Undoubtedly, the last few months have been very exciting for 3D printing technology. Not only has it helped immensely during COVID 19 pandemic but has also brought new ways to innovate and excel.

From facilitating print on demand to increasing customization, the industry continues to grow towards mass adoption and industrialization.

To suit the surging needs, experts are working hard to optimize 3D printers and make them even more competitive to fit the varying needs of the market. The question is: What would the printer of the future be like?

Apart from being an additive method, the new printers will certainly boast some of the basic key features that make these machines unique. However, we will certainly be witnessing smarter devices, increasingly getting mainstream within the wider manufacturing ecosystem.

But isn’t it difficult to keep up with the rapidly evolving industry? It sure is. Therefore, we have extracted some of the key insights from expert research and claims to understand the future of this revolutionary technology. Here is what you can expect 3D printers to be like in the coming years.

How Will 3D Printers Be in the Future?

Looking at the pace the technology is progressing towards advancements, it is clear that the future is bright. However, for clear vision, let us find out the areas where 3D printing is meant to come out strong and unbeatable.

The Future 3D Printers Will Become Mainstream for Serial Production

According to Andy Kalambi, the CEO of Rize, AM technologies are gradually moving towards becoming mainstream. Many companies and niches have already welcomed the capabilities of the technology to further their business goals. From automotive to end products, companies have been keeping a closer eye on the advantages of 3D printing.

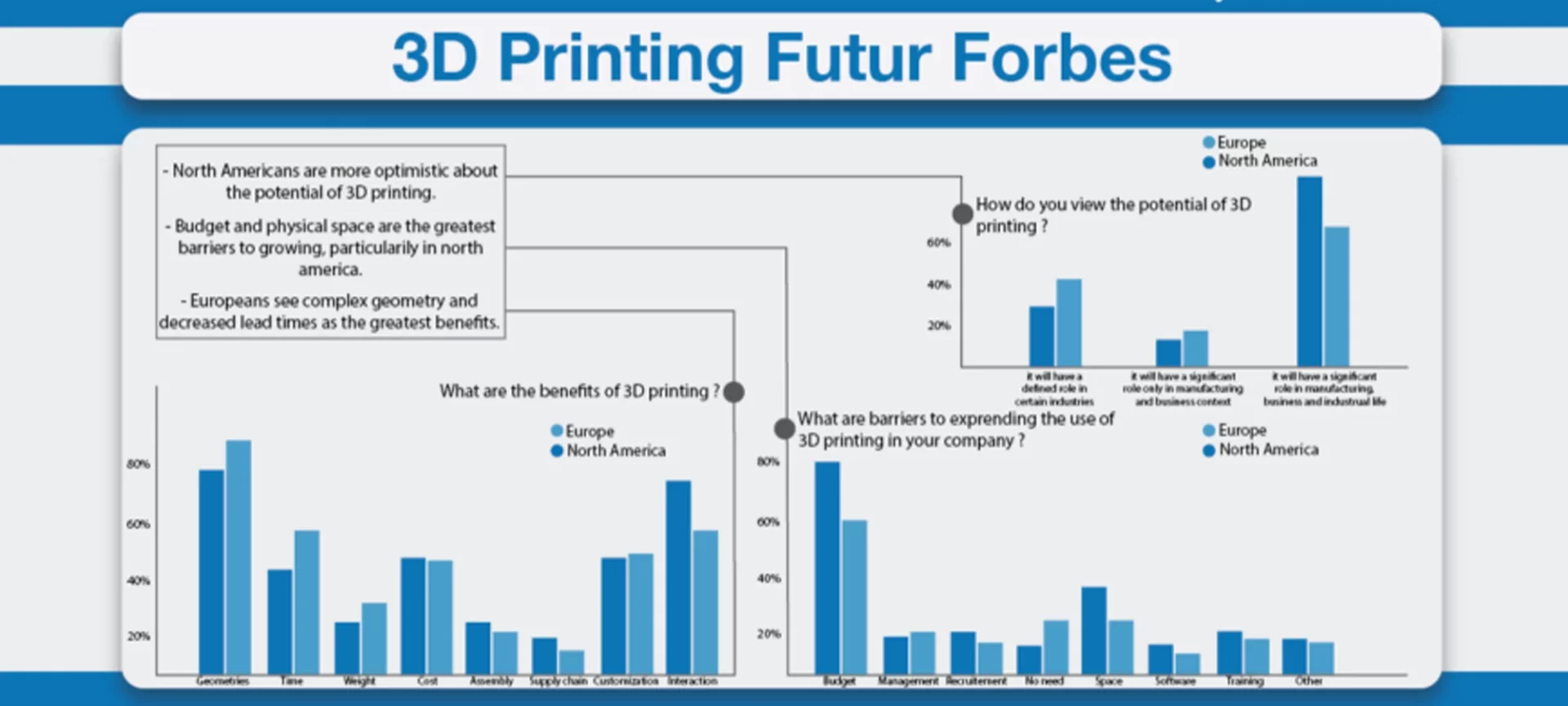

According to Forbes’s report, there are already 51% of businesses that area actively making use of 3D printing for production.

We already have a few examples such as the large automotive companies like Ford, and BMW. These companies are already involving the technology for manufacturing 3D printed components for their vehicles.

While the overall data for 3D printer parts still lag behind considerably relative to mass manufacturing volumes, the future is about to change. The number of 3D printed parts is set to increase.

Talking about the future, the technology along with the industries must maintain the rising momentum of adoption for enabling applications on a much larger scale. And, the technology is already doing its part.

For instance, metal 3D printers are now capable of working with more variety of materials including copper, aluminum, and more. Using the binder jetting machines from top companies such as 3DEO, HP, ExOne, and others, one can create high volume production of parts at a lower cost.

This does not mean that 3D printing will replace the traditional methods such as casting, CNC machining, or metal injection molding. On the contrary, the printer of the future will work in tandem with existing technologies for best results.

Simpler and Easy-to-Integrate 3D Printing Software

Along with 3D printers, experts are also working to develop design applications that are even simpler to use and easy to integrate.

Understand that fact that most of the conventional CAD software and design tools are not designed to handle the geometries 3D printing can handle, the need for seamless applications is increasing.

For example, using traditional CAD software, users find it really difficult to sculpt components made with graded materials. The problem becomes even more challenging when creating model porosity or lattice structures.

All these problems together significantly limit the AM technology to manufacture to the best of its capabilities. Thankfully, there are many software companies that have already started working on the development of integrated design solutions, especially for additive manufacturing.

Autodesk, PTC, and many other companies are exploring methods for designing solutions that could help engineers optimize designs with ease for multiple AM applications.

Higher Adoption within Dental Niche

As per the SmarTech Analysis, the adoption of 3D printers is only going to rise in the future within the dental niche.

3D printing is no more a naïve alternative within the dental industry. On the other hand, users are already creating crowns, surgical guides, and a variety of dental aligners and molds with the help of these machines. And, the printer of the future has the potential to not only remain as a choice but become the dominant technology.

A report issued by the SmarTech Analysis clearly states that the sale of 3D printers will eventually exceed machining hardware sales by 2025. In addition, 3D printing will be the leading production method within the dental industry by 2027.

And, to fuel, this paradigm shift is the development of highly efficient and precise resin-based printers.

Technologies such as SLA and DLP are enabling the production of custom dental devices that flaunt unprecedented surface quality. Not just that, these parts produced using these printers easily host fine features and geometries alongside abiding by faster production speed.

The 3D Print on Demand Services Will Expand

We are already witnessing the evolution of new companies serving customers with 3D printed items. And, the future will bring more such businesses to the forefront, offering users 3D printed parts on demand.

Manufacturing marketplaces such as Xometry, 3D Hubs, and more offers businesses a one-stop platform for accessing a global network of suppliers who can print on demand.

With Manufacturing-As-A-Service (MaaS) business model, it is possible for companies to utilize 3D printing technology for offering quicker turnarounds to the clients.

Metal 3D Printers Becoming More Agile

To be honest, metal 3D printing is just in its budding stage. Experts claim that they have just been able to scratch the surface, a little.

However, Metal 3D printing is one of the most popular and fastest-growing segments within AM technologies. Although metal 3D printing is evolving rapidly since the last decade, the real potential is still to be achieved. And, the future calls for the same.

EOS, the biggest name within powder bed fusion 3D printing method, is working hard to develop a wider range of materials for metal part production. Just a few years back in 2019, EOS released its four new materials: aluminum AlF357, stainless steel CX, along two grades of titanium.

Apart from offering a wider array of material selections, the companies are working to offer higher quality assurance to the users with metal 3D printing. Precisely, industries such as automotive, energy sectors, and industrial goods are starting to put faith in metal 3D printing as a solution.

For instance, BMW started its 3D printing production of metal roof brackets already. In addition, GE is up to develop better heat exchangers with the technology.

3D Printers Furthering Automation

The next step towards evolution is the higher automation of additive manufacturing. Enabling the same with advanced hardware and software, along with fine-tuned robotics, sensors as well as networks, the printer of the future will ensure better-streamlined processes ensuring automated end-to-end digital production cycle.

When looking at the current developments, experts are already launching better and integrated production units incorporating smart factory concepts. Hence, enabling automation to the next level and speeding the different steps involved within manufacturing workflows.

The examples are already out there. Digital Metal which is the manufacturer of binder jetting 3D printers has come up with its systems that are paired with robots.

Hence, the solution is able to handle manual work including removal of built parts and transfer of the completed models to the designated post-processing units.

When talking about software, companies are trying to automate workflow in every way possible. However, the task is not as simple as the automation of hardware and will involve an end-to-end management system in place.

Further, experts are also trying to expedite the post processing times by enabling automated solutions for the same. Combined together when all the efforts, the printer of the future will offer higher automation and greater ease of manufacturing.

Smarter 3D Printers in Creation

Manufacturers of 3D printers are welcoming smarter solutions such as sensors, cameras, etc. for enabling in-process monitoring. These tools placed closer to the printer’s build plate, offer users ease of measuring multiple aspects of part production in real-time.

These inclusions really help companies while documenting the build process. Thereby, enabling optimized manufacturing with all requirements in place.

For instance, cameras and sensors included in the powder bed metal 3D printers, help users in capturing the temperature as well as the size of the melt pool. These are the components that are directly responsible for material properties, the microstructure, surface finish, and more. In short, these factors impact the overall part performance.

The Conclusion

3D printing is certainly one of the most revolutionary technologies that we have come across. And, we do have witnessed the way it has evolved from being just a prototyping solution to handling small batches for production.

Talking about the printer of the future, we expect better innovation and progress leading to mass adoption.