|

This 3D printing system utilizes an ultra-fast four laser system that helps you create parts and functional prototypes that find application in various industries.

The printer is highly precise as well as offers faster results. Made by the German manufacturer EOS, M400-4 makes up for one of the most efficient industrial 3D printing systems in existence today!

Features

EOS M400-4 will turn up your productivity by four times. It has a massive build volume of 400 mm * 400 mm * 400 mm, which makes it perfect for industrial applications.

New Direct Metal Laser Sintering technology

Parts or functional prototypes manufactured on EOS M400-4 are created using DMLS 3D printing technology which is known for producing extraordinary surface quality.

DMLS 3D printing technology manufactures various mechanical objects that find application in many industries. These parts and functional prototypes are manufactured with metal powder.

For ensuring that the melting and fusion of the metal powder happens properly, there are four different ytterbium fiber laser sources of 400 watts each working independently inside the machine.

Productively automated

EOS M400-4 has a build volume of 400 mm * 400 mm * 400 mm and four lasers which enable it to achieve up to four times higher productivity which makes it perfect for making industrial parts and functional prototypes.

As mentioned above, four precise 400 watts fiber lasers work over an area of 250 mm * 250 mm each with a 50 mm overlap.

EOS M400-4 has an intuitive user interface that has flexible software tools and diverse accessories.

The complete system meets every usage requirement of an industrial production environment. With its highly automated procedures and processes, the printing system guarantees ease of operation.

Ability to print with multi-materials and build quality parts and functional prototypes

EOS M400-4 has a broad portfolio of materials starting from light metals, ending up to stainless steel, tool steels, and super-alloys.

- EOS Aluminum AlSi10MG: Parts and functional prototypes printed using this material offer strength, hardness, and dynamic properties as well as excellent thermal properties as well as low weight.

- EOS NickelAlloy IN718: Objects manufactured from this material manifests excellent tensile, fatigue, creep, and rupture strength at temperatures up to 700 degrees Celsius which make it ideal for many high-temperature applications.

- EOS NickelAlloy HX: High strength and oxidation resistance also at elevated temperatures such as 1200 degrees Celsius are the two chief qualities shown by parts and functional prototypes made from this material. These qualities made them ideal for applications in aerospace, gas turbines, etc.

- EOS Marging Steel MS1: Excellent mechanical properties and heat-treatable using a simple thermal age-hardening process of obtaining superior hardness and strength are what objects made from this material generally tend to have.

- EOS StainlessSteel 316L: Parts or functional prototypes made using this material show a high level of corrosion resistance, toughness, and ductility as well as high resistance to acids.

- EOS Titanium Ti64: Just like Titanium’s characteristics made it the ideal material for many high-performance applications in aerospace, automotive, and medical, so does it make EOS Titanium Ti64.

- EOS Titanium TiCP grade2: This material too has a similar kind of application as do the one mentioned above i.e. in aerospace, automotive as well as the medical industry.

Specifications

Credit: eos

Credit: eos

The maximum build volume offered by EOS M400-4 is 400 mm * 400 mm * 400 mm. It utilizes four Yb Fiber laser of 400 Watts power for manufacturing parts and functional prototypes.

With four laser sources, the printing system also contains four F-theta lenses and high-speed scanners that have a scanning speed of up to 7 meters per second.

These laser sources have a focus diameter of approximately 100 micrometers. And for operating the complete 3D printing system you will need three power supplies of 50 Amperes each.

EOS M400-4 consumes a maximum of 45 kiloWatts of power when on high loads, whereas in general, it consumes around 22 kilowatts.

The inert gas supply has a pressure of 7000 Hexa Pascal and a volume of 15 cubic meters per height.

EOS M400 prints a part or functional prototype using DMLS 3D printing technology which utilizes metal powder. And for metal powder handling, the German manufacturer gives you three options i.e.

- IPCM M Extra: manual and flexible powder handling.

- IPCM M Pro: Semi-automated powder handling.

- IPM M Powder Station L: Automatically closed-loop powder handling.

EOS M400’s machine dimensions are 4181 mm * 1613 mm * 2355 mm for which you need a minimum recommended installation space of 6500 mm * 6000 mm * 3300 mm.

Price

For getting the exact price of this 3D printing system you will have to request a quote from the printer manufacturer, EOS.

First Impressions

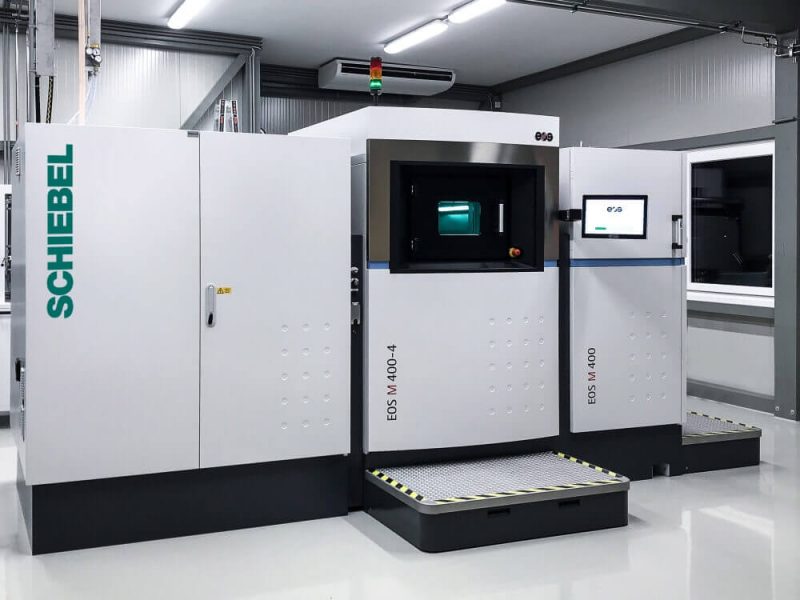

EOS as a complete printing system can be described as a collection of four different compartments, the third one of which holds the printing chamber as well as the touch screen user interface.

The printing chamber can be accessed via a door for reaching its height there is a step that you can climb.

When viewed from the front, the left of this 3D printing system seems like the space in which powdered metal can be stored at suitable temperatures so that moisture doesn’t affect its quality.

At the same time, there is an arrangement to collect it into the hopper during the start of the 3D printing process.

The left part of this printing system can be accessed via a door in its front. The right part of this 3D printing system can also be controlled and monitored via a touch screen user interface. From left to right, the 3D printing system is internally connected.

Setup

The company offers onsite assistance to ensure that the users are properly familiar with each part and process associated with the machine.

Controls, operation, and monitoring of features of this 3D printing system is something you can easily do with the software as well as the user interface that you have at your disposal.

Before 3D printing your first part or functional prototype on this 3D printing system it is recommended to learn about the complete process via the operator and also do some test prints.

There is also a sophisticated set of software and management systems that you’d have to get used to. And then you can also choose from different Powder handling systems.

Printing Type/Cost

EOS M400-4 is based on DMLS 3D printing technology. Although it follows the basic process sequence of the model, slice, and print layer by layer.

The start of any DMLS 3D printing procedure happens when a hopper is filled with the desired metal powder.

The printer’s heaters bring the metal powder to a temperature near the sintering range of the alloy and the printing system uses an inert gas that protects the heated powder and part as it is constructed.

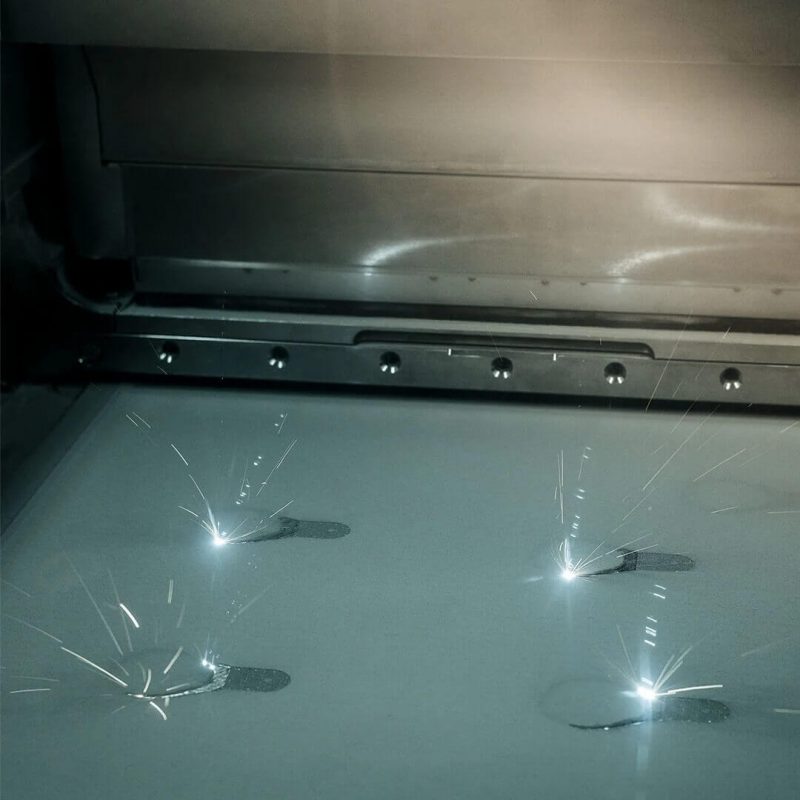

The building of part or functional prototype begins by dispensing a thin layer of metal powder on the build platform. Then the duty of laser pops in.

The laser source of the 3D printing system begins its path for the layer by selectively sintering the powder into a solid.

This sequence of dispensing a layer and sintering continues until the part is completely built.

After this the part is left to cool, the surrounding loose metal powder is removed from the printer. And the last step includes support material removal as well as post-processing, whenever needed.

The cost of 3D printing a part or functional prototype via DMLS 3D printing technology is generally higher than other 3D printing technologies because of its detailing.

However, the overall cost of 3D printing a part or functional prototype depends on the geometry of that object, the 3D printing material used in the preparation of it, the support structures, the level of infill, and a lot more.

Print Quality

Credit: eos

Credit: eos

Because of EOS’s groundbreaking 3D printing system and technology, it has been able to develop parts and functional prototypes that have found their application in making propulsion modules for Ariane 6.

Instead of using 248 elements, which was the scenario before; the injector head manufactured by this 3D printing system counts as just one compartment and finds an application in the rocket engine of a future upper stage propulsion module.

Other than this, due to the high quality of parts and functional prototypes manufactured by EOS M400-4, they also find their application in integrating functionalities, optimizing life cycles, and reduce maintenance times in turbomachinery applications.

Due to the dimensional accuracy in print quality of parts and functional prototypes manufactured using this 3D printing system, they find application in aerospace, medical, turbomachinery, automotive, and many others.

Software

The printer manufacturer offers tried and tested software solutions for all the steps of the 3D printing process, starting from the preparation of CAD design data and job preparation to quality control.

EOS SPRINT 2: It is an intuitive, open, and productive CAM tool for the company’s systems enabling the assignment and optimization of build parameters for your CAD data.

This software works with data preparation software such as SIEMENS NX or Magics by offering an extensive additive manufacturing CAM environment for a smooth 3D printing process.

EOSTATE Monitoring: This is a modular solution for seamless monitoring of all production and quality-relevant data in industrial 3D printing. It comprises four modules that can be used individually or in combination with each other.

EOSCONNECT Core: Here is the connectivity solution for monitoring your production. The company’s systems are IoT capable and therefore, can be integrated into existing IT infrastructure via EOSCONNECT Core. EOS provides an open interface for such a kind of connectivity to take place.

EOSCONNECT Machine Park: Using this system you can increase the capabilities of your EOS systems. It helps you in increasing your productivity with EOS Web Apps and monitor your complete EOS machine park from anywhere in an intuitive dashboard and receive automatic notifications on machine status and print jobs.

Customer Support

EOS’s customer support extends digital support for all its customers worldwide. There is information about Sales and Services offices and sales partners of the company in thirty-five countries that you can find online.

EOS offers separate technical services for additive manufacturing and extends the support that you need along the entire value chain.

Its highly flexible System Care Program packages are individually tailored to your needs. Apart from this, you are also offered financial services for refurbished used systems, flexible leasing, and financing models with special offers.

Parameters Influencing Buying Decision

A summary of the most important factors about this printing system is mentioned below.

3D Printer Cost: For buying this 3D printing system you will have to be ready for huge one-time investments, even more than other industrial 3D printers.

3D Printer Quality: Excellent quality parts and functional prototypes made from metal can be 3D printed using this system.

3D Print Speed: Compared to other 3D printers, this one has a four times higher production rate because of the use of four different laser sources in it.

3D Printer Capability: As mentioned in a section in this article, EOS M400-4 is capable of 3D printing with different metal powders.

3D Printer Practicality: When its operation, there is a sophisticated system that runs this 3D printer starting from modeling to post-processing. The complete system is automated.

3D Printer User Expectations: As a user, you’d be delighted by the quality of the parts and functional prototypes produced by this 3D printing system. All your expectations of creating objects specific to your needs would be catered to.

The Verdict

Overall, EOS M400-4 has a very efficient system of creating parts and functional prototypes that find application in a wide range of industries.

Although it will take a huge one-time investment to get it at your manufacturing facility, the 3D printing system manages to return your investment by producing some of the most extraordinary objects.