What is DMLS?

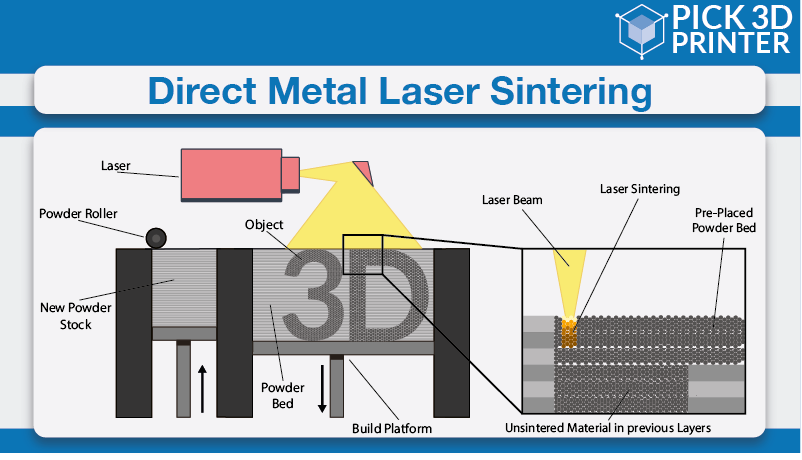

DMLS 3D printing is the ideal method for producing parts and prototypes using metal, especially when you are on a deadline. Direct Metal Laser Sintering, as the name suggests, involves the machine sintering layers using powder.

Advantages

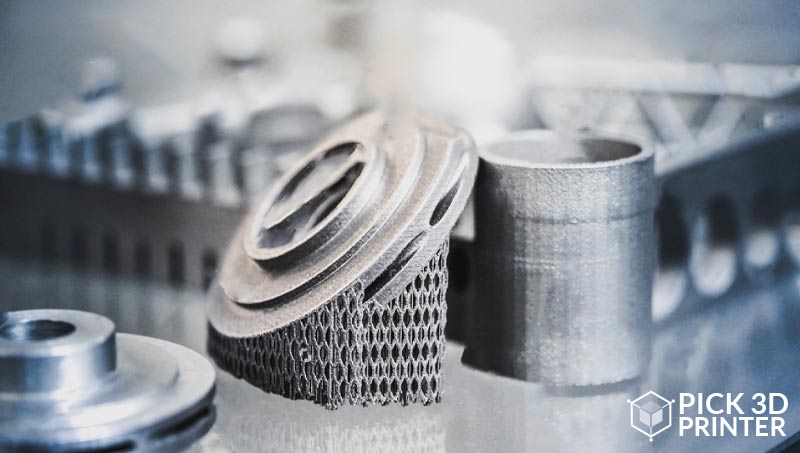

- Excellent for creating geometrically complex parts that require a great deal of customization. DMLS is an excellent alternative when other manufacturing methods are unable to produce parts with specific geometries.

- Can produce strong metal parts: the mechanical properties of the parts are far superior to those of binder jetting.

- Provides significant benefits by optimizing topology, reducing weight, and increasing the strength of rockets, planes, and cars; This is why 3D printing has become popular in Formula One, where milliseconds can mean the difference between a podium finish and glory.

Disadvantages

- In comparison to other technologies, DMLS has a small build size. Other technologies, such as FDM, can provide build sizes of more than 100cm3, which DMLS cannot match.

- DMLS is an extremely costly process. Metal 3D printers are all-industrial and can cost $250,000 or more. Furthermore, metal powders are exorbitantly priced. Binder Jetting is several times less expensive, but it is less accurate.

Where Is It Used?

The medical, dental, and aerospace industries all benefit greatly from the use of DMLS. Their parts frequently necessitate the use of exotic or high-performance materials. DMLS can create parts that traditional metalworking technologies simply cannot produce.

Medicine:

To replace bone fragments lost due to accident or disease, custom prosthetics can be designed and printed in materials such as titanium alloys. They have high strength, are immune to body attack, and the porosity promotes bone growth.

Dentistry:

Prosthetics, bridges, crowns, and partial dentures can be easily modeled and printed in high-strength materials such as cobalt chrome. The DMLS printing process provides quick access to custom fit, strength, and long-term durability.

Aerospace:

DMLS is an important part of reducing part count, creating complex geometries, and reducing weight while maintaining or increasing part strength and durability in the aerospace industry.

DMLS components range from simple brackets to complex turbine parts and probes in commercial aircraft and rockets. Complete rocket exhausts can be created.

Before investing in a DMLS 3D printer, it is critical to consider a few key factors so that you can select the best model. Here are some things to think about.

- What metal(s) or composites would you like to print?

- What mechanical properties are required for my final prints?

- Is speed and volume critical to my business?

Comparison Chart

| Name | Link | Nomination | Rating |

|---|---|---|---|

| 3D Systems ProX DMP 100 | High Precision | 9.6 | |

| 3D Systems ProX DMP 200 | High Efficiency | 9 | |

| 3D Systems ProX DMP 300 | High quality Material Printing | 9.3 | |

| EOS EOSINT M 280 | High Manufacturing Capability | 8.5 | |

| EOS EOS M 290 | Extremely Powerful | 9.1 | |

| EOS M 400 | Easy-to-use | 9.2 | |

| Renishaw RenAM 500E | Powerful Processing | 8.7 | |

| Velo3D Sapphire | High Production | 8.5 | |

| GE Additive Concept Laser M2 Series 5 | Repeatability | 8.8 | |

| LAR Technologies LAR100 | Affordability | 9.2 |

Best DMLS 3D Printers

3D Systems ProX DMP 100

The 3D Systems ProX DMP 100 is a professional DMLS 3D printer manufactured by 3D Systems in the United States. The ProX DMP 100 from 3D Systems is the smallest of the ProX DMP line.

The ProX DMP 100 operates with manual material loading and has an optional external recycling station. The ProX DMP 100 comes pre-loaded with 3D Systems software tools designed specifically for metal or ceramic manufacturing processes.

Uses:

- The ProX 100 Dental system allows you to use Direct Metal Printing (DMP) to create high-quality metal dental prostheses that dental laboratories can directly use.

- The ProX 100 Dental system, which supports certified Ni-free CoCr materials for dental use, is an excellent starting point for dental prostheses. To help you manage the manufacturing of fixed and removable dental prostheses, the ProX 100 Dental comes with a high-performance software solution.

- This smooth, user-friendly interface quickly guides you from dental file import to manufacturing file creation.

- With a build volume of 100mm x 100mm x 80mm, the ProX 100 Dental system is the smallest of the metal 3D printing systems.

- It has manual material loading and an optional external recycling station, as well as materials that can be manipulated safely.

- Increase productivity and dependability by creating metal dental prosthetics in a matter of hours.

- Make fully dense metal parts.

- Material wastage is minimized.

- Capable of producing parts that would not normally be manufacturable using traditional methods

- Parts that are extremely dense and non-porous

- Even on first-time builds, parts have consistently high accuracy.

- Expensive

3D Systems ProX DMP 200

The 3D Systems ProX 200 Dental DMLS 3D printer aims to produce high-quality metal dental prostheses for direct use in dental laboratories. The ProX 200 Dental is compatible with Ni-free CoCr materials for dental applications.

Uses:

- The 3D Systems ProX DMP 200 is a metal 3D printer that can print materials such as aluminum alloy, stainless steel, cobalt chrome, and others.

- The printer, which weighs 1500kg, is designed for use in industries such as manufacturing and dentistry.

- The printer is Windows 7 compatible and can print STL files.

- The DMP 200 can print large metal pieces thanks to its large build area of 140 x 140 x 125 mm.

- The ProX DMP 200 is ideal for high-quality, industrial-grade 3D printing because it is accurate to 50 m.

- No need for support structures as per the company’s claim

- Fully dense metal parts can be made

- Not affordable for a small business

3D Systems ProX DMP 300

|

The ProX DMP 300 DMLS 3D printer uses Direct Metal Printing technology. This 3D printing technique, also known as laser sintering, prints a part or functional prototype using a laser source and sintered powder material.

This printer can deliver high-performance and high-quality metal 3D printed part manufacturing systems by using less water during production. The printer is also known for its ability to produce extremely complex assemblies in a single part.

Uses:

- According to the company, this powder deposition system allows them to print parts and functional supports without the use of any support structures.

- The manufacturer claims that their application engineers have greatly enhanced expertise.

- It can hold a maximum build envelope of 250 mm * 250 mm * 330 mm. Furthermore, it can create dense as well as non-porous parts and functional prototypes.

- It is then followed by a reduced weight or lightweight design, which is an effective solution to the ongoing problem in the automobile industry.

- A large build volume

- Parts with high accuracy and functional prototypes

- Printing environments that are cleaner and safer

- Parts and functional prototypes can be manufactured using an integrated solution

- Creates objects that can be used in a variety of industries

- Cooling that conforms to the shape of the body

- Inserts for large tools.

- The printer is expensive, and it is unaffordable for a small business owner.

EOS EOSINT M 280

|

A long-term future in the field of 3D printing would not be a task that this DMLS 3D printer could not accomplish. It can provide a quick return on investment while also benefiting greatly. So, if you are thinking about doing business with a 3D printer, give this one a look.

Uses:

- There is an option for a stand-alone automatic powder-sieving station to be added to the printer.

- It is possible to control all aspects of printing during the construction process using the LPM that comes with it.

- The printer supports printing with a variety of powdered metal materials, each of which corresponds to parameter sets optimized in the printer for the application of that final part of a functional prototype.

- The printer’s entire system can be designed in such a way that it is a customer-oriented process.

- The printer includes PCM modules, which enable you to increase productivity, quality, and user-friendliness.

- The printer includes Integrated Process Chain Management (IPCM) modules, which enable you to increase productivity, quality, and user-friendliness, as well as some other features that can be added at any time.

- Laser with high power

- Monitoring of Laser Power with a Gas Management System

- Automatic powder sieving on its own

- Many people may be concerned about the printer’s price.

EOS EOS M 290

|

This DMLS 3D Printer has some incredible features as well as an excellent management system for monitoring and controlling every aspect of the 3D printing process. Therefore, if you are a professional in this field, this is a 3D printing system to consider.

Uses:

- Because the EOS M290’s design is robust, it can remain stable even while printing a part or functional prototype with a build volume equal to the maximum build volume that can be printed on this printer.

- CAM tool EOSPRINT allows for CAD data optimization, ensuring a quick and easy job and workflow management.

- You will be able to produce parts and functional prototypes of excellent detail solutions thanks to the high-power laser spot used in this 3D printing system.

- The EOS M290 3D printer has a maximum construction volume of 250 mm * 250 mm * 325 mm, including a build plate.

- It is possible to manage various aspects of the 3D printing process extremely well.

- There is no need for any support structures.

- Using this 3D printing system, you can create high-quality parts and functional prototypes for a variety of applications.

- You can select from a variety of 3D printing materials.

- When compared to other 3D printing technologies, the printing cost per part is quite high.

- DMLS parts are porous in comparison to other melted parts, and their porosity can be controlled but not eliminated during the 3D printing process during post-processing.

EOS M 400

|

The EOS M400 has an efficient system for creating parts and functional prototypes that can be used in a variety of industries. Although it will require a significant one-time investment to install it at your manufacturing facility, the 3D printing system will pay for itself by producing some of the most extraordinary objects.

Uses:

- The EOS M 400 DMLS 3D printer is useful for the production of complex metal parts. Nonetheless, the system is extremely simple to use. Touchscreen operation is quick and simple.

- For the EOS M 400 system, EOS offers an increasing number of metal materials. The system generates parts with standardized part property profiles using the corresponding Parameter Sets (PPPs).

- The Parameter Editor allows you to change parameters to meet your specific needs.

- Increased productivity as a result of its 1 kW laser

- Reduced non-productive time because of recoating on both sides

- Filter costs have been reduced because of the installation of a new recirculating filter system with an automated cleaning function.

- The EOS M 400 is made up of two parts: a Process Station and a Setup Station. This modular approach makes future innovations easier to incorporate.

- Its Extensive monitoring features raise the bar for quality management.

- Job planning and calculation are separated from the construction process: The job file that you prepared at your desk is transmitted over the network; the system is entirely focused on building parts.

- Material management and software systems that are sophisticated for ease of use and operation after, before, and during the 3D printing process

- Purchasing or leasing the EOS M400 necessitates a significant one-time investment.

Renishaw RenAM 500E

Renishaw’s RenAM 500E – Single laser (500W) Explorer system is an industrial DMLS 3D printer. Renishaw, based in the United Kingdom, is a manufacturer of 3D printers.

Uses:

- When loading powder into the RenAM 500E, the powder loading system will assist users. It assists the user in supporting the weight of a full powder flask while loading it into the powder silo at the top of the RenAM 500E system, reducing manual handling risks.

- RenAM 500S can be easily upgraded to a four-laser system to take advantage of higher build rates while maintaining finished part quality, increasing productivity, and lowering cost per part.

- The maximum build volume of this industrial AM metal system is 245 x 245 x 335 mm.

- RenAM 500S includes automated powder and waste handling systems that ensure consistent process quality, reduce operator intervention time, and ensure high system safety standards.

- Its intelligent gas flow ensures efficient removal of process emissions while also extending filter life.

- The single additively manufactured galvo mounting ensures the optical system’s excellent thermal stability.

- No need for any support structure

- Costly for a small business

Velo3D Sapphire

|

The Velo3D Sapphire “next-gen” metal 3D printer distinguishes itself as a volume production system with support-free 3D printing and a one-meter-tall build volume. The Sapphire can print in three alloys using dual 1-kilowatt lasers in its 315 x 1,000 mm print space.

Uses:

- Provides support-free geometries, which means the Sapphire can print with zero-degree overhangs – basically, flat surfaces on the horizontal plane.

- Aside from saving time on post-processing prints, the printer is capable of realizing internal channels and volumes without regard for support structures. It can print features that would otherwise be impossible to print.

- Microstructure control is just one of the advantages of Velo3D. It enables the construction of previously impossible designs as well as the improvement of part-to-part consistency.

- The parts meet or exceed metal manufacturing density requirements by more than 99.9%.

- The Velo3D solution reduces the need for supports by 3-5 times the typical support volume.

- Microcontrol structure

- Great build volume

- Expensive

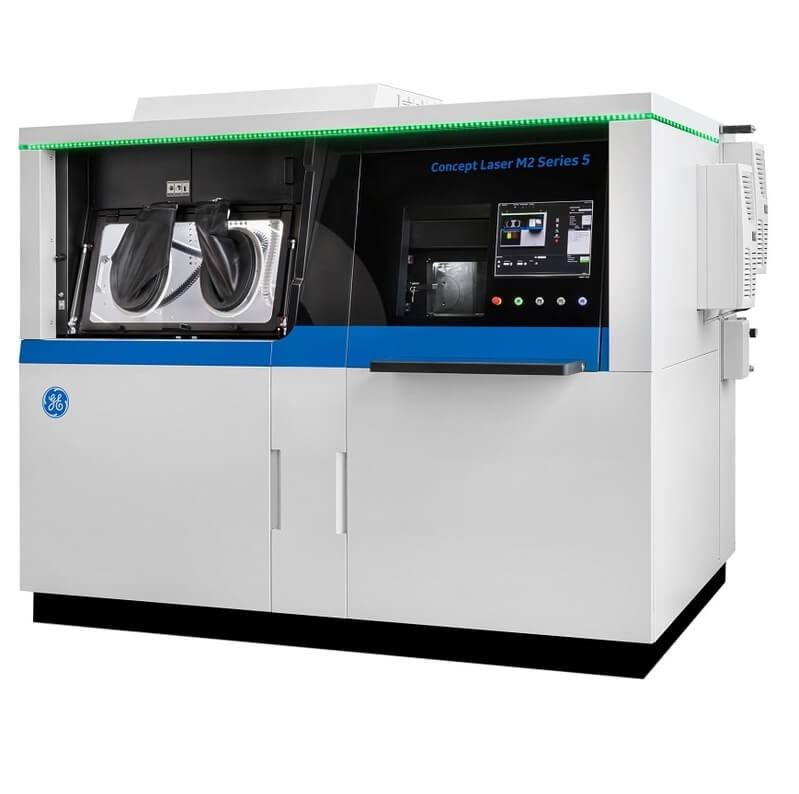

GE Additive Concept Laser M2 Series 5

GE Additive’s Concept Laser M2 Series 5 is an industrial DMLS 3D printer. GE Additive, based in the United States, is a manufacturer of 3D printers.

Uses:

- The build volume of this industrial 3D printer is 245 x 350 x 350 mm.

- features Full overlap 400W or 1kW dual-laser system

- This printer’s improved gas flow system has made working with it a breeze. Powder exchange and inert sieving

- comes with pre-calculation software, which saves time when working with complex parts

- The QuickStart feature will save you time.

- M2 Series 5 optimizes speed and productivity, as well as part-to-part and machine-to-machine consistency, reliability, uptime, and quality control.

- Offers good printing speed

- Not easily affordable

LAR Technologies LAR100

LAR Technologies, a DMLS 3D printer manufacturer based in Saint Petersburg, has launched the “first truly affordable machine for 3D printing metal.” This “unique engineering firm” creates and manufactures equipment for small and medium-sized businesses. It claims to be able to create equipment of any complexity or specificity, and its latest machine is no exception.

The LAR100 3D printer is priced at €69,900. Although this is a limited-time offer, the price is significantly lower than that of many similar metal 3D printers on the market.

Uses:

- Cost-effective machine

- 200W IPG Photonics laser with a construction speed of up to 15cm3/h

- You can upgrade to a 1kW source for an additional fee.

- Other potential features offered by the manufacturer include AI visual coating control, a two-way coating system (which reduces production time), and an auto powder recycling system.

- The 200W IPG Photonics laser is compatible with third-party materials

- Free and open-source software

- Construction that is modular

- argon gas Atmosphere.

- Expensive for a small business.

Buying Guide

Direct Metal Laser Sintering (DMLS) is the most popular 3D printing technique for producing fully dense metal parts and components.

DMLS is an additive manufacturing process that melts designs in layers sequentially. When starting a project for DMLS 3D printing, it is critical to remember a few key design facts to ensure you are optimizing your part for the process.

Speed and Volume

If speed is important to you, look for a printer that produces such a smooth finish that it does not require any post-processing. Furthermore, if you want to print multiple metal parts at the same time, choose a printer with a large build volume.

Accuracy and Print Quality

Carefully review the machine specifications to ensure that it has all of the features that will ensure impressive precision and unrivaled quality.

Support Structures

It requires support structures that must be removed during post-processing. Most 3D printing processes necessitate the use of support structures. Support material can be the same material as the final build, as with DMLS, or it can be a separate specially formulated material that is easily released from the final part.

Support structures are required during printing for a variety of reasons, including ensuring accuracy while a part is curing or hardening, as well as maintaining tolerances and shape for delicate features.

In the case of DMLS, once sintered, the metal becomes denser than the surrounding unsintered powder and can thus sink through the powder and break off the part or otherwise warp in the absence of support structures.

Because DMLS metals are melted at extremely high temperatures, DMLS parts can also suffer from “burn” (melt deformation) when delicate features are left unsupported. It is recommended that any angle less than 45° includes supports, and that wall thickness (while geometry varies) maintain an 8:1 thickness-to-height ratio.

Internal Features

While DMLS is preferred because it allows for the construction of no-access features, enclosed designs may still necessitate support structures that can become trapped within a part. It is recommended to incorporate gradations between features to eliminate the need for interior features.

Frequently Asked Questions (FAQs)

Are DMLS Components As Strong As Traditional Metal Components?

Yes. The mechanical properties of DMLS parts are comparable to those of cast metal parts. The DMLS materials page contains more information.

What Are Some Of The Current Metal Printing Technologies?

Metal 3D printing is rapidly evolving, and new technologies are being introduced on a daily basis. It includes various technologies from which you will have to select depending on the project that you are working on. Some of these methods are as follows:

- Binder Jetting

- Low wax casting

- Direct Metal Laser Sintering

- Bound Powder Extrusion

- Selective Laser Melting

- Fused Deposition Modeling

SLM and DMLS are the most popular metal 3D printing processes today, and they are especially well suited for high-end applications.

Are DMLS 3D Printers Overpriced?

Although certain metal AM systems are only affordable to large enterprises due to their high costs. However, other companies, such as Markforged and Desktop Metal, equipped their systems with more cost-effective components, making them more affordable for small businesses.

How Porous Are DMLS Components?

DMLS parts have a density of 99.5 percent. In fact, 3D printed metals outperform industry density standards.

What Level Of Detail Can DMLS Provide?

DMLS is available in a variety of resolutions. The layer thickness is 0.0008” – 0.0015” Z at its highest resolution, and the X/Y resolution is 0.012” – 0.016”. The minimum hole diameter ranges from 0.035” to 0.045”. To learn more, consult the DMLS design guidelines.

Conclusion

3D printers have quickly become commonplace in both the workplace and the home. 3D printers can create impressive objects from a wide range of materials, from small toys to machine parts. Due to the numerous types of devices and complicated printing methods, purchasing a DMLS 3D printer can be a daunting task.

The best place to begin is to decide what you will print and how frequently you will print it. These factors are important in determining the best machine for you and can help you understand the many different specifications of 3D printers.

DLP 3D printing has been one of the most notable developments in the AM industry in recent years. As technology has advanced, it has proven to be far superior to traditional methods. Although DLP 3D printing is an expensive option, we cannot deny that it can add a lot of value to the manufacturing process by allowing us to make parts that were previously uneconomical or design prohibitive.