3D printers are extremely interesting and innovative. We always fantasize about different objects in our minds. We could always draw them out on pen and paper but they would never turn into reality.

3D printing is more like magic. It lets you create a physical object from a digital model. All a person needs to do is to make a design, transfer the file to a 3D printer, and there you go. You bring your object to life with such little steps.

A 3-in-1 3D laser printer does not only print an object but also laser cuts it. It offers handyman adaptability across 3D printing, CNC machining, and laser etching.

These printers, in some cases called multifunction 3D printers or AIO 3D printers, include removable instrument heads that can be changed out to increase or decrease their capacity.

In the event that you need to make a model and need to cut a wood model first, utilize the CNC machine, and afterward switch back to the 3D printer extruder to make the last plastic model.

A 3D printer helps make inventions easier. They are powerful printers and get the work done with ultimate precision. It turns a desktop into a workshop as creativity is at its peak. They are very speedy and are a great solution for product development.

What is a 3-in-1 Machine?

A three-in-one printer has three main functionalities. 3D printing, laser engraving, and CNC machining are among the most practical modules that can be swapped out.

Interchangeable modules will save you money and space while allowing you to own only one cutting-edge computer.

These machines are ideal for in-house manufacturing and high-precision prototyping. The following are its primary features.

3D Printing

It’s the method of turning a digital file into a three-dimensional object. Additive processes are needed to produce a 3D print of an object.

Before the final object is crafted, an object is created by layering successive layers of content.

Each layer is a horizontally thinly sliced cross-section of the object. 3D printing helps you make different shapes with less material than traditional methods.

Laser Engraving

It is the process of engraving an item with the aid of a laser. Plastics, wood, and other fragile metals, such as aluminum, can all be laser etched with this 3-in-1 unit.

Since the laser head is optimized for heavy-duty use, laser engraving works efficiently. To achieve the best results, it is preferable to purchase an all-in-one unit.

CNC Cutting

Pre-programmed software guides the movement of equipment and machinery in this manufacturing process. 3-dimensional engraving activities are carried out in a series of prompts with the aid of CNC machining.

The entire method contrasts with manual operation, which requires operators to direct tool commands through wheels, buttons, and levers.

Comparison Chart

| Name | Link | Nomination | Overall Rating |

|---|---|---|---|

| Snapmaker Original | Editor’s Choice | 9.8 | |

| Snapmaker 2.0 | Best Value | 9.7 | |

| Zmorph Fab | Premium Pick | 9.5 | |

| Creality CP-01 | Runner Up | 9.4 | |

| Ecubmaker TOYDIY | Best Budget | 9.3 | |

| Flux Delta Plus | Small and Portable | 9.2 | |

| 5Axismaker | Most Practical | 9.2 | |

| Stepcraft M Series | Strong and Durable | 9.4 | |

| Diabase H-Series | Best Usage | 9.2 | |

| BoXZY CNC | Strong and Sturdy | 9.4 |

Best 3 in 1 3D Printers (CNC, Laser Engraver)

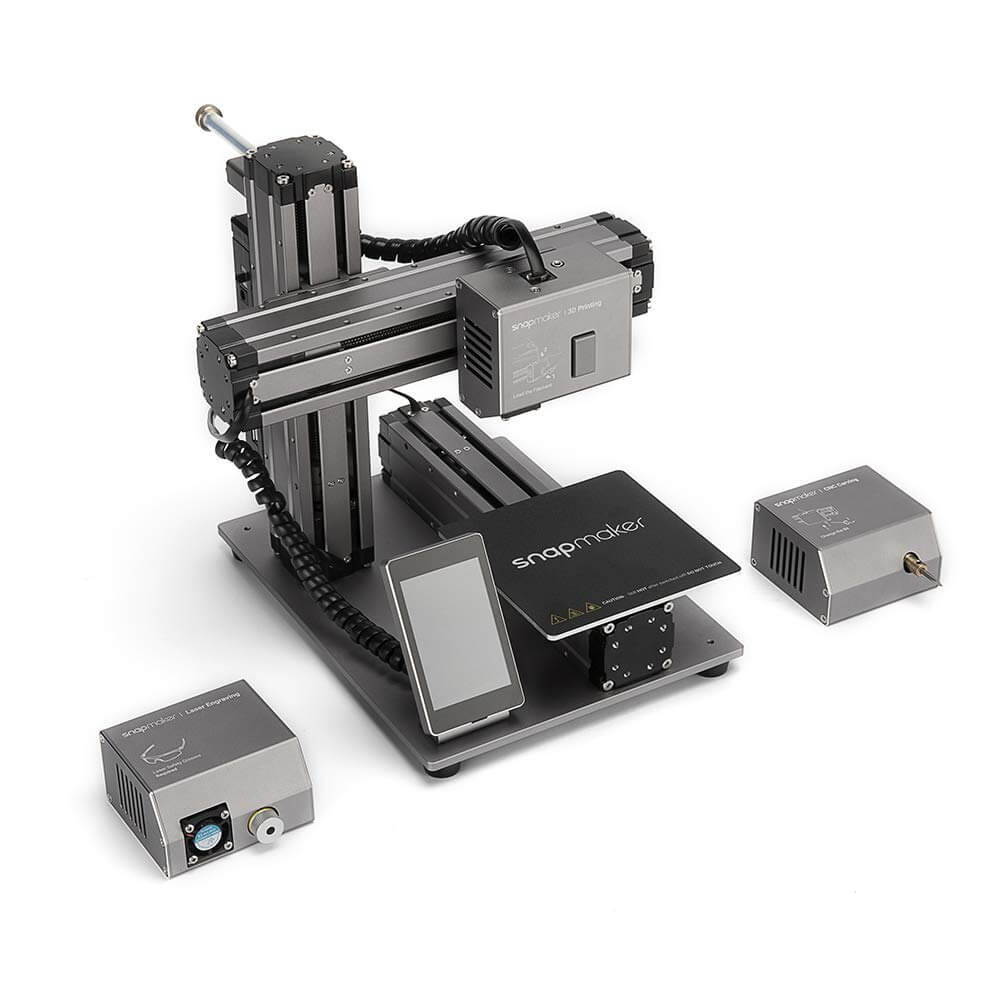

Snapmaker Original

Snapmaker became popular when it raised an impressive $2.2 million on Kickstarter for the Snapmaker Original, their first all-in-one 3D printer.

The Snapmaker Original, which can carve wood and engrave images on phone cases and other materials as well as act as a small 3D printer, won the hearts of many users around the world and became a roaring success.

The design of the module not only allows it to be compatible with future upgrades but also empowers users to enrich its uses with their own imagination. With the 3-in-1 software, Snapmaker Luban, a stunning creation is only a few clicks away.

The heated bed on the 3D printer will exceed 80 degrees Celsius, allowing ABS and PLA to be printed. It’s accurate, with layer resolutions of up to 50 microns.

The printer is anchored down by a heavy metal frame, which increases reliability and longevity. The heavier frame is less prone to vibrations, which can impact print quality and surface finish.

The CNC carver can carve intricate details in areas as small as 90 x 90 x 50 mm, while the laser engraver can work on 125 x 125 mm.

Snapmaker Luban, Snapmaker’s three-in-one app, can 3D print, CNC, and laser engrave all on the same platform and easily switch between tool heads.

Snapmaker claims that the 3D printer can be assembled in under 10 minutes and that changing tool heads to adjust the role of the all-in-one 3D printer is easy.

Makers have praised the Snapmaker Original as one of the best 3 in 1 3D printer in its price range, and the Snapmaker 2.0, which has larger build volumes and a higher price tag, has recently been released. Due to this, it can safely be called one of the best 3-in-1 3D printers.

- The structure is extremely strong and sturdy

- The printing quality is unique

- It gives a premium feel and outlook

- The UI is very quick and responsive and is handled through a touchscreen

- The CNC spindle speed has no control

- Work volume is small

|

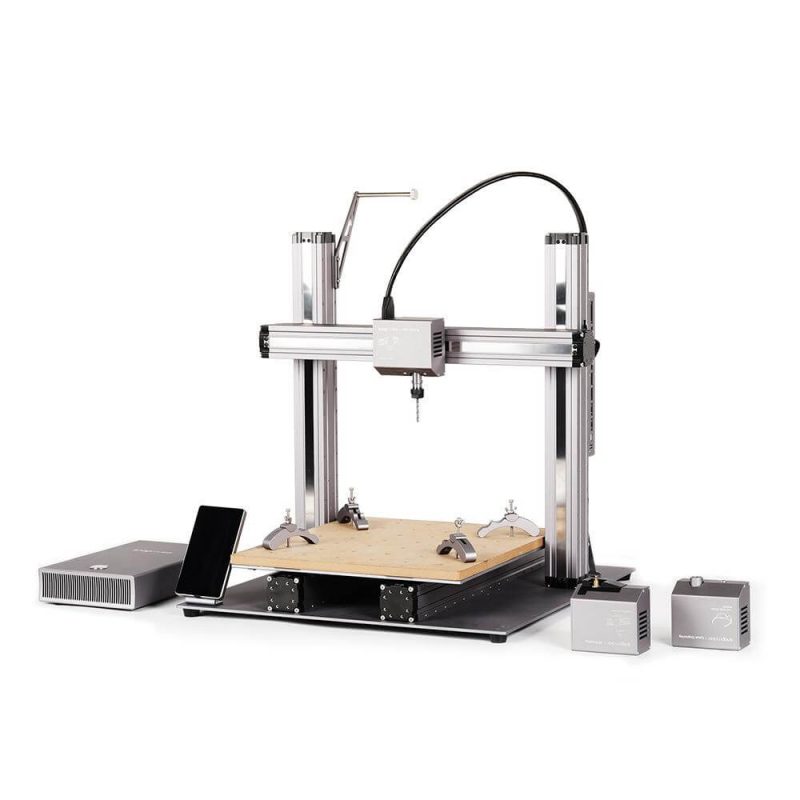

Snapmaker 2.0

Snapmaker 2.0 turned into the most subsidized innovation project in the historical backdrop which raised $7.85 million.

The Snapmaker 2.0 outperforms its predecessor in terms of its effectiveness and size. It is made of a metal frame which results in enhanced accuracy and durability, along with the great volume from the smallest of A150 models to the largest of 3D printer models.

Snapmaker has the ability to print different materials including PLA, ABS, and adaptable filaments. It also has WiFi and a USB port which lets one print easily and remotely whether operational or disconnected.

The printer is portable and moveable. It makes work easier as it can be used like an android or an Apple phone which can be carried around easily. It makes work easy, thereby making project control and management simple.

If you run out of filament, the Snapmaker will spontaneously come to a still, letting you load wire and start from the point where the work paused, and it will also save your progress if you lose power.

The printer’s laser engraver enables one to create different images on not only fabrics, but also other materials such as leather, plywood, and acrylic materials.

The built-in camera allows you to keep an eye on your design from afar and ensures that everything runs smoothly.

The CNC machine will carve designs into walnuts and woods, carbon fiber panels, acrylic, and wood, among other materials.

The improved speed of the Snapmaker 2.0 is a significant improvement, allowing larger projects to be produced in the best time. It is one of the best 3-in-1 3D printers.

- Compared to the previous model, this has a larger workspace

- Structurally and architecturally well-built

- Control panel and touch screen powered by Android

- Hardware that is both sleek and graceful

- A tried-and-true framework with new features

- Workflow can be frustrating at times

- Linear modules can be very noisy

Zmorph Fab All-in-One

ZMorph, is a 3D Poland manufacturing company that makes the most powerful all-in-one 3D printers on the market, with the ability to 3D print, CNC system, incise, and cut, as well as convert into a food 3D printer using ZMorph’s thick paste extruder.

Chocolate, along with other identical materials like frosting and baking dough can be printed using this edible material choice.

The Fab, like all ZMorph 3D printers, is known for its dependability, effectiveness, and efficiency. It’s a fantastic 3D printer, with a high-quality heated bed that can 3D print HIPS, ABS, and tougher filaments like Nylon with ease.

It performs greatly as a double extruder 3D printer with the dual head option, ready to 3D print several colors or decipherable support materials. It can blend two colors together for various shades in a single component.

The 3D laser printer CNC hybrid has a wide enough build area to print both 1.75mm and 3mm 3D printer filaments and can be calibrated to print both 1.75mm and 3mm 3D printer filaments. The 3-in-1 3D printer is ideal for printing prototypes.

- Excellent 3D Print Quality

- Effortless Tool Switching

- Production Techniques are handled by Voxelizer 2.0

- Masterfully structured to be rigid

- The User Manual Needs Improvement and Is a Little Expensive

Creality CP-01

The Ender 3, Ender 5, and CR-10 ranges from Creality are currently the most common and affordable 3-in-1 3D printers on the market. It is their foray into the all-in-one 3D printer market, which includes CNC cutting and laser etching in addition to 3D printing.

It has a print volume of 200 x 200 x 200 mm and accompanies a warm bed that can cross 100 degrees Celsius as a 3D printer.

Because of these temperatures, ABS, HIPS, and TPU 3D printing should be no concern, and in principle, filaments like Polycarbonate and carbon fiber could be printed as well.

In most cases, the direct drive extruder leads to an easier printing of flexible filament, and the finished glass print bed should assist with attachment and decrease distorting.

The three-in-one 3D printer has a 0.5W laser tool that can etch areas up to 100 x 90 mm as a laser engraver. On paper, plastics, and wood, the engraver may create contrasting greyscale art.

The CP-01 is a CNC carver with a 4800RPM spinning CNC spindle that can carve plastics, wood, and PCBs. It will carve the same 200 x 200 mm areas as the 3D printer.

Creality’s Workshop 3D printer program is included with the CP-01, and it supports engraving and CNC functions. Creality’s independent Creality Slicer functions admirably for 3D printing.

- For fast switching, use a universal connector

- Compatibility with a variety of materials

- Protect yourself from power outages

- Includes Creality Workshop Program

- The laser engraver is a beginner’s tool

Ecubmaker TOYDIY

Despite the fact that it advertises itself as a four-in-one 3D printer, the assertion is based on separating the 3D printing portion into regular FDM 3D printing and double color 3D printing, both of which are classified as 3D printing.

In fact, the printer is a three-in-one 3D printer with four tool heads for 3D printing, CNC cutting, and laser etching that are easily interchangeable.

The extruder can arrive at temperatures of up to 240 degrees Celsius, with a warm bed that can cross to 50 degrees Celsius.

As a result, printing higher temperature fibers like ABS and HIPS is preposterous, and the Ecubmaker TOYDIY can only be used as a PLA 3D printer. (Using the double extruder for printing PVA as help has been tested, but the company does not recommend it.)

As a laser etcher 3D printer, the TOYDIY highlights a 1500MW purple laser that can imprint wood, plastic, calfskin, cardboard, and a few different materials. Nonetheless, this is carefully a laser etcher, and can’t cut materials.

Ecubmaker’s Ecubware 4 in 1 3D slicer program is included with the TOYDIY for any application form. The 3D laser printer accompanies an SD card containing instructional exercises for the 3D printer, etcher, and CNC cutter.

- The structure is solid and rigid

- The EcubWare software is ideal for use

- The build area is small

- LCD might malfunction

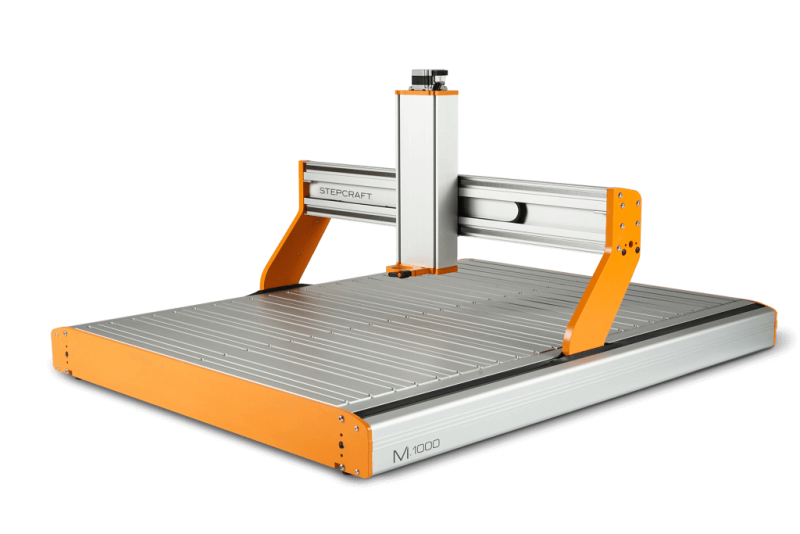

Stepcraft M-Series

Stepcraft has made many advancements by introducing the M-Series CNC machines, which are vastly superior to the D-Series. As a result, the M-Series gains a number of new capabilities.

Stepcraft is known for its diverse capabilities, and the latest M-Series is compatible with all attachments for milling 3D models, lasering, engraving, and other applications.

The Stepcraft M-Series is a high-standard CNC with three tool heads. The M-Series machines focus on producing more in less time and carrying on the tradition of the popular D-Series machining capabilities with 12 tool heads. The M-Series has several diverse models, the longest of which is the M1000, which is over a meter long.

In terms of software, the Stepcraft M-Series CNC machines come with UCCNC, which is the machine control software, as usual.

In terms of stability and design of a CNC Router with laser, the M-Series’ X-profile is very interesting.

- On this list, the best overall CNC Router

- Large Work Area, Powerful Drive System, and Spindle

- You can work almost anywhere with freestyle milling

- The efficiency of 3D printers may be poor

- A better user’s manual is needed

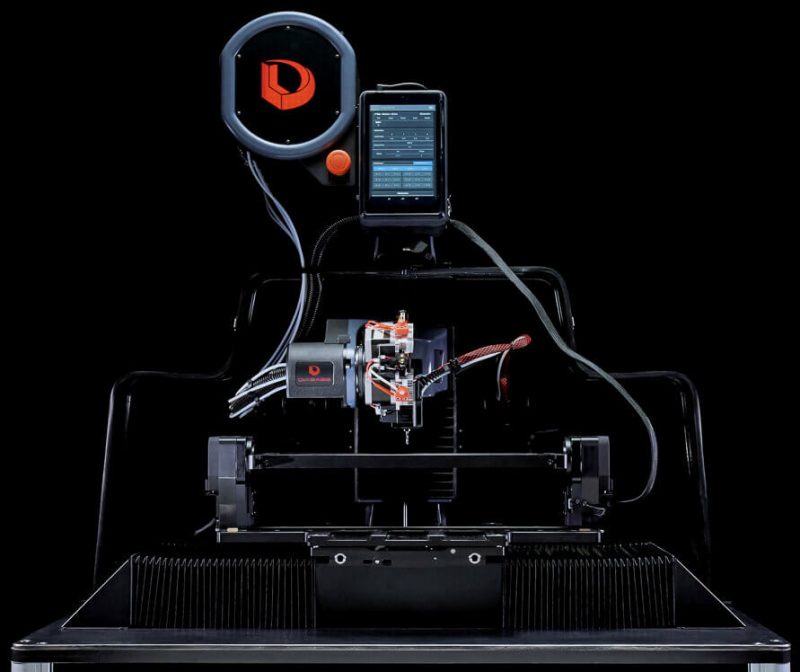

Diabase H-Series

Diabase produces the H-Series, which is an all-in-one unit. Diabase is a leading 3D printer manufacturer based in the United States.

The Diabase H-Series was introduced in 2018 and uses extrusion 3D printing technology. The construct volume of the all-in-one 3D Printer is approximately 400 x 180 x 180 mm.

The famous H-Series is a benchtop machine that is very interesting to see in action. It is a lightweight solution from the company that produced the Flexion extruder.

You may depend on a number of features on the computer. The tool holding mechanism is one of the machine’s most notable features.

It is now possible to print 3D objects in solid feedstock using cutting-edge new technologies. After that, its CNC milled into a net single component, with various configurations in between.

Based on Diabase’s experience with various types of flexible materials, the H-Series is confident in its ability to handle the broadest variety of materials.

- Filaments up to 300 degrees Celsius can be processed with Elite Versatility

- Models and factories benefit greatly from this product

- Strong and sturdy structure

- Material capabilities are limited

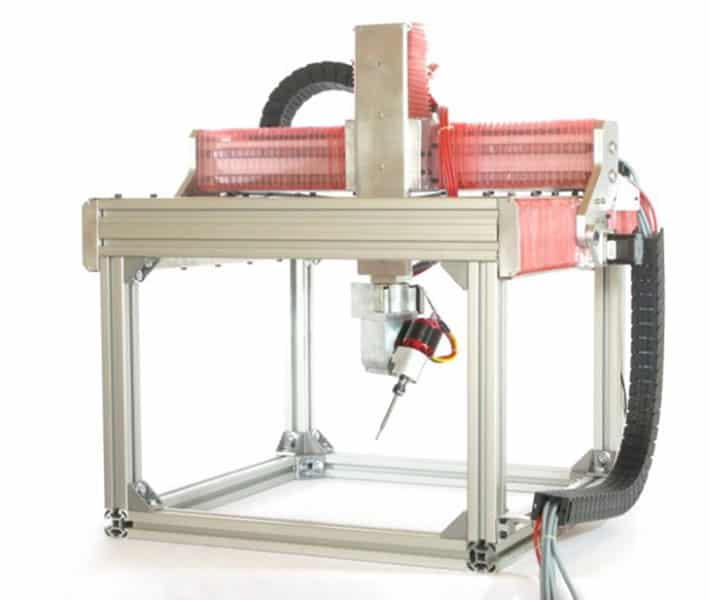

5Axismaker

The 5Axismaker is one of the best 3D printer and CNC mill combos made by 5Axisworks, a UK-based company. A larger version of this expert and instinctive 3D printing machine is accessible, with a build size of about 600 x 600 x 600 mm.

The 5Axismaker 3D printer is an all-in-one computer with a multifunction tool head. The 5Axisworks 5Axismaker makes stuff in 5 axes, as the name implies. A movable gantry with compatible instrument heads is just the start of something really interesting.

Notwithstanding, the way into its free development lies in the borer head that is mounted toward the finish of the Z-hub arm.

With such an arrangement, you can expect revolutionary errands like the 3-dimensional bents with 3D printing and improved CNC etching of materials. The natural apparatus head plan of this machine is commendable.

This fantastic all-in-one machine comes equipped with 3D printing and CNC milling tool heads right out of the box. The tool heads have a nozzle of around 0.6 mm for 3D printing.

However, if you order more tool mounts, they can be made available. There’s also the choice of ordering a touch tool head.

- CNC computer that is both subtractive and additive at a reasonable price

- Improved fabrication delivered directly to the workplace

- Position and adjustment are done automatically

- Sensors built-in for secure and dependable operation

- Tools that can be swapped out for a simple and quick workflow

- There is a limited variety of products during the use of a 3D printer

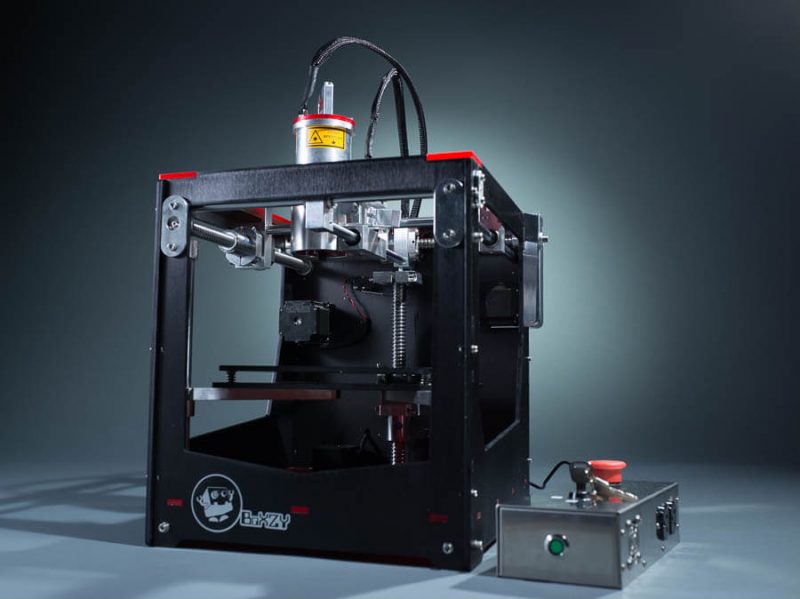

BoXZY CNC

The BoXZY CNC computer is a full-featured desktop 3D printer produced by BoXZY in the United States.

The 3D printing area of this CNC machine is approximately 165 x 165 x 165 mm, and the machining area is approximately 203 x 283 x 260 mm.

This across-the-board machine highlights laser etching and CNC processing functionalities.

This 3D printer machine is also available in a basic version without the CNC mill and laser engraver. As you can see, the company offers the best build area for the machine.

The milling work area is also very good. Aside from that, the company has added a new feature called the E-Stop power station to this unit.

The BoXZY computer has a number of interesting features, including the ability to do more than just print 3D objects.

The machine’s versatility is provided by two features: CNC machining and laser engraving.

- It has a sleek and stylish appearance.

- All-in-one 3D printer with high performance

- Spindle speeds range from 10,000 to 30,000 revolutions per minute

- The laser must be switched off using a G-Code instruction, or the component will be burned

Flux Delta+

The Flux Delta+ is a $1,000 all-in-one 3D printer that is relatively inexpensive. A 3D printing kit, a laser module, a blade module for vinyl cutting, and a holder module for drawing are all included in the complete package.

The Flux Delta+ is a medium-sized delta 3D printer with a clean and well-structured design that includes a durable metal frame and a stable print bed.

It has a magnetic build base that can be removed quickly to withdraw completed prints. It comes partially assembled and with an automatic bed leveling system, all of which help to speed up the initial setup.

The Flux Delta+ performs admirably in terms of 3D printing. When the settings are correct, it can produce smooth and detailed prints, though the print speed is disappointing, particularly given the delta mechanical arrangement.

The Flux Delta+’s print speed is hampered by the 3D printing module’s bulky construction, which prevents it from achieving its full potential as a high-speed delta printer.

- The printers are fast and speedy

- Ideal for printing tall models and prototypes

- The base size of the printers is limited which can result in printing in parts

- Not very user-friendly – difficult to troubleshoot

Buyer’s Guide

To make an informed decision on buying a 3D printer, we have compared the products on multiple criteria. This includes:

3D Printer Quality: The majority of these three-in-one 3D printers are produced by 3D printer manufacturers and are primarily used for additive manufacturing. As a result, the 3D printer’s output is critical.

CNC Mill Power: Some CNC machines can only engrave rather than a mill. CNC machines with more horsepower spin faster, carve harder materials and perform more precisely and for longer periods of time.

Laser Engrave Power: Some all-in-one laser engraver 3D printers can only engrave, while others can cut through fabrics, similar to a CNC system.

How easy it is to change the tool heads: It’s all well and good to have powerful tool heads that work flawlessly, but if changing them is too complicated or fragile, they may as well only serve one purpose.

Effectiveness of software: The majority of our suggestions include advanced tools for slicing models for 3D printing as well as preparing CNC and laser projects. The best software is simple to use while still being accurate and dependable in all areas.

Frequently Asked Questions (FAQs)

What type of materials can you print with it?

3D printing can be done with a wide variety of materials. The Onyx One, Onyx Pro, and Mark Two desktop 3D printers from Markforged will print parts made of Onyx, Carbon Fiber, Fiberglass, Kevlar, and HSHT Fiberglass (High-Strength High-Temperature Fiberglass). Markforged’s Metal 3D printer (Metal X) will print parts made of stainless steel, aluminum, tool steel, Inconel, and titanium.

What objects can you 3D print?

3D printing is becoming very popular and is being used by many industries to produce prototypes and other manufacturing components.

Various materials can easily be printed through the use of a 3D printer including – sprocket, end effectors, soft jaws, welding fixtures, brake lever, metal bracket, motor housing, vase, jewelry, water bottles.

Is there a limitation to what shapes you can 3D print?

Molds and cutting technologies are used in traditional manufacturing to create the desired shapes. Using these techniques, creating complex and complicated shapes can be challenging and costly.

This problem is easily solved with 3D printing because it allows you to print any shape or geometries you can think of, depending on the scale. When combined with cutting-edge software, the sky is the limit.

Conclusion

There are different types of 3D printers and each of them has its own unique property which makes them different. They all have their own pros and cons.

From the printers reviewed above, Creality CP-01 is the most cost-effective and is ideal for printing small projects. It helps to print small prototypes and bring the ideas to life.

The Snapmaker 2.0 is although one of its kind and provides a big space to work with, the printing from this device is not very flexible.

The StepCraft M-series is the jack of all trades. it has multi-function capabilities and is made up of advanced engineered technology.

it can work absolutely anywhere or everywhere whenever needed and the machine can be placed in any direction.

The main focus of the Stepcraft M-series is on CNC cutting and is ideal for those who are looking for this functionality.

All 3D printers have their unique selling point and this article provides the ultimate buyer’s guide for those looking for exclusive properties in a 3D printer.