3D printing technology is known to produce and personalize parts and functional prototypes that could not have been produced and personalized before.

However, the technology has its own limitations, because of which turning even simple models into reality is also unsuccessful.

There are many 3D printing issues that we believe every 3D printer owner should be aware of, even if you’re just a 3D printing enthusiast and don’t own one yourself, there are a couple of 3D printing issues that you should know about in order to understand how the technology works in general.

In this article, we are going to discuss some of the most common issues faced while printing with an FDM 3D printer or an SLA 3D printer.

Problems while Printing with FDM 3D Printer

Nothing is Setting Printed

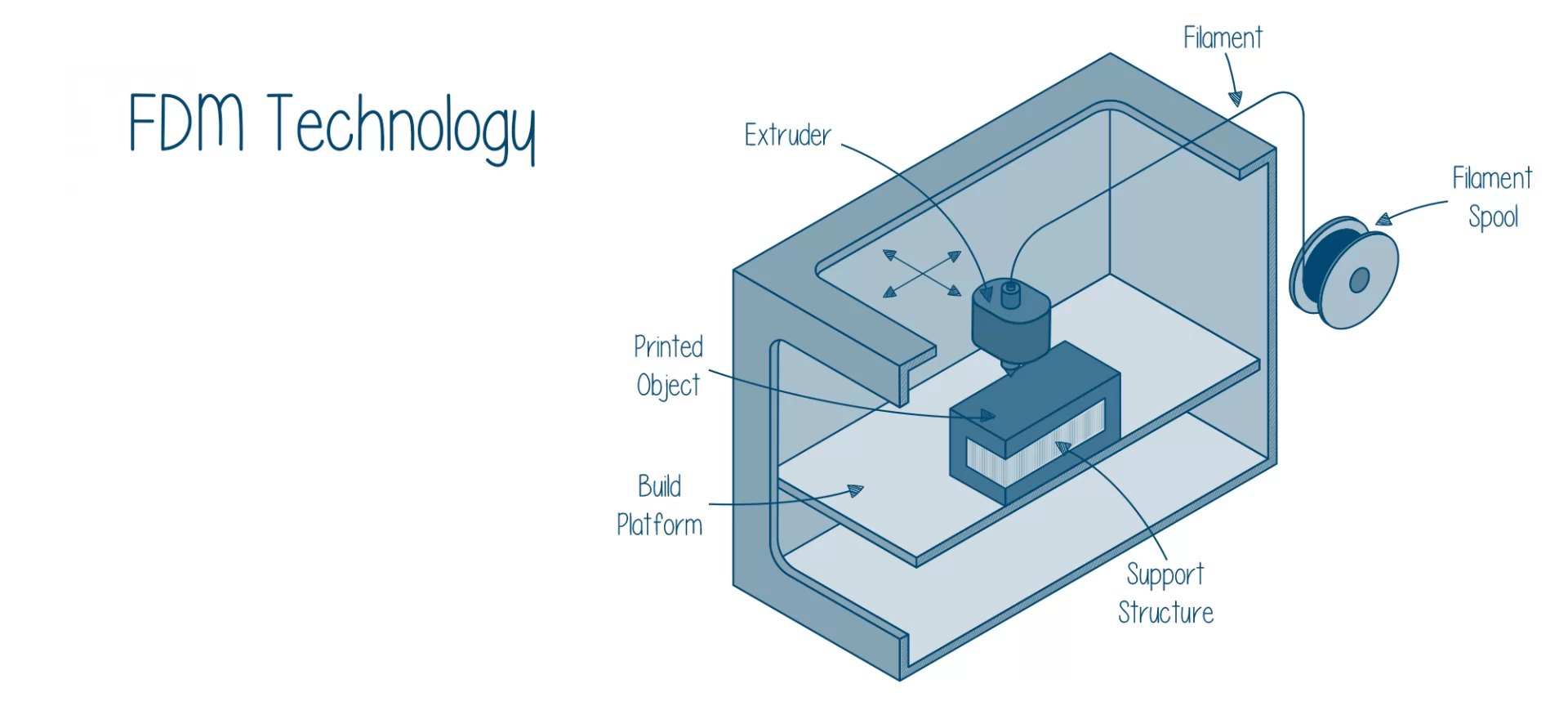

FDM 3D printing utilizes a 3D printing filament material for printing parts and functional prototypes.

Though this technology is known to produce parts of lower quality than SLA, it is able to manufacture parts and functional prototypes of large volumes.

Below mentioned are the common 3D printing issues that you will face while printing with FDM 3D printers.

Out of Filament

When nothing is printing even while the printing model has been set and configured correctly in the software that you are using to slice the model, you may try to repeatedly send the print to the printer, and then to nothing will happen.

At such a moment you can guess that your printer has run out of filament and needs to be refilled.

It is to note here how some printers come with smart spools that send the feedback data to software and notify you about the filament reel whenever it is close to getting over or out of material.

Also, in cases especially with Bowden style extrusion systems, you will have to extract the remaining filament and then feed in the fresh filament.

Nozzle too Close to Print Bed

In this kind of problem despite loading the filament as well as the print head’s movement without a hitch, no filament gets deposited on the print bed.

Whenever such a problem occurs you can conclude that the problem is that, the nozzle is too close to the print bed of the printer.

In case you have tuned your printer’s print bed close to microns from your nozzle’s opening, the melted filament will have less room to escape.

The printed part in these cases would be missing the first layers that are considered to be the foundational layers.

The rest of the layers would have fewer chances of getting stuck with each other. This would end in a blockage.

In this 3D printing issue, raising the height of the nozzle is the simplest solution. Most of the 3D printers would allow you to do this in their system settings, by Z-axis offsetting.

You will have to increase the offset value by keeping on adding more to the present value. Although the point to keep in mind while doing this is, even more, offset value is not beneficial.

The same result can also be achieved by lowering the print bed of your printer. Although this is more troublesome and hence avoided by most of the users because it requires you to re-calibrate and level your print bed for even prints.

Your Print Fails to Deliver

Did you too encounter the problem wherein things were looking great, but for some inexplicable reason, the print has failed? It didn’t stick to the bed, or the 3D printing filament just stopped extruding! Below mentioned might be one of the reasons why this has happened.

The Extruder Stopped in the Middle of the Print

The hotend will stop extruding molten filament either when something is wrong with your filament supply or when there is a problem with the hotend or nozzle itself.

This could be as simple a case as your filament has run out because some printers obscure the spool, so you would never know if this is the case otherwise it could be too tight of an idler on your extruder resulting in the stripped filament spool that isn’t being fed into the hot end or extruder.

Apart from this, having a blockage in your extruder could also prevent any further filament from being extruded.

In this case, you should check whether or not you have enough amount of filament.

Many slicers nowadays offer a material estimation for your prints and judging it against the weight of your spool and the amount that is left on it can generate a feeling if there is enough filament left to complete printing of part or a functional prototype.

Often, at times a stripped filament is also responsible for failing the print in the mind way. Check whether your nozzle is clogged or not, if it is, it can also cause this 3D printing issue.

The Printed Part does not Stick to the Print Bed

This is one of the most common problems while 3D printing a part or functional prototype. And because of its commonality, it is also grown easy to resolve this problem.

Unfortunately, the truth is that any print can break free almost anytime from the first foundational layer to the last final layer that makes it a part or functional prototype.

Every time for this break the printer should not be held responsible. This problem is especially seen when you are printing a model that has little like negligible contact with the print bed.

For example, you are trying to print a showpiece of an airplane, what are the parts that are going to remain in contact with the print bed? Only the wheels, ya?

Because of this reason, it is also considered unlikely to print without some build plate adhesive as well as brim to gain assurance.

This problem can be caused when the print does not bond to the print platform and to make sure it happens, you need to create a strong bonding between the part that touches the print plate and the print plate itself.

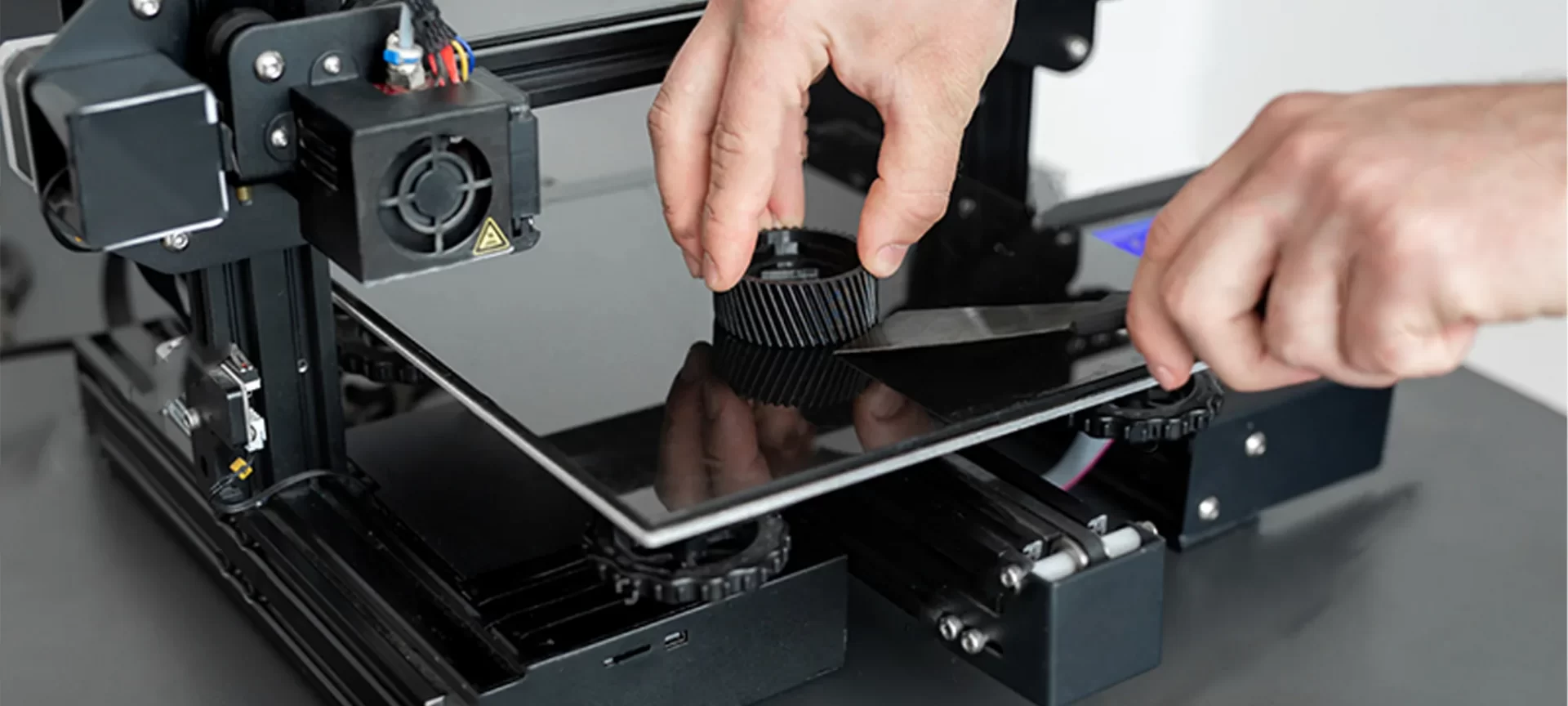

Calibration can also be a major issue in this problem, over time the distance between the nozzle and platform can increase to the point wherein the first layer, also known as the foundation layer, is dragged rather than pushed into the print platform.

In all of the above-mentioned cases, you’re likely to see some part of the filament appear above your half-formed model or around your print platform.

The most common solution in these cases is to apply a thin layer of stick glue to those that especially come in the market for the print platform, which can then be easily washed away with hot water so that the post-processing is also improved.

The decorator’s tape is another alternative while printing with PLA material.

Your Print Bed Looks Bad

There are times when from start to finish you encounter no problem, but then you also do not get the required kind of quality.

During such times, the below-mentioned problems could be the 3D printing issues that you need to troubleshoot.

The First Layer is Messy

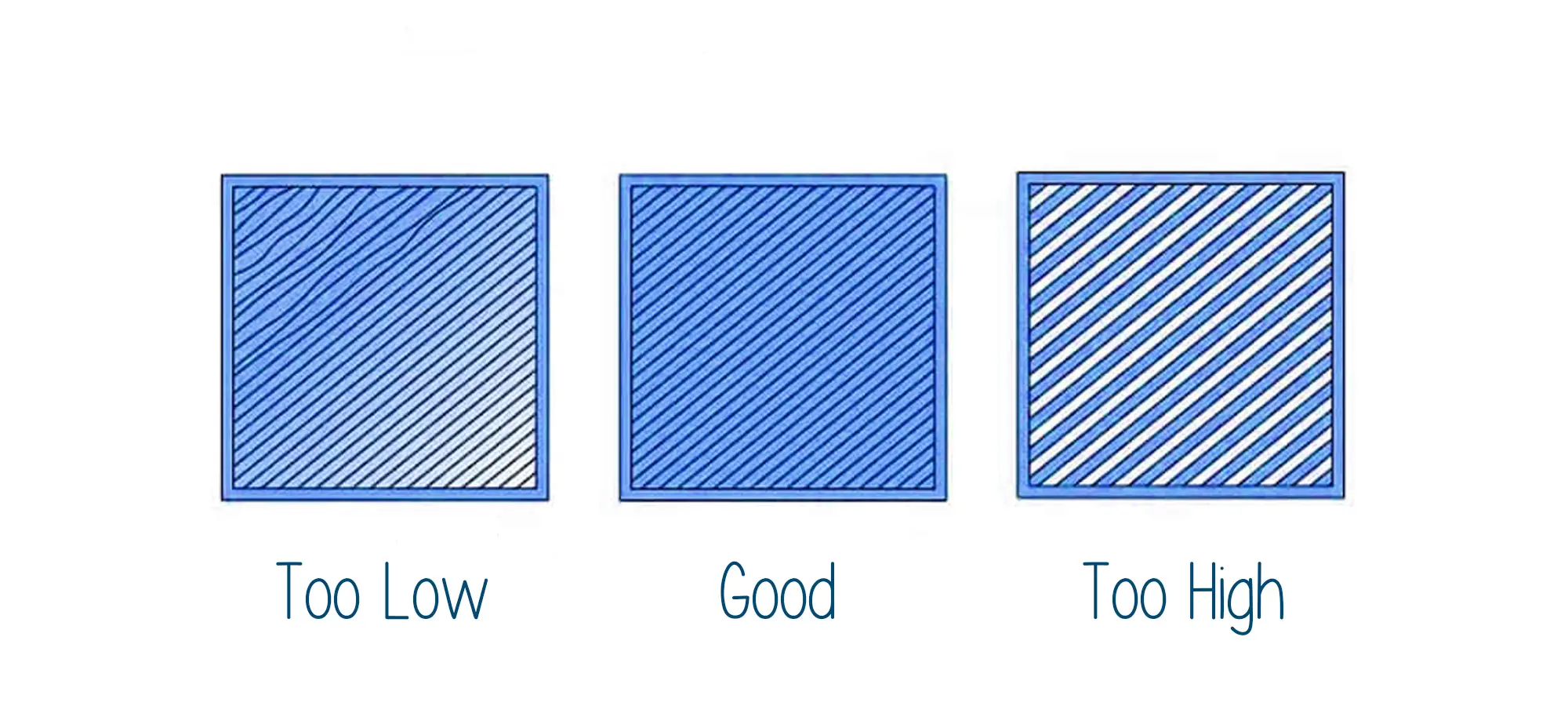

Everyone who is into 3D printing knows how important the first layers are to 3D printing a part or functional prototype.

When the first layer is messy there are chances that your print does not appear as you wanted it to be.

This 3D printing problem is a typical sign that the print bed of your printer hasn’t been leveled properly as it should be.

It could be that your nozzle is too far away from the bed, or the bottom surface often shows unwanted lines, or even possible that the first layer does not stick.

In case the nozzle is too close, blobs may be the result of the part or functional prototype.

For leveling the bed of the printer every printer needs to undergo one or the other procedure which could be either manual or automatic.

Click Here For More About The Main Factors To 3D Print Perfect First Layer.

Print Edges are Bending

When the part or functional prototype that you have created has edges that are not sharp but bent, the base of your model bend upwards until it is no longer with the print platform.

If this problem is not paid attention to there can be horizontal cracks in the upper part of the part or functional prototype that you have manufactured.

Warping is a common issue because of which this problem can occur as it’s caused by a natural characteristic of the plastic which is the material from which the filament is made.

As the ABS or PLA filament cools down it starts to contract very slightly; the problem of warping arises if the plastic is cooled too quickly.

The easiest solution for getting rid of this 3D printing issue is to use a heated print platform and set the temperature to a point just below the plastics melting point. In scientific terminology, this is called the “glass transition temperature”.

It is important to note that if you get that temperature right then the first layer will stay flat on the print platform, the temperature of which is often set by the slicer software.

The recommended temperature for your filament is often printed on the side of the packaging or on the spool.

Problems while Printing with SLA 3D Printer

Nothing is Getting Printed

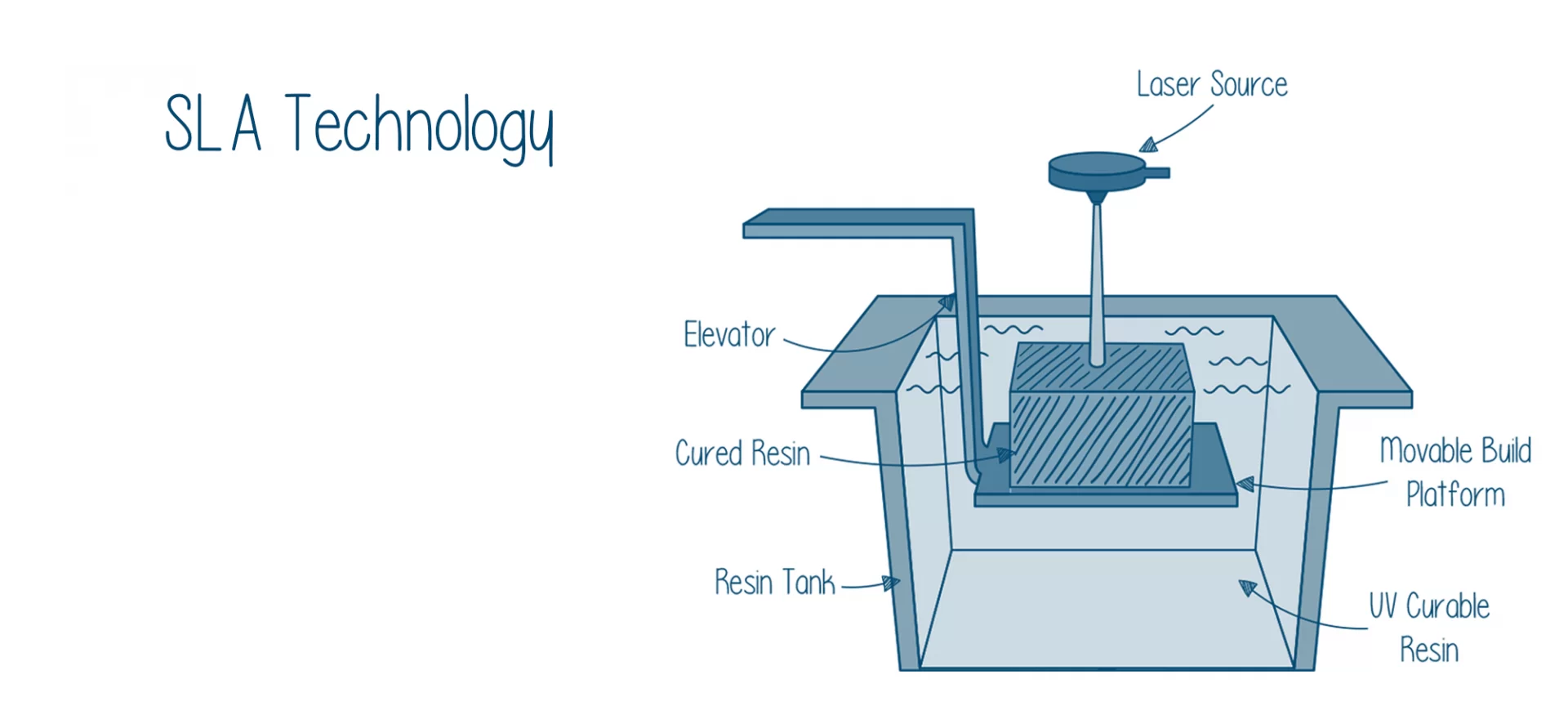

Unlike the FDM 3D printer, the SLA 3D printer uses liquid resins for the 3D printing part of a functional prototype.

Below mentioned are some of the 3D printing issues with the printer when nothing is printing using it.

Resin is too Cold

Because ambient temperature can play a big part in whether a photopolymer resin will set during the SLA printing process

if your resin is too cold, it’s unlikely to set and, if it does, will set inconsistently, resulting in partial prints and poor plate adhesion. Temperatures as high as 25-30 degrees Celsius are considered necessary from some resins. It’s possible to pick up an incubator heating kit that includes a heater, fan, thermostat, and power supply and costs around $50 for ensuring the resin does not remain too cold.

Your Prints Fail

Support base not sticking to the print plate because it is partially peeling away, or separated completely and is left floating around the resin tank can be a reason why your prints are failing.

This can happen due to:

- The way your SLA 3D printer repositions to the next printing layer generates more peel force than how your printer can handle.

- Whether the print plate of your printer is sufficiently prepared or not. In the case of bottom-up SLA printers printing onto a flat metal plate stick well when the plate is finely textured, or rough even. It is also possible that your interfacing layer in the resin vat has some ghosting which is hindering the laser in setting the resin.

If your printer utilizes a tilting resin vat as part of its printer mechanism remember that this creates a gradient across the print plate of your printer where said force goes from very strong, to weak.

For solving this 3D printing issue you can also try searching for some kind of bed leveling instruction for your printer, or advanced calibration steps and give them a try.

The Conclusion

Apart from the above-mentioned 3D printing issues, there are other issues too. And new issues just keep on spiking up with the creation of new techniques and the new mechanism by 3D printer manufacturing companies.

However, the solutions to troubleshooting those problems, just like the ones mentioned above, keep on coming.

In case of facing an issue while printing, it is always important to find and identify the correct problem otherwise you often try applying a solution which is for other problems to the problem that you are facing, and then your problem remains unsolved.