Since ancient times, copper has been popular for its visual appeal. The architectural designs constructed using copper stand as a testament to the same. Traditional manufacturing methods for creating copper parts take exceptional skill. However, this is not the case when 3D printing with copper filament.

Metallic filaments allow users to create parts that look and feel like metals. And, Copper filament does the same. Not only does the material add room for more creativity, but the printed parts are also stronger and heavier when compared to the standard PLA.

This material is one of the most popular metal-filled filaments offering great print results to the users. Therefore, let us explore Copper filament and its various benefits and limitations.

What is a Copper Filament?

Unlike the filaments in their pure form, Copper filament comes as a composite material. These are combined with PLA to make copper compatible to print using FDM Printers.

We all know that FDM 3D Printers are limited to certain applications. Especially when it comes to working with high temperatures, it is not impossible for the extruders to reach a 1400 degrees Celsius temperature required for melting metals.

Therefore, some parts of PLA are mixed with powdered Copper to offer printed parts with a similar look and feel that copper parts exhibit. Depending on brands, the percentage of Copper differs.

When you print using copper filament, the parts will be heavier along with metal texture and finish. However, these won’t exhibit the entire properties of metal parts. But still, these filaments are very popular among users.

And, the reason is its high accessibility. Spending hundreds of thousands of dollars to buy an industrial 3D Printer isn’t something everyone can afford. In addition, 3D printing with these machines needs extra care and precaution.

On the other hand, these specialty filaments are cheaper and affordable. So, why not choose the Copper filament that offers the look and feel of the metal parts while offering you a cheaper price tag?

How to 3D Print Using Copper Filament?

Although the copper-filled polymers consist of PLA as the base material, it is not always the same experience as printing with PLA. Also, depending on the percentage of metal included, the temperature and other settings vary hugely from one brand to another.

However, in most cases, the standard range of 190 to 220 degrees Celsius will do the job. For perfect results, do not forget to check the instructions provided by the filament manufacturer though.

Let’s find out some more tips to carry Copper Filament 3D Printing for less hassle and better results.

Copper is Abrasive

One major issue that makes 3D printing difficult with Copper-infused filament is its abrasive property compared to soft materials.

Hence, when printing with Copper filament, you may need to invest in a more robust and wear-resistant nozzle. The standard brass nozzles are prone to wear and tear while working with abrasive metals.

If you think the solution may put extra pressure on your wallet, use the standard nozzle, however, with a bigger size diameter. To put it precisely, try using a 0.5mm to 0.6mm size nozzle instead of the usual 0.4mm.

Also, when working with the metal-filled filament, keep checking the nozzle head for any damage. Otherwise, your results won’t be satisfactory. Leading to poor-quality parts.

Heated Bed Isn’t Needed

This is good news for those struggling to fight warping with their PLA parts. Unlike the PLA filament, these metal composites aren’t susceptible to warping. Therefore, users do not necessarily need a heated bed to complete their prints.

But, in case, your 3D Printer already has a heated bed, it’s fine to keep the settings to lower temperature. Somewhere between 45 to 60 degrees, Celsius is the recommended temperature for the heated bed.

When it comes to bed adhesion, you can choose to go with the methods you usually pick for PLA printing. However, blue painters’ tape has mostly been able to get the best results for the users with non-heated beds. On the flip side, for a heated bed, you can make use of glue sticks. Apply the glue directly to the build glass surface.

Print at a Higher Speed

Copper is popular for its thermal conductivity. And, the property can help users print at a higher speed.

With metal powder infused with PLA, the filament tends to heat up faster right after it reaches the hot end. Therefore, users can increase the print speed and work at a faster pace when compared to the PLA. However, the conductivity will differ for different metals. So, check the manufacturer guide to understand what setting will work for your Copper filament.

How to Use a Cooling Fan?

Now, as the filament heats up faster, it cools down faster too. So, many users consider not using a cooling fan with Copper filament printing. However, with various test results, we have concluded that using a cooling fan is beneficial. You can set the fan to its highest speed because the warping issue isn’t relevant at all in this case.

Retraction May Seem Challenging

Apart from the various perks and limitations, retractions settings are often a bit challenging. Especially when working with a metal-infused filament.

With faster heating, ensuring the metal filament stays inside the melt chamber during retraction is really a difficult task. Therefore, often resulting in blobs sections, especially on those sections where the extruder begins and stops.

But there is a solution for the same. Setting your software in order to minimize retractions when the printing happens, you can tackle the issue. In case, it seems too challenging, you can always choose to print a design that requires minimal to no retraction.

Enhancing the Looks of the Print

Individuals often find it interesting to enhance the looks of the metallic prints. And, while doing so, they keep coming with interesting alternatives.

The most common one is to lightly polish the part surface with the help of coarse steel wool. The process offers prints with a great metallic luster. Alternatively, you can also use a thin coat of metal polish or spray paint to ensure that your parts look more attractive and polished.

What Brand Makes The Best Copper Filament?

Before you start buying filaments with metal powder in them, remember to make the right choice. Not all Copper filament comes with actual metal powder. Some only offer similar color and texture but none of the properties associated with Copper.

Therefore, you must choose to work with Copper fill or Copper-infused filament. Here are some recommendations that might help you make the right choice.

GizmoDorks

If you have been 3D Printing for quite some time, you must have heard about this brand. The company is popular for its variety of materials, especially metal-infused filaments. It has a wide array of choices for its customers.

Along with Copper filled, the company also provides Bronze filled filament for printing. Their filaments are available in one standard size, 1.75 mm. What’s best is that GizmoDorks has small quality spools for starters. You can buy 200 gms spools and test printing with the metal filament without spending too much in the beginning.

Once you feel comfortable, you can order more. For experienced users, they do have 1 kg spools of metal-infused filaments. In short, if you are not sure how to print Copper filament, go for the 200 gms spool. However, once you feel comfortable printing, you can choose to buy large spools.

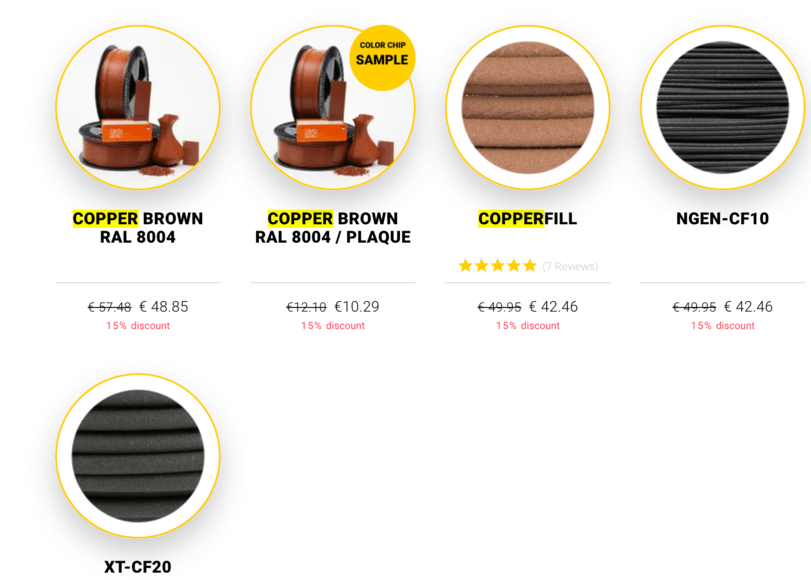

ColorFabb

One more popular brand among 3D Printing users – ColorFabb. As the name suggests, the company offers a huge collection of different color materials. However, the choices aren’t just limited to colors.

On the contrary, they have metal-filled filaments too. Hence, when looking for Copper filament, do not forget to check this brand. You can get filaments in two different diameter sizes: 1.75 mm and 3.00 mm. Moreover, the spool sizes are available in two different variants. Either you can pick their 0.75 kgs spool or the 1.5 kgs spool.

Depending on your need, you can order accordingly. The filaments are high quality and provide users with great results.

TVF

The Virtual Foundry has been trying out many ways to provide complete metal printing using FDM 3D printers. Its innovative Copper filament comes with 90% metal and PLA only being 10 percent of the composition.

After printing with this material, users must carry the sintering process for getting rid of the PLA and achieving 100 percent copper parts. These parts showcase the actual properties of copper metal. For instance, these have exactly the same electrical conductivity, hardness, strength, and more.

SainSmart

SainSmart is again one of the popular 3D printing material companies offering Copper filament. Apart from Copper, you can also get hands-on experience printing with bronze, and aluminum. The company may sound a little new to a few users, but it certainly is gaining popularity with its high-standard filaments that are easy to print.

They offer metal-infused filament in one size, 1.75mm. And, the spools are available in 0.5kg weight.

The Pros and Cons of Copper Filament

If you are printing with the copper filament for the first time, do not forget to address probable challenges in advance. The results will definitely be worth your efforts and patience.

Pros

- Beautiful Appearance: Copper filaments could really help boost your designs and take your creativity to the next level. The beautiful and unique dark-brown color of copper feels amazing when used for custom display parts. You can also use the material for jewelry making.

- Best Results After Post Processing: Copper parts won’t look attractive right after printing. However, these require a little bit of extra work. The printed parts have visible lines and may seem dull. Hence, to achieve the expected results, users must carry sanding and polishing to enhance their appearance.

- Stronger than Standard PLA: Have you printed with PLA before? If yes, you will right away feel the difference when printing with copper-infused filament. Unlike plastic parts that look cheap and light, copper parts are heavier and sturdier. In addition, not only do copper filament parts weigh twice or thrice as much as the PLA models, with polishing, they can offer a gorgeous finish too.

Cons

- The Filament is Expensive: Do not expect the copper-infused filaments to be as cheap as PLA materials. Moreover, the copper-filled filaments’ cost differs depending on the percentage of copper infused into the PLA material. And, when compared to the standard PLA, these are highly expensive. For instance, TVF, a popular filament brand sells a 1 kgs spool for around $120. Their filament composition consists of 90% copper to 10% PLA.

- Brittle filament: The copper powder mixed with PLA results in brittle as well as a rigid material. Because the filaments are thin and vulnerable, users need to invest extra care when handling copper filaments. There are instances when copper filament snaps between the printing process, leading to various problems.

- Abrasive material: Almost all the metal-filled filaments are abrasive. And, the same fact stays true for copper filament. The presence of copper powder makes the material unfit for printing with standard nozzles. Hence, you may have to spend extra bucks for a stronger nozzle or for a standard nozzle with a bigger diameter.

The Conclusion

Printing with Copper was not very common a few years back. The task was carried out using industrial 3D Printers that were too expensive for commercial users. However, everything is changing as we keep progressing to innovate and create better alternatives. And, the best example of the same is the metal-infused filaments.

Although restricted and limited in quality when compared to the pure metal parts, these are accessible. Hence, if you wish to print with Copper filament, try our recommendations. And, do not forget to follow the tips for ensuring safe printing. The precision and accuracy will certainly improve as you accumulate more experience with time.