Since modern technology has come up with exciting and life-changing innovations, it is no doubt that one of those is 3D printing.

It is an exceedingly intelligent technology that is now contributing to major industries such as medicine, architecture, prosthetics, military, engineering, education, automotive, manufacturing, and aerospace. 3D printing is now an essential contributor to the economy by its capabilities of widespread production.

Not only this, but it has been developing creativity and imagination in individuals who have chosen to learn it, no matter what their background is.

3D printing tutorials and courses are available on the internet and in many colleges. People have started owning their own businesses or are working freelance or for on-demand projects from home.

3D printing is one of those technologies that do not damage the environment at all. 3D printers are built in a way that they do not release any harmful chemicals or toxins and are safe to use at your house and around children as well. It uses recyclable composites and materials and does not require a lot of labor, as it is easy to learn and operate by just one person.

Compared to traditional printing methods, modern 3D printing methods do not take weeks to print an object, but merely take a few hours or minutes depending on the build volume.

What Is 3D Printing And How Does It Work?

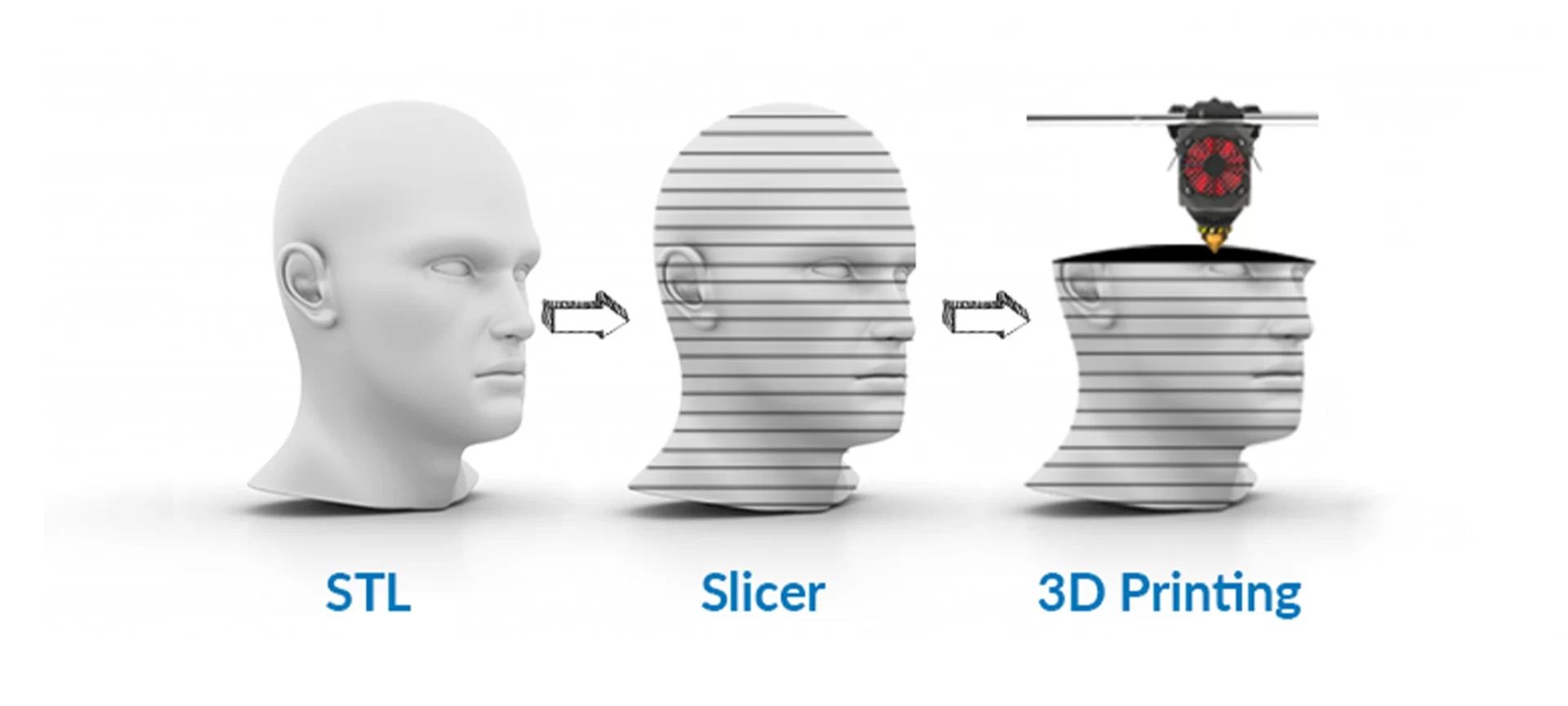

The 3D printers allow designers to create intricate and visually pleasing shapes by using particular laser beams that liquefies 20-60 micron layers of metal powder, something that is not possible with traditional printing methods. By using CAD (computer-aided design) software, 3D printers design and effortlessly print out any product.

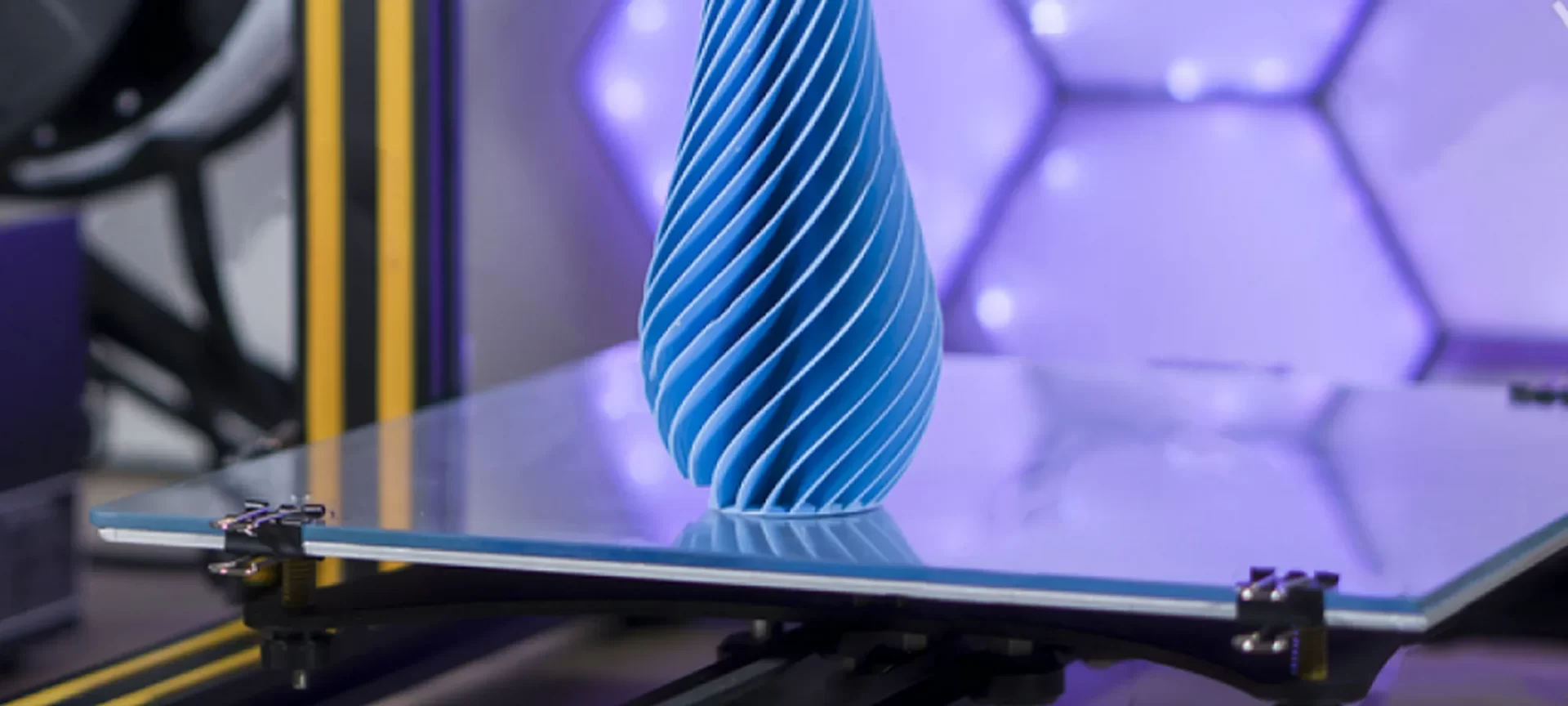

After the completion of the print, the printed object is then post-processed by eradicating support structure, heat-treating, sanding, and washing.

Post-processing is important because it reduces room for errors or deformities in your printed item, and makes sure that you have a high-quality print job in front of you. A post-processed part can be displayed for sale and really shows your dedication and skills as a 3D printing expert.

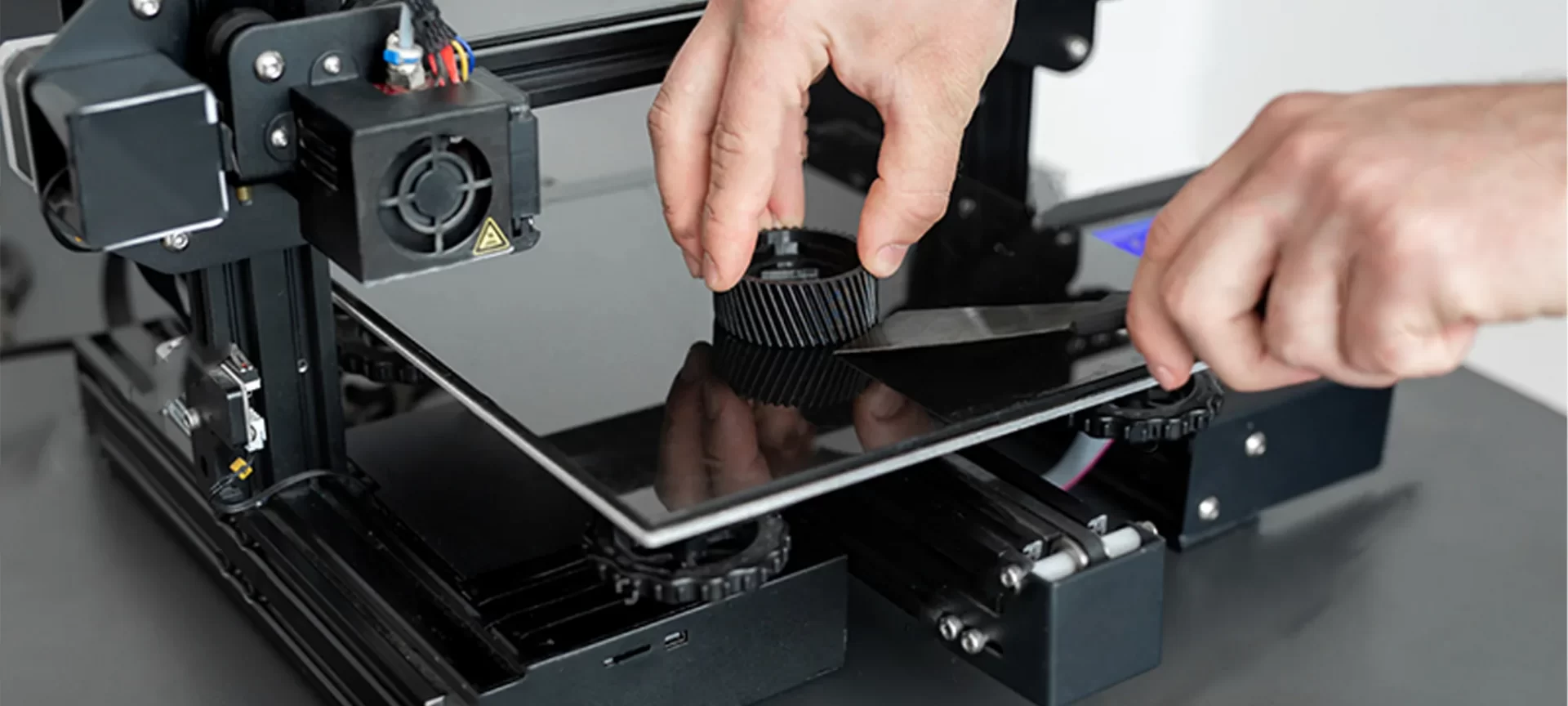

Why Do You Need a 3D Printing Glass Bed?

If you need an effortless print bottom, a 3D printing glass would be your best choice. It allows you to remove your prints very easily without any trouble, which means you would have no choice of error and it will not compromise the quality of your printed object.

Other surfaces may deform easily and destroy the look and quality of your prints and may need to be replaced every now and then. In addition, they are problematic when it comes to leveling which adds to the destruction of not only your print job but also the 3D printer itself.

Below are all the reasons why you need a 3D printing glass.

- Build Plate: You need to figure out the kind of build plate you need and that mainly depends on what you are going to print. Glass print bed has many advantages that you must know about.

- The flatness of the Print Bed: To eradicate any chance of errors, the print bed has to be flat. Since glass is naturally stiff and thermally stable, it stays flat and makes sure the leveling of the bed is consistent.

- Smooth Finishing: You would want the bottom of your printed objects to be smooth to the max and a glass print bed will give you just that. It gives a glossy, smooth base that you may not be able to achieve from other surfaces.

- Toughness: Many surfaces cannot be reused due to heating and contraction, such as acrylic or plastic bases often need replacement as they would start to warp, peel, scratch, or chip. A glass print bed rarely needs any replacements, which means you can enjoy making great quality prints for a relatively long period of time.

- Cost: Glass print beds are durable and do not require frequent replacements, which means you will not have to spend a lot of cash once you buy one.

- Simple Removal: Usually it takes force to remove an item from the print bed, which increases the chances of it breaking, damaging the item or the printer, and also poses the risk of you hurting yourself. This is why you need a glass print bed so you can remove the printed items without breaking a sweat.

- Easy Cleanup of Print Bed: Beds may accumulate dust, grease, and leftover plastic pieces that lead to an uneven and less adhesive surface. For that, you need to clean them often and glass surfaces are easy to clean due to their smooth and flat surface.

- Even Heating: The quality of your prints highly depends on how you have heated the print bed. Although glass beds take longer to heat up due to their lack of thermal conductivity, they do spread heat evenly and much better than other surfaces. This really helps in case you experience first-layer issues.

What to Look For When Replacing or Buying a Glass Bed

Listed below are some points you need to consider.

Size of the Print Bed

Your glass plate must match the size of your print bed. You will need the snug fit between your print bed and glass plate to eradicate any chances of wobbles while printing.

Perfect Thickness

As long as the glass is not susceptible to shock, it is a strong material. If you have a standardized bed, a 3- to 4-mm glass plate is ideal, as this particular thickness is enough to endure strength and spread heat.

By choosing a thinner glass plate, such as 1mm, the bed might be posed to cracking from high temperatures or an unforeseen contact with the hot end. In addition, the thickness has to be elevated according to the size of the print bed. For a large print bed, a thickness of approximately 6 mm is ideal.

Resistance to Thermal Shock

It is extremely important for a glass print bed to be heat-resistant. A glass plate may shatter or crack when exposed to abrupt changes in temperature that will sabotage your printing process. To avoid such accidents, you need a bed that will not fall apart when heated up to 200 °F and put into 40 °F water. To achieve this durability, look for glass beds that are tempered or borosilicate.

Resistance to Thermal Fatigue

Constant heating and cooling make the tempered glass gradually shed its strength. However, some types of glass are able to endure constant cycles of heating and cooling.

Overall Comments

Since print beds are exposed to high temperatures, you might want to consider getting a borosilicate glass plate.

Borosilicate is made of boron trioxide and silica, and resists thermal expansion and thermal shock, and will not change physically when exposed to high temperatures. You can purchase the right kind of borosilicate plates (size and thickness) from Amazon, MatterHackers, and others.

Conclusion

3D printing requires you to invest in the right kind of technology and machinery, and so it is important for you to carry out thorough research on what you need for your printing endeavors and the kind of project you are creating.

Make sure you know about the size of your print job, the kind of 3D printer you own, and its requirements. Fully knowing what you need for high-quality prints and a smooth, trouble-free printing process will help you avoid any problems and allow you to have fun while printing.

It is immensely necessary to have adequate knowledge about what you may need and that can be done by seeking help from a professional 3D printer you might already know, or you can look up different blogs and websites on 3D printing. An exceptionally large community of dedicated 3D printers or 3D printing enthusiasts will be happy to assist you.