Known for its unique properties, Copper is one of the most difficult metals to print. However, the innovations have led to better prospects. Today, we have various copper 3D printers that allow users to print with this difficult metal. From high-resolution printing to faster throughput, the industrial 3D printers designed to work with copper provide amazing results.

Many consider Copper to be a very unique metal. Popular from older times, metal has been gaining huge importance with time. This ductile metal can conduct heat as well as electricity. With various unique chemical and thermal properties, the metal showcases unparalleled results when coupled with 3D Printing.

Using a Copper 3D printer, one can create parts with pure Copper. Not just that, with better techniques and advanced features, the process is less labor-intensive and time-consuming when compared to other traditional methods.

Hence, if you are interested in buying a printer that can create copper parts, here are a few recommendations that would help.

List of Copper 3D Printers a

Metal 3D Printers do not come cheap. On the contrary, they can cost you a fortune. If your business is expanding and you want to adapt to additive manufacturing, the choice is feasible.

However, if it is just an interest in finding out how it feels creating Copper parts using 3D Printers, it is recommended to go for the 3D printing services.

For the rest, here is what you can consider as the best buy:

MarkForged Metal X

Based on Atomic Diffusion Additive Manufacturing technology, MarkForged Metal X is a very reliable machine for Copper printing. Apart from Copper, the machine also supports printing with Inconel and various steels.

The printer has a build volume of 300 x 220 x 180 mm. And, it costs almost $99,500. To work with metals, the MarkForged 3D printer makes use of a metal-filled plastic filament.

However, there are certain post-processing methods in order to complete the part production. The printed part must go through the washing process using a special debinding fluid. This completes in the Wash-1 Station.

Further, the part goes through sintering inside a heating furnace. To accomplish this process, the manufacturer offers two different machines: Sinter-1 and Sinter-2. You can choose between these when buying the Metal X 3D Printer.

The sintering process eliminates the binding polymer and leaves the part with 100 percent pure copper. This amazing technology is easier to carry. Hence, the Copper 3D Printer is quite popular among users.

Another important benefit of using the machine is its affordability compared to DMLS 3D printers, popular with copper. In short, the price of the printer is 5-10 times less than DMLS metal 3D printing systems.

Not just that, the Metal X 3D Printer does not require a dedicated operator. Users can work with minimal PPE and without needing to invest efforts in power management.

In short, providing users with a seamless experience, the printer sits among the favorite choices within various industries.

|

Xact Metal XM200C

The 3D printer from the United States manufacturer, Xact Metal is a wonderful choice for printing Copper parts. XM200C has a small build space, sufficient to work with small models. It has a build volume of 127 x 127 x 127 mm. Also, the cost is pretty affordable compared to the various metal 3D Printers.

Being an entry-level 3D printer, XM200C results with metal printing aren’t as competitive as advanced machines available at a higher cost. But those with limited funds still can plan to get this printer up and running.

Talking about the applications, the machine is good for research purposes as well as small-batch productions. Making use of the manufacturer’s proprietary Xact Core gantry system, the machine ensures precise movements when creating parts at a high fusing speed of up to 500 mm/s.

The manufacturer has its own materials to provide high-quality printing. Apart from Copper, the other materials include different Stainless Steel, Tooling Steels, Super Alloys, Aluminum, Titanium, and Bronze.

In case you have experience working with metal printing, you certainly can make use of your choice of metal powders.

SPEE3D LightSPEE3D

SPEE3D is an Australian manufacturer that has come up with its own line of printers. The design of its LightSPEE3D is based on Supersonic Deposition from the family of Metal Jetting.

Released back in 2017, the printer is very reliable and has been able to gain a lot of appreciation in these many years. That is why it does deserve a say in our list of Copper 3D printers.

What’s fascinating is its great build and a pretty spacious area for creating parts. The printer flaunts 300 × 300 × 300 mm space for printing. Australian manufacturer SPEE3D has come up with this impressive technology that could work without the involvement of heat.

For creating Copper parts, the machine uses metal powder and no heat. Sounds confusing? But SPEE3D has found out a unique 3D printing process for the same. Using a very uncommon technique, the material is jetted at supersonic speeds using a single nozzle.

Also, the nozzle does not move and stays static throughout the printing process. It is the print bed that keeps changing the angles from time to time on different axes. Because of this, the weight limit of parts is 4 kilos for now.

Talking about speed, the printer can print at a rate of 100 grams/minute. This certainly is a huge leap for metal 3D Printing. And, we wait for more to come from this innovative company in the future too.

The cost of the printer is around $650,000.

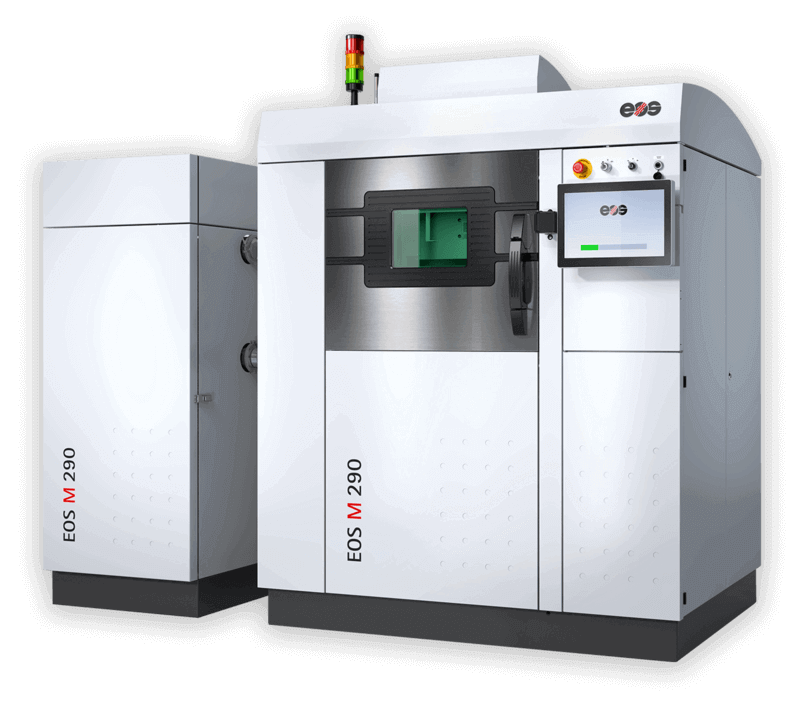

EOS M 290

Offering a build volume of 250 x 250 x 325 mm, the EOS M 290 provides users with the best quality copper parts. The printing system is reliable and offers fast, flexible as well as cost-effective production. One can start printing directly from the CAD files.

With so many amazing features, the 3D printer ensures that the users find it easy to work with the machine. For instance, it has an intuitive user interface that is user-friendly and simple to operate. In addition, the company has intelligent software catering to the different design needs of the customers.

Moving on, the EOS M 290 features an improved filter system. This helps the machine to offer industrial production with the highest level of safety.

The printer is based on DMLS technology. In order to provide precise prints, M 290 uses a 400-watt fiber laser. Hence, offering an exceptionally high beam quality as well as consistent performance stability.

The printing system performs manufacturing in protective nitrogen and argon atmospheres. Therefore, it is compatible with a wider range of materials including Copper.

In addition, the 3D printer can help in various applications. Using the standardized Part Property Profiles (PPPs), the machine can create accurate parts, according to the specific needs of the various industries.

|

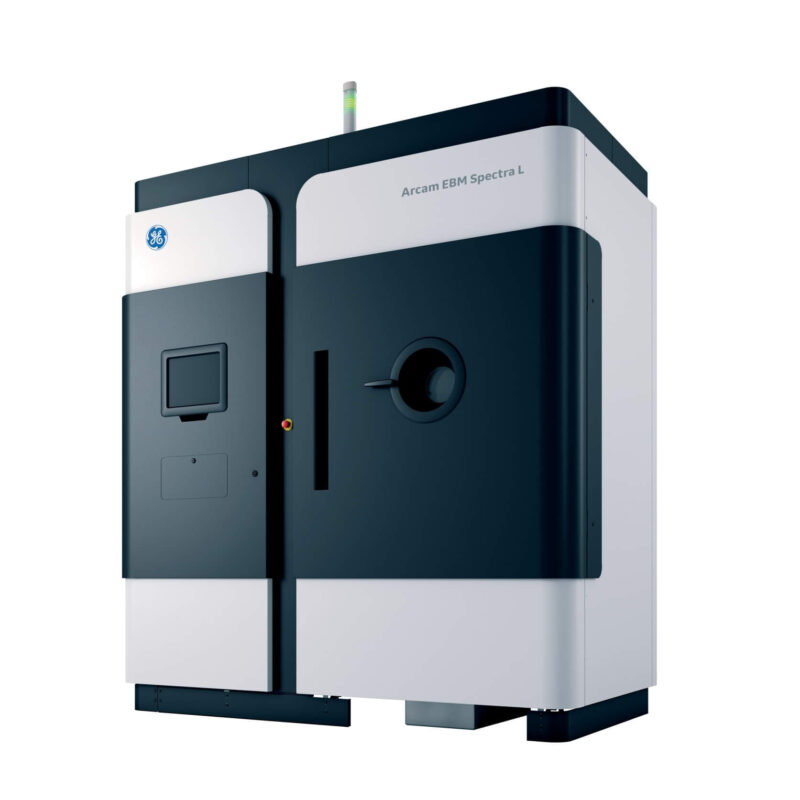

Arcam EBM Spectra L

One of the biggest machines, the Arcam EBM Spectra L is a very amazing 3D printing system offering unprecedented results.

With a building envelope of Ø350 x 430mm, the machine ensures that the users can easily print large objects in one go. Not only has the manufacturer come up with an increased build space, but also offers 4.5 hours faster print speed than its EBM Q20plus.

To make copper printing possible with high precision, Arcam EBM Spectra L can create parts with 20% finer feature resolution. It can create models with small spot sizes ranging between 70 and 500 microns.

Among the other upgraded features, the printer includes an improved gas flow system. Based on electron beam melting technology, the copper 3D printer can accomplish jobs with the highest level of accuracy.

Users can print parts with a smoother finish as well as with enhanced material properties, even for thinner walls. Offering mass production by including a feature to tightly stack parts, the printer enables high production throughput.

Overall, the printer is a very reliable machine ensuring great design flexibility for creating copper parts.

|

Application of Parts Printed with Copper 3D Printers

Credit: webshopapp.com

Credit: webshopapp.com

Copper has various uses. From automobile to jewelry designing, the material can help a large number of sectors to accomplish their design goals. Here are some of the examples where copper 3D Printers can help speed up the manufacturing processes.

- Bus Bars

- EDM Electrodes

- Welding Shanks

- Heatsinks

- Custom Fitting

- Induction Coils

- Adapters and more

So, if you are thinking of experimenting with 3D printed copper parts, this is the right time to invest some money to enhance your business capabilities.

The Conclusion

Copper 3D Printing isn’t as old as polymer printing. However, soon after the innovation of additive manufacturing technologies, the series of developments took huge momentum. Today, we can find plenty of 3D printers that can work seamlessly with Copper.

Coupled with the latest and advanced features, Copper 3D printers allow users to accomplish complex jobs with ease. Hence, if you are planning to try Copper printing, do not forget to check our recommendations, before you make any decision.