|

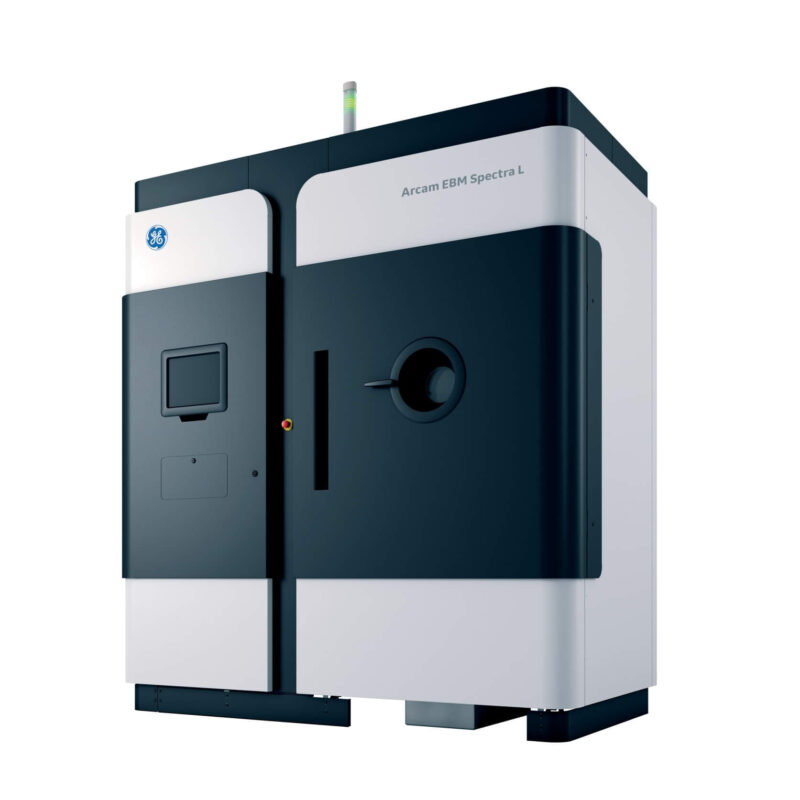

Arcam EBM Spectra L is the latest innovation by GE in 3D printing. The printer manufacturer and electronics giant claim how it increases productivity and reduces the cost per part by 10 percent. For both the achievements, GE credits its increased beam power to 4.5 kilowatts and enhancements in the beam control.

Moreover, the printing system offers a 20 increase in build speed compared to its predecessor. So, users can rely on successful prints with a commendable print speed. In addition, Spectra L allows for mass production of parts by providing a feature to tightly stack parts without compromising on quality.

The highly innovative Electron beam technology provides users with a lot of freedom in design, allowing you to build free-floating parts in sintered powder.

The support structures are chiefly used for heat equalization and can be easily removed while completing the build. There are many intriguing facts about Spectra L that will explore while getting to know it in-depth. So, let’s get started.

Features

Arcam EBM Spectra L features an integrated system architecture with a standardized IoT interface and data analytics for machine health monitoring. Additionally, there is the new Powder recovery station called PRS 30 which allows for smoother recovery of powder after the printing process.

The printing system offers excellent part quality, with improved surface finish and improved material properties for thin-wall geometries.

Spectra L is packed with many such wonderful features that are mentioned and explained below one after the other.

Increased Productivity

Spectra L’s predecessor made use of a less powerful electron beam for sintering metal powders. Because of which it was able to deliver parts with a lower surface finish and layer resolution range than the printer.

Thanks to GE for updating its electron beam’s power to kilowatts. This leads to an increase in the overall productivity of the machine.

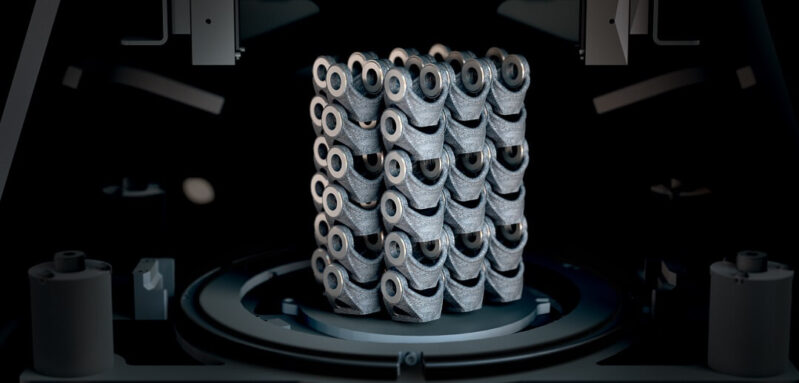

Not only does this reduce the cost per part, but also increases the build speed. The manufacturer claims how Spectra L can offer the largest build volume to tightly stack parts. The build volume offered by the printing system is 350 mm * 430 mm.

Excellent Part Quality

EBM 3D printing technology provides users with freedom in design and also permits them to build free-floating parts in sintered powder.

The supports are chiefly used for heat equalization and then are easily removed when the build is finished. The improved melt process results in enhanced surface finish and consistent material properties for thin and bulky geometries.

Such a process permits the user to have freedom for designing parts with thin as well as bulky geometries. While building metal parts with intricate geometries the main task is to build thin-wall geometries and that’s where Spectra L steals the show.

It builds parts with lesser layer resolution providing extraordinary surface finishes and improved material properties.

Integrated System Architecture

Credit: ge.com

Credit: ge.com

The complete workflow of Arcam Spectra L is similar to other 3D printing systems offered in a similar price range.

Spectra L features the state-of-the-art management architecture to process, monitor, and control various aspects of printing metal parts and functional prototypes via EBM 3D printing technology.

The printer is equipped with a standardized IoT interface, data analytics for machine health monitoring, and a new Powder recovery station called PRS 30.

When these components work in coordination with each other, they produce an outcome that is worth appreciating. All the calculations regarding optimal use of printing materials, powder recovery, and hassle-free 3D printing are done in advance.

A result of the highly optimal workflow that this integrated system architecture can put up is low-cost 3D printing with minimal efforts and yet high-quality parts production.

New and More Efficient Powder Recovery Station

One of the most unique benefits of powder additive manufacturing is the ability to recover unused excess powder. PRS 30 does this work for Spectra L. It is an advanced powder recovery station offering a high level of automation for high-volume production.

The station is efficiently able to automatically blast with an EMB build tank. Moreover, it is capable of self-diagnostic and easy troubleshooting.

In addition, PRS 30 can do closed powder recovery as well as an automatic cleaning cycle of the machine. It features exchangeable cyclone and powder transport tubes to enable better cleaning of the entire machine.

Lastly, the station has great operator ergonomics and a nine inches wide HMI panel that enables users to gain complete control over the station.

Supporting the powder station are the vacuum cleaners that assist in cleaning the finished build. Secondly, a sieving station that helps to filter unused powder and eliminate oversized particles. Thirdly, the hopper filling station aiding the loading of sieved powder from the barrels to the machine hopper.

Lastly, there are trolleys and powder barrels for transporting the build tank, powder hoppers as well as barrels, and for keeping the powder in a protected environment respectively.

The PRS 30 supplies virtually contact-free handling of the build module as well as enhanced automation for the safe cleaning of EBM builds.

Specifications

Spectra L offers a maximum build volume of 350 mm * 350 mm * 430 mm i.e. 52.675 liters. It is based on Direct Energy deposition 3D printing technology also known as Electron beam melting 3D printing technology.

The printing system operates using an electron beam of 4.5 kilowatts. Users can print with two specific types of 3D printing materials known as:

- Arcam EBM Ti6Al4V Grade 5, P-Material

- Arcam EBM Ti6Al4V Grade 23, P-Material

The unit is compatible with PRS 30 which is a new automated powder retrieval system suited for serial additive production environments providing safe, efficient powder handling for operators.

The machine also features a standardized internet of things interface that is built on an OPC unified architecture that not only helps in connecting multiple machines but also facilitates data analytics.

Price

To know the exact price at which Arcam Spectra L is available one will have to request a quote from the manufacturer.

First Impression

Being a professional-grade industrial 3D printer, Spectra L comes with onsite assistance. It has robust machinery featuring highly efficient parts.

With it comes the PRS 30 – powder removal station that works in an integrated fashion in many parts such as the vacuum cleaners, sieving station, hopper filling station, trolleys, and powder barrels.

Each of these components has its part to play. The powder removal station efficiently helps users to automatically blast with the EBM machine build tank. It has self-diagnostic and easy troubleshooting with closed powder recovery.

Moreover, it enables them for an automatic cleaning cycle of the machine. Also, it features exchangeable cyclone and powder transport tubes for better cleaning of the machine. A nine inches wide HMI panel lets users monitor as well as control the machine.

Overall, you’d need a completely dedicated workplace to work with Spectra L.

Setup

Before starting to 3D print with Spectra L, users will have to go in-depth about various components and their functioning on the printing system.

Spectra L’s initiation process is not too complicated as well as not completely straightforward. Users will have to have exposure to 3D printing before starting to print with the printer.

Print Type/Cost

Electron beam 3D printing technology appears very similar to SLS 3D printing technology. However, instead of the CO2 laser’s use as an energy source, an electron beam is used and the material chosen for manufacturing is not thermoplastic filament, but metal powder.

Before EBM 3D printing begins, the powder bin is filled with desired metal powder. Then it is pressurized in a build chamber after which an electron beam is fired up heating the built platform to high temperatures typically in the order of 600 to 700 degrees Celsius.

The printing starts with a powder re-coater that deposits a single layer of preheated powder onto the build platform.

Once that is set, the electron beam melting takes place in a controlled environment by a set of electromagnetic coils that accurately points the beam towards the desired points on the build platform.

It moves selectively while melting the powder and causing the powder particles to fuse. After one layer is completed, the built platform moves a layer down and the same process is repeated until the part is completely manufactured.

The cost of 3D printing a part using this process is higher than most other 3D printing technologies because of the use of electron beams as compared to UV light or laser sources.

However, the cost depends on many factors and it might vary depending on the increase and decrease in the amount of those factors.

Print Quality

Credit: ge.com

Credit: ge.com

Spectra L generates enhanced surface finishes and consistent material properties for thin as well as bulky geometries. This allows users to enjoy design freedom without any sort of limitations.

A high level of accuracy is possible to achieve on metal parts or functional prototypes with Spectra L. All thanks to the high-powered electron beam as well as highly efficient PRS 30.

Software

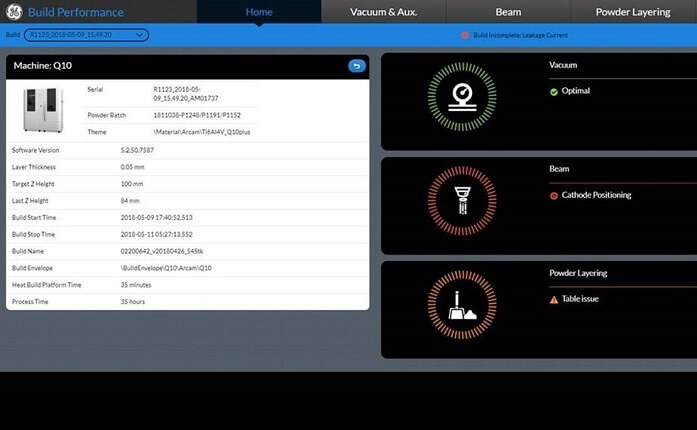

Credit: ge.com

Credit: ge.com

EBM Spectra L comes with an EBM BPA analytics software combining machine behavior, physics as well as domain knowledge of the system into an in-depth analysis for giving users a quick and easy understanding of the performance of each build job.

It analyzes the performance of the key machine and process sub-systems such as vacuum unity, beam unit, power distribution unit, and auxiliary units.

Customer Support

GE is a renowned name in the market of electronics as well as 3D printing technology and needs no introduction with its word-class reliable customer support. Its highly efficient technical team can be reached out via email or phone. Moreover, users can make use of the material that’s available online.

Parameters Influencing Buying Decision

Below mentioned are the key points that you need to take care of before buying Arcam EBM Spectra L.

3D Printer Cost: Being an industrial-grade metal 3D printer, Spectra L demands huge one-time investment.

3D Print Speed: GE claims how Spectra L has an increased build speed than its predecessor which overall above average, considering other 3D printers in the same price range.

3D Print Quality: Excellent part quality with improved surface finishes and improved material properties for thin-wall geometries is possible using Spectral L.

3D Printer Capability: The printing system is capable of machine health monitoring. It comes with integrated architecture, a standardized IoT interface, and data analytics. Also, like cherry over the top is the PRS-30 powder removal station that contributes a lot to ease the complete workflow as well as develop fine prints.

3D Printer Practicality: Spectra L allows for mass production so if you are a metal part manufacturer looking for an innovative 3D printing system that lets you build considerable build volume with commendable print quality, the printer is practically the same thing that you’ve been looking for.

3D Printer User Expectations: With 10 percent of cost reduced per part, increased beam power as well as speed, the Spectra L is a joy to work with.

The Verdict

According to its printer manufacturer, Spectra L is primarily meant for manufacturing orthopedic implants and aerospace industries.

Overall, it’s an eccentric industrial-grade 3D printing system based on EBM 3D printing technology for making metal parts utilizing rare metal powders. Its powder recovery station is very efficient and makes the complete workflow of the printing system very optimal.

For metal part manufacturers, the machine is truly a gift because it allows mass-producing metal parts with high integrity, larger and faster than ever before. Truly innovative, ain’t it?