-

...

|

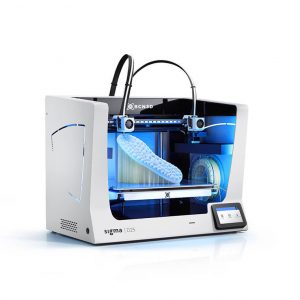

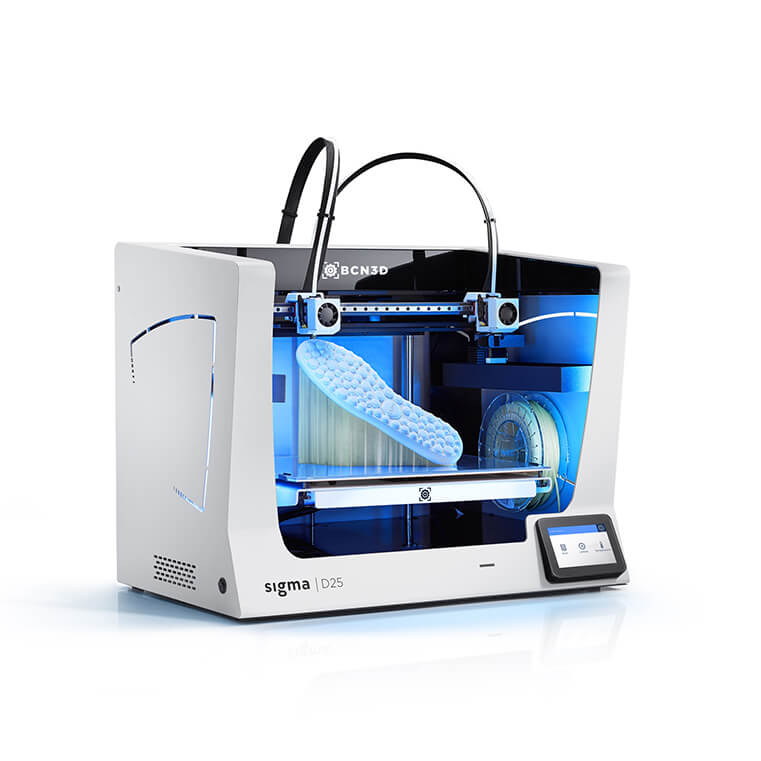

The company BCN3D is one of the leading 3D printer manufacturers in the world. It has Epsilon series of 3D printers and Sigma series of 3D printers.

In its Sigma series, this is the only 3D printer offering that the company has to date.

Features

Below mentioned are those key features that the company believes are the marketing features of this printer.

So, you can, after you read them, compare them with other printers in the same price range and decide which one amongst them is a more “buyable” printer.

Comes with a unique Ecosystem

Sigma D25 3D printer is not only equipped with the latest connectivity features but also gives you a free workflow on its hassle-free BCN3D cloud platform.

Using these features, sending your print files to the printer is easier than ever before.

Unlike other printers that require you to manually update the firewall for ensuring the files undergo no breach, thanks to the over the air updates that this printer comes with.

Due to such a setup mechanism, the printer is always up to date, and its activation can be on-demand.

Bondtech Extruders and filament run-out sensors

Bondtech is a company that provides unique and customized mechanisms for the printer’s extruders.

The manufacturer of this printer has installed in it, a high-tech dual drive gear by the Bondtech company.

Installation of these dual-drive gears offers its user more control and sharper details on the printer.

They also ensure the superior performance of the printer irrespective of the type of filament used in it. The filament run-out sensor is the key thing in the market currently.

So, if you are looking to buy any 3D printer, do look for this feature in that printer. As the name of this feature suggests, it is a sensor that senses something about the filament.

So, when the filament is over, the sensor instructs the printer to pause its 3D printing procedure until the reloading of the filament has been accomplished.

In that sense, it is a job-saving sensor, an absence of which can cause you the major flaw in your 3D printing.

An aluminum-framed printer with e3D Hotends and touchscreen interface

Sigma D25 is a desktop 3D printer that, like every other desktop 3D printer that has a probability to vibrate when given duties of 3D printing a part or functional prototype.

So, to ensure anything of this sort does not happen, the manufacturers have equipped it with an aluminum frame that makes the outer body of the printer sturdy.

Extrusion is the most important phenomenon in FDM 3D printing technology.

To ensure that this phenomenon is done in a smooth fashion, the manufacturers of this printer uses e3D Hotends which have earned the reputation of the most reliable extrusion carrying out hot ends.

In addition to ensuring its user a steady printing procedure and reliable extrusion, the manufacturers of Sigma D25, to ease out the interaction between user and the printer added a multilingual touchscreen.

This touchscreen is five inches in length. And the anomaly because of which it can make this printer a leader in the price range that it is offered is the languages that it supports i.e. German, Spanish, French, Italian, Japanese, Portuguese, and Chinese.

Operating any device in the language that you know primarily is a luxury on its own.

And realizing this fact, the manufacturers of this printer have offered this feature.

Compatible with multiple filaments

PLA, PETG, TPU 98A, and PVA are the name of some filaments that the printer is compatible with.

Sigma D25 can work comfortably from the desktop with most of the safe to print materials that BCN3D company has selected for you.

These filaments, unlike other printers, have been developed by renowned chemical companies like BASF and Mitshubishi Chemical.

The chemicals are known to ease your workflow by operating on preset configurations and a simple set of commands.

Advanced features with surface heating and calibration

The printer uses an aluminum build plate and silicone thermal pad that is known to distribute the heat evenly.

And for the part to gain high-qualities, it is necessary that the heat needs to be distributed evenly, not only on the build plate but on the complete print chamber.

For the calibration, the manufacturer of this printer has developed an optimized firmware calculation system that allows a more accurate adjustment of the level.

And you may ask any 3D printing expert, if you are a newbie, about the level adjustment and how important that is.

The accurate the calibration, the more dimensional accuracy on the print job.

For preventing the overheating issue which is one of few major concerns while printing with the help of FDM 3D printing technology, the manufacturer of this printer has positioned this printer on its back.

This also reduces the distance of the extruders to the hot end.

The X and the Z-axis of this printer have been reinforced in the printer.

The X-axis of this printer is changed to Stainless Steel from the previously used material, whereas the Z-axis of the printer because of the multiple changes in the printer’s mechanical structure.

Wireless Printing and disruptive independent dual extrusion system

As mentioned above too, this 3D printer is equipped with the latest connectivity features which can easily send your print files whenever you are connected to the network.

The complete system of this 3D printer works in three simple steps i.e. Design, Configure, and Print.

When you land on the webpage dedicated to this 3D printer, you come across a video when you scroll down from the first section of the website.

This video shows you 3D printing going on in two different areas of the printer, in the exact same manner.

That is the interesting feature of this independent dual extrusion system of the printer.

But, BCN3D takes it’s to another level by giving you four modes to operate its amazing independent dual extrusion system.

- Duplicate Mode: A setting that claims to print identical modes simultaneously.

- Mirror Mode: A mode that enables printing exactly the same designs symmetrically and speeding up the iteration part.

- Soluble Support Mode: The process which prints only the soluble parts for creating intricate 3D parts and functional prototypes.

- Multimaterial Material Mode: The mode which can let you print with two different materials at the same time.

Specifications

Credit: crea3d.com

Credit: crea3d.com

Sigma D25 is based on FFF 3D printing technology. The printer comes with an independent dual extruder and offers a print volume of 420 mm * 300 mm * 200 mm.

The number of extruders as offered by the company are two. The extruder system of the company consists of an Extruder running on the Bondtech company’s high-tech dual drive gears with Hotends that are optimized and manufactured by e3D company.

The printer can print using five modes i.e.

- Single-mode.

- Duplication mode.

- Mirror mode.

- Multimaterial mode.

- Soluble Supports mode.

Electronics used in the printer are Single Board Computer: Toradex ARM Compute Module. Whereas the Motion Board used in the printer is: BCN3D Electronics with Independent Stepper Drivers.

The firmware used by Sigma D25 is BCN3D Embedded Linux distribution, BCN3D Sigma D25 – Marlin. As mentioned above the printer comes with a touchscreen that is five inches long.

While operating the sound produced by this printer is in the order of 49 decibels. Sigma D25 uses a nozzle made of Brass which has a 0.8 mm diameter.

The printer offers offline connectivity via SD card, and online printing via Wi-fi or Ethernet.

The filament diameter used by the printer is in the order of 2.85 mm with a tolerance of 0.5 mm.

Overall dimensions of the printer are 690 mm * 530 mm * 550 mm, and the weight of the printer is 30 kilograms.

layer height range visible on the parts and functional prototypes printed by the printer is 0.05 micrometers to 0.5 micrometers.

The recommended operating temperature range of the printer is 15 to 30 degrees Celsius.

The maximum Extruder temperature that the printer can withstand is 300 degrees Celsius and the maximum heated bed temperature is 80 degrees Celsius.

Price

Right next to the printer’s picture, you can find the price written on the company’s website, which if you convert into dollars comes down to $4530.

The estimated delivery time given to you by the company is two weeks, which is not that bad.

First Impression

Seeing Sigma D25 from the front would make the printer seem like a box with fancy lighting.

Apart from the outlining body, the printer’s other parts are kept transparent.

So, the nozzle system, the print head, its connection to the rails that make the nozzle move up and down on the print bed is all visible. Even the filament spool holder is visible.

The multilingual touchscreen is present at the right bottom of the body of the printer which is made of aluminum. That’s all for the first glance over the printer.

Setup

The printer is a desktop one, comes almost completely assembled. Although you would have to check the calibration because if it’s shipped to your place, the transportation is known to change the calibration.

Apart from the calibration, once you read the instruction manual that the printer comes with, or refer online to the information provided about the printer’s part on its website, you are good to go for the printing part.

Printing Type/Cost

The FDM 3D printing technology prints a part or functional prototype using filament of the part you wish to 3D print with.

Here in the part is heated in the extruder, and then when it starts melting the flow falls on the print bed as per the layer design of the part.

Once the first layer is completed, the nozzle system moves the print head opposite to the gravity and that’s how the complete part is printed.

Because of the process being simple and not utilizing any expensive parts for its curing process apart from cooling fans in some cases, the printing cost per part is lower than other processes.

Print Quality

Credit: bcn3d.com

Credit: bcn3d.com

Although the layer resolution is in the range of micrometers, they will be visible when consciously made an attempt to see them.

However, stating the fact mentioned by the company about the industries in which parts or functional prototypes made by this printer are used, there is Engineering, manufacturing, schools, service bureau, and professional individuals. So, the overall quality of the parts should be good.

Software

Credit: bcn3d.com

Credit: bcn3d.com

Sigma D25 supports BCN3D Cura software which is easy to use as it avoids the use of technical language.

It can be operated using any of the three available operating systems in the market.

The supported file formats on this software include STL, 3MF, OBJ, and AMF.

The printer can be connected wirelessly via a BCN3D Cloud. Sigma D25 supports Chrome, Firefox, Edge as well as Opera browsers.

Customer Support

A tab on the company’s website is titled Support. When you click on it, you are opened up to the knowledgebase that the company has made for each of its visitors looking for knowledge regarding any of its printers.

This is one way to solve the doubts you have regarding the printer, the other is the Customer Support form.

Apart from that calls and emails are somethings you can always do for the company.

Parameters Influencing Buying Decision

The factors that will help you judge this printer, in brief, are mentioned below.

3D Printer cost: Small business owners and professionals can afford the printer.

3D Print quality: Average.

3D Print speed: Can be speeded up while printing small parts.

3D Printer capability: Not just capable of printing with multi-materials, but also in multi-modes.

3D Printer Practicality: The independent dual extruders of this printer expands its practicality that compared to competitors.

3D Printer User expectations: If cost is not a huge constraint for you as a beginner, the printer is meant for fulfilling every individual user’s expectations.

The Verdict

If 3D printing technology is where you wish to build your career, you can start, scale-up, or continue your experiments with this 3D printer.