3D Printing technology is changing the way in which manufacturing has been perceived to date. Manufacturing a part or functional prototype had always remained a subject of subtractive thought.

So, say, for example, you take any traditional manufacturing method, it would always be starting to think from a whole and manufacturing a perfect or close to perfect part or functional prototype from that whole.

Thanks to 3D printing technology, and the developments in the field of software modeling that humans can now enable a complete part and design its 3D model, before starting to manufacture the same.

And this nuanced thought of manufacturing gained a very impactful perspective from the additive manufacturing layer and that’s how 3D printing found its feet. In this article, we are going to share 3D printing costs per hour.

Now it may seem awkward to those who do not know much about the flexibility that this manufacturing technology offers. Unlike traditional manufacturing technologies that require you to manufacture parts and functional prototypes with some basic prerequisites, 3D printing technology offers freedom.

The standard language of Engineering drawings has complied with software tools and offered flexibility to an extent that if you have a 3D design file and you share that with the printer manufacturer, it would yield to the product that you are imagining.

This is something one could never imagine with the previous manufacturing techniques. So, in all, we have shared till now two eccentricities that have made 3D printing technology more popular than ever.

The first one being the complete change of perspective than the traditional manufacturing techniques and the second one being the flexibility of it. Today we are going to talk in detail about the second criteria.

But before going right to the point we will take a little detour to 3D printing services providers to give readers who don’t know much about 3D printing, an overview.

3D Printing Service Providers

These are companies that offer you the flexibility of sharing your 3D printing design file with them and the quality and quantity of parts or functional prototypes that you require and in turn, for this, they offer you the part or functional prototype delivered to your place.

So, even without a 3D printer, you can get a product manufactured from that 3D printer to your place. Isn’t that amazing? And with the Internet, this whole process is fueled up.

So for a traditional manufacturing technique to offer in terms of flexibility, all it had got was: renting a machine for hours from your favorite manufacturer.

But with 3D printing technology, you can get your design file ready, share it with your favorite manufacturer that might be anywhere across the globe, and get the parts and functional prototypes printed how you want them, without traveling anywhere.

In fact, there are companies that offer to design 3D file for you, there are repositories which offer either paid or free 3D design files that you can download from your device.

Now that you know about the 3D printing service providers, it’s time to tell you about how do they calculate 3D printing cost per hour! How many criteria do they consider? And what effect does it make on the overall cost of 3D printing?

Factors Included in Calculating 3D Printing Cost per Hour

Calculating the cost of printing a part or functional prototype is like taking into account a lot of factors. And there is no standardization in the technique, but then there are some factors which no one can neglect to calculate otherwise it may lead to loss of the company.

The list of these criteria starts from the basic…

Cost of 3D Printing Material

Different types of 3D printing methods employ different kinds of 3D printing materials for printing parts or functional prototypes.

There is filament when you are printing with FDM 3D printing, there is resin when you are printing with SLA or DLP 3D printing, there is a powder when you are printing with multi-jet fusion 3D printing technique, and so on.

Naturally, the cost of material is dependent on the type of 3D printing technology you are employing, the 3D printer used by you, and the materials that the 3D printer is compatible printing with.

So, say you submit a design to any of the 3D printing service providers, they are going to ask you the 3D printing material with which you want to get your part or functional prototype printed.

Based on the cost of that 3D printing material at that point in time and the material quantity that’s going to be used, they are going to tell you the cost which will be a summation of this and a lot of other factors.

Typically a 3D printing filament cost is based on per kilograms of spools that are willing to purchase. For example, one kilogram of a specific brand of PLA filament may cost $30.

The Time that Will be Taken for 3D Printing

3D Printing service providers decide on their fixed charges when it comes to charging the operating time for which their printer will have to function.

Each 3D printing business sets its own hourly cost for these criteria. But again, this cost is dependent on the type of 3D printer that they are going to employ for 3D printing your part or a functional prototype.

Whether that is an industrial 3D printer, a desktop 3D printer, or a medium-sized 3D printer. And of course the amount of electricity it is known to consume.

A typical business may charge $1 per hour, knowing that the life span of the printer employed for 3D printing a part or functional prototype is 2000 print hours, if they have paid $2000 for buying that printer.

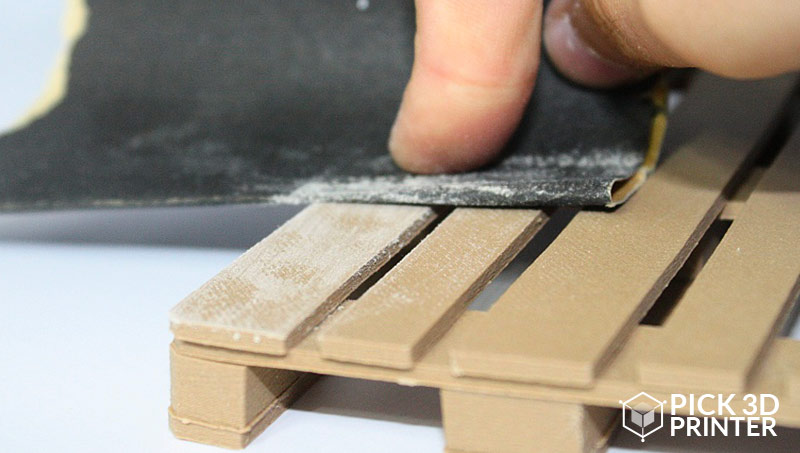

Post Processing

For making the complete part and functional prototype customer-ready, every 3D printing business owner would need to do some of the other kinds of post-processing which will include methods such as sanding the part or functional prototype which is manufactured.

The post-processing also includes packing that part and sending them to the customers. So, this part is where the companies are going to mostly add manual labor into their 3D printing cost per hour.

And of course, no one does business for charity, so after all these criteria have been calculated the companies are going to add the profit percentage depending on the market situation at that time.

Going through the above-mentioned facts, you would now be able to picture in a correct way in which 3D printing a part or functional prototype is charged to its customers.

In addition to all these, there are 3D printing cost per hour calculators which you can use, to get an idea of an estimated cost that the companies are going to charge you.

3D Printing Cost Per Hour Calculators

Here is a list of some of the calculators that do the math for you and present to you a numeric cost that lets you have an estimate of how much would you have to pay for the design that you hold.

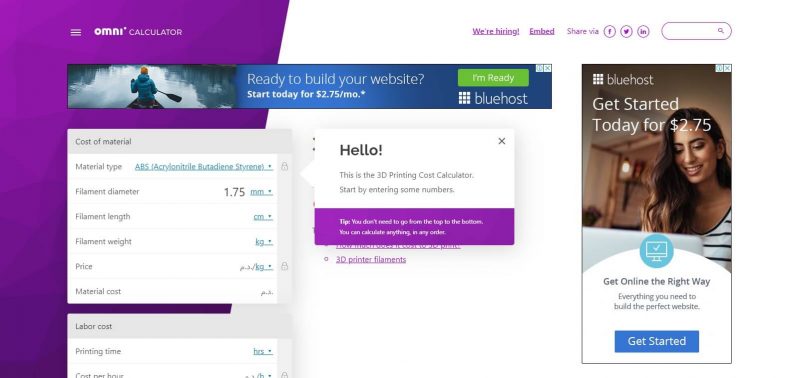

Omni

The website of this company lists many calculators that can be employed for various purposes including science as well as finance. Someone has calculated the exact calculators and it has come out to be 825 to date.

Pretty impressive ha? The user interface that Omni uses, does not make you feel that you are being driven back into the old days when the calculator was the most important invention of the time.

It takes inputs from you and provides you the output, that is the simplest way one can term the effectiveness of this calculator used by Omni.

As a user, you need to enter the price and length of the filament for making your part or a functional prototype. In case you are wondering where could you get these inputs from?

The slicer software that you have used for designing your model already has it, all you have to do is notice the same and jot it down here.

Similarly, the second section of this calculator deals with the price of labor, and the last portion is where the profit percentage is added.

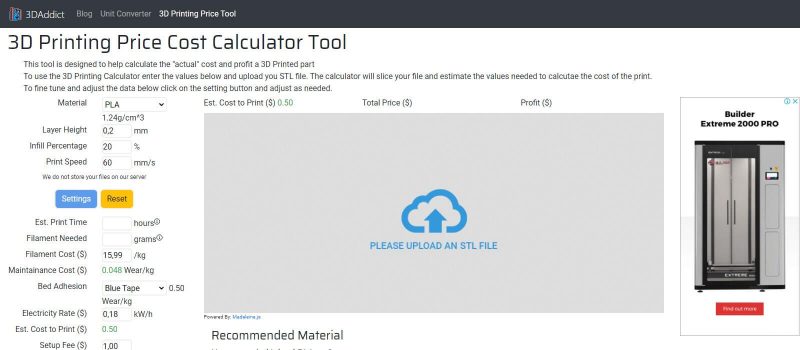

3D Addict

The website’s utility stands by its name. Addicts are generally known for knowing any and everything in detail.

The website offers addicts of 3D printing to enter every criterion in detail to know and get an estimate of the cost of 3D printing a part or functional prototype.

It starts with the usual price calculation wherein you would have to choose the material you wish to 3D print with, followed by filling up the layer height you wish to see in the final product, infill percentage, and print speed values.

After you are done entering these values, in the next step the makers of these websites make you go through an interesting feature.

They let you see a 3D model which is a result of a fully functional slicer integrated into the calculator.

The slicer not only estimates the print time but also the amount of material needed for calculating the displayed cost.

The calculator also features factors such as maintenance of the printer, electricity, packaging, as well as shipping cost.

So, if you are a manufacturer this might seem lucrative as a calculator to you, more than any other on this list.

3D Printing Pro

Apart from offering a 3D printing cost per hour calculator the website also offers online courses for learning 3D printing technology.

Like Omni and 3D Addict, 3D Printing Pro is known to calculate the cost of 3D printing per hour using its own sets of parameters.

Primarily intended to help businesses quote to their customer the cost that will be charged for 3D printing their part or a functional prototype.

An eccentricity from Omni and 3D Addict is that 3D printing Pro has criteria called tax percentage.

Of course, the calculator calculates the profit percentage, and explanations for each criterion that is taken into account by this calculator are explained below.

So, there is no confusion even for a first-timer who is using this 3D printing cost per hour calculator.

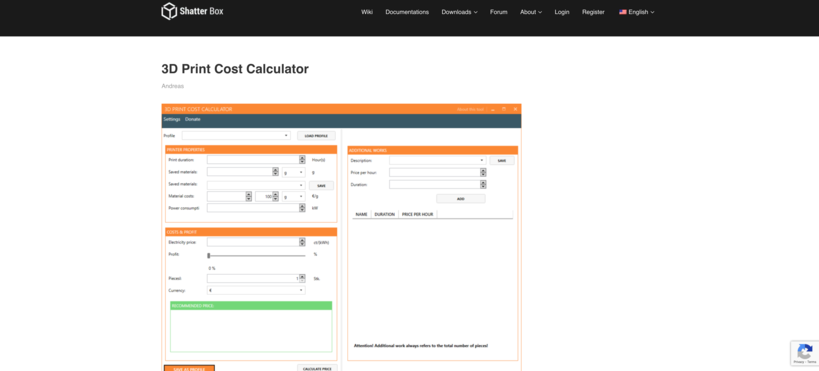

Shatterbox

Primarily a knowledge-based website, Shatterbox also hosts a 3D printing cost calculation tool.

Users of this website can know the cost of 3D printing a part or functional prototype by manipulating print duration, material cost, profit margin, as well as printer power consumption, electricity price, pieces that are to be manufactured, etc.

The calculator is known to leave a good impression on anyone who wishes to estimate the cost of 3D printing in detail.

There is also a paid version of this calculator that is known to come with additional features known as: The Manage interface, The Print jobs interface.

The former is known to give an organized look at materials that are required for 3D printing, diameters of the nozzle, and the 3D printers themselves.

Whereas the latter gives the ability to the user for tracking multiple ongoing print jobs as well as their statuses.

The Conclusion

These are some of the most important criteria that every user looking for 3D printing services online must take into account.

As well as their significance is seen if you are a manufacturer who happens to provide your customer with 3D printing services.

Although these calculators might not take into account all the factors that you want them to take in, they can obviously give you a start.

3D Printing cost per hour calculators are a gift for all those who do not have a complete idea of all the parameters that one must go through for 3D printing a part or functional prototype.

It can also act as a tool to learn the 3D printing process as a whole because it covers a lot of parameters about which one dealing with the process for the first time, might now generally know.