Formlabs 3D printers are a choice of more than 50,000 professionals for developing amazing products used in daily life. When looking for reliable printers with professional results, Formlabs is the name you can blindly trust!

Formlabs designed printers that marked high standards of 3D printing for fulfilling all printing needs, in each business worldwide.

Formlabs printers provide you ease in selecting the one that best suits your workspace. They are available for benchtop as well as for desktop use.

The professional results drive-by every single printer of Formlabs is guaranteed and the golden point is that they don’t even fall heavy on your pocket!

Formlabs is a name trusted by professionals. The company has a wide range of accessible 3D printers. You might be thinking about which one will work best for you?

Don’t worry! We have done this hectic task for your ease by carefully selecting the five best Formlabs 3D printers so that you can get your best pick right away in your workplace or home!

Comparison Chart

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| Formlabs Fuse 1 | Industrial-Grade printer | 9.5 | |

| Formlabs Form 2 | Powerful & Reliable | 9.3 | |

| Formlabs Form 3 | Industry Leader | 9.7 | |

| Formlabs Form 3L | Plug & play printer | 9.8 | |

| Formlabs Form 3B And 3BL | Dentist's pick | 9.6 |

List of Popular Formlabs 3D Printers

Fuse 1

|

Formlabs’ Fuse 1 helps people by bringing their dreams to reality. The printer marks a leap forward in reliability and print quality. Fuse 1 is a smart choice for small businesses when doing SLS 3D printing with industrial quality.

It is a compact Selective Laser Sintering (SLS) 3D printer, offering high-quality prints at its price point. It reduces the cost of its equipment, uses affordable materials, and requires minimal upkeep.

Salient Features:

- Fuse 1 has a build volume of 6.5 x 6.5 x 11.8 inches. With this great build volume, you can build models used in industries of medical and aerospace. None of the SLS printers ever had build volume like the Fuse 1 has.

- It has a removable chamber; you can remove the part on which your model is printed and can take off your model with ease without damaging the print.

- In SLS, powder of printed material is applied on the print bed, and 50% of this powder can be recycled. This saves overall printing cost too.

- Its working dimensions are 677 mm x 668 mm x 1059 mm.

- The Fiber laser with a wavelength of 1066 nm and 10-Watts Power is used for curing materials. The spot size is 200 microns.

- It can print using only the powder of Nylon PA 12 and a minimum layer thickness of 100 mm, you can create prototypes and end-use parts easily.

- Fuse 1 has a massive build volume for creating larger models. This compact SLS 3D printer combines advanced features. Print size offered by Fuse 1 in its price range was never available before in SLS 3d printers.

- It uses the most user-friendly slicing software i.e. PreForm.

- Larger build volume

- Printer comes assembled

- Available at affordable price

- Consist of a removable chamber

- Complex geometries can be created without support

- Print speed is not fast

Form 2

|

Formlabs’ Form 2 is a smart combination of affordability and professional 3D printing. It is one of the best and most in-demand Formlabs’ 3D printers. It prints a sturdy model with precise detailing and a stunning surface finish.

Form 2 is a reliable SLA 3D printer with an affordable price tag.

Salient Features:

- Form 2 has a print bed of 145 x 145 x 175 mm providing good space to print with high precision.

- Print layer resolution of 25-100 microns

- Custom galvanometers manage a high-powered laser for printing models with exceptional details

- Form 2’s integrated resin system helps you to manage and clean materials easily

- You can import STL/OBJ files into PreForm software after designing your model in regular CAD software. PreForm’s one-click feature will automatically orient, support, and layout your 3D model.

- The sliding peel mechanism removes the printed model gently from the print bed

- Resin is warmed to a consistent temperature with a responsive heating system

- For getting desired mechanical properties and results, the SLA parts are rinsed and post-cured with IPA

- Smart resin system automatically refills the tank when running short

- It has four integrated sensors to help in maintaining and detecting ideal printing conditions.

- Form 2 takes time to print, but it’s worth the wait as it makes high-quality objects. It has a removable print platform and the resin tank is also easy to replace. It can be easily managed and used.

- Reprint previous jobs efficiently

- Send prints over Wi-Fi

- Produces high-quality results with limited time and effort

- 24/7 online support

- Best for small scale production

- 3rd party resins can be used

- Printed objects require cleaning

- Materials and printer is little expensive

Form 3

|

If you’re looking for a printer that requires little effort and gives professional results, needs minimal maintenance, and is easy to learn, the Formlabs Form 3 is the right choice for you!

Form 3 works with a variety of materials and can be controlled by a touchscreen. Its PreForm software is easy to use and editing models, changing their settings with it is super easy.

Salient Features:

- Form 3 has a larger print area of 5.7 x 5.7 x 7.3 inches and gives good volume, so you can get decent-sized models.

- Form 3 is a Low Force Stereolithography (LFS) at the bottom it consists of flexible plastic, which makes printing reliable as the printer uses limited force to lift the hardened layer.

- It has a print bed on top and at the bottom; it has a removable resin tank to hold liquid resin during printing.

- Form 3 prints model layer by layer, for printing each layer the build platform is lowered to this transparent layer. There it traps in a thin layer of liquid resin.

- The UV laser of 85 microns burns resin and makes it stick to the bed. So, layer by layer, it builds the model slowly.

- It can print up to 25 microns on the XY axis and 25 to 300 microns, which can be set manually on the Z-axis. Prints are of higher quality, smoother surface, organic curves, and are crisp.

- Form 3 gives you a decent size to create 3D models; it is a reliable combination of features necessary for hassle-free 3D printing.

- Friendly user interface

- Can withstand print failures

- Supports a wide range of materials

- The printer automatically fills the resin tank

- The dashboard sends a message to the cell phone upon print’s completion and if it needs maintenance

- Supports parts and materials from Formlabs only

- Expensive if you do 3D printing as a hobby

Form 3L

|

Form 3L allows you large format SLA 3D printing that enables you to bring 3D printing in-house instead of outsourcing. With it, you can bring everything that comes to your mind into existence!

It is powered by Low Force Stereolithography (LFS) Now you can push your 3D printing journey even further with Form 3L, which truly casts magical spells by developing great products.

Automation features of Form 3L deserve a huge shout-out! It does most of the work itself. The huge build space allows you to use a lot more resins.

The build volume offered by Form 3L was never available before in this price range.

Salient Features:

- Form 3L comes with a massive build volume of 13.2 x 7.9 x 11.8 inches, which is 5x the size of Form 3. It provides you with enough space to create larger models.

- The automatic dispenser on the side of the machine refills the resin tank. It can add up to two cartridges, which will dispense automatically when needed. Therefore, your machine doesn’t need to stop and wait for you to manually replace the cartridge and fill the resin tank.

- Form 3L provides you with ease of use. It uses PreForm for slicing files and sending them over to your machine. It uses the same material portfolio and resin cartridges as Form 3.

- It offers great flexibility. Two staggered Light Processing Units (LPUs) with twice the laser power of Form 3 helps you take the advantage of the large build volume to print big parts.

- An enclosed laser system uses special filtering and for uniform illumination across the build area, a parabolic mirror is present.

- Form 3L offers good print space to work. The automation features make 3D printing fun and save a lot of your time in which you can watch your favorite Netflix show, go swimming or perform any important task.

- Supports two cartridges, with which the machine automatically fills a resin tank

- Easy to switch between materials with an auto-dispensing resin system

- Allows you to print batches of smaller parts much faster than Form 3

- Consistently delivers flawless prints

- Huge, but worth it

Form 3B and Form 3BL

|

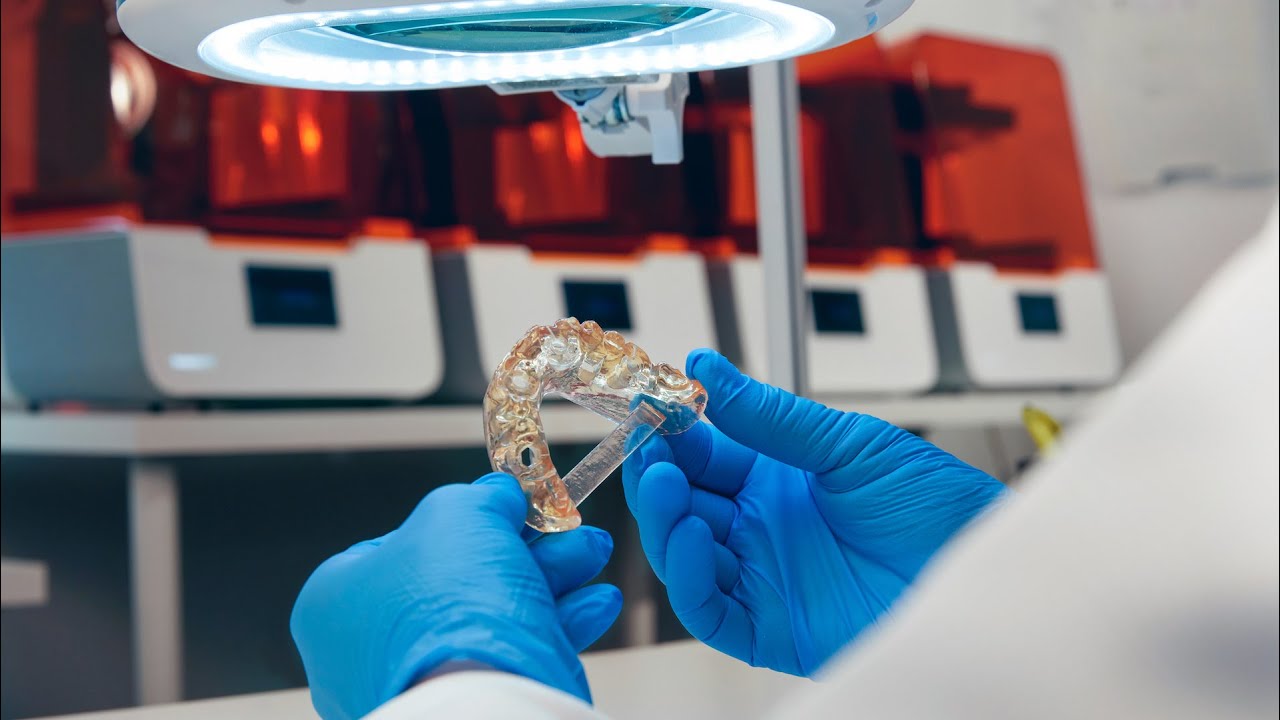

Formlabs’ Form 3B and 3BL are specially designed to manage your digital workflow of dentists, orthodontists, lab managers,s and technicians. Both use LFS technology.

They allow you to work hassle-free, save your time and help you in carrying out dental practices efficiently for faster and better clinical outcomes.

Salient Features:

- The build volume of Form 3B is 5.7 x 5.7 x 7.3 inches while Forms 3BL has a comparatively larger build space of 13.2 x 7.9 x 11.8 inches.

- XY resolution of 3B and 3BL is 25 microns, and a laser spot of 85 microns allows the printer to print precisely and speedily.

- The layer thickness of 3B and 3BL ranges from 25 to 300 microns.

- Easy to use PreForm software helps in preparing your part with ease by integrating CAD solutions and existing images

- Form 3B has a single resin cartridge while 3BL has two resin cartridges, for avoiding printing interruptions.

- Build plate and resin tank can be easily replaced, making it easier to change materials.

- LFS technology gives an optimal performance with dental-specific or other biocompatible materials.

- Smart sensors in printers help you monitor progress and address potential issues promptly.

- Isopropyl Alcohol (IPA) washes and post-cures printed parts and prepares them for use at the finishing station.

- Auto-Generated Light Touch feature helps remove support structures easily.

- With Form 3B and 3BL, you can do affordable chairside 3D printing of biocompatible products. Creating surgical guides, models, aligners, splints, etc isn’t a headache for Forms 3B and 3BL.

- Prints objects of high quality and clarity

- An interactive touch screen of 5.5 inches helps in switching between options easily

- They inform progress and alert issues through SMS/email

- Contains speakers for audio alerts

- Best if used by professionals

- Not a home-hobby printer

Buyer’s Guide

A great number of 3D printers are available in the market with promising performance. Below are a few features you should check before purchasing for carrying out your 3D expedition smoothly!

- Large Build Volume: Print space matters a lot in 3D printing. It varies depending on your needs, either you want to print larger models or batch print miniatures.

- Resolution and Speed: You should not compromise on print resolution! It is measured in microns. The smaller resolution does printing with better detailing. The speed of a printer matters when 3D printing is part of your profession, but if you are doing it as a hobby, you neglect this factor.

- Supporting Filaments: You need to know the materials you want to print using a particular filament. Get the printer that supports your desired filament/filaments.

- Easy Removal of Printed model: Do ensure that you can take the print off from the print bed or you will need a toolkit to remove it and eventually end up damaging your print.

- Helping Online Community: Responsive online support plays a great role! Make sure the community of people who owns the printer values their users and are available to put forward a helping hand, as gadgets can mess up anytime!

It’s better to be safe than sorry. Not checking upon the above-mentioned features may turn the fun of 3D printing into a tiring workload!

Frequently Asked Questions (FAQs)

Which Is Better: PLA Or ABS?

PLA and ABS are thermoplastics that freeze upon cooling and are soft & malleable when heated. PLA is best for creating household items; it cools quickly and gives a glossy look to printed objects.

While models built with ABS take longer to cool, PLA models may deform at high temperatures because of their low melting point where ABS has a comparatively higher melting point.

PLA is not the right pick if you are creating interlocking parts and you should consider using ABS because of its flexibility.

Is 3D Printing Safe?

Frankly, 3D printing isn’t a game. As you are playing with highly heated materials, if you have a printer with an extruder, their print bed has a high temperature and can give you bad burns if not handled carefully.

Does 3D Printing Emit Fumes?

Yes, it does. Particularly if you’re using ABS plastics, you should expect fumes. It’s better to keep the 3D printer in a well-ventilated room.

Conclusion

As mentioned, each printer has features that are worth appreciating and has a few pointers that might require improvement. Your purchasing intent helps you to get the best one for getting your desired results!

Forms 3 is the best fit for getting easier post-processing and a better surface finish. It balances speed and detail perfectly. It’s a bit expensive, but 3D printing professionals agree its cost is worth the time it saves and the features it provides.

Forms 3L gets you into the shoes of professionals! It does most of the work for you and requires minimal intervention for printing. It doesn’t require tweaking like other SLA printers with an advanced print process to adapt the geometry of parts.

Fuse 1 is best for small-scale businesses. It requires minimum maintenance. It offers high-quality prints in its price range. It comes assembled, you just need to plug it in and start printing!

Form 3B and 3BL are magic wands of dentists! They have an audio alert system. It generates detailed prints with unquestionable clarity at great speed. They’re designed to work 24/7 you just need to hit print.

Form 2 can literally start printing objects right after taking them out of the box. It is known for producing parts with high precision without compromising on speed.

Results-driven by Formlabs 3D printers are incomparable with any other printer on the market. Formlabs know that prints without desired quality hold their place in the trash bin. That is why they’ve developed 3D printers offering high-quality prints with an affordable price tag offering every feature to make 3D printing fun and easy. Formlabs 3D printers never fail to steal the show!

Happy Printing!