The relation between Aerospace and 3D printing was established years back in the early 1980s. Since then, Aerospace 3D printing is been continuously evolving and adapting to 3D printing.

Statistically, the Aerospace and Defense contributed sixteen percent of 3D printing’s more than $4.9 billion global revenues in the year 2015.

A more recent report by Research and Markets found the growth rate of Aerospace in 3D printing at 23 percent from 2017 to 2021.

Equipment manufacturers, designers, and suppliers search for cost-effective, quick, and efficient solutions. This is leading them towards 3D printing.

As more and more people increase their commercial air travel, the demand for new aircraft and their parts is also increasing. And there are many benefits that Aerospace 3D printing provides.

Starting from reducing air drag by 201 percent, which leads to a reduction of fuel costs by 5.41 percent. Waste reduction, faster production times, greater consistency, and better surface finishes across aircraft, are also some of the main benefits that lead to 3D printing of Aerospace parts and functional prototypes.

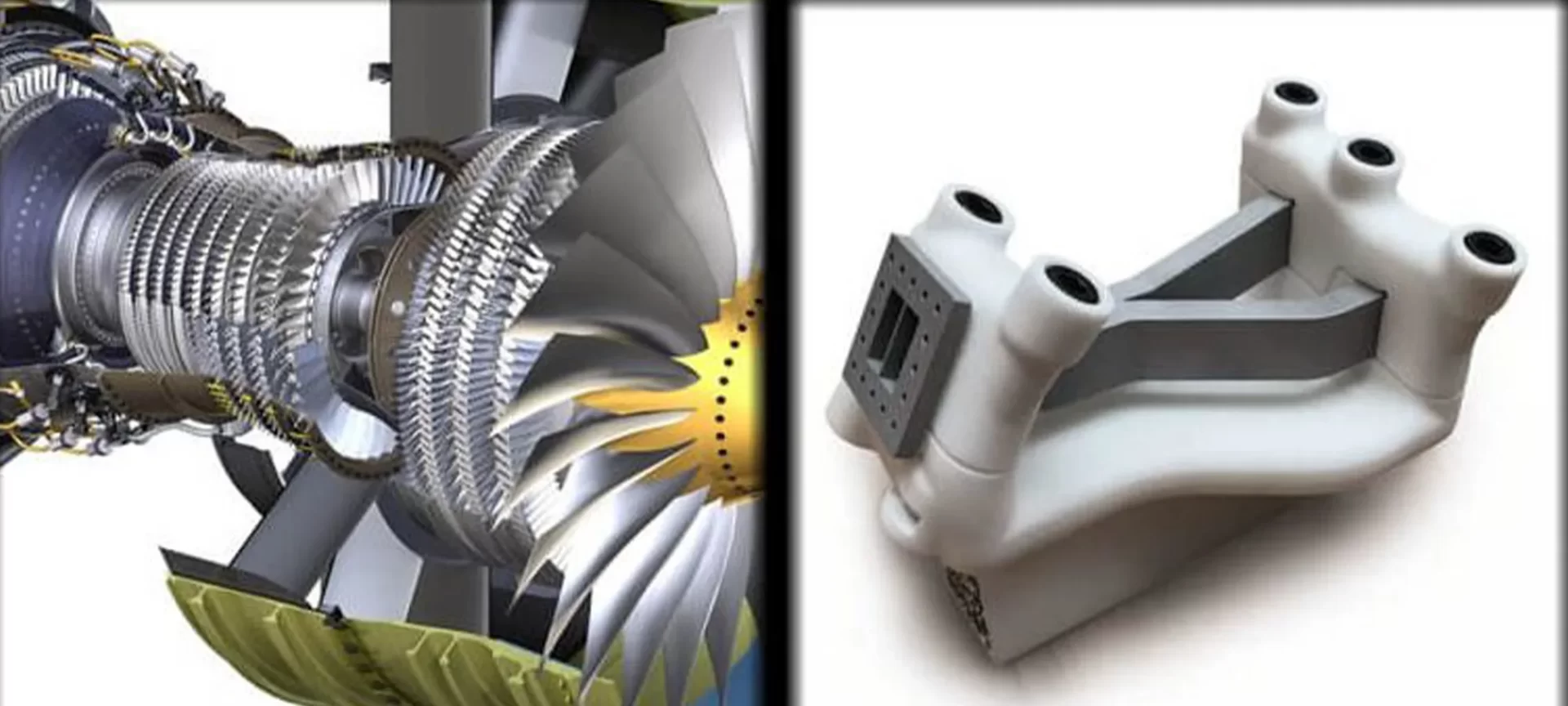

Which are those 3D printed parts used in the Aerospace field? What are the 3D printing materials used for making those parts? The 3D printing technologies employed for manufacturing them and the 3D printers used for making those parts are the key points that we’d take you through, in this guide.

How is 3D Printing Used in Aerospace?

One of the main advantages of Aerospace 3D printing is customization. Parts used in this industry can be tailored to specific aircraft. Doing this increases the overall efficiency of the aircraft.

The fact that these parts can be made at a lower cost than when manufactured using other technology leads to a decrease in cost.

Jigs and Fixtures

In a single aircraft, hundreds of fixtures, guides, templates, and gauges are to be 3D printed. There are around 60 to 90 percent reductions in manufacturing cost and lead time when manufactured using 3D printing compared to other manufacturing technologies.

Surrogates

These are placeholder parts used throughout production representing components that are then installed in final assemblies.

Surrogates are primarily used for training purposes. NASA and other air forces commonly use this part for the production floor.

Mounting Brackets

3D printing is commonly utilized for manufacturing structural, low-volume metal brackets that mount complex lifesaving systems for the interior wall of a plane. These parts are printed using DMLS or SLM 3D printing technologies.

Visual Prototypes with High Detailing

Using Material Jetting 3D printing you are able to produce a multicolor design with a surface finish that can be compared with injection molding.

They are visually appealing models that allow designers a larger understanding of the form and fit a part before production decisions.

The final finish of the prototype often represents the surface finish of the part, imagine the level of accuracy that can be achieved with this method! It is ideal for aerodynamic testing and analysis.

Aerospace 3D printing is regularly utilized for manufacturing aerospace components relying on aesthetics than function. Parts such as door handles, and lights housing for control wheels and full interior dashboard designs.

These are the four most common parts that are 3D printed and currently used in the Aerospace industry. Having looked at them; it is time to look at the technologies that are employed for making these parts.

What Technologies are used in Aerospace 3D Printing?

The level of accuracy needed for manufacturing the above-mentioned parts and functional prototypes makes it necessary for you to employ technologies that fall majorly under the powder bed fusion category.

So you will encounter Selective Laser Sintering, Material Jetting, Direct Metal Laser Sintering is the chief technologies used for making aerospace 3D printed parts.

Apart from powder bed fusion, there is Stereolithography, which is also able to provide dimensional level accuracy in 3D printed aerospace parts.

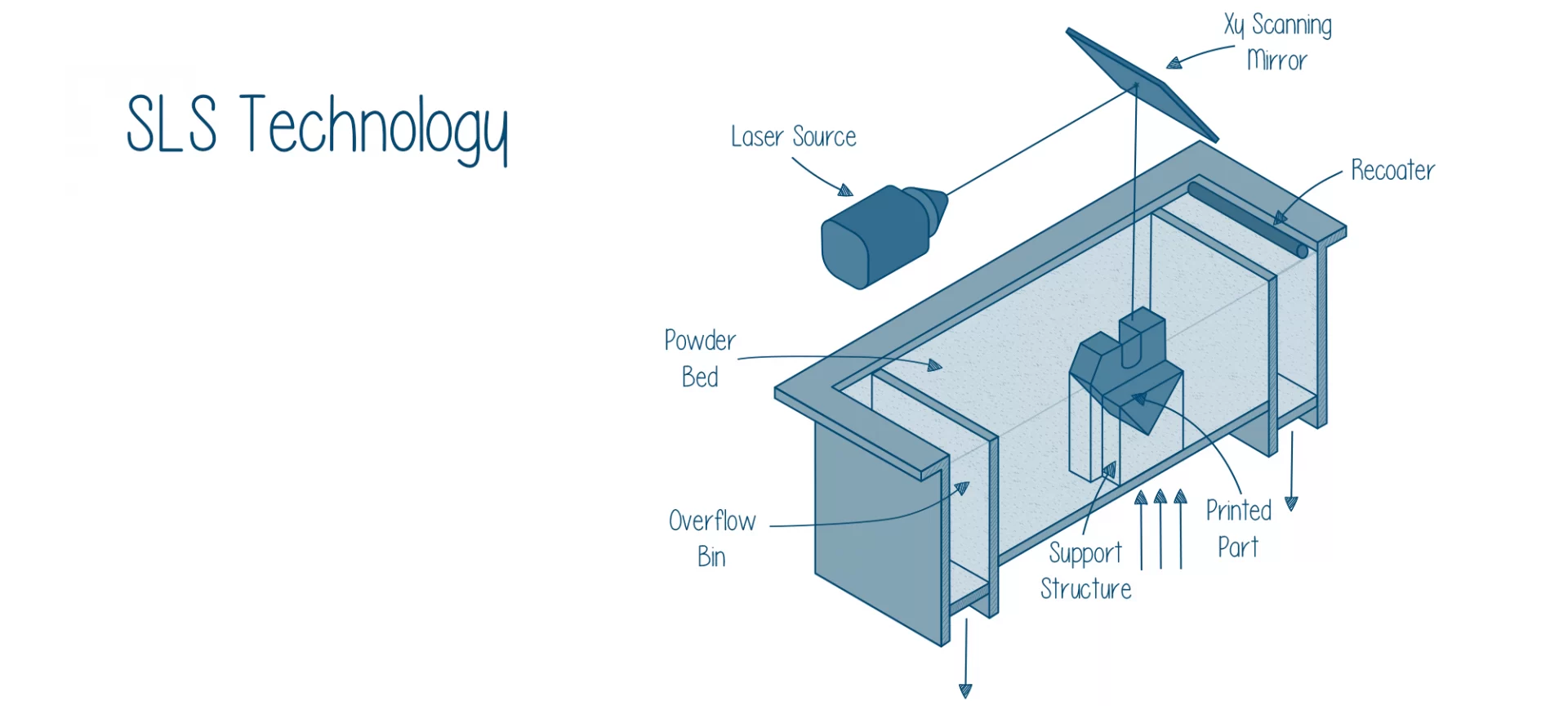

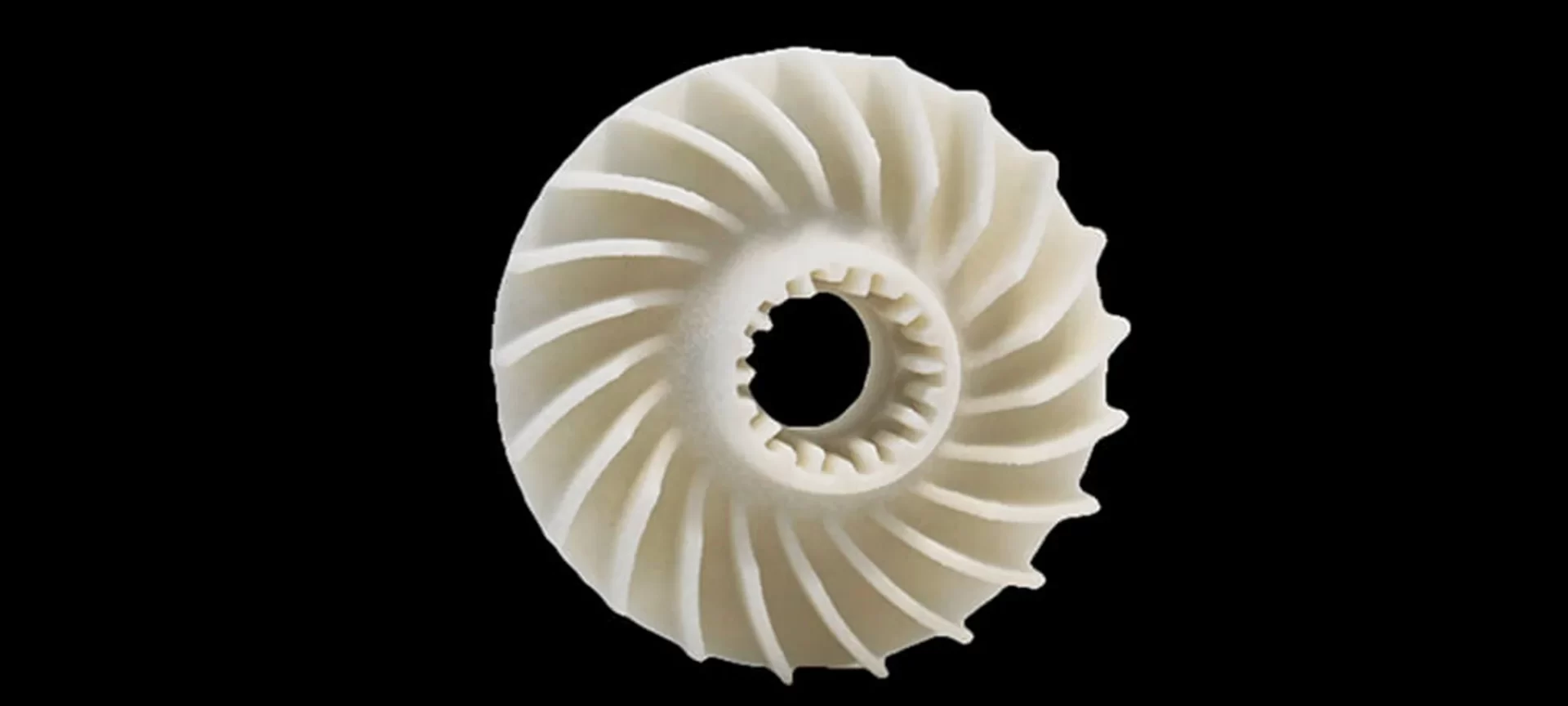

Selective Laser Sintering

A laser particularly sinters the particles of polymer powder, fuses them with each other, and builds a part in SLS 3D printing. The materials that are used in SLS are thermoplastic powder coming in granular form.

This technology is famous for prototyping as well as functional polymer components for small production runs.

It offers a very high level of design freedom, accuracy, and consistent mechanical properties. While designing parts and functional prototypes using this technology, the designer must take into consideration the limitations and benefits.

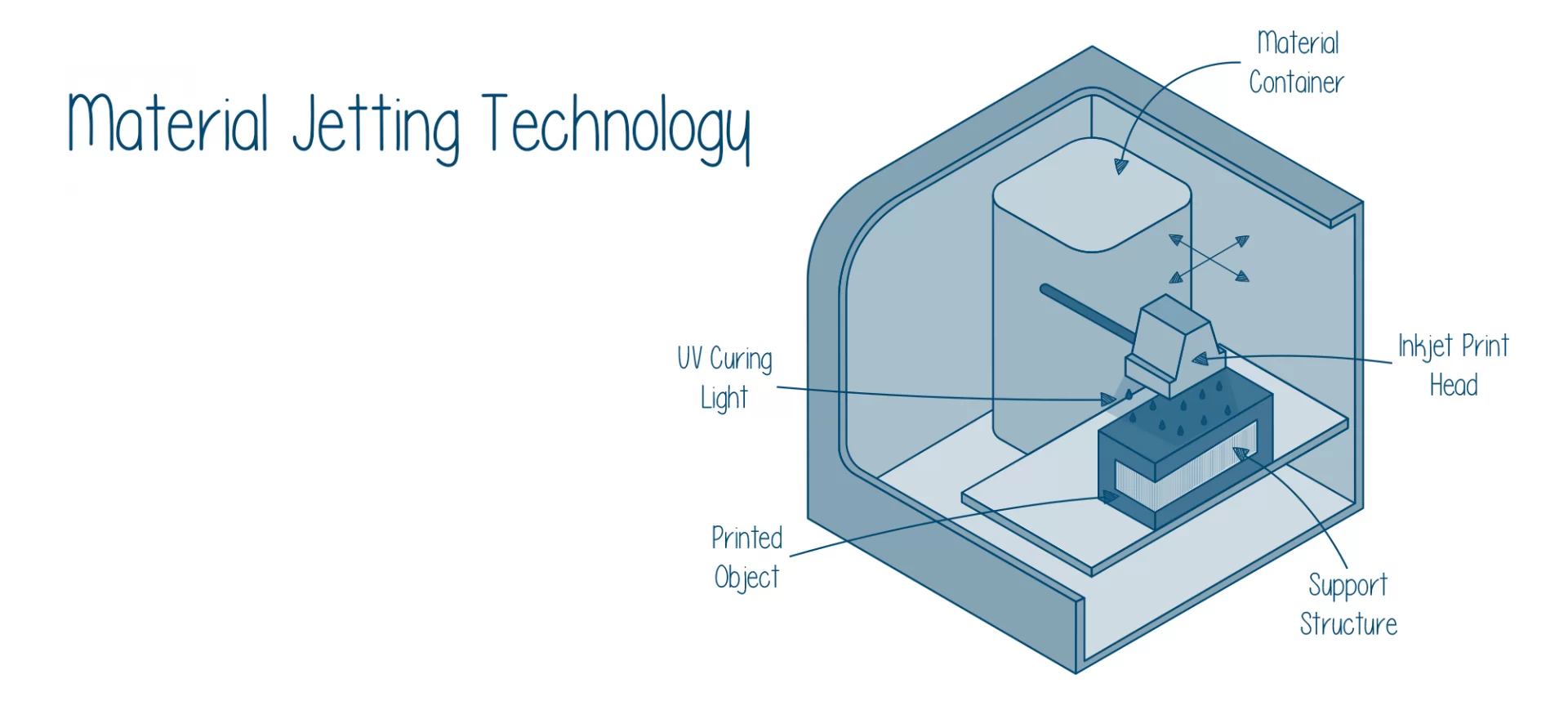

Material Jetting

For understanding this technology, you need to take into account inkjet 2D printing technology. They both are pretty similar. Herein a printhead dispenses droplets of a photosensitive material solidifying it under UV light. The parts are build layer by layer.

The 3D printing material used for making parts and functional prototypes using this technology is a thermoset polymer.

They are generally available in liquid form. MJ 3D printing is known for creating dimensionally high accurate parts with a smooth surface finish.

The main characteristics of these parts are that they are visually appealing for prototypes as well as tooling manufacturing.

Drop on-demand print heads are used for dispensing viscous liquids and wax-like parts overprint beds.

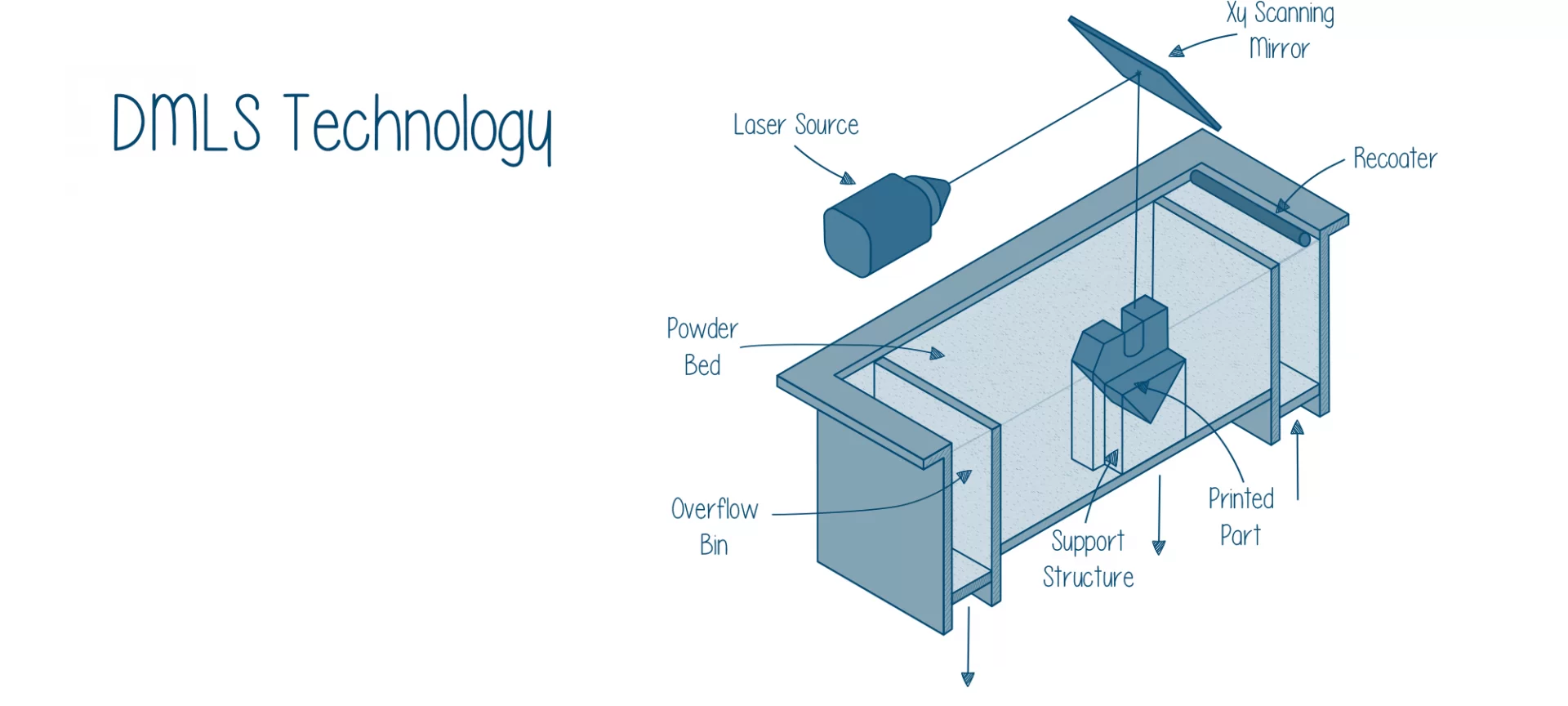

Direct Metal Laser Sintering

This process can be understood as advanced powder metallurgy. The 3D printing material employed in this 3D printing process is finely powdered metal typically in the order of 20 to 40 micrometers.

Due to such a small-sized and shaped 3D printing material, detail resolution can be achieved in the final part.

The DMLS process starts with the hopper getting filled with desired 3D printing material. In the next step, the printer heater brings the powder to a level wherein it’s the sintering range of the alloy.

For doing so, DMLS printers utilize inert gases that protect the heated powder and part during its building process.

Dispensation of a thin layer of metal powder starts the building process, which continues until the part completion layer by layer.

The part is then cooled down; the surrounding metal powder is then removed from the printer followed by post-processing.

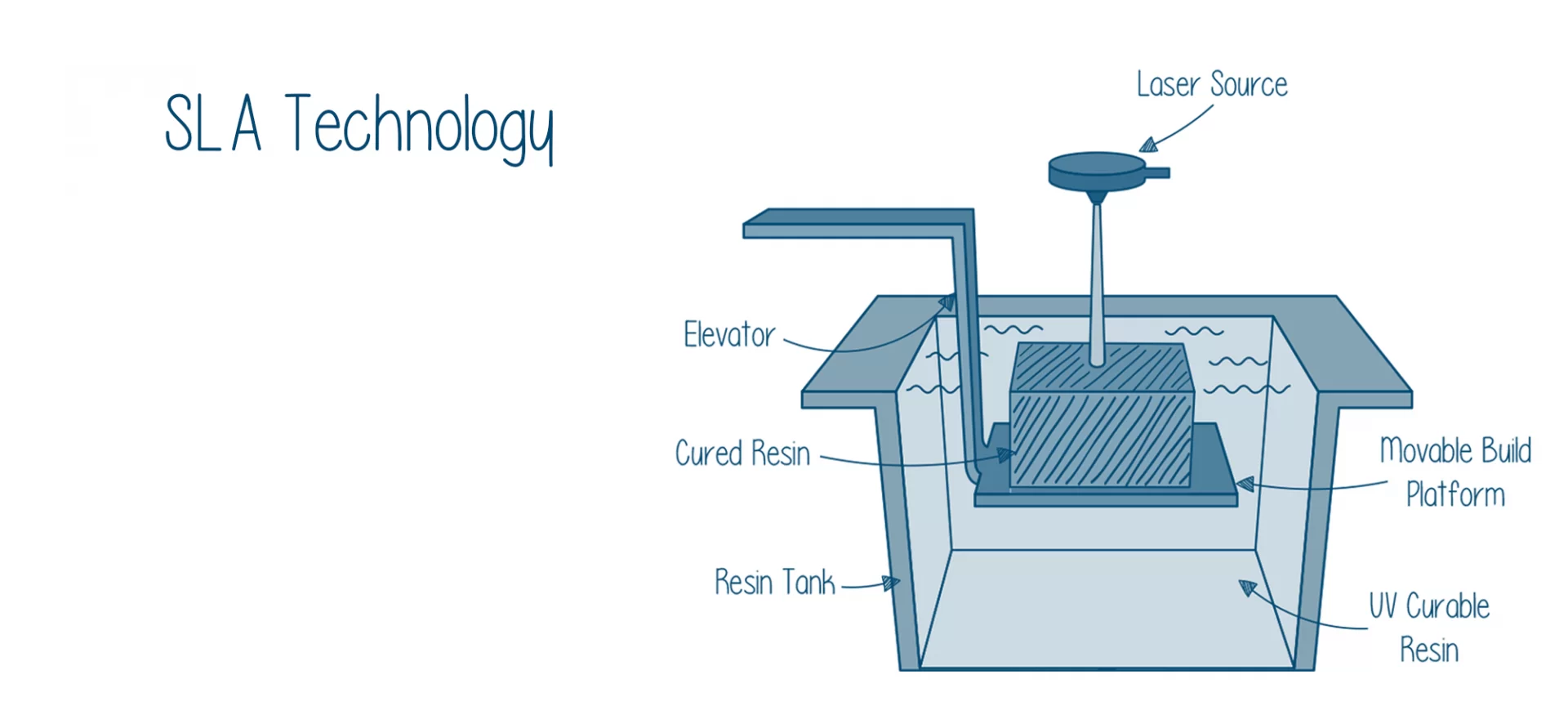

StereoLithography

This is the only technology that falls under the Vat polymerization category and still is able to provide the accuracy needed in Aerospace 3D printing.

While printing a part with this process the 3D printing material i.e., the polymer resin is cured layer-by-layer using a UV laser beam.

The material is present in liquid form. SLA holds the title of being the most cost-effective 3D printing technology in the 3D printing industry.

It is similar to Digital Light Processing 3D printing technology and is often considered as its synonym.

What Materials are Suitable for Aerospace 3D Printing?

Now that we are halfway into the guide and have explored the parts that are made in Aerospace 3D printing along with the technologies involved, let’s dive into more details.

Wouldn’t you like to know the materials that make these parts? We have a list of them and their characteristics that makes them the most suitable material for making these parts. Excited? Let us get started.

Parts such as Tarmac nozzle barrel, console control, airflow ducting, seat backs and entry doors, brackets and door handles, suspension wishbone and GE jet engine, dashboard interface, and headlight prototypes go into applications such as engine compartment, cabin accessories, air ducts, full-size paneling, bezels, and lights. They are made using:

Glass-filled Nylon

Nylons have very high rigidity, mechanical strength, hardness as well as toughness, and high creep strength.

They are also known to have high dimensional stability, good fatigue strength, and high mechanical damping properties.

Due to these properties, they are suitable for applications subjected to high static loads for long periods in high-temperature conditions such as the Tarmac nozzle barrel.

Digital ABS

This high-resistant resin is known to achieve good performance with high impact strength with high-temperature resistance and superior finish.

Using this you can create realistic parts that are precise, tough, and can resist heat for a long time.

Parts made by this material are known to possess high mechanical and thermal resistance. Bezels are manufactured using this 3D printing material.

Clear Resin

They have similar properties to standard resin. They possess fine features and high detailing. Parts produced by this 3D printing material are known to have a smooth surface finish and are transparent in looks.

Apart from these three, Titanium as well as Aluminum is also producing excellent results, but are not as much in use, as much as these three.

Before concluding this article let’s explore the machines that let you process these materials into functioning parts and prototypes.

3D Printers That Makes Parts For Aerospace 3D Printing

There is a huge market for 3D printers and its increasing day after day as the technology progresses. We’ve handpicked some of the leading 3D printers that are primarily meant for producing parts related to the Aerospace 3D printing industry.

The key manufacturers that are into manufacturing 3D printers keeping in mind the Aerospace industry are EOS, ExOne, and Stratasys.

EOS M 400

With four times more productivity, four precise 400-watt fiber lasers, and a build volume of 400 mm * 400 mm * 400 mm, EOS M 400 is a benchmark of productivity, automation, and quality.

Its success stories consist of making propulsion modules, turbomachinery and turbines, and a lot more.

You can print on this 3D printer using a wide range of 3D printing materials ranging anywhere from light metals to stainless steel, tool steel as well as superalloys.

Pros:

- Four precise 400-watt fiber lasers for high-quality parts.

- Fully automatic and intelligent material management solution.

- Tried and tested software.

- Intuitive user interface.

- Four times higher productivity.

ExOne X1 160Pro

Based on Binder Jetting 3D printing technology this is the largest metal 3D printer from ExOne.

It lets you build aerospace parts and functional prototypes of 800 mm * 500 mm * 400 mm which is 2.5 times more than the build volume of competitors in the market.

The printer can manufacture using twenty different types of 3D printing materials including ceramics and composites.

The printer features a newly patented Triple Advanced Compaction Technology system delivering industry-leading port density and repeatability.

The print speed of this printer is 10,000 cubic centimeters per hour depending on the material.

Pros:

- Unparalleled material flexibility.

- The best balance of speed and quality.

- Patented quality feature.

- Largest metal 3D printer from ExOne.

|

Stratasys F120

Not just this 3D printer but also the complete F123 series of Stratasys is used for Aerospace 3D printing. F120 is an industrial 3D printer that’s easy to use, reliable and safe.

It offers zero downtime, 45 percent faster print time, and 97 percent accuracy while building parts and functional prototypes.

The company claims how this printer can print for 250 hours straight. All you have to do to start printing with this printer is just plug and play. Currently, you can print with two colors i.e. Ivory and Black.

Pros:

- Parts made by this 3D printer have high surface quality.

- In terms of accuracy, the printer is 97 percent more accurate than 57 percent of its competitors.

- F120 prints are two to three times faster than desktop 3D printers do.

- You need no specialized technician or training to install this printer.

|

The Conclusion

Realizing the potential of Aerospace 3D printing, more and more companies are getting involved in it. The research and development section regarding 3D printing materials used for it is continuously expanding.

More and more 3D printers are made for manufacturing parts and functional prototypes that find application in this industry.

Overall, this industry has a very bright future and has very good potential for the application of 3D printing technology.

Experts foresee a significant rise in Aerospace 3D printing from the current situation because of the increasing demands in the industry.

The airplane remains the fastest means of long-distance travel and therefore is the most preferred one for the same. Post globalization traveling to different geographies for work has become an ordinary thing.

In addition, if the ambitious idea of flying cars is to be taken into account there is a lot that can be done in this field.