|

There is a gigantic machine’s picture right next to the text that is smart enough to let you appreciate itself,” made by professionals for professionals.”

The machine’s color is also smartly divided into black and silver. Black for the transparent part and the display, and silver for the rest. Just beneath the text, you have the “Request a Quote,” option colored in red.

The overview, specifications, materials, and document options are visible even without scrolling down. But you want to chuck everything and click on the video which shows a person sitting with his laptop.

And when you start the video, you would be able to know he is none other than Director of Manufacturing Product Management, Stratasys.

How cool is the concept of learning about the machine from the director of the team, that developed the machine?

This machine is Stratasys’ flagship machine. Not only in the FDM 3D printing technology-based list of 3D printers but the entire range of 3D printers.

Apart from the size that is of course something that the company terms to be “unbeatable,” the materials that this 3D printer can 3D print with are also very long-lasting.

The F900 was developed by the company over ten years from the time when this video was uploaded. Since the time, the printer has gone through three generations of improvements.

As per the claims, by the director of product management, after these improvements, the machine has grown more versatile, reliable, and repeatable on the market today.

You can use this 3D printer for many types of applications. It could be anyway from early prototyping, functional prototyping, etc. You can use the printer also for production tooling.

The most important claim raised by the company in the video is that the printer is currently the only printer in the market to print thermoplastic material of the size of its build volume!

Features

Whether you wish to print a full tray of small parts or one large part, the F900 can be toggled to your requirements of the parts or functional prototypes that you wish to 3D print.

The print confidence becomes more important on large parts than on smaller ones. With over, fourteen material options the F900 is incredibly versatile.

Whether you need basic prototyping with ASA or high-strength with Nylon 12CF, the F900 can print many different use spaces.

The dimensionally correct part is something that the company guarantees you through F900.

Accuracy and repeatability are the two main pillars of F900. Parts printed by F900 are used for various industries like aerospace defense.

If you are a manufacturer, all you need is a reliable and consistent machine that would print continuously and the company guarantees F900 is one such machine.

In the paragraph that is beneath this video, F900’s reliability, accuracy, and versatility are the focus center.

The printer’s large build volume and proven accuracy provide users with consistent results that they need to meet production demand.

Above this, the printer has a diverse material selection ranging from engineering-grade thermoplastics to high-performance polymer that lets you cover a varied range of applications.

Optional Fast 3D Printing

The makers of this printer have left it up to the user on deciding whether they need to add an accelerating kit or not. Adding the kit would mean that the printer can print with more speed than it did.

This is something that the company recommends when you are sure shot in need of mass amount at a particular time and need assurance.

Printing with various materials

Variability is something very rarely offered in 3D printing. The fact that F900 offers printing with fourteen different materials is in fact a wonder.

Because the more materials you offer 3D printing with, the more sure you need to be about the printer’s print bed and whether it can withstand temperatures till these materials are melted.

And this essentially also means, more number of varieties in parts and functional prototypes. Because there are specific areas in the industry that demand specific materials.

And the fact that if a printer can provide printing with numerous materials, the printer should also be able to find applications in various industries.

Production Optimization

This step is related to the efforts that are laid before starting to 3D print. When you upload a file and want to convey the same to the printer in terms of design.

Everything is dependent on that file and the design which it carries. So, if there are any flaws, you want to know them beforehand. And not after you get the final part.

F900 comes with product optimization that lets it to change the design of the user’s 3D models very fast and on the go.

To recalculate production without creating delays is a feature that F900 can provide all its users with. This helps them avoid major flaws in the end product part or a functional prototype.

Internal Cameras and minimizations of breakdowns of production: When you are investing heavily in the machinery, you do not want to forget the complete monitoring aspect of this.

And that’s exactly where cameras come into play. They enable you to monitor the production from outside in real-time.

So, you can decide even when you are in the middle of the printing process to stop or pause it and make changes before continuing further.

Although based on the completely modern technique of 3D printing, the complete printing system is very much similar to the traditional engineering and high-performance providing thermoplastics for avoiding mistakes that can happen a lot during any manufacturing procedure.

So, the minimization of breakdowns of production is a huge aspect of the printer.

By giving this, the manufacturer has made sure it is connected with both the traditional aspect of the techniques as well as by providing the machinery, just the overall modern aspect of it.

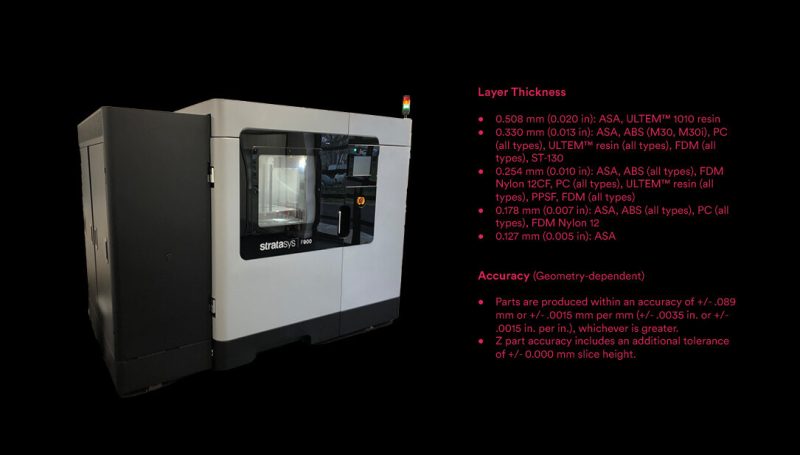

Specifications

Credit: fluxaxis.com

Credit: fluxaxis.com

F900 is 2772 mm * 1683 mm * 2027 mm in size and 2869 kilograms in weight. The building envelope offered by this giant printer is 914.4 mm * 609.6 mm * 914.4 mm.

There are two build canisters that the machine has which are 1508 cubic centimeters in volume and two support canisters which are also of the same volume.

The accuracy of this printer as claimed by the manufacturer is +/- 0.089 mm or +/- 0.0015 mm per mm depending on the geometry that you are willing to 3D print.

The Network Communication on the printer is done via a 10/100 base T connection. Ethernet protocol.

As suggested by the company. operator Attendance is limited attendance during the job start and stop is required. The operating Environment Maximum room temperature for F900 is 29 °C (85 °F).

Whereas the Maximum room humidity should be 80%. And the power Requirements 230 VAC (three-phase) 50/60Hz, Voltage fluctuation +/- Current 40A Additional Requirements Compressed Air Required 90-120 psi with a minimum flow of 20 CFM.

The printer has regulatory Compliance as listed by the CE, NRTL.

Price

For knowing the price of this printer, you need to ask for a quote from the company, by clicking on the Get A Quote tab which is present on the website. Fill in your details and submit them to the company.

You can also contact the company if you have any doubts regarding the printer. A form will open up on the website when you click on Get A Quote, you need to fill it and the company will get back to you.

Moreover, Stratasys also gives you an option to buy parts on-demand from the machine. You can also opt for that option from the same webpage. There is an option on the right that will allow you to do so.

First Impression

Credit: aero-mag.com

Credit: aero-mag.com

The first impression of the printer is huge! There are compartments on the front, the display is very big and it would surely let you monitor every aspect of the 3D printing process that goes inside the printer.

There are compartments on the right side view of the printer as per the schematics given on the website. The transparent part of the body is where the print bed is accommodated.

That part of the printer is what one is showing an opening in the video, once the printing of part or functional prototype is completed.

You can take the print sheet on which you have printed the part and easily remove it by folding it or bending it. You do not need to wait for the post-processing while manufacturing in bulk.

Setup

There is a complete tab titled Support on the website of the printer that you can refer to if there are any doubts.

There is also a complete academy titled Stratasys Academy that keeps you informed with the existing as well as new coming 3D printing technologies.

You can contact the printer’s manufacturer using the Contact Us tab if you find any difficulty in operating any part of the printer.

The printer comes completely assembled, you need to learn about the different parts of the printer, learn to operate the software that the printer is compliant with, and start 3D printing.

Printing Type/Cost

Fused deposition modeling, or FDM 3D Printing, is the method that the printer uses for 3D printing of parts and functional prototypes.

This is the technique of additive manufacturing where layers of materials are fused in a pattern to create an object.

The raw material that is usually used, is melted just past its glass transition temperature, and then extruded in a pattern next to or on top of previous extrusions, creating an object layer by layer.

In other words, the F900 printer takes a plastic filament and squeezes it through a hot end, melting it and then depositing it in layers on the print bed.

The layers are then fused, building up throughout the print, and eventually, they will form the finished part. The printing cost of this technique is the lowest compared to other techniques.

Print Quality

Credit: javelin-tech.com

Credit: javelin-tech.com

FDM is the most ancient 3D printing technology and there are layers visible on the parts which have led to the invention of SLA, Polyjet, DMLS, and other 3D printing technologies. So the print quality of this printer is average.

Software

Insight and Control Center, GrabCAD Print, and MT Connect ready to manage the complete software side of this printer.

There is a GrabCAD community which you can access by clicking on the printer’s website.

Customer Service

The printer is backed by the end-to-end, on-demand service and world-class support that is guaranteed by its makers i.e. Stratasys.

Any field issues that you get will be fixed fast, and Stratasys’ 30 years’ experience in 3D printing will enable them to help you make the most of your 3D printing investment.

Parameters Influencing Buying Decision

A quick recap of the important factors that we have been talking about in this article is given below.

3D Printer Cost: You have to get a quote from the company to know the printer’s cost.

3D Print Quality: As good as any other FDM based 3D printer.

3D Print Speed: Excellent.

3D Printer Capability: You are able to print with fourteen different materials.

3D Printer Practicality: Aerospace defense is one of the key areas where parts and functional prototypes printed by the printer is subject to application.

3D Printer User Expectations: Industrialists who face the issue of the deadline, would love to print with the printer and accelerate with printing when they wish to.

The Verdict

The printer carries a sort of wide history and has seen many times faced by the 3D printing industry and yet survived the worst of those times. It is reliable, comes from the company that has invented a 3D printing technology.

So, if you are sure of mass-producing, you should consider this 3D printer. It will save you time like no other.