Are you tired of working with similar filaments and need something more? If that is the case, why not try Aluminum filament? Yes, it is possible to print using this material. But before you go ahead and start expecting to get the results offered by proper metal 3D Printers, wait.

While it is true that FDM 3D Printers can now have more variation in print results, it still far away from getting any closer to the metal printers.

For those wanting a little extra from their FDM printers, the Aluminum filament could turn out to be the best choice. But what is this material, and can users create models made of complete Aluminum?

Well, our article answers all those questions in brief. So, read along and find out some interesting facts about Aluminum filaments and the best brands offering this particular material.

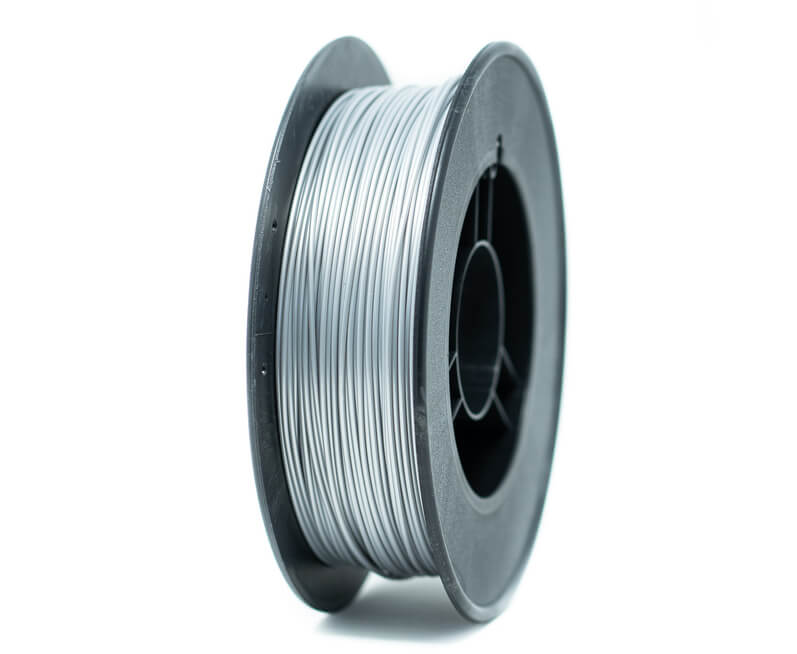

What is Aluminum Filament?

As already explained, FDM printers are far from creating parts made completely of metal. However, with alternatives such as Aluminum filament, users can attain results closer to the metals’ look and feel.

Metal-filled filaments aren’t complete metal. However, as the name suggests, they are available in combination with polymer, preferably PLA.

The filament contains very fine metal powder along with PLA. There are many metals available with PLA including Aluminum. Such as Bronze, Copper Brass, and even Stainless Steel.

These metal-filled filaments consist of varying percentages of metal powder. And, the difference may vary widely depending on the choice of your brand or manufacturer.

Because of the presence of powdered metal, these filaments weigh heavier than the standard plastics. Hence, the parts are also significantly heavier as compared to the ones printed using standard PLA.

Even if users involve similar setting parameters along with the equal amount of material consumed.

While it certainly is a great experience to work with Aluminum filament, one must take care of the issues concerning these materials. To start with, these tend to be abrasive when extruded through the hotend.

Therefore, working with the usual brass nozzle may seem like an unstable solution.

Moreover, many brands offer Aluminum filaments that only contain metal coloring. Hence, the results aren’t the same as those provided by actual metal powder-infused filaments.

So, you must be wary of those materials, if you wish to enjoy the perks of metal-filled filaments.

What Are The Pre-Requisite to Print with Aluminum Filament?

Here are some of the basic settings that you must have when printing with the metal-filled filament.

Bed Temperature: While the metal powder is mixed with PLA, you won’t essentially need a heated bed. However, it is preferred to use a 3D printer with a heated build plate enabling a temperature between 45 to 70 degrees Celsius.

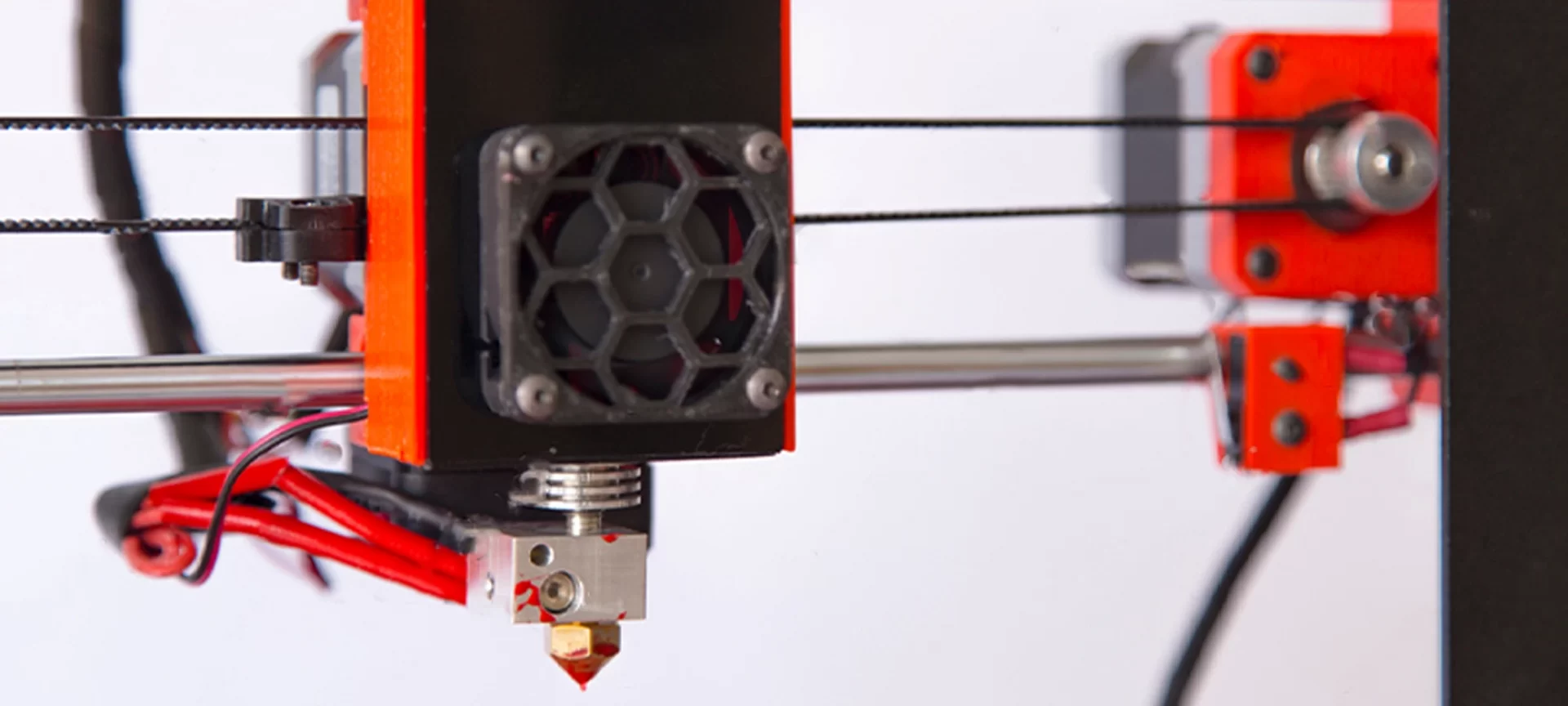

Extruder Temperature: First of all, you must take care of the nozzle you are using. If it’s the usual brass one, replace it with a wear-resistant hardened steel nozzle. Also, you will require an extruder temperature between 190 to 220 degrees Celsius for working with Aluminum filament.

Cooling Fan: You will require a part cooling fan for accomplishing printing using this filament.

These are some of the basic pre-requisites that you will need when starting to print with a metal-filled filament.

How to Work with Aluminum Filament?

As you know that 3D printing comes with its own challenges, it is important to consider those problems at the beginning itself. Especially when you are changing your filament and shifting from PLA to a metal-filled one.

In order to avoid issues such as clogging, poor bridging, wearing down of nozzle, and bad surface quality with blobs all over it, you must follow the best printing practices.

Swap Your Nozzle

Usually, a desktop FDM 3D printer comes with brass nozzles. These are soft and can handle softer filaments such as PLA and ABS. But metals have different chemical properties than plastics. And, the most notable one is their abrasive nature. Therefore, brass nozzles aren’t equipped to handle metal-filled filaments such as Aluminum filaments.

However, that does not mean you cannot print with this material. All you need to do is upgrade the old nozzle with a wear-resistant nozzle. This significantly reduces the problem of nozzle wearing down.

Now, when you plan to swap your nozzle, do not forget to check the nozzle size. As you know that Aluminum filament has metal particles, these may tend to clog around the orifice of the standard 0.4mm nozzles. And, with repeated use, it may become difficult to clean your nozzle.

For the same reason, it is recommended to use Nozzles with sizes between 0.5 to 0.6 mm. But even after that, you must keep an eye on the orifice of your nozzle to find any visible wear or tear.

The worn-out nozzles may work but would provide inconsistent extrusion. Therefore, harming the overall quality of your 3D models.

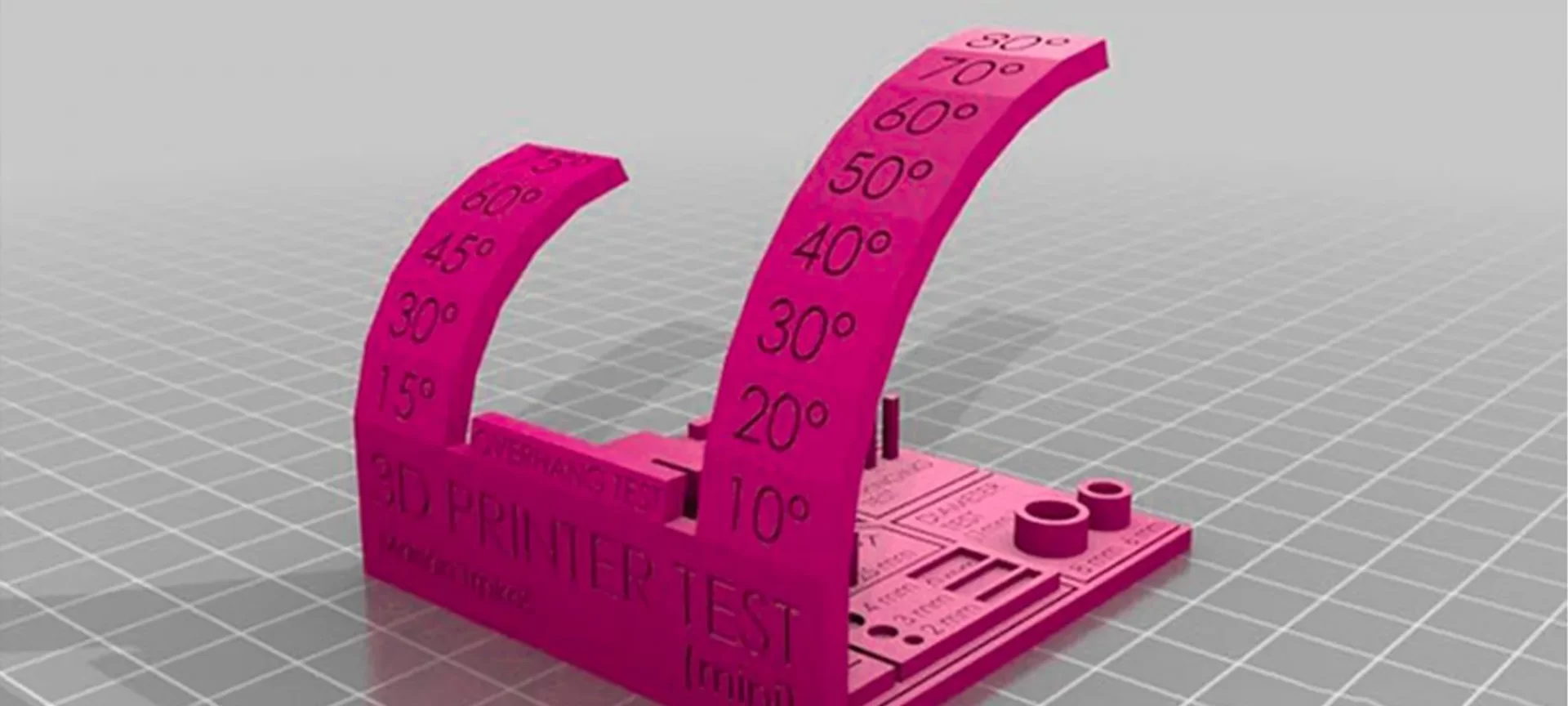

Look for the Bridging Limitations

To have a subtle bridging performance isn’t a cakewalk. Especially when you are printing with a metal-filled filament. This is because the metal particles are heavy and tend to drop across the sides of the bridge when the filament is extruded in molten form.

The problem worsens when it starts drooping excessively. Subsequently, the part falls down before the bridge completes. Therefore, it becomes a difficult job to print parts with multiple larger bridging regions.

If it’s difficult to avoid the same in your design, you can still print it. But you will require the correct settings for your slicer related to bridging. A few trials and errors may help you overcome the problem.

You may have to set the specific fill angle and see if that works best for your part’s design and material. Playing around with extrusion rate as well as print speed, you can also print bridges without issues. However, it still is a safer choice to avoid bridges, if not necessary.

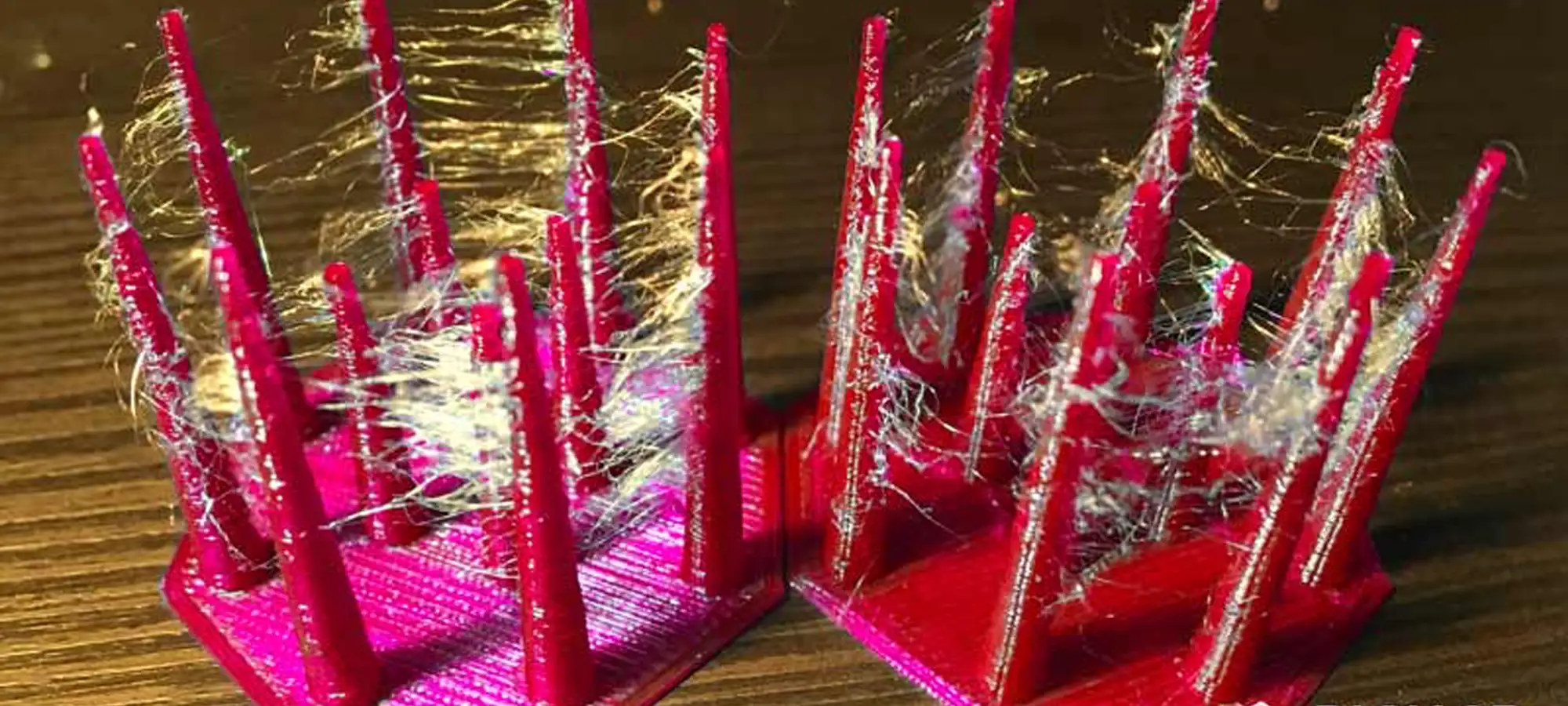

Look Out for Sharp Bends

Aluminum filaments are highly brittle. And, the same property applies not only to the final parts but even to the raw material that you use for printing.

Therefore, it is imperative to ensure there aren’t any sharp bend in the path that leads filament to the extruder.

Therefore, when printing with the filament, you must check for the filament path that starts from the spool holder and leads to the extruder. Any sharp angle in between will eventually concentrate too much stress at a single point on the filament.

This may result in the breaking of filament while printing is still in progress. As the nozzle head keeps moving to different positions, the filament will experience different levels of stress. Causing it to snap in between.

To curb the problem, users can simply change the position of the filament spool and change it to a different location for mounting.

The top of the printer would be the best place to mount the spool as the distance from the extruder will be minimal. You can also try other locations, depending on the design of your 3D printer.

If nothing works, get a strong filament guide tube. This will considerably limit the bending of filament at sharp paths while preventing breakages.

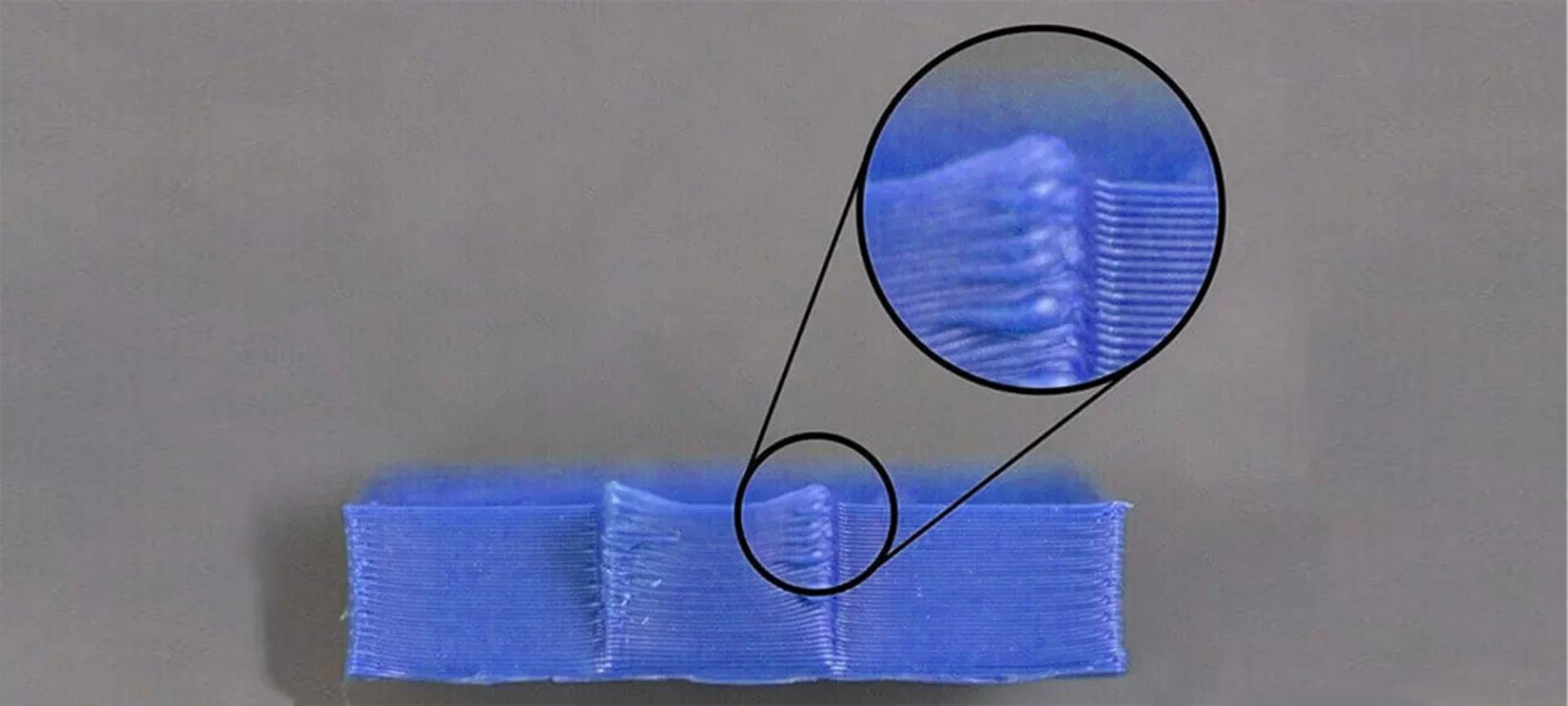

Check Your Retraction Settings

Almost every composite material is challenging to tame when it comes to retraction settings. And, Aluminum filament is no different. With metal powder in the material, the nozzle’s suction pressure sometimes does not work as expected inside the melt chamber as the retraction happens.

Hence, users may experience blobs at the beginning as well as at the end of each printed segment. To check the problem, may 3D printer applications include specific features.

Simplify 3D’s Coasting feature, for instance, automatically reduces the nozzle’s pressure just before the print segment is about to end.

What Are The Best Brands of Aluminum Filament?

Now, that we have already learned a lot about working with Aluminum filament, let’s take a look at the brand recommendations.

Filament 6061 Aluminium

The filament is from one of the most popular companies, The Virtual Foundry (TVF). This material consists of over 65 % aluminum metal powder along with PLA.

TVF is based out of American and was started by great professionals and experts who have huge experience in the molten metal sector.

Aluminum filament from TVF is free from any exposed metal particles along with the volatile solvents to avoid any problem during printing.

With PLA as the base material, the filament is simple to tame during printing. Also, users with FDM 3D printers can easily use the filament to create 3D models of their liking.

In addition, without needing to buy a professional or industrial 3D printer, spending tons of money to work with Aluminum.

Aluminum-Infused PLA Filament

Afinia’s Aluminum filament offers users a shiny and bright metallic appearance for the printed parts. The filament is simple to print and is compatible with its H-Series printers.

One can also print the material using any other FDM 3D printer that can attain an extruder temperature range between 190 to 240 degrees Celsius.

You can use this material for different applications. Easy to create toys and jewelry with added strength.

Along with Aluminum infused filament, the company also offers a range of other composite filaments.

Aluminum PLA Filament

A product by filaments.ca is very popular among 3D printing users. The material is very easy to work with and offers a lot of added advantage over standard PLA. This particular Aluminum Fill filament contains around 10% to 15% aluminum.

Hence, the filament can easily provide users the sufficient content of metal to provide 3D models with a metallic finish. At the same time, users do not need to compromise with ease of use. Also, one can print the material using usual strength and flow settings with the standard nozzles’ size.

Moreover, users can also post-process the parts as usual after printing. The results are even better after the parts go through the traditional buffing or polishing methods. Therefore, one can easily achieve the desired finish and without working too much for the same.

The material being abrasive will certainly require a wear-resistant nozzle though. The brass nozzle may wear down with repeated use. Apart from that, any FDM 3D printer will be compatible to work with this material with a desired nozzle temperature range.

The Conclusion

There has been a lot of changes in the way we use to create parts. While some methods have completely gone extinct with time, other methods exist parallelly. And, 3D printing is among those manufacturing methods that seem to evolve with time gaining more popularity over time.

Starting as a rapid prototyping alternative, the technology has become an inseparable part of production today. A lot of companies have already started working on 3D printers and many wanting to follow the same path.

In the midst of all this, manufacturers are often coming with new innovations to keep the interest rising among users.

And, Aluminum filament is one such example. In order to reach home users and the commercial industry, more discoveries are taking place.

With invent of better and innovative materials, companies are trying to increase the application of the technology to broader spaces.

The interest does seem to be increasing too. With usual home printers, users can now attain results of metal finishes. This certainly is a great innovation.

Users now can simply buy the metal-infused filament and add better properties to the resultant parts. Although the difference isn’t close to proper metal 3D printing, it still seems to be gaining popularity among commercial users.

What’s fascinating is the ease of use of these materials. Think about using your FDM 3D printer, with no too small change in the components for bringing variety to your creation. That says a lot about why filament is so desirable among users.

And, you can use it too. You do not require much expertise to handle Aluminum filament. On the contrary, with a few setting changes, you can print parts that appear strong and provide metal finishing.