Stratasys has developed a number of 3D printers for various applications. And, of course, with varying levels of capability and power. The print quality and ease of use are two things that all of Stratasys’ products have in common.

There is a variety of 3D printers available for various applications with varying levels of capability and power. The print quality and ease of use are two things that all of Stratasys’ products have in common.

Stratasys is known for its high-volume 3D printing. As a result, you can expect these machines to complete the tasks more quickly than their counterparts. In addition, the company offers the highest printing quality as well as easy machine interaction.

Following are Stratasys’ most common options and their features that differentiate them from one another.

Comparison Chart

| Name | Link | Nomination | Rating |

|---|---|---|---|

| Connex3 Objet260 | High volume printing | 10 | |

| Stratasys F120 | Speed | 8.1 | |

| Stratasys J55 | Reliability | 8.7 | |

| Stratasys V650 Flex | High Volume Printing | 8.3 | |

| Stratasys J8 Series | Unparalleled Capability | 8.2 | |

| Stratasys F900 | Versatility | 8.4 | |

| Stratasys Objet1000 Plus | Speed | 8.1 | |

| Stratasys J700 Dental | Exceptional Reliability | 9.5 | |

| Stratasys J720 Dental | Easy to use | 8 | |

| Stratasys Objet30 | User-friendly | 9.8 | |

| Stratasys Fortus 450mc | Editor’s Choice | 9.8 | |

| Stratasys J4100 | Best Value | 9.7 | |

| Stratasys Objet30 Dental Prime | Premium Pick | 8.4 | |

| Stratasys Fortus 380mc Carbon Fiber Edition | Affordable price | 9.5 | |

| Stratasys F770 | Best Budget | 9.4 |

List of Best Stratasys 3D Printers

Connex3 Objet260

Colorful designs are ideal for fulfilling your 3D printing needs. The Connex3 Object260 will create designs that are transparent, thermally resistant, and rigid.

The computer will assist you in completing complex tasks with ease, thanks to its large build volume and high accuracy for minute data.

Working with this computer allows you to print with a wide range of materials (over 1,000). The 3D printer could justify a variety of other materials that are versatile, colorful, biocompatible, or robust.

Uses:

- A minimum layer thickness of 16 microns can be achieved. Prototypes with a lot of detail can be made.

- The Connecx3 Object260 measures 87 x 120 x 73.5 cm and weighs about 264 kg. The content cabinet has dimensions of 33 x 117 x 64 cm. Despite this, the build volume remains the same at 255 x 252 x 200 mm.

- Combining the versatility of multi-material printing with the brilliance of color is a winning combination. Choose from a palette of 20 colors, ranging from rich opaque to vibrant stained-glass-like translucent.

- Combines materials with varying translucency, rigidity, color, and thermal resistance in a single prototype without the need for assembly.

- Not only is soluble support material easy to remove, but it also leaves models smooth, perfect, and ready to use without the need for additional curing or post-processing.

- Prints at a good speed.

- Parts produced are average.

Stratasys F120

|

If you do not want to spend a lot of money but still want to get a good return on your investment, the Stratasys F120 is a good option. It offers a smoother flow than any other 3D printer in a comparable price range.

This printer is part of the F123 series, which includes the F170, F270, and F370 models. Fused Deposition Melting 3D printing technology is used in both.

The F120 uses the same types of raw materials as injection molding to produce components and usable prototypes.

Uses:

- Offers a higher level of accuracy, allowing you to design even the most complex parts and functional prototypes with precision.

- Along with the precision of a higher degree, you get the same repeatability.

- According to the company’s statement, they are capable of providing the rigidity needed for speed and accuracy, as well as handling higher load capacities.

- It has a Kevlar belt that maintains the correct tension without rubbing out or stretching over time, allowing the print to be set up rather than calibrated and replaced.

- For superior parts quality, its closed-loop servomotors provide precise head positioning speed as well as motion control.

- Double Wall Oven with High-Quality Insulation is available. The interior of the oven is kept hot for precise sections, while the outside is cold so it can be touched.

- Insulating Accordion, Textured, and Flexible Build Tray are also included, while the create heads move in the X-Y plane, the former retains the correct temperature.

- This industrial-grade 3D printer is affordable.

- Trustable company.

- Home consumers and makers would not be able to afford it, as it is built specifically for companies.

Stratasys J55

|

If you are a 3D artist looking to print items in a range of colors, you have come to the right place! The primary goal of Stratasys’ J55 3D printers is to meet the demand of users for quickly producing completely colored parts at an affordable price.

The Stratasys J55 has an appealing body and is marketed as the printer that can produce the most colorful parts and practical prototypes.

It is a fantastic 3D printer with a wealth of features to explore. It has a substantial build. It does, however, seem to be elegant and easy to use.

Uses:

- It manages to give its users the ease of printing with five materials, excluding the support content, while still supplying them with a large build volume.

- The J55 3D printer can handle the entire design process, including same-day print and limited post-processing. It is quieter in service and has a rotating print platform that allows for more design versatility. In addition, the users will have easy access to the parts after the 3D printing process is completed.

- You can experiment with colors and get a variety of choices for printing a component or usable prototype with the J55 3D printer. Pantone’s partnership with Stratasys makes this possible.

- This odor-free device employs a Pro Aero Air Extractor to efficiently absorb and filter fumes, resulting in a clean and odor-free environment.

- J55 has a print area of 1,174 square centimeters. It has horizontal build layers that are 18 microns thick. LAN-TCP/IP can be used to bind J55.

- Huge building volume.

- High-quality objects and working prototypes.

- Printing from a variety of materials.

- This printer introduces a completely new idea into the world of 3D printing: colored printing.

- Users can easily print extremely accurate geometrical models.

- Very costly.

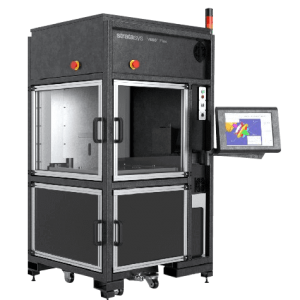

Stratasys V650 Flex

|

You will find this particular choice to be worthy of your attention in terms of cost, quality, and pace.

There are nine 3D printers that use FDM technology and thirteen that use Polyjet technology. However, at the time of writing, Stratasys’ V650 Flex is the only one that uses Stereolithography.

Rather than focusing solely on appearances, the manufacturer has placed a premium on ease of use and performance. With interchangeable resin trays, the V650 Flex provides a large build volume.

As a bonus, the creators have taken care of not just the ability to print large parts and usable prototypes, but also the post-processing chore.

Uses:

- The large build print capacity is one of the key reasons why this printer would appeal to you. There are many advantages of having a wide build area. To finish the model, you do not need to break the 3D file and print sections one by one.

- In the event of a power loss, the computer has a resume mode.

- V650 Flex provides a specific layer resolution that can be printed at unrivaled print speeds in the industry for the same price point.

- It has a 0.0005-inch XY resolution, a 1.6-micrometer vertical resolution, and the same location repeatability.

- The company excels at providing complete information about the printer.

- This printer allows the consumer to print with more materials than most printers.

- Expensive and heavy.

Stratasys J8 Series

The only PolyJet systems capable of producing bold, full-color, multi-material pieces in a single print are the Stratasys J8 Series of 3D Printers.

You can now 3D print Pantone-approved colors, versatile fabrics, and the latest Vero UltraClear transparent material all at the same time, thanks to unprecedented flexibility.

The Stratasys J850 will assist you in achieving best-in-class realism and consistency without sacrificing efficiency.

Uses:

- The Stratasys J850 allows you to print seven different materials at the same time. By making the most practical and usable parts possible, increases R&D and reduces time to market.

- Only the J8 Series 3D printers have this capability, enabling you to produce complex, lifelike prototypes on a single platform.

- Vero UltraClear is a refined version of the well-known VeroClear material. Regardless of print orientation, UltraClear approaches visual clarity in all directions.

- The J850 is the next phase in the development of the hugely popular J750 3D printer. Stratasys compiled and executed the most popular requests from J750 operators, in addition to the additional material bay.

- Not every part necessitates extreme precision; in many cases, speed takes precedence over consistency. As a result, on the J850 and J835, Stratasys implemented Super High-Speed Mode.

- The company provides all details on the website.

- Expensive.

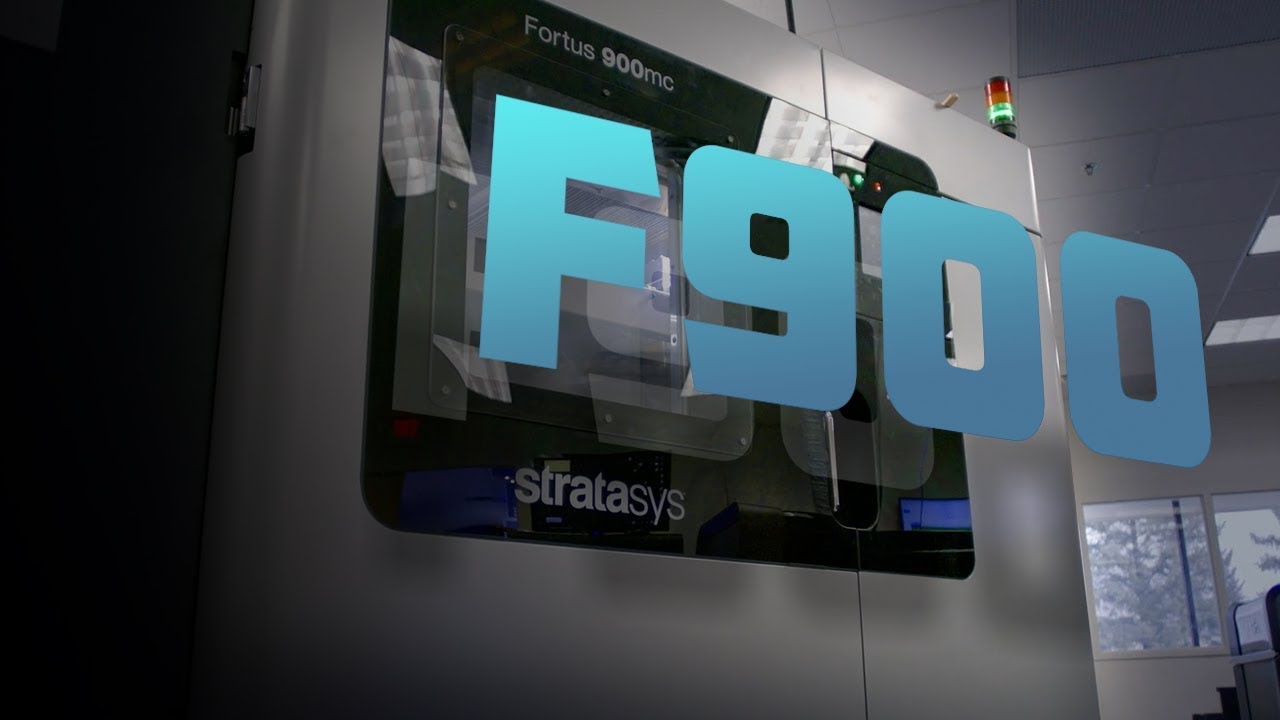

Stratasys F900

|

The F900 can be toggled to your specifications of the parts or usable prototypes that you wish to 3D print, whether you want to print a complete tray of small parts or one large part.

Next to the text is an image of a massive computer that is smart enough to make you appreciate it,” made by professionals for professionals.”

Uses:

- The printer’s designers have left it up to the customer to decide whether to use an accelerating kit. By adding the package, the printer would be able to print at a faster rate than before.

- Variability is a feature that 3D printing seldom provides. F900’s ability to print on fourteen different materials is truly remarkable.

- F900 has product optimization, which allows it to quickly and easily alter the configuration of the user’s 3D models.

- The manufacturer claims that the accuracy of this printer is +/- 0.089 mm or +/- 0.0015 mm per mm, depending on the geometry you want to 3D print.

- The color of the unit is also cleverly divided into black and silver. The transparent part and the display are black, while the rest is silver. The “Request a Quote” choice is highlighted in red just beneath the text.

- Production in large quantities.

- Printing speed is good.

- Structures of support are needed.

- The parts produced are of average quality.

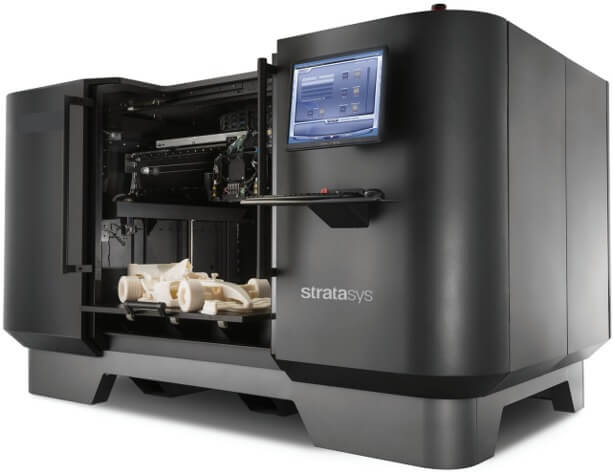

Stratasys Objet1000 Plus

|

The Stratasys Objet1000 Plus is a 3D printer for professionals. Its main feature is that it can print with a variety of materials at a very fast 3D print speed.

The Stratasys Objet1000 Plus is a professional 3D printer manufactured by Stratasys, a corporation headquartered in the United States.

The PolyJet 3D printing technology used by the Stratasys Objet1000 Plus is similar to inkjet printing.

Uses:

- The printer can print and create large 3D printed parts as well as usable prototypes due to its large build scale.

- That means that if you were printing with a different printer, you’d have to split the template to produce those pieces.

- The large build envelope and efficient workflow increase efficiency to the point that you can print large or small parts at a low per-part cost.

- Not every component generated with an FDM 3D printer necessitates comprehensive post-processing. To achieve a smoother appearance, all that is needed is scraping and cleaning.

- The printer gives you the option of 3D printing with any material you like.

- Allowing printing without the use of support systems.

- Apart from home consumers, it is not ideal for many small businesses.

Stratasys J700 Dental

|

This printer is something you can think about if you want to see your long-term future in the dental industry. The PolyJet 3D printing process, which is similar to inkjet printing, is used by the Stratasys J700 Dental.

Liquid photopolymer is used for 3D printing parts and functional prototypes, and it is directly UV cured after jetting to produce a stable layer.

A removable gel-like support material called FullCure 705 is also jetted by the PolyJet advanced 3D printers. A non-toxic gel-like photopolymer serves as the support material.

Uses:

- The printer has enormous capabilities for producing both small and large-scale pieces.

- All of the files you send to the printer are saved in the cloud-based source where it receives its orders.

- To use this printer, you do not need to assemble any pieces.

- The printer is an industrial printer with all the bells and whistles. Therefore, just like the conventional printers, Stratasys has designed this printer to fulfill the same need.

- All of your work will be saved, and in the event of a power outage, you will be able to resume where you left off.

- The printer will print in around three hours, which is significantly faster than the company’s previous printers from the Stratasys Objet500 series.

- Printing speed is excellent.

- Capable of producing high-quality aligner parts in batches.

- Designed specifically for the dental industry.

Stratasys J720 Dental

Stratasys’ J720 Dental is a dental 3D printer for industrial use. Material Jetting 3D printing technology is used in the Stratasys J720 Dental. The build volume of this 3D printer is 490 x 390 x 200 mm.

Uses:

- With a large print capacity, you can expect a fast turnaround.

- All model sizes, including aligner arches, C&B, implant cases with gingival masks, research models, and diagnostic wax-ups, can be printed in a single print job.

- A tangible representation of how a procedure would appear

- Reduced Labor and faster time-to-part

- Color matching for restorations is made easier with highly accurate replicas.

- 1.75 times the throughput of the leading DLP printers

- Printing with six materials at once reduces material changeovers and eliminates the need for multiple printers.

- Models that are highly personalized and can be used for a variety of dental and orthodontic applications

- Good printing quality.

- Good speed.

- Expensive.

Stratasys Objet30

Stratasys’ rich legacy as one of the best manufacturers on the market is continued with the Objet30. We could not find anything wrong with this excellent 3D printer. It is powerful, lightweight, accurate, and flexible.

Uses:

- The Objet30 Pro, billed as a desktop printer, has the look and feel of a professional printer, with a sleek black and white color scheme.

- The build area is 294 x 192 x 148.6 mm, with 600 dpi, 600 dpi, and 900 dpi axis resolutions for the X-axis, Y-axis, and Z-axis, respectively.

- The Objet30 Pro has two extruders, one for printing material and the other for support material, both of which are connected to the UV light that cures the material.

- Its precision makes it one of the most detailed printers on the market, regardless of price, and it is a long way from most consumer models’ best of 100 microns.

- Rigid Opaque in white, black, green, and blue allows for high-quality prototyping prints that match the quality of finished goods.

- The printer also employs the non-toxic gelatinous FullCure 705 support content, which is not only suitable for creating complex overhangs and the like but is also easily removed using the DT3 Clean Station that comes included with the printer.

- Good quality parts.

- No controls and LCD on the printer.

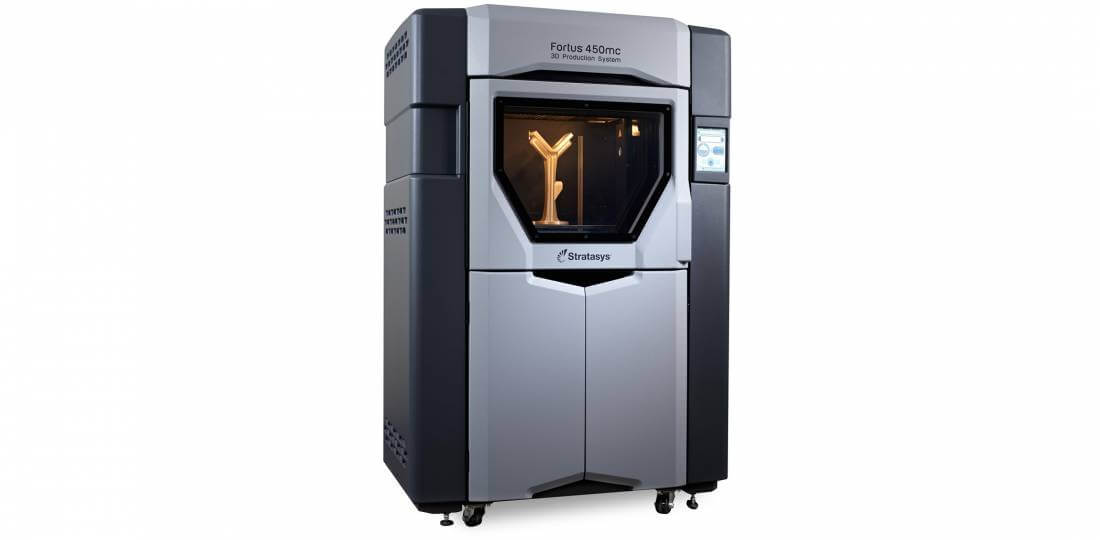

Stratasys Fortus 450mc

The Fortus 450mc is a beautiful and sleek design industrial printing machine, taking up 129.5cm x 90.2cm x 198.4cm in size and weighs 601kg.

They are specifically designed for accurate, reliable, and repeatable print manufacturing, which makes them ideal for engineers or large-scale manufacturers since they require the flexibility of printing large-scale or large-sized parts with high-speed printing and accuracy.

Uses:

- The Fortus 450mc has set the bar very high for high speed and accurate 3D printing.

- The Fortus 450mc has the ability to use up to 10 different engineering-grade thermoplastics and has been designed to be intuitive and easy to use.

- The Fortus 450mc has a build volume of 406 x 355 x 406mm, a low layer resolution of 330 microns, and a high layer resolution of 127 microns with a touch-screen interface.

- You can also strike the right balance between strength, precision, and FDM’s fastest build time with four-layer thicknesses to choose from.

- It is easy to use and user-friendly.

- High speed and accurate printing.

- Ideal for engineers or large-scale producers.

- Can use up to 10 different engineering-grade thermoplastics.

- Four-layer thickness.

- Touch-screen interface.

- No special ventilation is required since it does not produce any noxious fumes.

- Its heavy weight and large size make it not very suitable for portability.

- Only suitable for large-scale productions.

- Takes up a lot of space.

Stratasys J4100

The J4100 is a complex design printer but it can handle any design printing. It has a large build tray with a multi-material capability, high-speed printing, and a vast variety of printing materials properties.

Uses:

- Its large build tray allows you to print up to about a meter long parts in one go and for the smaller part, space allows you to print multiple small parts or objects at once.

- It provides flexible printing and has the versatility to choose the right and accurate material for your projects.

- The J4100 can use flexible polymer that copies the look and feel and gives the texture of rubber-like objects and has 192 nozzles for different material printing.

- It is a user-friendly and has an easy-to-use interface. The J4100 is 1906 x 2868 x 2102mm in size and weighs 2200 kg.

- It has a range of printing models including high speed and super high-speed printing, which lets you choose the most accurate setting for each job to optimize the printing time.

- 192 nozzles

- High speed and super high-speed printing

- Optimized printing time

- fast and accurate printing

- Large build space or meter long objects

- Multiple small object printing at once

- No dangerous fumes

- Multiple material printing

- Not easily portable.

- Suitable only for large-scale manufacturing and production.

- Not compatible with most software and devices.

Stratasys Objet30 Dental Prime

The Objet30 Dental Prime 3D printer is a compact and sleek design printer for any dental lab.

Uses:

- It has high print speed and accuracy that allows you to print any 3D dental models in-house to avoid any outsourced production.

- It has a high-quality print mode, which enables fine detailing like diagnostic wax-ups and removable partial-denture casting.

- It also includes three dental materials specifically designed for digital dentistry allowing printing of accurate crown and bridge models.

- The Objet30 Dental Prime has a build volume of 300 x 200 x 100mm and produces fine details up to 16 microns, a high-speed mode up to 28 microns, and a draft mode p to 36 microns layer thickness.

- It is 825 x 620 x 590 in size and weighs 106 kg.

- High-speed printing.

- Fine detailing and accuracy.

- Affordable price.

- 3 different printing materials.

- Large build space.

- Not easily portable.

- Only suitable for dental object printing.

Stratasys Fortus 380mc Carbon Fiber Edition

This printer is not expensive, yet offers some great features that you can only find in high-end models. For one, you can use these carbon-reinforced capabilities to print using FDM Nylon 12 and ASA.

Uses:

- The Fortus 380mc Carbon Fiber Edition incorporates the strength and resilience of carbon-fiber material with the processing capability of Fortus 3D printing.

- To prevent warping and curling, it uses the same build chamber as the regular Fortus 380mc, ensuring consistent component production regardless of scale.

- It is most suitable for industrial printing with its durability, strength, and lightweight production in minimal time.

- It has a build volume of 355 x 305 x 305mm. It is 129.5 x 90.2 x 198.4cm large and weighs 601 kg. It is also easily compatible with any Windows system.

- Cost-effective.

- Lightweight.

- Compatible with several systems.

- Durable, strong, and fast production.

- Only prints with carbon fiber.

- Takes up a lot of space.

- Only suitable for industrial printing.

Stratasys F770

With an inexpensive large-format 3D printer, you can print large parts up to a meter long. With the reliability and accuracy of Stratasys FDM technology, the F770 offers a large build capacity in an easy-to-use platform.

Uses:

- The F770 allows you to print large objects up to meters long with its elegant design with high-speed printing.

- It has a user-friendly and easy-to-use platform with reliability and consistency.

- It is best suitable for large-scale projects with its 13 cubic foot build volume. You can easily print manufacturing tools, prototypes, and end-use parts.

- Its large build volume allows you to print large several objects or several small objects at once for optimizing the printing cost and time. It also has the largest fully heated build chamber in the market, which allows you to even print a part, which is 46 inches long diagonally. Some of this printer’s key features include easy operation, reliable FDM materials, thermal management, lights out/24/7 operation and material density options etc.

- The F770 is 175 x 124 x 196cm in size and weighs 658kg. It has a build space of 1000 x 610 x 610mm with a layer thickness of up to 0.013 inches and has easy software installation.

- Produce accurate parts.

- Excellent printing speed.

- Not affordable.

Buying Guide

It is a good idea to find out which features are important before purchasing a 3D printer. We have gone through a few of the most significant features so far.

These features in your printer will make your 3D printing experience more enjoyable! Your hard-earned money would not be wasted if you follow the steps outlined below.

To prevent turning the thrilling 3D adventure into a disaster, double-check them.

- High-Quality Printing: Any 3D printer manufacturer needs their machines to produce the highest-quality prints possible. Performance disparities are often a result of technology and budget decisions. It is difficult to include all of the newest features while staying on a tight budget. However, 3D printer kits allow you to save money on print costs while still getting a competitive 3D printing system.

- Customer Support: In addition to all technological requirements, the company’s support is essential. Users may also understand the company’s level of customer service. For the printer’s evaluation, anything must be included. Even if it is the best on the market, it comes with a warranty and offsite support. Any computer can fail at any time. Failure to provide technological help would only result in money being wasted.

- Speed and Volume: If speed and volume are important to you, look for a printer that can produce a smooth finish. It does not necessitate any post-production. Additionally, select a printer with a wide build volume if you want to print several parts at once.

- Reliability: it is something that any consumer wants, whether it is an open-source design or not. What if the 3D printer works for a few days before failing to function as well as it once did? What if your 3D printer breaks down every now and then? It is also untrustworthy if the findings are not reliable. So, keep an eye out for it and get involved in online communities. This will assist you in learning more about the 3D printer’s popularity in terms of dependability.

- Heated Bed: This is also an optional feature that is not necessary to get started with 3D printing. It does, however, play an important role in improving the initial layer’s bonding power. It keeps the bottom of the print hot, allowing the printed model to be formed without wrapping.

Frequently Asked Questions (FAQs)

What Is The Method Of 3D Printing?

An “additive method” is used to make a 3D printed item. When the object is completed, successive layers of material are laid down to create the three-dimensional object.

What Is 3D Printing Good For?

You can 3D print everything from a frame for your drone project to a doorstopper and anything in between. On the industrial side, 3D printing has enabled various industries, ranging from healthcare to automotive, to do things that were previously impossible and to bring goods to market much faster.

The medical field is one impressive place where 3D printing shines. In laboratories, custom-made prostheses and 3D printed tissue are becoming more popular. 3D printing, on the other hand, excels at producing small quantities of products.

What Are Some Of The Advantages Of 3D Printing?

3D printing, like other new technologies, has a wide range of applications. Improvements in the industrial, logistical, healthcare, artistic, and environmental sectors are among them.

For starters, the technology allows for infinite design and material customization. The healthcare industry is a good example of this value. For a much cheaper price, complex prosthetic limbs can be made specifically to individual needs.

What Are The Different Types Of 3D Printing Technologies?

To construct an object layer by layer, 3D printers use one of the following methods:

Fused Deposition Modeling (FDM)

In desktop 3D printers, this is the most popular technology. Heat is applied to thermoplastic material, which is then extruded through a nozzle.

The molten material is deposited layer by layer onto a create base by the nozzle. Each layer adheres to the previous one.

Stereolithography (SLA)

The create platform is submerged in a bath of unique liquid photopolymer resin. When exposed to a laser beam, the resin becomes light-sensitive and solidifies.

Each cross-section of the 3D model is traced onto the previous layer of cured resin. Layer by layer, this is done until the 3D object is complete.

In FDM, the object is constructed from the bottom up, while in SLA, the object is built from the top down.

Selective Laser Sintering (SLS)

A laser beam is used to fuse powdered material together in this process. The first layer of powdered material is uniformly rolled onto the building frame, and then a laser is used to fuse the layers of the 3D model together.

The build platform is then lowered by one layer’s width, and the next layer of powder is rolled into place. This procedure is carried out until the 3D object is complete.

Support structures, which are often required with the FDM process, are not required because the object is surrounded by (unused) material during the construct.

Selective Laser Melting (SLM)

SLM uses a higher-intensity laser and just metal powder to achieve the same results as SLS. The tiny metal particles are actually fused together in this process to create a solid structure.

Binder Jetting

Binder Jetting also gets its material from a powder bed. Rather than a laser, the powder, such as metal, is first “glued” together with an adhesive binder, then heat-treated in a kiln to set or fuse the material.

Is It True That 3D Printing Is Just Good For Plastic?

No, it is not true. Three-dimensional printing can be achieved with a wide range of materials. Almost any material can be 3D printed as long as it has a solid-state that is usable.

For example, a gaseous substance like oxygen has a solid-state, but only at extremely low temperatures, making 3D printing with it impractical and pointless.

What Are The Different Forms Of 3D Printing Filaments?

Filaments for 3D printing come in a variety of shapes and sizes. First, they are available in two standard diameters: 1.75mm and 3.00mm. PLA and ABS are the most popular materials used in FDM 3D printing.

They are famous because of how simple they are to use and how inexpensive they are. Metal, food, and various thermoplastics can all be printed, though metal and food do not come in filament form for obvious reasons.

If you see a spool of filament with the word metal on it, do not be alarmed. Metal dust is combined with thermoplastic content, in this case, to be used in desktop FDM 3D printers.

Conclusion

Stratasys is well known for its high-quality 3D printers, and the company has been working hard to improve its offerings to customers. Moreover, in terms of consistency, they are all comparable.

With these machines, you will still reach the highest level of accuracy. With so much under one roof, Stratasys is leaps and bounds ahead of the competition.

Apart from the ones mentioned here, the manufacturer offers a wide range of other 3D printers.

As a result, the company has been able to come up with solutions that are not offered by other manufacturers. It displays 3D printers with a variety of capabilities and price points to meet the needs of various customers.

In addition, each of the company’s products is tailored to meet the needs of large-scale industries. As a result, these machines would be larger and heavier than traditional 3D printers. After all, why not? The Stratasys 3D printers are designed to be excellent and to meet certain 3D printing needs that have yet to be identified.