|

WASP, the manufacturer of the DeltaWASP 20 40 Turbo2 is based in Italy. The 3D printer is the successor of the DELTA TURBO 2040.

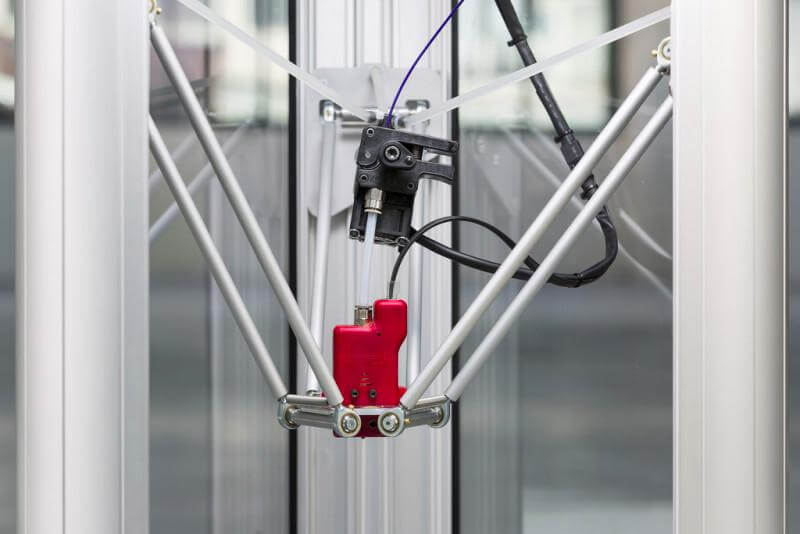

This printer is available in two extruder versions i.e. Spitfire Red Extruder which comes with a Spitfire LT Cartridge that is a compatible LDM extruder featuring paste extrusion.

Secondly, ZEN Dual Extruder: including two 0.4 mm ZEN LT Cartridges, which enables multi-material and/or multi-color 3D printing.

The printer comes with a newly integrated 32bit board of industrial technology. Delta Wasp 20 40 Turbo 2 is presented with a supply system that can support 2 high power extruders.

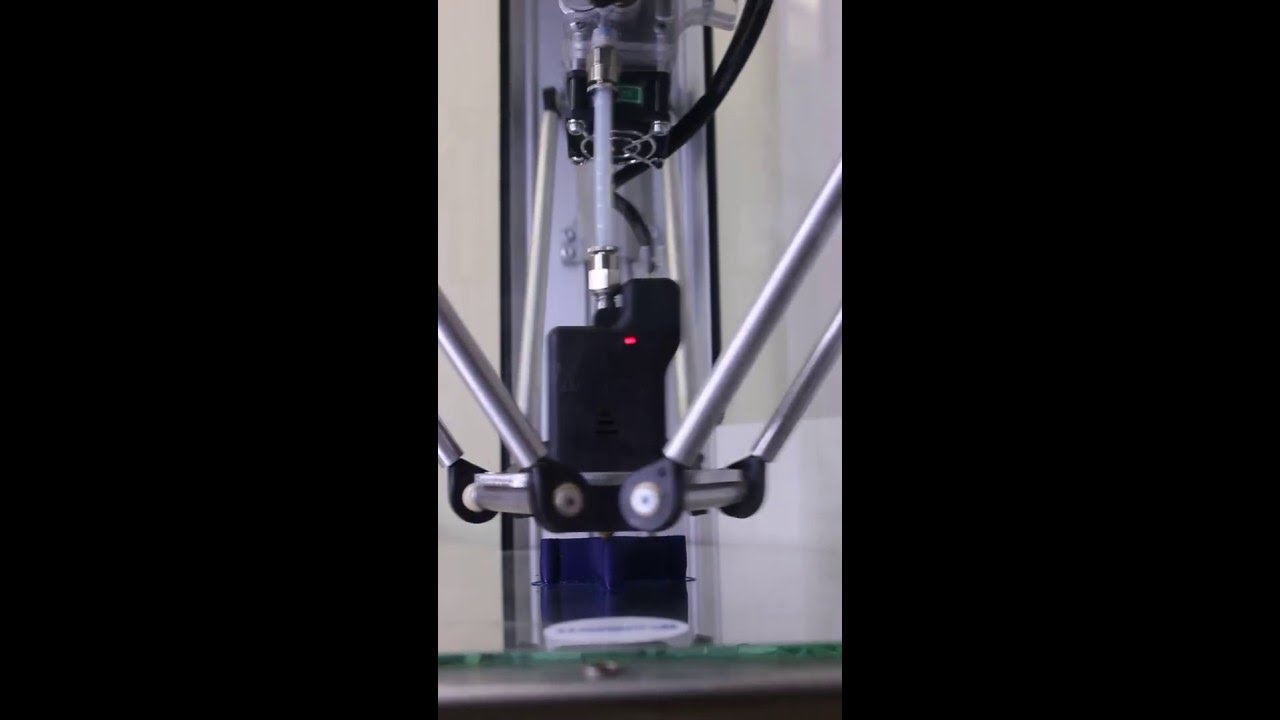

The new TURBO 2 introduces a carriage-sliding system that has improved speed and accuracy.

The room for printer parts has been better insulated to reach a temperature that can suit fast 3d printing of technical materials.

The printer also has a cool system for the engines and the boards and kinematics for high temperatures.

In this review, we will let you know about various features of the printer, specifications, overall print quality, and a lot more.

Features

This printer features an upgraded control board that allows it to control the optional dual print head in the Red Extruder or the high flow rate Spitfire extruder.

The sliding mechanism of this printer has also been improved to increase the speed and accuracy of the printer.

The chamber insulation has increased along with the increase in cooling for the motors and board.

Turbo 2 is capable of printing advanced materials up to 350 degrees Celsius at amazing speed.

A filament detection sensor is placed along with the resurrection system that is standard on Wasp printers.

This means that there will be fewer failed prints due to power issues or filament running out.

The Turbo 2 is a powerful desktop 3D printer that makes quick work of large print jobs. Let’s take a look at its features one by one.

Resurrection System

This feature allows users to save and resume their 3D print. Especially useful in case of a power failure, the resurrection system is an evolution of the Stop and save function.

The need to stop or block the printing of the walls because of some reason and then resume it the following day from the place that you had left is how this feature came into being.

The Logic of this Feature is Quite Simple

The coordinates on which you are currently extruding are saved on an SD card. From those coordinates, the printing continues. The main role is played by the limit switch of the machine that is positioned at the top.

In most of the printers, this is at the bottom left, therefore the extruder, while returning to its place could hit the piece.

But this is not the case with Delta WASP 20 40 Turbo 2. The system saves the coordinates in a file that is named Resurrection.g.

FREE Z-SYSTEM

The machine automatically measures the height of the interruption of the print and it restarts there.

The Free Z or Zeta System is a recovery system for a print, which has stopped for some reason stopped and resurrection from that point is not possible.

Or even after following the Resurrection, you realize that the piece that is being printed is going bad and you want to partially repeat the print starting from a precise height.

This system allows you to start printing a file, from the height of the model to be printed, that was previously selected.

Self-Calibration System and Integrated end Filament Sensor

The printer does not need manual calibration and it can be automatically calibrated according to the part or functional prototype that is being printed.

This essentially increases the quality of print which is sometimes lower in manual calibration.

After the filament is completed, you would be indicated by the machine to fill in the filament again.

This feature is helpful when you are continuously printing and especially when you are printing with the help of remote devices. Imagine the printer is somewhere and you are away from the printer.

How important is for you to be conveyed, then, that the printer has stopped or is going to stop in some time because the filament that was filled has been utilized?

LDM Clay Extruder Compatible and Superior Motor Cooling

The extruder of this printer is compatible with lower density materials. Unlike other printers that do not have this feature.

Also, the motor cooling is very superior to that of other printers. This enables users to cooling as fast as possible.

Overall, the printing time is decreased due to faster cooling. And on the other hand, when the extruder is compatible with more materials, you have more options to print.

Specifications

Credit: top3dshop.com

Credit: top3dshop.com

The print volume produced by this printer is 200 mm * 400 mm. The print chamber of this printer is closed and heated. The minimum layer height produced by this printer is 50 microns.

The maximum print speed that can be availed with this printer is 500 mm per second. Whilst the maximum travel speed is 1000 mm per second.

The maximum bed temperature that can be generated within this printer is 120 degrees Celsius. The suitable filament diameter is 1.75 mm.

Materials such as ASA, PLA, ABS, Flex, HIPS, PETG, TPU, POLYPROPYLENE, ABS+PC, and PA carbon can be used for printing of parts and prototypes using this printer.

Price

The manufacturer price of this 3D printer is $3481 for the Spitfire Red version and $3871 for the ZEN Dual Extruder version.

First impressions

Credit: top3dshop.com

Credit: top3dshop.com

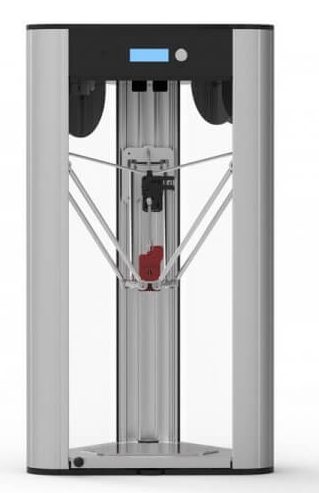

Delta WASP 2040 TURBO2 is available in a black and gray combo, this color combination makes it look stylish and ideal for a variety of professional uses. The printer dimensions are 490 x 440 x 870 mm and its weight is 20 kg.

The spool holder of the printer is mounted on its left side. Delta Wasp 20 40 Turbo 2 has an open design.

It does not have a touch screen interface, but a little rectangular screen on its head. The overall shape of this printer is also rectangular.

It’s like a head that has been placed on the support of three columns. Inverted triangles make up for the support that the print head requires for its up and down movement.

There is a circular button just beside the rectangular screen that’s on the head.

Setup

The printer comes fully assembled, so all you have got to do is just plug and start printing.

There are just a few things to ensure before starting the print and all of which are mentioned in the user manual that is given with the printer.

With the printer, you also have in the box the ZEN dual extruder, which is optional to use. There is HT and LT Core that you get with the printer.

These things are accompanied by a power supply that you would need to start printing with the printer. And then there is this startup guide or manual.

Printing Type/Cost

FDM printing uses the filament of material that you wish to start printing with. As in this printer, you can print with more than one filament, the printing cost varies from the cost of the filament.

However, the overall printing cost is pretty average. It is a known fact that the printer is based on FDM printing so printing of part or prototype will happen layer by layer.

Print Quality

Credit: deltawasp.com

Credit: deltawasp.com

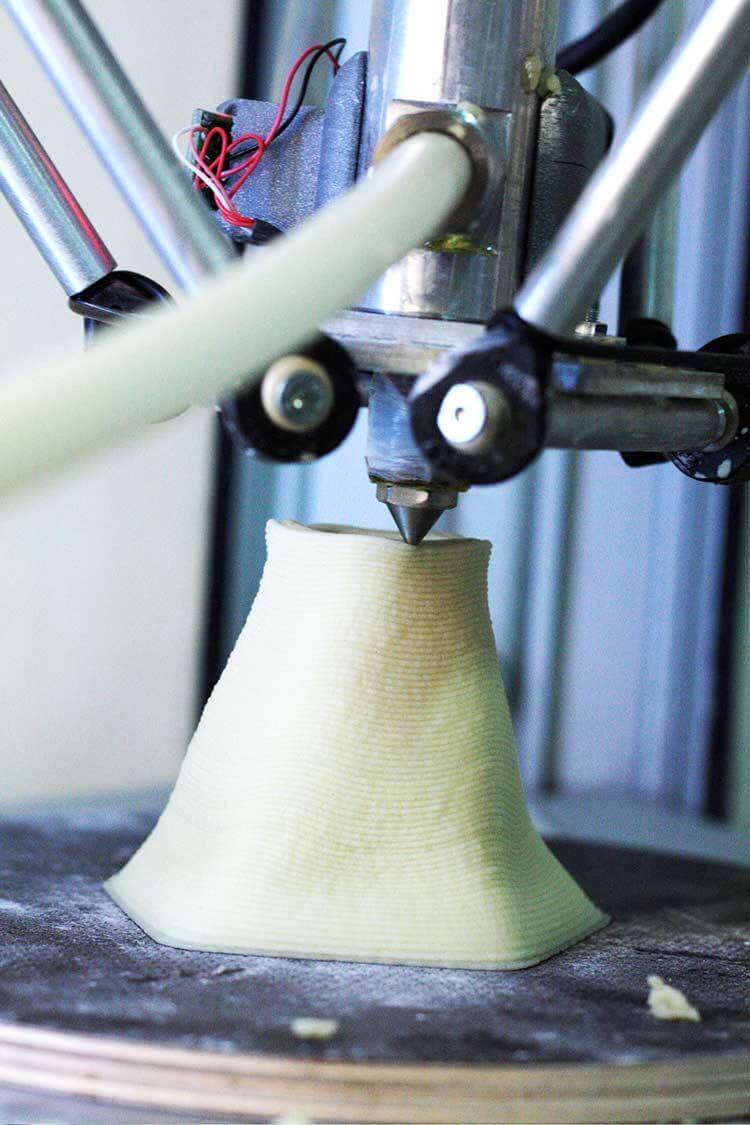

Using the Delta WASP 2040 TURBO2, users can print layers at 50 microns. So you can produce parts with smooth exterior surfaces.

According to the version that you choose, the printer might come with a Spitfire LT Cartridge or two Zel LT cartridges.

The former is a compatible LDM extruder that features paste extrusion for printing with ceramic and fluid materials. While the latter is used for multi-material and multi-color printing.

Delta Wasp 20 40 Turbo 2 is composed of an aluminum frame and polycarbonate and Flexi glass covers, the printer ensures constant printing temperature and high stability for advanced accuracy and reliability.

The resurrection system reduces the risk of printing failures in case of blackouts.

The Delta WASP 2040 TURBO2 has a 0.4 mm nozzle that is kept for giving its users the best balance between speed and detail.

This is a delta-type 3D printer but with high print speed. It also features nylon wheels that run on aluminum slides. Because there is minimal vibration of the print bed, the print quality is high.

Software

Credit: top3dshop.com

Credit: top3dshop.com

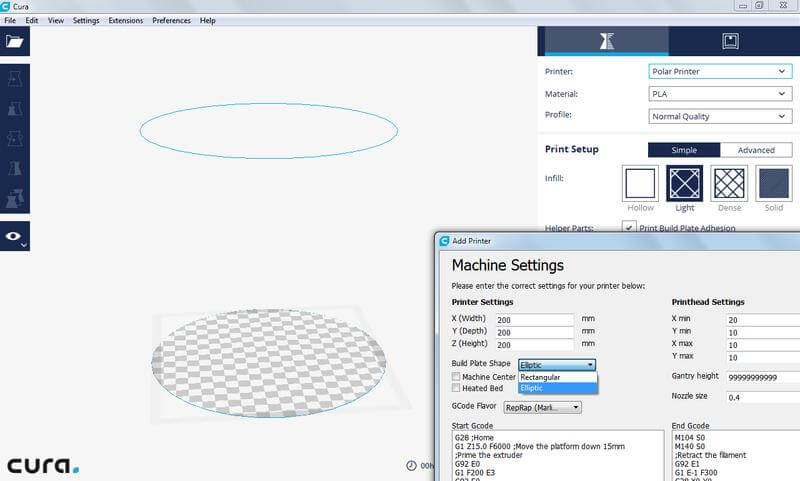

The operating systems that this printer is compatible with are Windows, Mac, and Linux.

The Slicing software that Delta Wasp 20 40 Turbo 2 is compatible with is all the general slicing software such as Cura, SLic3r, and Simplify3D. File type that can be available by using this printer are .stl, .obj, .gcode.

Customer Service

The website of the manufacturer features a support form that has to be filled before contacting the telephone assistance number.

This is a way for letting the company’s technicians know about the information necessary for them.

In case of returning the machine or part, you have to download the technical assistance module, compile it, and place it inside the original packaging.

The warranty and assistance policy are also mentioned on the company’s website which you can easily have a look at.

Parameters Influencing Buying Decision

Before concluding the article let’s take a look at some of the important parameters that are supposed to shape your buying decision in brief.

3D Printer Cost: Affordable to those who want speedy printing of parts and prototypes.

3D Print Quality: For an FDM desktop printer, the quality offered by Delta WASP 20 40 is commendable.

3D Print Speed: Above industry standard.

3D Printer Capability: Being an FDM 3D printer that to a desktop one, the printer is capable of producing with 3D materials of a very wide range. That’s because of the high temperature the printer can withstand.

3D Printer Practicality: Practically the printer is for those who wish to do small business in the field of 3D printing for the long term.

3D User Expectations: The printer might not stand upon expectations of newbies in the field of 3D printing in terms of the price it is available in the market. But for those who know a little bit about 3D printing and have experimented in the past would value the printer.

The Verdict

The Delta WASP 20×40 Turbo 2 is known to be amongst the fastest printing machines within the FDM desktop 3D printer category. After its launch in 2017, the printer has maintained this title undisputedly.

This 3D printer was released by an Italian company known as World’s Advanced Saving Project and the printer is a successor of Delta WASP 20×40. So, it has been created with better configurations and for better results.

As mentioned in the review above, one would find a lot of additions to this variant.

If you want speed with quality at a price that is average, you can opt for one amongst the two versions offered by Delta Turbo 2 i.e. Spitfire Red Extruder setup or with the ZEN Dual Extruder setup.

So the call is for you to make. Whether printing with a top speed is the most urgent need or not!