Industrial springs are the most functional thing you will find across the world. Even if you give a glance at what exists in plenty, you will find many products functioning on the base of spring. You can get a ball pen, remote control, a clipboard, a chair, and even the computer keys. All of them make use of spring.

They are the most utilitarian thing ever created by humans. So, it is natural to associate the most utilitarian thing with the current state-of-the-art technology 3D printing and know whether it’s possible to 3D print spring? If yes, what are the tips for a 3D printing spring?

That’s exactly what our article aims to take you through! And we will start with how to generally 3D print a spring – any type of spring; a compression spring, torsion spring, a spring that produces tension or squeezing effect.

The process of 3D printing Spring

One of the benefits of 3D printing over all other traditional manufacturing processes is that this technology has a general way of creating things. So just like every other part, there are three basic steps of 3D printing spring.

Creating a 3D Model of Spring

The 3D model of any part or functional prototype can be made via an online 3D model creator. CAD software is typically used for this process and there are many options available online.

You can own CAD software, use its tools, shapes, and other functions and create the exact geometry of spring that you have in your mind using the preferred software. And, you are ready to go the step number two in the process of spring 3D printing.

Alternatively, and this is because of the development of 3D printing technology and the increase in its accessibility – you can download a 3D model file of a spring that closely represents the one in your mind.

And this is possible from the online 3D printing repositories such as Thingiverse, MyMiniFactory, GrabCAD, Cults3D, or any other.

There are paid as well as free versions of a 3D model of spring available on these websites that are generated by professional 3D model designers, which are not only safe but also reliable to 3D print. Typical examples of which are mentioned below.

Options of Springs Available Online for Download

These models are available on GrabCAD

Tension Spring

Available on Rendering as well as SolidWorks software this is a typical 3D model of tension spring which finds its use in many mechanical devices and industries. The 3D model of this file can be downloaded for free.

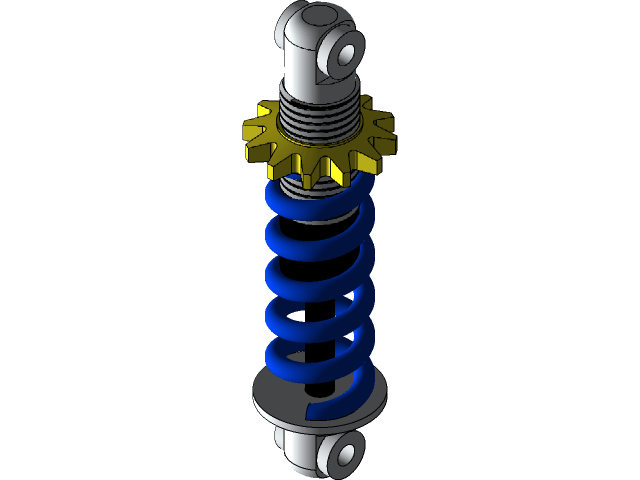

Shock Absorber

As the name itself suggests, the use of these types of springs is made in parts that are subjected to high loads.

The designer suggests such type of springs is typically used in a two-wheeler for saving the bike or scooter from the shocks its arrangement is subjected to while going above the bumps.

Shock Absorber is also available for a free download.

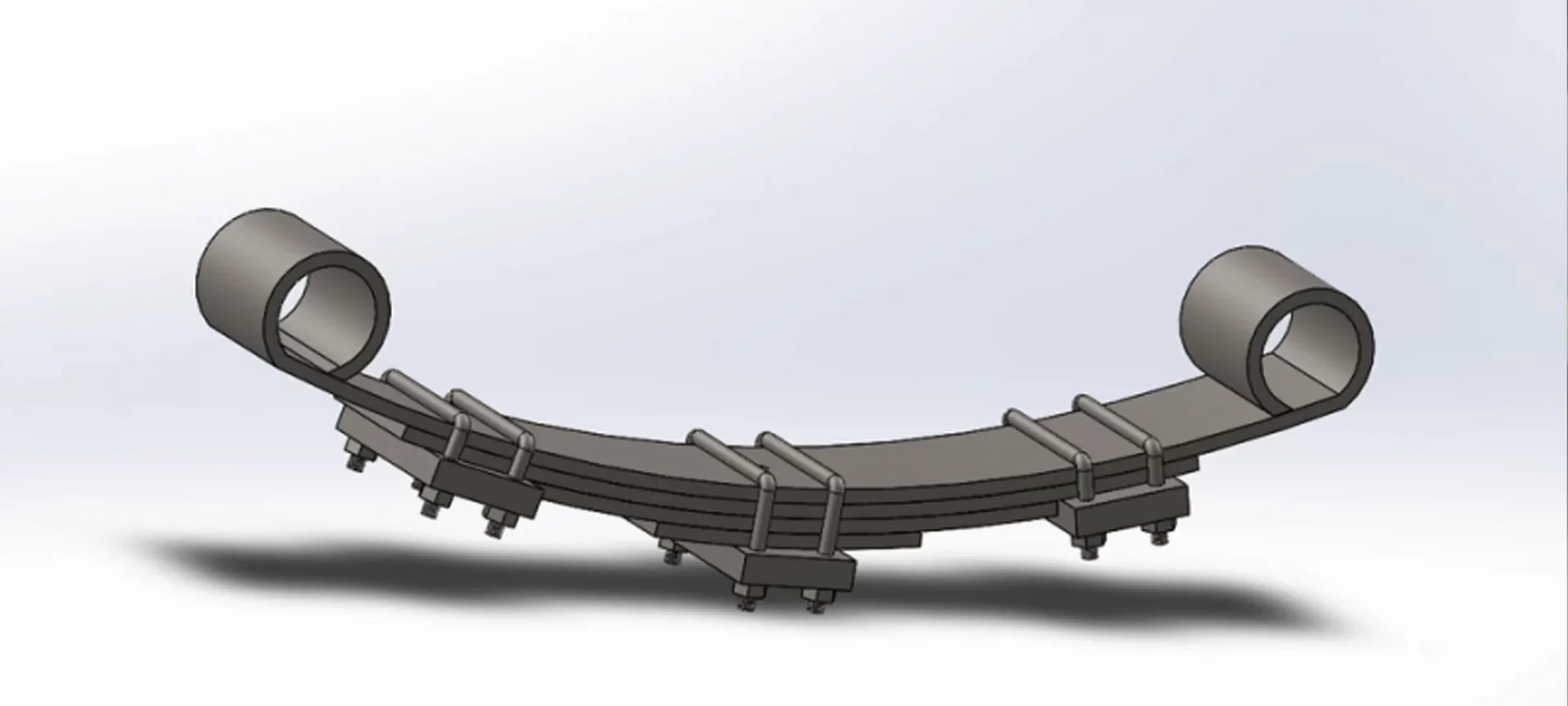

Leaf Spring

Generally, leaf springs are known to be used in a trailer or a caravan. This 3D model by the designer is available for software such as Solidworks and Rendering. At the time of writing the file has already been downloaded 25 times.

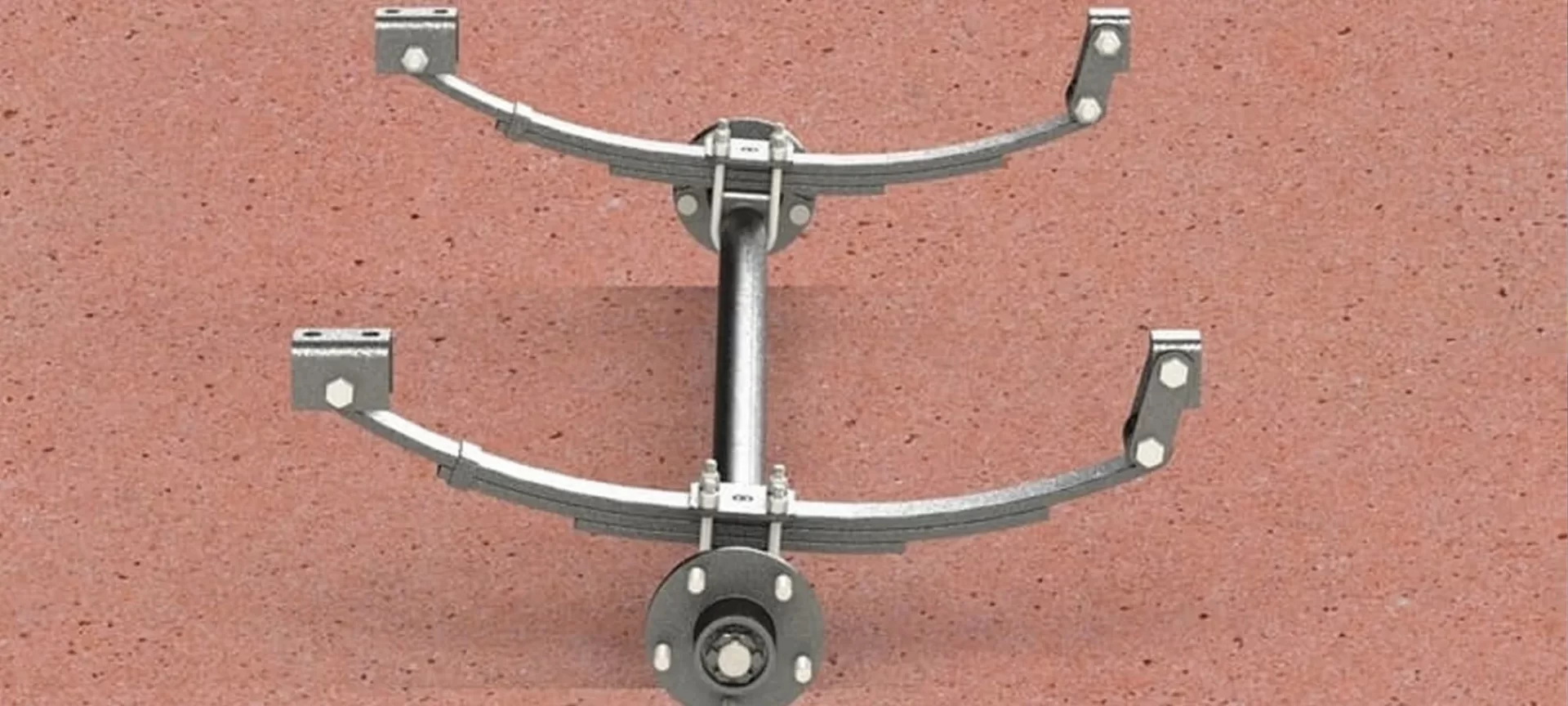

Trailer Leaf Spring

Available for download on software such as Rendering, Step/IGES, and Solidworks this trailer leaf spring has the hub face to hub face length of 57.05 inches, the bolt pattern 5 on 4.5 inches, and a weight capacity of 1875 lbs.

At the time of writing, the 3D model file has already been downloaded 33 times.

So, such models are always available at your disposal that will let you be free from the efforts of making a 3D model.

3D Printing Spring

After having a 3D model at your disposal, you have cleared the first checkpoint. The second step thereafter is slicing the 3D model.

Slicing is the process of converting the 3D model into a GCODE pattern that a 3D printer can be fed and after which it can start 3D printing actual spring.

And you can do this with slicers that are compatible with your 3D printer. If your printer is an open-source 3D printer, it will compatible with Simplify or Cura software.

And here is where you got to take care of the expert tips if you are 3D printing spring for the first time.

Easy Tips for 3D Printing Spring

Below mentioned the lessons learned by experts who have tried to 3D print a spring for themselves.

Going With the Flow

This suggestion deals with the typical flow rate that you need to maintain to make sure you are not over or under extruding. The ideal extrusion flow rate is 1:1 for the amount of distance traveled.

Because, by not extruding enough material you will pull on the part, deform it and also sometimes get it too much thin or eventually break it.

On the other hand, if you are extruding too much material it will cause uncontrollable ripples, sags, or globs in case it collides with previous layers that you’ve 3D printed.

Moving Slowly and Evenly

Working with plastic is taking too much amount of time for cooling even if you are working with artificial fans. And this would also demand that you work extremely slowly with the print head in the midair so that the plastic hardens as you move forward.

Many plastic materials are also known to ooze differently than others as their feed rates and temperature change. Printing the first few layers is quick but then eventually you need to move much more slowly.

Bubbles are Known to Break Things

Ensure the filament that you are using should be dry and unlikely to bubble. Having stated so, the older filaments are known to have moisture trapped in the plastic that boils and comes out as it gets heated.

This would lead to uneven flow rates and weak sections. While solid part printing, small bubbles are a concern as they cause the part to fail. This is where you need to take care of the most while 3D printing springs.

Compensating for the Extruder’s Pull

Every filament is known to tugging slightly on the existing cooled strand, once it’s extruded. Near the filament’s bottom where the part is known to have enough support all of it has very little impact, but as the part grows taller the force simply displaces the strand even more.

Note that fully modeling an extruder’s pull or push is very tricky in the case of under/over extrusion. So, prints that only stretch out into midair don’t need to compensate too much, but others like tall springs are known to produce accurate parts.

By following these tips, you can simply gain a result with which you’ll be satisfied. And since these are proven and tested by experts, they are completely reliable.

Also, you will reduce the chances of 3D printing spring failure and get a spring of decent quality that you can actually put into application.

Post Processing

After having sliced the files, and 3D printing spring using above mentioned tips, you will have to let the printed spring cool down.

Once the spring has cooled down, you can decide whether or not to post-process it! Springs too, like other 3D printed parts can undergo a simple process of post-processing starting from sanding, to finishing.

You use regular sandpaper of normal grit to sand it. Of course, post-processing is not compulsory, it will depend on the application that you wish to use the spring for. After sanding, you can also color the springs and finally polish and finish it to get a certain kind of matte, or suede finish.

But be careful while doing the post-processing as springs are very delicate parts and messing with them is very simple. You can very easily end up ruining them while actually trying to better them.

So, always gain a bit of confidence with any of the process of post-processing that you are working on your 3D printed spring with, and only then try to apply it full-fledged.

The Conclusion

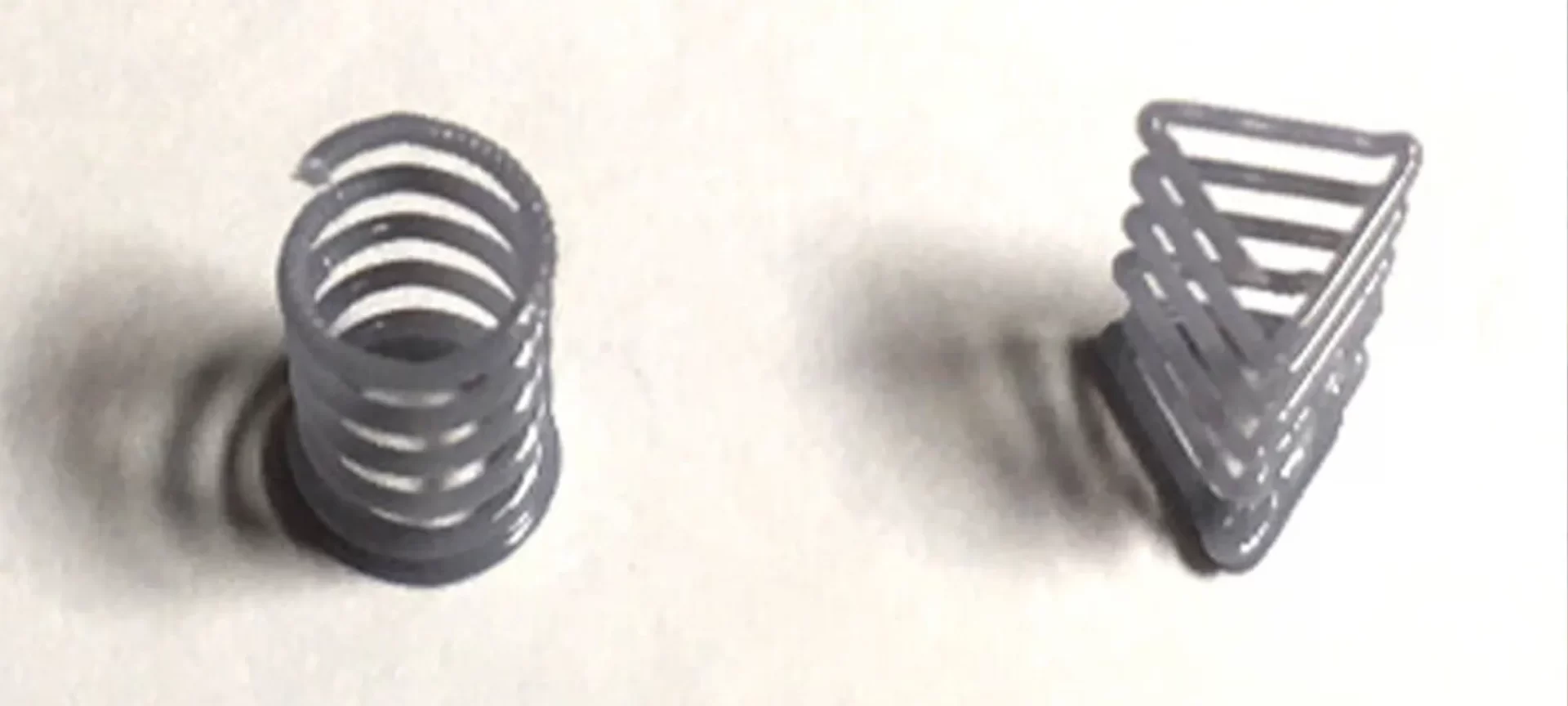

Although this all reads very easy, it’s always “easier said than done.” As mentioned above, springs are those mechanical parts that find their application almost everywhere. And 3D printing springs is a region wherein there are still not many options.

Things are still getting experimented and there is little success. But we hope, in the coming time there will be more options. And once that crack has will made, it will be a lot easier to 3D print springs.

At the moment prototyping of springs is where 3D printing is extremely useful, because of the accuracy it can provide. So, follow these easy tips to achieve excellent results with 3D printing springs.