Stereolithography or how it is popularly known, SLA is the 3D printing technology that emerged in the 1980s. Before this technology came into existence there was FDM i.e. Fused Deposition Melting into place.

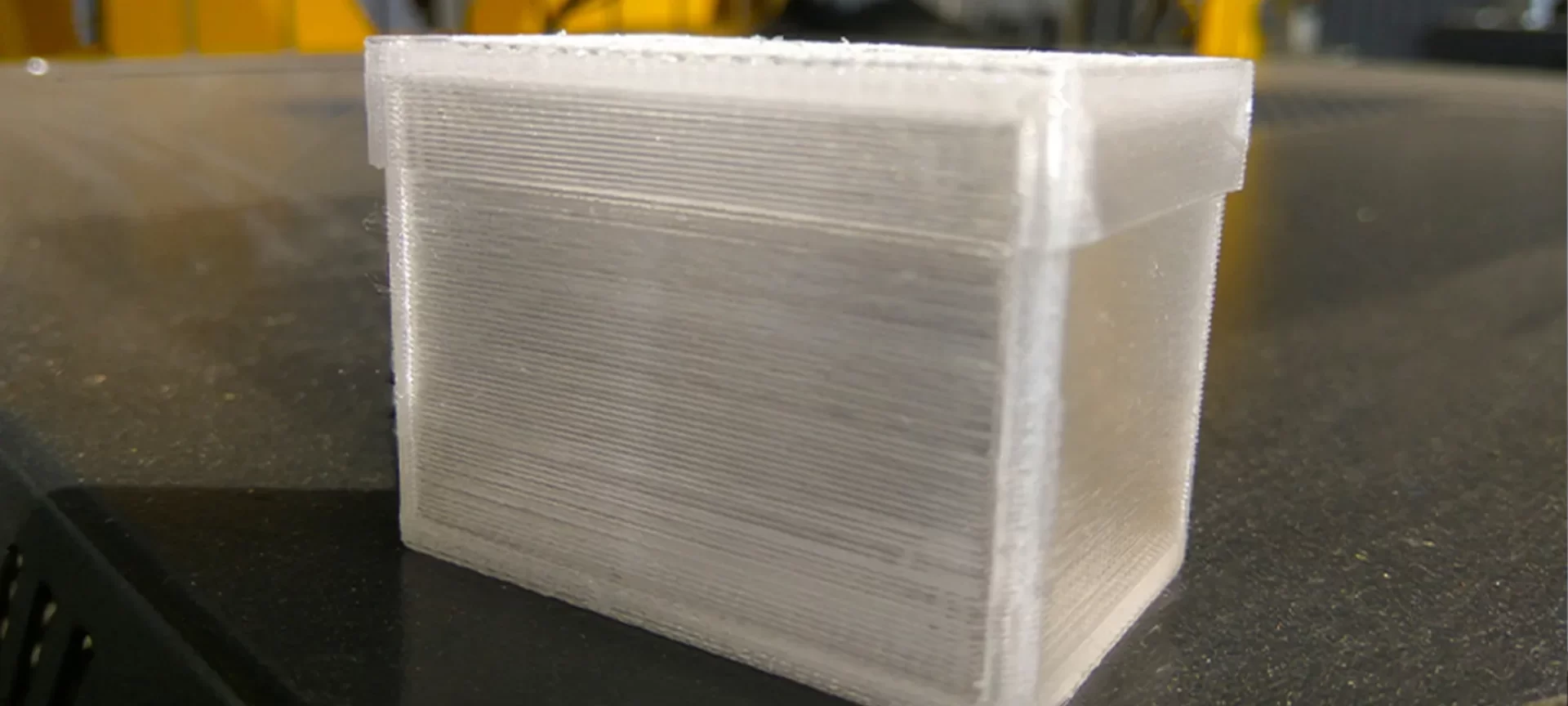

The problem with Fused Deposition Melting was not that it wasn’t able to produce parts and functional prototypes of huge build volume, it was with the quality. Manufacturers using this technology to 3D print parts and functional prototypes weren’t satisfied by seeing layers visible on the final product.

That’s when SLA came into being. It’s a 3D printing technology and like every other 3D printing technology the objects can be generated out of a prototype.

Different 3D printing technologies have different ways in which prototypes can be generated and hence the parts or functional prototypes from them. In this article, we are going to put in front of you information about making SLA prototypes.

Prototypes are the starting step of any 3D printing technology. If you do not have one, you are never going to manufacture a part, even if you own an expensive 3D printer.

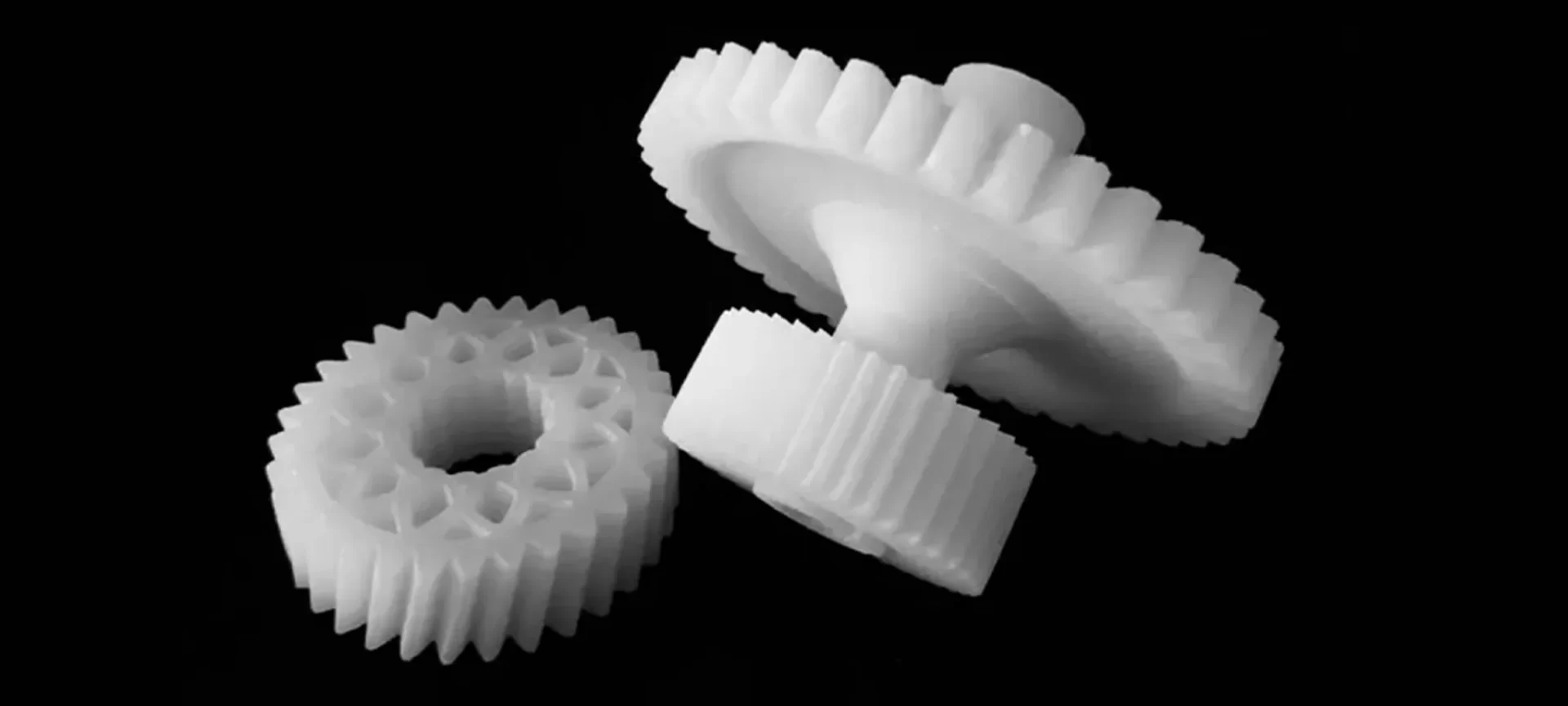

SLA, since its inception, has been able to quickly and accurately generate complex geometries with dimensional accuracies like never before. And this is something that led to the increase in popularity of this technology.

When it comes to making an SLA prototype, everything starting from the SLA resin, part or functional prototypes layer thickness and resolution, other considerations, and ways in which you can finish plays a part. But for all those who are new to 3D printing or SLA in general, let’s first start by talking about how this technology in brief.

How Does SLA Printing Work?

SLA falls into those class of additive manufacturing processes which rely on lasers to do the heavy lifting part. Some other technologies which do the same are Selective Laser Sintering and Direct metal laser sintering.

Parts or functional prototypes that you wish to build by this technology are made by curing resins of liquid thermostats that are paper-thin. An ultraviolet laser turns the material from a liquid resin into a solid layer which is one of the many building blocks for the part.

As soon as one layer is built, the printer gets to know by its coding and moves. This mechanism of the printer then spills over some more resin over the layer and the laser is again employed to solidify the new spilled resin into another part.

The same is repeated until you get to see the part or functional prototype that you were willing to build. After the building of the object is completed, you need to do a little bit of post-processing usually in all the SLA 3D printers.

This includes cleaning of the part, removing it and all. But before that, the laser is again employed on the complete part which will solidify the outer surface completely and add any other surface quality which wasn’t there otherwise.

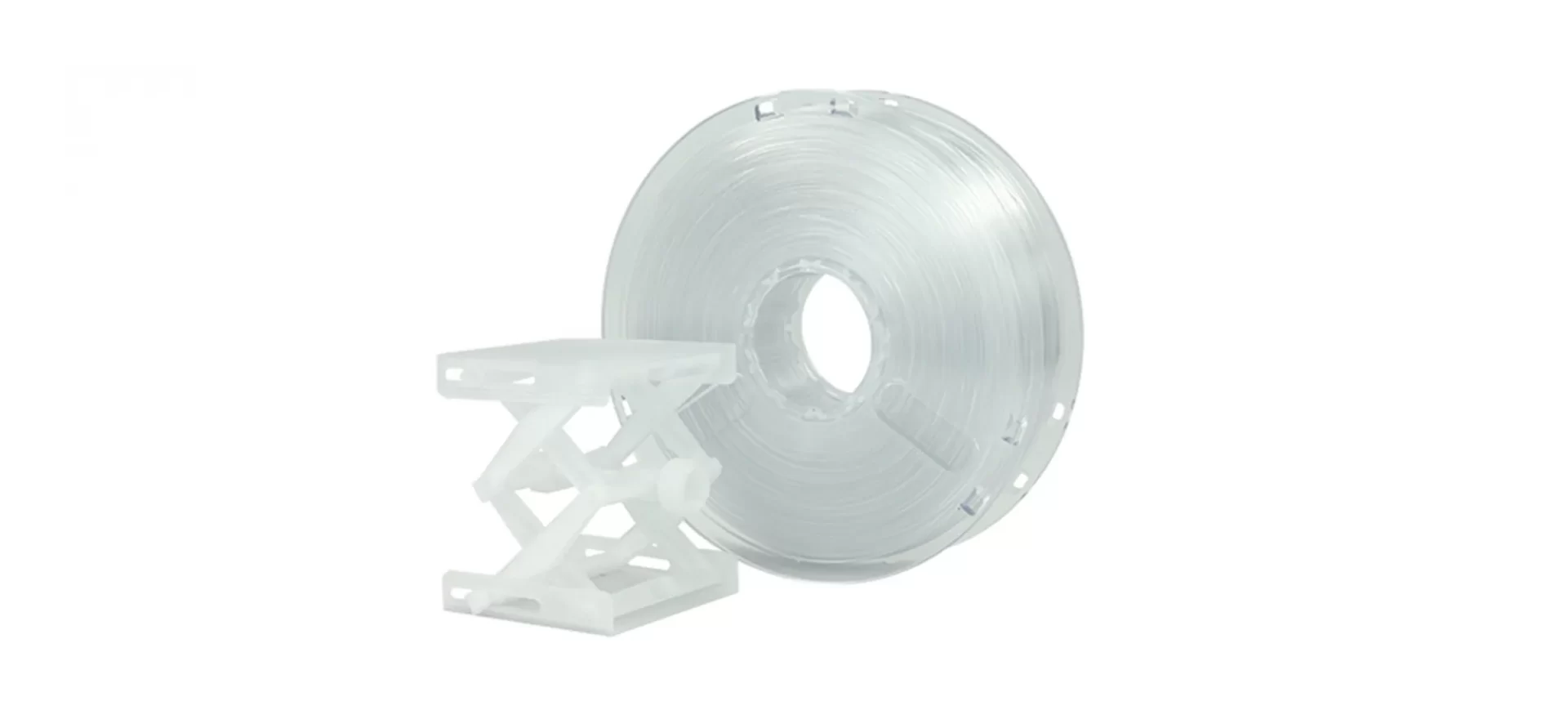

This is the SLA process in general, now you should know a little bit about the SLA resins which are going to be converted into the parts or functional prototypes for real.

So, we have tried to explain in the next section about the names and characteristics of those resins. For making an SLA prototype this is the first decision that you will have to make i.e. to choose a resin. By knowing the properties of various materials you will be able to do this at ease.

SLA resins

The range of materials that can be used as SLA resins has evolved since the invention of SLA 3D printing technology. Today a lot of SLA 3D printers like thermoplastic can be chosen to print from.

You can even add some flavors for copying the polypropylene, ABS, and glass-filled polycarbonate that are very popular materials in the market. Below mentioned are some of the most common resins and their properties after reading which you can decide which one you wish to make an SLA prototype with.

Polypropylene

With FDM 3D printers, the material that is one of the most popular is polypropylene. This is the resin form of the same. So it carries almost the same properties that the stiff version has i.e. it is flexible, it is durable and can withstand high temperatures.

Polypropylene is great when used for creating fine detailing in parts and functional prototypes. The point to note here is that, if you use stiff polypropylene which is a famous material for FDM 3D printing technology, it won’t give you the same accuracy as the resin polypropylene.

You can manufacture sharp corners in parts and functional prototypes, also thin walls and small holes. Detailing which is otherwise not easily available even after using other materials can be made available with this material.

Polypropylene/ABS Blend

ABS an abbreviation for another most popular material for 3D printing of parts and functional prototypes. This resin can be a mixture of both polypropylene and ABS.

In looks, the resin appears to be white plastic that is similar to CNC machined polypropylene/ABS blend. Overall, it is a strong material and can be used to manufacture parts and functional prototypes like snap-fits, assemblies, and other demanding applications.

Because it is a mixture it has combined strength which depends on the type of mixing that has been done. The strength of CNC machined polypropylene/ABS blend is something that most manufacturers are familiar with and is no new.

Imagine if something like that can be in liquid form and an object can be made out of it using 3D printing technology? That is exactly an SLA prototype generated for this material that would enable you to do.

ABS

If you are new into the field you can get an idea about the popularity of this material by asking someone who is in the field of 3D printing. ABS is extremely compatible with 3D printing technologies as well as 3D printers.

This resin mimics ABS in terms of being clear material, less viscous. It looks like black colored plastic that blocks almost all the visible light.

The rule is applicable even when you make thin sections or clearer parts and functional prototypes. You can get to see this property even with colorless SLA prototypes as well as water-resistant materials.

ABS is a plastic that is good for lenses and flow-visualization models, it is a green micro-resolution resin that enables the manufacturing of parts and functional prototypes inhibiting extremely fine features of complex geometries and let you get dimensional accuracy in the same.

Polycarbonate & SLArmor

Polycarbonate is material is full of ceramic and strength-providing. The material is known for its stiffness and temperature resistance, but don’t get any assumptions that this material cannot be brittle.

SLArmor is a nickel-plated material that is known to give SLA prototypes very much strength and toughness associated with die-cast aluminum.

The thing to note here is these are thermoplastic-like and not completely thermoplastic. There is a distinction when we talk about the mechanical properties of the two.

However, do not get any misconceptions about SLA prototypes just because they are made out of liquid resins. You can pound hammer on the material made from SLA resins, they would provide the same strength and durability as the parts that were sintered, cast, machine, or molded. It is this quality of SLA 3D printing that makes it a more convenient choice for developing functional prototypes.

Layer Thickness and Resolution of SLA Prototypes

Although there is a considerable amount of difference in the mechanical and thermal properties of the materials that are used to make parts in FDM technology and SLA technology, SLA is a winner in terms of the accuracy that it can provide on the final object.

The parts and functional prototypes manufactured using SLA technology have an amazing surface finish. Resins used for making them provide layer thickness ranging anywhere from 0.004 to 0.001 inches.

This level of layer thickness means that you almost need a microscope to see the layers that have built the object. FDM on the other hand manufactures parts and functional prototypes but cannot guarantee you any layer thickness even closer to what SLA does. It is this fine detailing in SLA prototypes and the presence of cosmetic surfaces that has made it popular in front of the final user.

Now that we have been talking about the kind of accuracy this technology provides, you might think that there must be something wrong with the kind of build volume it provides. But that’s not the case.

SLA prototypes are known to manufacture parts and prototypes with huge build volume as well. The average huge build volume using SLA printing is 736 mm * 635 mm * 533 mm. From huge to micro, SLA is an excellent choice for microfluidic devices. We see its applications in fields where accuracy and fine detailing is of utmost importance.

After choosing the correct type of resin, you need to choose the targeted layer thickness. This is another important thing to ponder upon and its answer needs to be matched with the area of application for which parts and functional prototype manufactured using this technology are going to be useful.

Now let’s look at some of the other considerations for making SLA prototype.

Other Considerations for Making SLA Prototype

After you have taken into consideration the layer thickness, you need to take care of small things that make a huge difference. Extremely small holes are advised by the experts to be avoided. A technical reason which is given by them is simple and easy to understand.

They say that since the material with which you are building the part or functional prototype is liquid, it is of relatively high viscosity than a solid part, so it can pose huge challenges for small holes during the printing process is going on.

The other thing which demands special attention just like small holes does is thin walls. In practical application, if you are developing a hair strainer, you are advised to not keep the holes in it smaller than 0.004 inches.

Whereas if you are developing a sandwich container, make sure you do not have walls thinner than 0.003 inches.

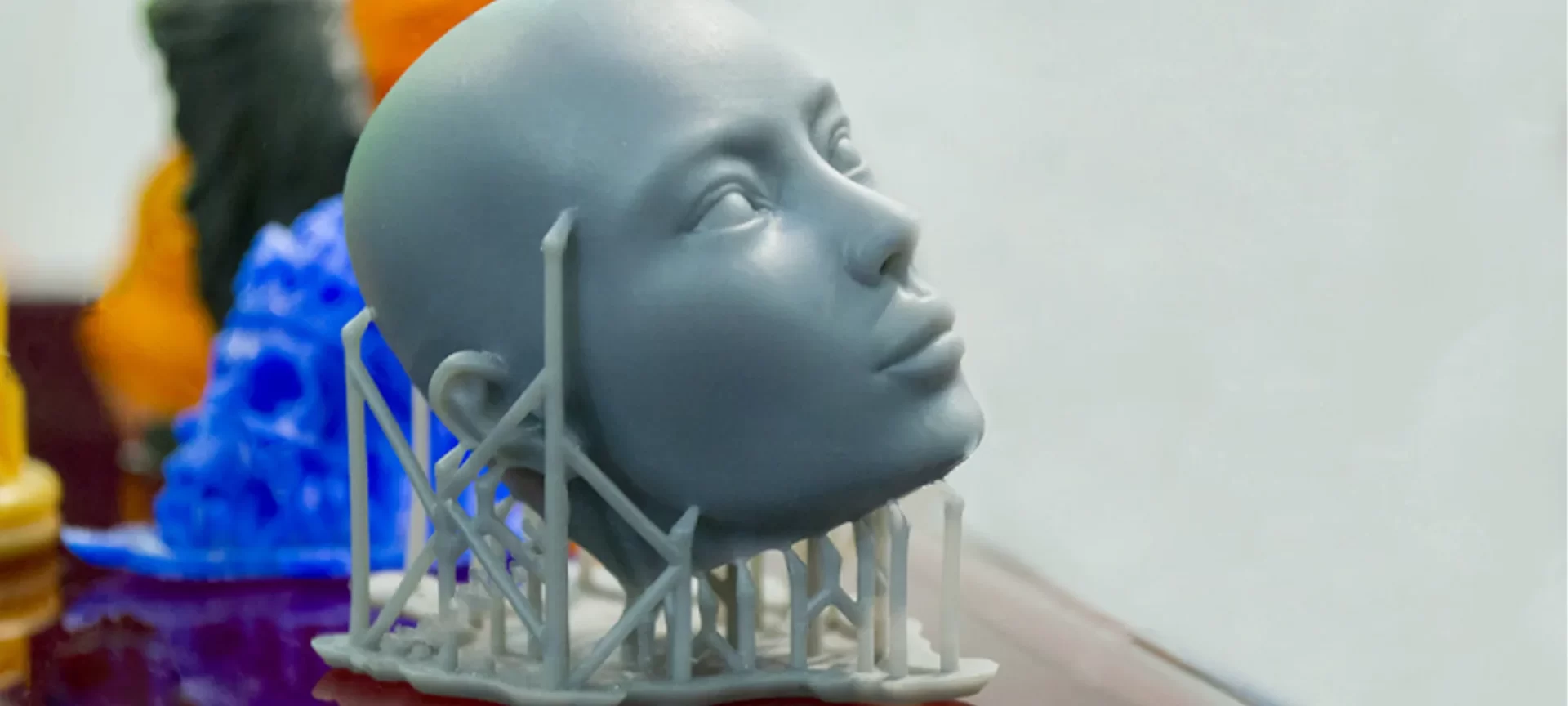

The other point to note here is about the support structures. You might have to create them while printing some parts or functional prototypes but will have to remove them before delivery.

This can affect the cosmetic appearance just as the orientation of the workpiece for facilitating a better build does. So, if certain cosmetic features are to be taken care of, which you think are going to affect the overall surface finish of the part or functional prototype, it’s better that you mention them while making the design of the SLA prototype.

Options in Which you Can Finish

If you talk with most of the customers, they would like light sanding done on the part or functional prototype that they want.

There are also some websites that suggest sending the final part as it is just to let the customer know what support structures you have used, but that is advisable only for customers who understand this technology and not with all.

Coating choices available here are all to do with painting and masking. Painting typically is recommended for all the parts, because not everyone wants to see the part in the same color of the resin from which it was made.

The Conclusion

STL is the most common extension for SLA prototype files, it is universally accepted. Overall what the SLA prototype does is, builds a gap between the imagined object and the real one and it tries to build the shortest one. It enables you to feel and touch the object that is very close to the image you’ve had before making it.

While making any prototype, always look to avoid mistakes that can cost you, these resins are very costly so maintain them how their manufacturers have instructed you to. That’s all the advice we have for you.