|

There was a time when, if you were a small business owner that operated depending upon the 3D printing processes, your bread and butter were on FDM and SLA techniques.

Before that was the time when based upon these two processes, only industrial 3D printers were made. So, there weren’t, for a fact a lot of small business owners in this field.

This has been the case whenever a new technology emerges, it is first tried and tested and business made by the industrial class and then made available for the small business owners. The same happened with SLS 3D printing two years ago.

In the year 2017, the 3D printer manufacturer Formlabs announced the Fuse 1 priced at a $9,999 SLS.

Then came the announcement of the printer which is tucked within the vicinity of the breath-taking pre-war architecture based in Kraków, Poland, the 3D printing company Sinterit which has been working for over three years for fitting the industrial process into a compact and inexpensive machine named Lisa. Which we are going to be talking about in this article.

Sinterit Lisa is a desktop SLS machine, which is incredibly affordable for this type of technology. Not only is the Lisa system low in price, but also it’s essentially a plug-and-play printer.

The Sinterit Lisa is a symbol of a similar disruption that was once going on with the FDM and SLA printers. It is a participator in making SLS technology available to more makers and businesses than ever before.

In this article, we are going to be reviewing the Sinterit Lisa in depth. So let’s start with the most interesting thing about 3D printers i.e. their Features.

Features

Something that makes the Sinterit Lisa unique is how they have managed to successfully integrate SLS technology into a compact and easy to use machine.

In other words, there are very many advantages that SLS technology offers over its predecessors i.e. FDM and SLA. Like, when you are printing using SLS technology you do not need any supports.

The other one is you can nest multiple objects in one printer. Followed by, the ability to produce parts and functional prototypes that offer increased durability and temperature resistance. Below is a list of more such features that the machine has.

All of the features that we are going to talk about are available in this printer by spending not more than a little that you would be spending if you are buying FDM and SLA printers.

Though the printer manages to sell itself as a printer for small business owners, designers, or engineers that need to produce functional prototypes and parts, it has been much appreciated by the professionals in this industry as well.

And because it is based on SLS 3D printing technology users can get the benefit of building high-quality parts with minimum layer thickness.

There has been record-holding layer thickness which is offered by this technology that leaves users with no choice but to appreciate the accuracy with which parts are produced with this technology.

No need for support

So why are support these important? In FDM technology when a part was made by melting filament of material, there was a little bit of uncertainty involved regarding the final shape of the part that was produced.

So, because of this uncertainty, what you needed to do what to keep structures around the dimensions with which you assumed that the part would be made out. This was necessary to keep the part away from getting damaged.

The same was the case with SLA technology too. But here in the SLS 3D printing technique, you do not need to have such structures because of the accuracy of the system.

Neither do we use a filament in this technique, nor do we use any resin. SLS 3D printing uses powder of the material with which you plan to print.

This powder is then spread evenly over the print bed and just beneath the print bed, there is a laser.

The laser does similar work as melting did in FDM technology or light source did in SLA technology. So, with Sinterit Lisa you need no support structures which is a huge benefit.

Multiple parts can be printed simultaneously

Imagine you have to print more than one part in the same printing time. What would you need to make this happen? You are going to need the exact number of printers, as much as parts you need to print.

And then giving the input of every part in the printer, you need to start printing, yeah? What Sinterit Lisa has, is compartments. The manufacturers of this printer have taken into consideration such a situation when you would have to print simultaneously.

And after taking that into account, the manufacturers have given this facility with which you can print multiple parts at the same time.

Not only does this make printing speedier, but also it does give you a backup when you are printing a product in a huge number.

It is because of this reason that small business owners have welcomed this printer as a turning point in the way they did business before.

Because neither do you get this facility in FDM 3D printers nor SLA’s. And if you do get it, it’s not at the same price at which you get in Sinterit Lisa. Truly a breakthrough printer, ain’t it?

Temperature Resistance and Durability

Because these are powders of the metal that you wish to print, in general, the temperature resistance of an SLS printer has to be more than FDM or SLA. So, compared to the printers operating with FDM and SLA technology, the temperature resistance of Sinterit Lisa is of course a lot higher.

This enables users to print using materials that have higher melting points than usual.

Also, the printer’s design is such that it is overall durable. Unlike other printers of the same price range, it does not get much affected by the printing process that is going on inside.

The frame of the printer is designed in such a way, keeping in mind the vibration produced during the SLS printing process. So, this is a huge benefit over the printers that do not offer durability with their frames.

Specifications

Credit: 3dprintingindustry.com

Credit: 3dprintingindustry.com

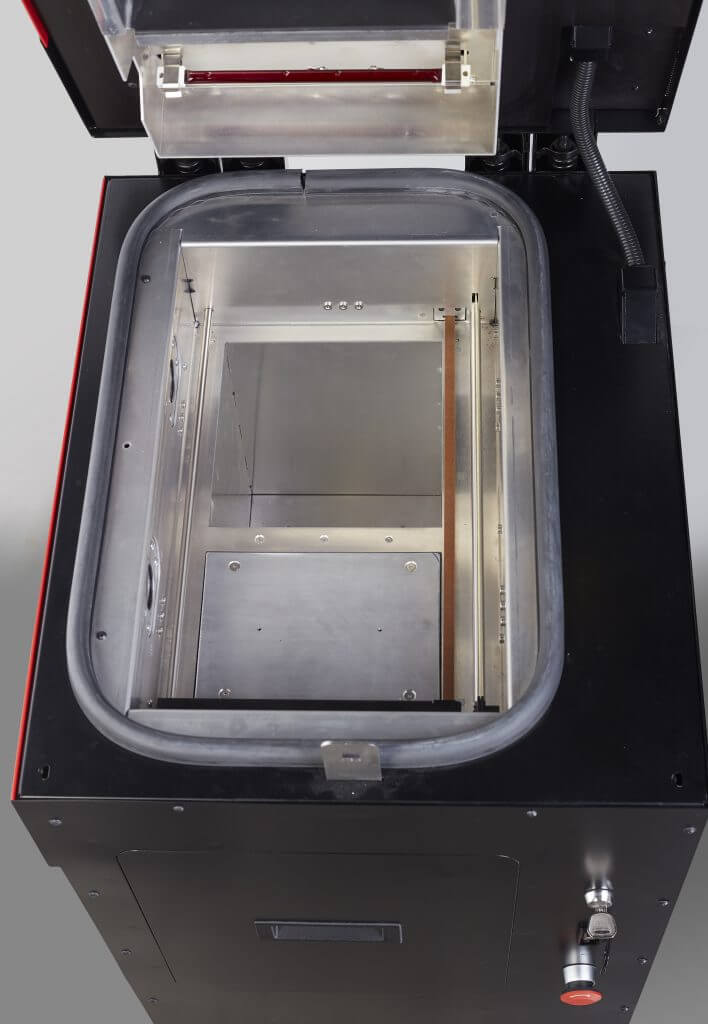

The powder diameter used in Sinterit Lisa is from 20 to 100 microns. And the recommended minimum wall thickness is 0.8 mm. The build volume of the printer is 150 mm * 200 mm * 150 mm. The printing temperature that Sinterit Lisa can withstand is 190 degrees Celsius at max.

The weight of the printer is 35 kg. The light source used by the printer is a Class four infrared Laser of 5 watts and 808 nanometers. The material type with which you can print using this printer is PA 12 powder and TPU powder.

The printer also has a built-in camera with which you can monitor the printing process.

The minimum layer thickness offered by the printer is in the range of 75 to 175 microns. The dimensions of this printer are 650 mm * 550 mm * 400 mm.

The print speed offered by the printer in the Z direction is 10 mm per hour although it completely depends on the part that you are printing, this is the speed on average.

Price

This printer is a desktop SLS printer that has a starting price in the market of just $6,990. We care to mention just over here because never before had an SLS 3D printer have the price which it did.

This is just the starting price, for those who want to buy a complete package, you will be charged $2000 in addition to the starting price. The complete package would include sandblasting stations and a powder sieve.

First Impressions

A printer is a rectangular machine colored in red and black. All you have to do is plug its wire and start printing. While getting the first impression of the printer, you would come across the four-inch touchscreen user interface that is hard to not notice.

When you start it, you get to avail of different functions using which you can operate the printer. It takes you to print some of the test prints to know that it is an industrial printer that you have at your home, sitting on your table.

Once you start printing is when you know how 3D printers can print without using any support structures and as accurately as this printer does.

Setup

This is a printer that is available individually as well as in a package. As mentioned above in the price section, the complete package comes with the printer and the sintered powder sieve, and the sandblaster with the powder materials and other assorted accessories.

So unpacking experience would be two different ones. One for those who buy it individually and the other one for those who buy a complete package that is available.

So, when you unpack the Sinterit Lisa, you get a whole lot more than an SLS machine if you have bought the complete package. The Sinterit Lisa is equipped with a wide range of tools and protective gear.

You might have noted that SLS technology requires a high powered laser source and powdered metal to print a part or functional prototype. Lisa has gloves, protective glasses, and a dust mask with the 3D printer.

Something that also comes with the printer is different sized brushes, metal detail purifiers, plastic spatulas, silicone grease, and a lot more. You take some time figuring out the use of every part that you get with the printer. But that’s pretty much it.

Apart from parts, you do have some integral tools that will help during the post-processing. A list of them includes print cooling molds, plates for carrying the prints, and a powder trowel.

Along with those you’ll also get spare recoater wires, heating lamps, and laser protective glass. But remember for getting all of these, you need to opt for the full kit.

Otherwise, you’ll also get the Sinterit Powder Sieve, Sinterit Sandblaster, as well as PA12 fresh powder and print-ready powder not as a package but you can buy them from the Sinterit’s website differently.

Printing Type/Cost

The printing cost of the SLS printing technique is more than FDM and SLA printers. But then when you see the parts that are produced by the technique, you term the cost to be justified.

Print Quality

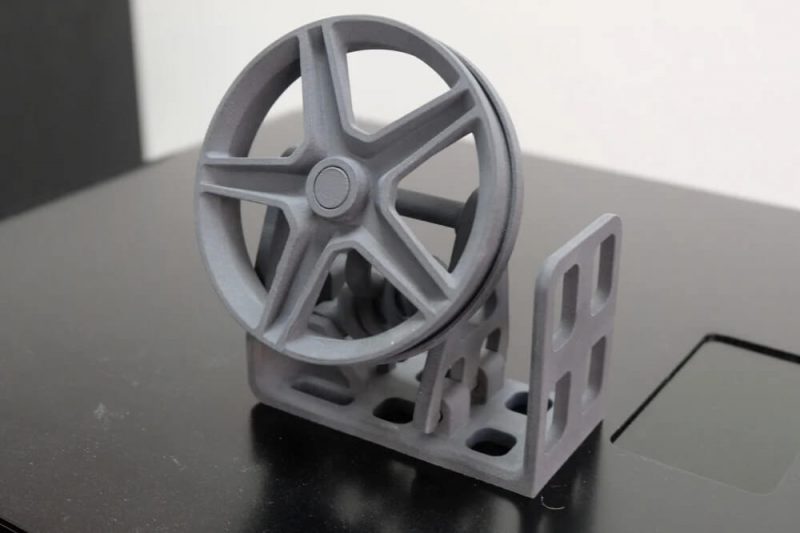

Credit: all3dp.com

Credit: all3dp.com

This is the part at which the printer excels. Normally the buyer of the printer is never ready to pay a higher cost for whatsoever quality, but Sinterit Lisa convinces the buyer at this point too. You’ll be ready to pay the cost once you see the dimensional accuracy in the most intricate parts as well.

Software

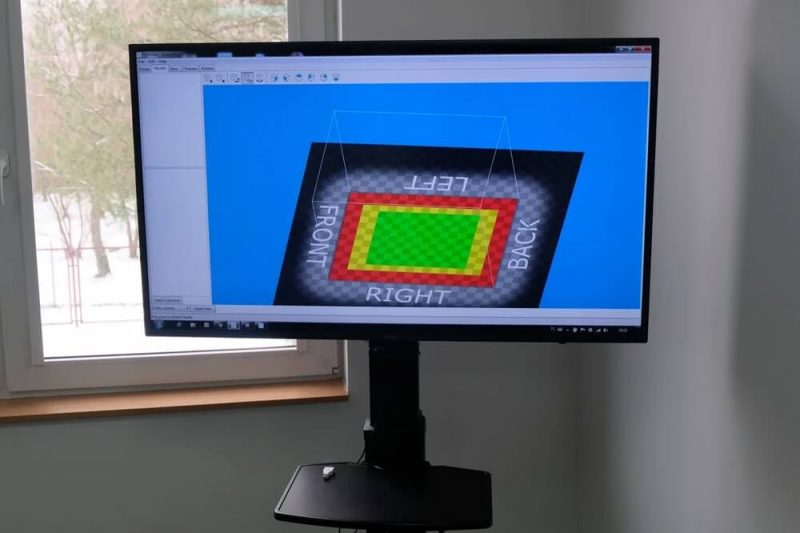

Credit: Sinterit Lisa

Credit: Sinterit Lisa

Sinterit Studio is the name of the software that is compatible with the printer. The file format of the slicing software is STL. And it is compatible with the Windows operating system.

Customer Service

Sinterit is known to give satisfactory answers to their customers at any time via any source, be it a phone call, an email, or s Skype call.

Parameters Influencing Buying Decision

Below are some of the parameters and judgment about them in brief.

3D Printer Cost: Affordable.

3D Print Quality: Very high.

3D Print Speed: Industry Standard.

3D Printer capability: Can print with the most trending materials.

3D Printer Practicality: Parts and prototypes of various industries can be made.

3D Printer User Expectations: Small business owner’s expectations are something that the printer satisfies.

The Verdict

You cannot get an SLS printer for a cheaper price than this, which delivers the same level of quality as this printer does.