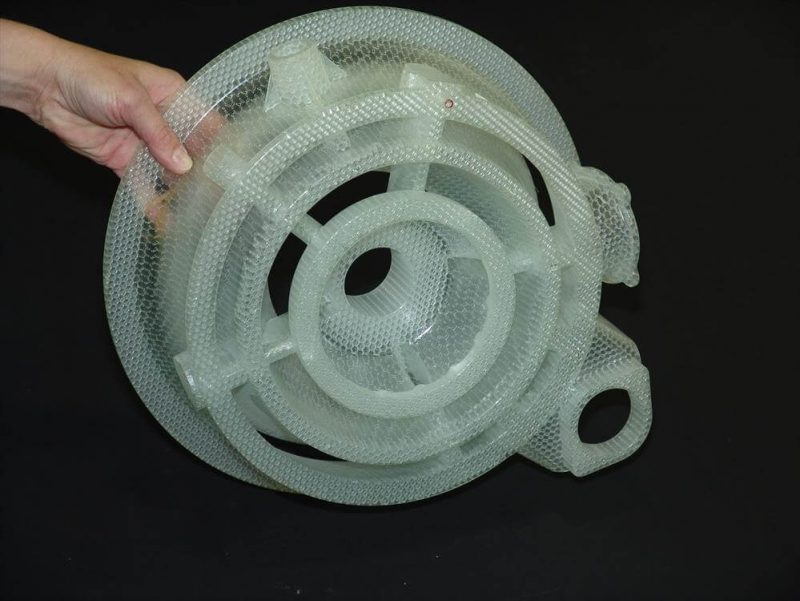

Print Quality

Credit: treatstock.fr

Credit: treatstock.fr

Throughout the webpage, if there is one thing that the company boasts a lot about this 3D printer, it is the quality.

The company’s claim that the 3D printer is able to print with the same precision in small as well as large parts is something one should really look out for.

There is a video that you see just behind the text when you land on the webpage, it shows the production of different types of parts and functional prototypes on the print bed of this 3D printer and they are all worth seeing, extraordinary.

Stating the layer resolution range in which the 3D printer prints, is not explicitly mentioned on the webpage but your eyes somehow trust the photographs of parts that you see as well as the video in which production of more than one part is seen.

And you come to the conclusion that each one of those is manufactured with extra care.

The printer’s manufacturers also boast of not losing the print speed while manufacturing high-quality parts, which is an add on.

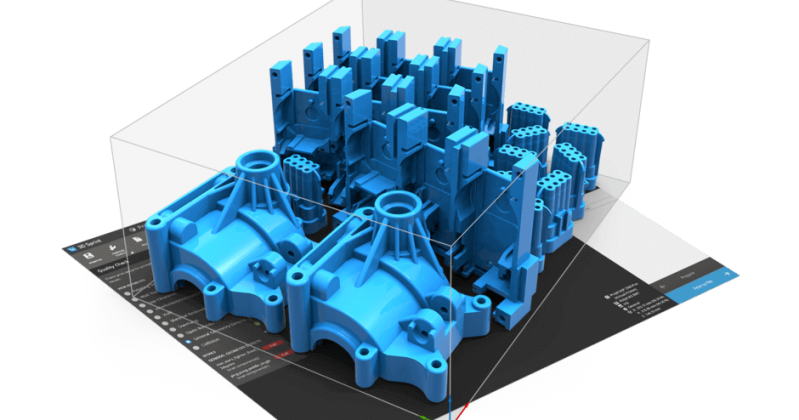

Software

3D Sprint is the name of the software that comes with the printer.

Using this software with the ProX 950, you would not need any other slicing software as per the company’s claims.

With this software, you can prepare as well as optimize the CAD data and then manage the complete 3D printing process.

The software also allows you to 3D print parts and functional prototypes without needing any other high-priced software.

Software that the 3D printer accompanies you is 3D Connect. This is a new level of management 3D production software which is based on Cloud connection.

This software supports you with the company’s service team which is there to help you with the complete support that you need.

You can improve your uptime and deliver production assurance for your system using this software.

Customer Service

You have the brochures as well as resources that you can download in all languages which you are comfortable and this is something you should do before thinking of getting in touch with the team of the 3D printer manufacturer.

Apart from this, there is a complete Support tab which has the option of 3D printers wherein you can select your region and get in touch with a local support team.

Apart from this you can download the support documentation, get in touch with the customer support center, and see the printer service contracts.

Parameters Influencing Buying Decision

Below mentioned points contain some of the most important factors in brief that you should think of before making the decision for purchasing a 3D printer.

3D Printer cost: You need to Get A Quote from the company.

3D Print quality: The printer is able to reflect dimensional accuracy in the small as well as large parts or functional prototypes printed by it.

3D Print speed: Extra-ordinary.

3D Printer capability: The printer is capable of printing with various 3D printing materials.

3D Printer Practicality: Larger parts or functional prototypes can be printed in a single go.

3D Printer User expectations: Manufacturers who were looking to print the build volume they were able to with FDM 3D printers, using SLA 3D printers would be satisfied.

The Verdict

This printer is one of the few SLA 3D printers which is able to keep up with the large build volume that is available in FDM 3D printers only.